Professional Documents

Culture Documents

DIN 2080 en

Uploaded by

alphatoolsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DIN 2080 en

Uploaded by

alphatoolsCopyright:

Available Formats

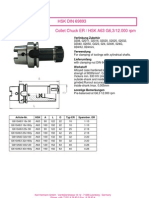

DIN 2080

Collet Chuck ER / SK30

Verlinkung Zubehör

0208, 02011, 02016, 02020, 02025, 02032,

02040, 02050, G023, 024, 024IK, 024G,

024HU,

Verwendung

For clamping of toolings with zylindrical shafts

Lieferumfang

with clamping-nut DIN 6499.

Werkstoff

Alloyed case-hardened steel with a tensile

strengh of 800N/mm². Carbonized according to

Vickers min. 630 HV (min. 56 HRC),Thread,

outside-shank and inside-shank for collets

grinded.Runout accuracy of outside-shank to

inside-shank lmax. 0,005mm

Article-Nr. SK A Form L D Typ ER Spannber. ER

G110 30x16x 42 30 42 AD 110 28 16 1-10

G110 30x25x 42 30 42 AD 111 42 25 2-16

G110 30x32x 50 30 50 AD 116 50 32 3-20

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Collet Chuck ER / SK40

Verlinkung Zubehör

0208, 02011, 02016, 02020, 02025, 02032,

02040, 02050, G023, 024, 024IK, 024G,

024HU,

Verwendung

For clamping of toolings with zylindrical shafts

Lieferumfang

with clamping-nut DIN 6499.

Werkstoff

Alloyed case-hardened steel with a tensile

strengh of 800N/mm². Carbonized according to

Vickers min. 630 HV (min. 56 HRC),Thread,

outside-shank and inside-shank for collets

grinded.Runout accuracy of outside-shank to

inside-shank lmax. 0,005mm

Article-Nr. SK A Form L D Typ ER Spannber. ER

G110 40x16x 50 40 50 AD 143 28 16 1-10

G110 40x25x 50 40 50 AD 143 42 25 2-16

G110 40x32x 47 40 45 AD 153 50 32 3-20

G110 40x40x 80 40 80 AD 173 63 40 4-26

G110 40x50x120 40 120 AD 213 78 50 6-34

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Collet Chuck ER / SK50

Verlinkung Zubehör

0208, 02011, 02016, 02020, 02025, 02032,

02040, 02050, G023, 024, 024IK, 024G,

024HU,

Verwendung

For clamping of toolings with zylindrical shafts

Lieferumfang

with clamping-nut DIN 6499.

Werkstoff

Alloyed case-hardened steel with a tensile

strengh of 800N/mm². Carbonized according to

Vickers min. 630 HV (min. 56 HRC),Thread,

outside-shank and inside-shank for collets

grinded.Runout accuracy of outside-shank to

inside-shank lmax. 0,005mm

Article-Nr. SK A Form L D Typ ER Spannber. ER

G110 50x25x 60 50 60 AD 187 42 25 2-16

G110 50x32x 70 50 70 AD 197 50 32 3-20

G110 50x40x 80 50 80 AD 207 63 40 4-26

G110 50x50x 72 50 71 AD 199 78 50 6-34

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Collet Chuck OZ Ortlieb / SK30

Verlinkung Zubehör

01616, 01625, 01632, G017, 018, 018IK,

Verwendung

For clamping of toolings with zylindrical shafts

Lieferumfang

with clamping-nut DIN 6499.

Werkstoff

Alloyed case-hardened steel with a tensile

strengh of 800N/mm². Carbonized according to

Vickers min. 630 HV (min. 56 HRC),Thread,

outside-shank and inside-shank for collets

grinded.Runout accuracy of outside-shank to

inside-shank lmax. 0,005mm

Article-Nr. SK A Form L D Typ OZ Spannber. OZ

G116 30x16x 50 30 50 AD 118 43 16 1-16

G116 30x25x 80 30 68 AD 136 60 25 2-25

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Collet Chuck OZ Ortlieb / SK40

Verlinkung Zubehör

01616, 01625, 01632, G017, 018, 018IK,

Verwendung

For clamping of toolings with zylindrical shafts

Lieferumfang

with clamping-nut DIN 6499.

Werkstoff

Alloyed case-hardened steel with a tensile

strengh of 800N/mm². Carbonized according to

Vickers min. 630 HV (min. 56 HRC),Thread,

outside-shank and inside-shank for collets

grinded.Runout accuracy of outside-shank to

inside-shank lmax. 0,005mm

Article-Nr. SK A Form L D Typ OZ Spannber. OZ

G116 40x16x 70 40 70 AD 163 43 16 1-16

G116 40x25x 70 40 70 AD 163 60 25 2-25

G116 40x32x 80 40 80 AD 173 72 32 3-32

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Collet Chuck OZ Ortlieb / SK50

Verlinkung Zubehör

01616, 01625, 01632, G017, 018, 018IK,

Verwendung

For clamping of toolings with zylindrical shafts

Lieferumfang

with clamping-nut DIN 6499.

Werkstoff

Alloyed case-hardened steel with a tensile

strengh of 800N/mm². Carbonized according to

Vickers min. 630 HV (min. 56 HRC),Thread,

outside-shank and inside-shank for collets

grinded.Runout accuracy of outside-shank to

inside-shank lmax. 0,005mm

Article-Nr. SK A Form L D Typ OZ Spannber. OZ

G116 50x25x 70 50 70 AD 197 60 25 2-25

G116 50x32x 80 50 80 AD 207 72 32 3-32

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Tapping Chuck / SK30 with compensation

Verlinkung Zubehör

013 1mit, 013 1ohne, 013 2mit, 013 2ohne, 013

3mit,

Verwendung

For fixing bushes for tapping chucks see Group

013.The torque of chamfer start can be

adjusted mechanical with an hexagon socket

screw. With compensation on press and pull

Werkstoff

Alloyed case-hardened steel with a tensile

strength of 800N/mm². Carbonized according to

Vickers min. 630 HV (min. 56 HRC),Shank

surface is grinded.

Article-Nr. SK A Form d. D Größe Gewinde

G117 30x 1x 50 30 50 A 19 38 1 M3-M12

G117 30x 2x 95 30 86 A 31 53 2 M8-M20

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Tapping Chuck / SK40 with compensation

Verlinkung Zubehör

013 1mit, 013 1ohne, 013 2mit, 013 2ohne, 013

3mit,

Verwendung

For fixing bushes for tapping chucks see Group

013.The torque of chamfer start can be

adjusted mechanical with an hexagon socket

screw. With compensation on press and pull

Werkstoff

Alloyed case-hardened steel with a tensile

strength of 800N/mm². Carbonized according to

Vickers min. 630 HV (min. 56 HRC),Shank

surface is grinded.

Article-Nr. SK A Form d. D Größe Gewinde

G117 40x 1x 52 40 52 A 19 38 1 M3-M12

G117 40x 2x 77 40 77 A 31 53 2 M8-M20

G117 40x 3x118 40 118 A 48 78 3 M14-M33

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Tapping Chuck / SK50 with compensation

Verlinkung Zubehör

013 1mit, 013 1ohne, 013 2mit, 013 2ohne, 013

3mit,

Verwendung

For fixing bushes for tapping chucks see Group

013.The torque of chamfer start can be

adjusted mechanical with an hexagon socket

screw. With compensation on press and pull

Werkstoff

Alloyed case-hardened steel with a tensile

strength of 800N/mm². Carbonized according to

Vickers min. 630 HV (min. 56 HRC),Shank

surface is grinded.

Article-Nr. SK A Form d. D Größe Gewinde

G117 50x 1x 60 50 60 A 19 38 1 M3-M12

G117 50x 2x 79 50 79 A 31 53 2 M8-M20

G117 50x 3x125 50 125 A 48 78 3 M14-M33

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

End Mill Holder WELDON / SK30

Verlinkung Zubehör

01032B, 01020,

Verwendung

For milling-tools with zylindrical shaft type

Weldon DIN 1835 Form B. Suitable for central

coolant flow

Lieferumfang

with 1 clamping screw, from Dia 25mm with 2

screws

Werkstoff

Alloyed case-hardened steel with a tensile

strength of min. 800 N/mm². Carbonized

according to Vickers min. 630 HV (min. 56

HRC) Shank and zylindrical surface are

grinded.

Article-Nr. SK d1 A Form L D

G120 30x 6x 40 30 6 40 AD 108 25

G120 30x 8x 40 30 8 40 AD 108 28

G120 30x10x 40 30 10 40 AD 108 35

G120 30x12x 40 30 12 40 AD 108 42

G120 30x16x 50 30 16 50 AD 118 48

G120 30x20x 63 30 20 63 AD 131 52

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

End Mill Holder WELDON / SK40

Verlinkung Zubehör

01032B, 01020,

Verwendung

For milling-tools with zylindrical shaft type

Weldon DIN 1835 Form B. Suitable for central

coolant flow

Lieferumfang

with 1 clamping screw, from Dia 25mm with 2

screws

Werkstoff

Alloyed case-hardened steel with a tensile

strength of min. 800 N/mm². Carbonized

according to Vickers min. 630 HV (min. 56

HRC) Shank and zylindrical surface are

grinded.

Article-Nr. SK d1 A Form L D

G120 40x 6x 50 40 6 50 AD 143 25

G120 40x 8x 50 40 8 50 AD 143 28

G120 40x10x 50 40 10 50 AD 143 35

G120 40x12x 50 40 12 50 AD 143 42

G120 40x14x 50 40 14 50 AD 143 42

G120 40x16x 63 40 16 63 AD 156 48

G120 40x18x 63 40 18 63 AD 156 48

G120 40x20x 35 40 20 35 AD 128 52

G120 40x20x 63 40 20 63 AD 156 52

G120 40x22x 63 40 22 63 AD 156 52

G120 40x25x 35 40 25 35 AD 128 63

G120 40x25x 60 40 25 60 AD 153 63

G120 40x25x 80 40 25 80 AD 173 63

G120 40x32x 80 40 32 80 AD 173 70

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

End Mill Holder WELDON / SK50

Verlinkung Zubehör

01032B, 01020,

Verwendung

For milling-tools with zylindrical shaft type

Weldon DIN 1835 Form B. Suitable for central

coolant flow

Lieferumfang

with 1 clamping screw, from Dia 25mm with 2

screws

Werkstoff

Alloyed case-hardened steel with a tensile

strength of min. 800 N/mm². Carbonized

according to Vickers min. 630 HV (min. 56

HRC) Shank and zylindrical surface are

grinded.

Article-Nr. SK d1 A Form L D

G120 50x 6x 63 50 6 63 AD 190 28

G120 50x 8x 63 50 8 63 AD 190 28

G120 50x10x 63 50 10 63 AD 190 35

G120 50x12x 63 50 12 63 AD 190 42

G120 50x14x 63 50 14 63 AD 190 44

G120 50x16x 63 50 16 63 AD 190 48

G120 50x18x 63 50 18 63 AD 190 48

G120 50x20x 63 50 20 63 AD 190 52

G120 50x22x 63 50 22 63 AD 190 52

G120 50x25x 80 50 25 80 AD 207 65

G120 50x32x 80 50 32 80 AD 207 72

G120 50x40x 90 50 40 90 AD 217 90

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

End Mill Holder Whistle-Notch / SK40

Verwendung

For milling-tools with zylindrical shaft type

Whistle Notch DIN 1835E / 6359HE

Lieferumfang

with 1 clamping screw and 1 set screw

Werkstoff

Alloyed case-hardened steel with a tensile

strength of min. 800 N/mm². Carbonized

according to Vickers min. 630 HV (min. 56

HRC) Shank and zylindrical surface are

grinded.

Article-Nr. SK d1 A Form L D

G121 40x 6x 50 40 6 50 A 143 25

G121 40x 8x 50 40 8 50 A 143 28

G121 40x10x 50 40 10 50 A 143 35

G121 40x12x 50 40 12 50 A 143 42

G121 40x14x 50 40 14 50 A 143 42

G121 40x16x 63 40 16 63 A 156 48

G121 40x18x 63 40 18 63 A 156 48

G121 40x20x 63 40 20 63 A 156 52

G121 40x25x 80 40 25 80 A 173 63

G121 40x32x 80 40 32 80 A 173 70

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

End Mill Holder Whistle-Notch / SK50

Verwendung

For milling-tools with zylindrical shaft type

Whistle Notch DIN 1835E / 6359HE

Lieferumfang

with 1 clamping screw and 1 set screw

Werkstoff

Alloyed case-hardened steel with a tensile

strength of min. 800 N/mm². Carbonized

according to Vickers min. 630 HV (min. 56

HRC) Shank and zylindrical surface are

grinded.

Article-Nr. SK d1 A Form L D

G121 50x 6x 63 50 6 63 A 190 25

G121 50x 8x 63 50 8 63 A 190 28

G121 50x10x 63 50 10 63 A 190 35

G121 50x12x 63 50 12 63 A 190 42

G121 50x14x 63 50 14 63 A 190 44

G121 50x16x 63 50 16 63 A 190 48

G121 50x18x 63 50 18 63 A 190 48

G121 50x20x 63 50 20 63 A 190 52

G121 50x25x 80 50 25 80 A 207 65

G121 50x32x 80 50 32 80 A 207 72

G121 50x40x 90 50 40 90 A 217 90

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Taper shafts / SK30

Verwendung

For mounting drill chuck heads

Lieferumfang

Without drill chuck head

Werkstoff

Alloyed case-hardened steel with a tensile

strength of min. 800 N/mm². Carbonized

according to Vickers min. 630 HV (min. 56

HRC) Shank and cone are grinded.

Article-Nr. SK A Form L D

G130 30x12x 13 30 13 A 100 12

G130 30x16x14,5 30 15 A 107 16

G130 30x18x14,5 30 15 A 115 18

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Taper shafts / SK40

Verwendung

For mounting drill chuck heads

Lieferumfang

Without drill chuck head

Werkstoff

Alloyed case-hardened steel with a tensile

strength of min. 800 N/mm². Carbonized

according to Vickers min. 630 HV (min. 56

HRC) Shank and cone are grinded.

Article-Nr. SK A Form L D

G130 40x12x 15 40 15 A 127 12

G130 40x16x16,5 40 17 A 134 16

G130 40x18x16,5 40 17 A 142 18

G130 40x22x16,5 40 17 A 150 22

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Taper shafts / SK50

Verwendung

For mounting drill chuck heads

Lieferumfang

Without drill chuck head

Werkstoff

Alloyed case-hardened steel with a tensile

strength of min. 800 N/mm². Carbonized

according to Vickers min. 630 HV (min. 56

HRC) Shank and cone are grinded.

Article-Nr. SK A Form L D

G130 50x16x 20 50 20 A 171 16

G130 50x18x 20 50 20 A 179 18

G130 50x22x 20 50 20 A 187 22

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

High Precs. Drill Chuck / SK30

Verwendung

For clamping of toolings with zylindrical shafts

Permissible rotating speed: Clamping range 0,5

- 8 mm max. 25.000 U/min Clamping range 1 -

13 mm max. 20.000 U/min Clamping range 3 -

16 mm max. 15.000 U/min To fit these rotating

speed

Lieferumfang

with spanner

Werkstoff

Alloyed case-hardened steel with a tensile

strengh of min. 800 N/mm². Shank, jacket,

clamping jaw and other relevant pieces are

hardened and grinded. A manual is attached to

every Drill Chuck

Article-Nr. SK d1 A Form l1 D

G134 30x08 30 0,5-8 60 A 63 36

G134 30x13 30 1-13 98 A 104 50

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

High Precs. Drill Chuck / SK40

Verwendung

For clamping of toolings with zylindrical shafts

Permissible rotating speed: Clamping range 0,5

- 8 mm max. 25.000 U/min Clamping range 1 -

13 mm max. 20.000 U/min Clamping range 3 -

16 mm max. 15.000 U/min To fit these rotating

speed

Lieferumfang

with spanner

Werkstoff

Alloyed case-hardened steel with a tensile

strengh of min. 800 N/mm². Shank, jacket,

clamping jaw and other relevant pieces are

hardened and grinded. A manual is attached to

every Drill Chuck

Article-Nr. SK d1 A Form l1 D

G134 40x08 40 0,5-8 62 A 65 36

G134 40x13 40 1-13 83 A 89 50

G134 40x16 40 3-16 84 A 95 57

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

High Precs. Drill Chuck / SK50

Verwendung

For clamping of toolings with zylindrical shafts

Permissible rotating speed: Clamping range 0,5

- 8 mm max. 25.000 U/min Clamping range 1 -

13 mm max. 20.000 U/min Clamping range 3 -

16 mm max. 15.000 U/min To fit these rotating

speed

Lieferumfang

with spanner

Werkstoff

Alloyed case-hardened steel with a tensile

strengh of min. 800 N/mm². Shank, jacket,

clamping jaw and other relevant pieces are

hardened and grinded. A manual is attached to

every Drill Chuck

Article-Nr. SK d1 A Form l1 D

G134 50x13 50 1-13 100 A 106 50

G134 50x16 50 3-16 100 A 111 57

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Combi Shell Mill Holder / SK30

Verlinkung Zubehör

G040, G041,

Verwendung

For mounting of milling cutters with tenon drive

or clutch drive

Lieferumfang

With clamping screw DIN 6367,drive ring DIN

6366 and feather key.

Werkstoff

Alloyed case-hardened steel with a tensile

strength of 800N/mm². Carbonized according to

Vickers min. 630 HV (min. 56 HRC), Shank,

journal and contact surface are grinded.

Article-Nr. SK d1 A Form l1 l5 l6 d2 L

G140 30x13x 35 30 13 35 A 22 12 25 28 115

G140 30x16x 35 30 16 35 A 27 17 25 32 120

G140 30x22x 35 30 22 35 A 31 19 25 40 122

G140 30x27x 35 30 27 35 A 33 21 25 48 124

G140 30x32x 50 30 32 50 A 38 24 40 58 142

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Combi Shell Mill Holder / SK40

Verlinkung Zubehör

G040, G041,

Verwendung

For mounting of milling cutters with tenon drive

or clutch drive

Lieferumfang

With clamping screw DIN 6367,drive ring DIN

6366 and feather key.

Werkstoff

Alloyed case-hardened steel with a tensile

strength of 800N/mm². Carbonized according to

Vickers min. 630 HV (min. 56 HRC), Shank,

journal and contact surface are grinded.

Article-Nr. SK d1 A Form l1 l5 l6 d2 L

G140 40x16x 52 40 16 52 A 27 17 40 32 162

G140 40x16x 75 40 16 75 A 27 17 63 32 185

G140 40x22x 52 40 22 52 A 31 19 40 40 164

G140 40x22x 75 40 22 75 A 31 19 63 40 187

G140 40x27x 52 40 27 52 A 33 21 40 48 166

G140 40x27x 75 40 27 75 A 33 21 63 48 189

G140 40x32x 52 40 32 52 A 38 24 40 58 169

G140 40x32x 75 40 32 75 A 38 24 63 58 192

G140 40x40x 52 40 40 52 A 41 27 40 70 172

G140 40x40x 75 40 40 75 A 41 27 63 70 195

G140 40x50x 52 40 50 52 A 46 30 40 90 172

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Combi Shell Mill Holder / SK50

Verlinkung Zubehör

G040, G041,

Verwendung

For mounting of milling cutters with tenon drive

or clutch drive

Lieferumfang

With clamping screw DIN 6367,drive ring DIN

6366 and feather key.

Werkstoff

Alloyed case-hardened steel with a tensile

strength of 800N/mm². Carbonized according to

Vickers min. 630 HV (min. 56 HRC), Shank,

journal and contact surface are grinded.

Article-Nr. SK d1 A Form l1 l5 l6 d2 L

G140 50x16x 55 50 16 55 A 27 17 40 32 199

G140 50x22x 55 50 22 55 A 31 19 40 40 201

G140 50x27x 55 50 27 55 A 33 21 40 48 203

G140 50x32x 55 50 32 55 A 38 24 40 58 206

G140 50x40x 55 50 40 55 A 41 27 40 70 209

G140 50x50x 55 50 50 55 A 46 30 40 90 212

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Mill. Arbor Tenon Drive / SK30

Verlinkung Zubehör

G041,

Verwendung

For mounting of milling cutters with tenon

Lieferumfang

With clamping screw DIN 6367 and feather key.

Werkstoff

Alloyed case-hardened steel with a tensile

strength of 800N/mm². Carbonized according to

Vickers min. 630 HV (min. 56 HRC), Shank,

journal and contact surface are grinded.

Besonderheit

Only sales of rest-stock - no new production

!!!!!!!!!

Article-Nr. SK d1 A Form l1 l3 d2 L

G141 30x13x 35 30 13 35 A 25 25 23 128

G141 30x16x 35 30 16 35 A 25 30 28 133

G141 30x22x 35 30 22 35 A 25 40 36 143

G141 30x27x 35 30 27 35 A 25 60 43 163

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Mill. Arbor Tenon Drive / SK40

Verlinkung Zubehör

G041,

Verwendung

For mounting of milling cutters with tenon

Lieferumfang

With clamping screw DIN 6367 and feather key.

Werkstoff

Alloyed case-hardened steel with a tensile

strength of 800N/mm². Carbonized according to

Vickers min. 630 HV (min. 56 HRC), Shank,

journal and contact surface are grinded.

Besonderheit

Only sales of rest-stock - no new production

!!!!!!!!!

Article-Nr. SK d1 A Form l1 l3 d2 L

G141 40x13x 37 40 13 37 A 25 25 23 155

G141 40x16x 37 40 16 37 A 30 30 28 160

G141 40x22x 37 40 22 37 A 40 40 36 170

G141 40x27x 37 40 27 37 A 60 60 43 190

G141 40x32x 37 40 32 37 A 60 60 48 190

G141 40x40x 37 40 40 37 A 60 60 56 190

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Mill. Arbor Tenon Drive / SK50

Verlinkung Zubehör

G041,

Verwendung

For mounting of milling cutters with tenon

Lieferumfang

With clamping screw DIN 6367 and feather key.

Werkstoff

Alloyed case-hardened steel with a tensile

strength of 800N/mm². Carbonized according to

Vickers min. 630 HV (min. 56 HRC), Shank,

journal and contact surface are grinded.

Besonderheit

Only sales of rest-stock - no new production

!!!!!!!!!

Article-Nr. SK d1 A Form l1 l3 d2 L

G141 50x16x 40 50 16 40 A 30 30 28 197

G141 50x22x 40 50 22 40 A 40 40 36 207

G141 50x27x 40 50 27 40 A 60 60 43 227

G141 50x32x 40 50 32 40 A 60 60 48 227

G141 50x40x 40 50 40 40 A 60 60 56 227

G141 50x50x 40 50 50 40 A 60 60 70 227

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Face Mill Holder / SK40

Verlinkung Zubehör

G041,

Verwendung

For mounting inserted tool milling cutters with

clutch drive.

Lieferumfang

With two fixed drive keys and clamping screw

DIN 6367.

Werkstoff

Alloyed case-hardened steel with a tensile

strength of 800N/mm². Carbonized according to

Vickers min. 630 HV (min. 56 HRC), Shank,

journal and contact surface are grinded.

Article-Nr. SK d1 A Form l3 d2 L

G142 40x22x 30 40 22 30 A 19 50 142

G142 40x27x 17 40 27 17 A 21 60 131

G142 40x27x 30 40 27 30 A 21 60 144

G142 40x32x 17 40 32 17 A 24 78 134

G142 40x32x 30 40 32 30 A 24 78 147

G142 40x40x 17 40 40 17 A 27 89 137

G142 40x40x 30 40 40 30 A 27 89 150

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Face Mill Holder / SK50

Verlinkung Zubehör

G041,

Verwendung

For mounting inserted tool milling cutters with

clutch drive.

Lieferumfang

With two fixed drive keys and clamping screw

DIN 6367.

Werkstoff

Alloyed case-hardened steel with a tensile

strength of 800N/mm². Carbonized according to

Vickers min. 630 HV (min. 56 HRC), Shank,

journal and contact surface are grinded.

Article-Nr. SK d1 A Form l3 d2 L

G142 50x22x 35 50 22 35 A 19 50 181

G142 50x27x 35 50 27 35 A 21 60 183

G142 50x32x 40 50 32 35 A 24 78 186

G142 50x40x 33 50 40 33 A 27 89 187

G142 50x60x 55 50 60 55 A 40 129 217

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Long Milling Arbor / SK30

Verlinkung Zubehör

030A, 030B, 030S, G034, 03513, 03516,

03522, 03527, 03532, 03540, 03550,

Verwendung

For mounting disc millers and sawing discs

Lieferumfang

Form A: Long milling arbor with nut, endring

and feather key Form B: Long milling arbor with

nut, set of spacing collars and feather key Form

C: Long milling arbor with nut, set of spacing

collars, feather key and 1 bearing collar

DIN2083 with length of

Werkstoff

Alloyed case-hardened steel with a tensile

strength of 800N/mm². Carbonized according to

Vickers min. 630 HV (min. 56 HRC), Shank,

journal and contact surface are grinded. The

diameter d1 is manufactured to tolerance h6.

Article-Nr. SK d1 Form l1 L

G150 30x16x200 30 16 A 200 316

G150 30x16x250 30 16 A 250 366

G150 30x16x315 30 16 A 315 431

G150 30x16x400 30 16 A 400 516

G150 30x22x200 30 22 A 200 322

G150 30x22x250 30 22 A 250 372

G150 30x22x315 30 22 A 315 437

G150 30x22x400 30 22 A 400 522

G150 30x27x200 30 27 A 200 328

G150 30x27x250 30 27 A 250 378

G150 30x27x315 30 27 A 315 443

G150 30x27x400 30 27 A 400 528

G150 30x32x200 30 32 A 200 332

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Long Milling Arbor / SK40

Verlinkung Zubehör

030A, 030B, 030S, G034, 03513, 03516,

03522, 03527, 03532, 03540, 03550,

Verwendung

For mounting disc millers and sawing discs

Lieferumfang

Form A: Long milling arbor with nut, endring

and feather key Form B: Long milling arbor with

nut, set of spacing collars and feather key Form

C: Long milling arbor with nut, set of spacing

collars, feather key and 1 bearing collar

DIN2083 with length of

Werkstoff

Alloyed case-hardened steel with a tensile

strength of 800N/mm². Carbonized according to

Vickers min. 630 HV (min. 56 HRC), Shank,

journal and contact surface are grinded. The

diameter d1 is manufactured to tolerance h6.

Article-Nr. SK d1 Form l1 L

G150 40x13x315 40 13 A 315 460

G150 40x16x250 40 16 A 250 398

G150 40x16x315 40 16 A 315 463

G150 40x16x400 40 16 A 400 548

G150 40x16x500 40 16 A 500 648

G150 40x22x250 40 22 A 250 404

G150 40x22x315 40 22 A 315 469

G150 40x22x400 40 22 A 400 554

G150 40x22x500 40 22 A 500 654

G150 40x22x630 40 22 A 630 784

G150 40x27x250 40 27 A 250 410

G150 40x27x315 40 27 A 315 475

G150 40x27x400 40 27 A 400 560

G150 40x27x500 40 27 A 500 660

G150 40x27x630 40 27 A 630 790

G150 40x32x250 40 32 A 250 414

G150 40x32x315 40 32 A 315 479

G150 40x32x400 40 32 A 400 564

G150 40x32x500 40 32 A 500 664

G150 40x32x630 40 32 A 630 794

G150 40x40x315 40 40 A 315 487

G150 40x40x400 40 40 A 400 572

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

Article-Nr. SK d1 Form l1 L

G150 40x40x500 40 40 A 500 672

G150 40x40x630 40 40 A 630 802

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Long Milling Arbor / SK50

Verlinkung Zubehör

030A, 030B, 030S, G034, 03513, 03516,

03522, 03527, 03532, 03540, 03550,

Verwendung

For mounting disc millers and sawing discs

Lieferumfang

Form A: Long milling arbor with nut, endring

and feather key Form B: Long milling arbor with

nut, set of spacing collars and feather key Form

C: Long milling arbor with nut, set of spacing

collars, feather key and 1 bearing collar

DIN2083 with length of

Werkstoff

Alloyed case-hardened steel with a tensile

strength of 800N/mm². Carbonized according to

Vickers min. 630 HV (min. 56 HRC), Shank,

journal and contact surface are grinded. The

diameter d1 is manufactured to tolerance h6.

Article-Nr. SK d1 Form l1 L

G150 50x16x315 50 16 A 315 505

G150 50x16x400 50 16 A 400 590

G150 50x22x400 50 22 A 400 596

G150 50x22x500 50 22 A 500 696

G150 50x22x630 50 22 A 630 826

G150 50x22x800 50 22 A 800 996

G150 50x27x315 50 27 A 315 517

G150 50x27x400 50 27 A 400 602

G150 50x27x500 50 27 A 500 702

G150 50x27x630 50 27 A 630 832

G150 50x27x800 50 27 A 800 1002

G150 50x32x400 50 32 A 400 606

G150 50x32x500 50 32 A 500 706

G150 50x32x630 50 32 A 630 836

G150 50x32x800 50 32 A 800 1006

G150 50x40x400 50 40 A 400 614

G150 50x40x500 50 40 A 500 714

G150 50x40x630 50 40 A 630 844

G150 50x40x800 50 40 A 800 1014

G150 50x50x400 50 50 A 400 620

G150 50x50x500 50 50 A 500 720

G150 50x50x630 50 50 A 630 850

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

Article-Nr. SK d1 Form l1 L

G150 50x50x800 50 50 A 800 1020

G150 50x60x500 50 60 A 500 730

G150 50x60x630 50 60 A 630 860

G150 50x60x800 50 60 A 800 1030

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Morse Taper Adaptor / SK30

Verwendung

For toolings with morse taper and flat tang

Werkstoff

Alloyed case-hardened steel with a tensile

strengh of 800N/mm².Carnonized according to

Vickers min. 630 HV (min. 56 HRC), Outside

shank and inside morse taper are grinded.

Article-Nr. SK A Form L D Innen MK

G160 30x1x 50 30 50 AD 118 25 1

G160 30x2x 50 30 50 AD 118 32 2

G160 30x3x 72 30 72 AD 140 40 3

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Morse Taper Adaptor / SK40

Verwendung

For toolings with morse taper and flat tang

Werkstoff

Alloyed case-hardened steel with a tensile

strengh of 800N/mm².Carnonized according to

Vickers min. 630 HV (min. 56 HRC), Outside

shank and inside morse taper are grinded.

Article-Nr. SK A Form L D Innen MK

G160 40x1x 50 40 50 AD 143 25 1

G160 40x1x100 40 100 AD 193 25 1

G160 40x1x150 40 150 AD 243 25 1

G160 40x2x 50 40 50 AD 143 32 2

G160 40x2x150 40 150 AD 243 32 2

G160 40x2x200 40 200 AD 293 32 2

G160 40x3x 65 40 65 AD 158 40 3

G160 40x3x100 40 100 AD 193 40 3

G160 40x3x150 40 150 AD 258 40 3

G160 40x3x200 40 200 AD 293 40 3

G160 40x4x 95 40 95 AD 188 48 4

G160 40x4x150 40 150 AD 243 48 4

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Morse Taper Adaptor / SK50

Verwendung

For toolings with morse taper and flat tang

Werkstoff

Alloyed case-hardened steel with a tensile

strengh of 800N/mm².Carnonized according to

Vickers min. 630 HV (min. 56 HRC), Outside

shank and inside morse taper are grinded.

Article-Nr. SK A Form L D Innen MK

G160 50x1x 45 50 45 AD 172 25 1

G160 50x2x 50 50 50 AD 177 32 2

G160 50x2x100 50 100 AD 227 32 2

G160 50x2x150 50 150 AD 277 32 2

G160 50x2x200 50 200 AD 327 32 2

G160 50x3x 65 50 65 AD 192 40 3

G160 50x3x100 50 100 AD 227 40 3

G160 50x4x 70 50 70 AD 197 48 4

G160 50x4x100 50 100 AD 227 48 4

G160 50x4x200 50 200 AD 327 48 4

G160 50x5x105 50 105 AD 232 63 5

G160 50x5x150 50 150 AD 277 63 5

G160 50x5x200 50 200 AD 327 63 5

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Draw Thread Morse Taper Adap. / SK30

Verwendung

For toolings with morse taper and thread

Lieferumfang

with internal clamping screw

Werkstoff

Alloyed case-hardened steel with a tensile

strengh of 800N/mm².Carnonized according to

Vickers min. 630 HV (min. 56 HRC), Outside

shank and inside morse taper are grinded.

Besonderheit

Only sales of rest-stock - no new production

Article-Nr. SK A Form L D Innen MK

G161 30x1x 50 30 50 A 118 25 1

G161 30x2x 50 30 50 A 118 32 2

G161 30x3x 77 30 77 A 145 40 3

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Draw Thread Morse Taper Adap. / SK40

Verwendung

For toolings with morse taper and thread

Lieferumfang

with internal clamping screw

Werkstoff

Alloyed case-hardened steel with a tensile

strengh of 800N/mm².Carnonized according to

Vickers min. 630 HV (min. 56 HRC), Outside

shank and inside morse taper are grinded.

Article-Nr. SK A Form L D Innen MK

G161 40x1x 50 40 50 A 143 25 1

G161 40x2x 50 40 50 A 143 32 2

G161 40x3x 65 40 65 A 158 40 3

G161 40x4x 95 40 95 A 188 48 4

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Draw Thread Morse Taper Adap. / SK50

Verwendung

For toolings with morse taper and thread

Lieferumfang

with internal clamping screw

Werkstoff

Alloyed case-hardened steel with a tensile

strengh of 800N/mm².Carnonized according to

Vickers min. 630 HV (min. 56 HRC), Outside

shank and inside morse taper are grinded.

Article-Nr. SK A Form L D Innen MK

G161 50x1x 45 50 45 A 172 25 1

G161 50x2x 60 50 60 A 187 32 2

G161 50x3x 65 50 65 A 192 40 3

G161 50x4x 70 50 70 A 197 48 4

G161 50x5x120 50 120 A 247 63 5

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Reduction Arbor / SK40

Verwendung

For reducing SK to SK

Lieferumfang

with internal clamping screw

Werkstoff

Alloyed case-hardened steel with a tensile

strengh of 800N/mm². Carnonized according to

Vickers min. 630 HV (min. 56 HRC), Outside

shank and inside cone are grinded.

Article-Nr. SK Innen SK A Form L D

G162 40x30x 50 40 30 50 A 152 50

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Reduction Arbor / SK50

Verwendung

For reducing SK to SK

Lieferumfang

with internal clamping screw

Werkstoff

Alloyed case-hardened steel with a tensile

strengh of 800N/mm². Carnonized according to

Vickers min. 630 HV (min. 56 HRC), Outside

shank and inside cone are grinded.

Article-Nr. SK Innen SK A Form L D

G162 50x30x 50 50 30 50 A 186 50

G162 50x40x 50 50 40 70 A 208 70

G162 50x50x120 50 50 120 A 261 97

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

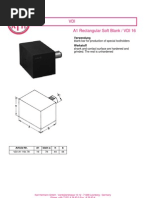

DIN 2080

Blank Bar / SK40

Verwendung

For production of special toolholders

Werkstoff

Alloyed case-hardened steel with a tensile

strengh of 800N/mm². Shank and collar

carnonized according to Vickers min. 630 HV

(min. 56 HRC) and grinded. Cylindrical

Diameter D is unhardened for further

manufacturing.

Article-Nr. SK A Form L D

G199 40x405x160 40 160 A 253 41

G199 40x405x250 40 250 A 343 41

G199 40x635x160 40 160 A 253 64

G199 40x635x250 40 250 A 343 64

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

DIN 2080

Blank Bar / SK50

Verwendung

For production of special toolholders

Werkstoff

Alloyed case-hardened steel with a tensile

strengh of 800N/mm². Shank and collar

carnonized according to Vickers min. 630 HV

(min. 56 HRC) and grinded. Cylindrical

Diameter D is unhardened for further

manufacturing.

Article-Nr. SK A Form L D

G199 50x955x315 50 315 A 442 95.5

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

Karl Hermann GmbH - Varnbülerstrasse 10-12 - 71299 Leonberg - Germany

Phone: +49 (7152) 9 39 92-0 Fax: -9 39 92-4

Status: 29.08.2005

You might also like

- CarpenterBook PDFDocument80 pagesCarpenterBook PDFmico alilaya100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Alloy CuCr1ZrDocument53 pagesAlloy CuCr1ZrPrashant PuriNo ratings yet

- Hand - Power Tools SafetyDocument49 pagesHand - Power Tools SafetySanjana Ganesh100% (3)

- Tightening Torque SN 60084 3 2009Document7 pagesTightening Torque SN 60084 3 2009cahyoNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Arc Stud Welding Solutions GuideDocument42 pagesArc Stud Welding Solutions GuideRajan SteeveNo ratings yet

- Popular Mechanics - DIY Fly CutterDocument3 pagesPopular Mechanics - DIY Fly CuttersonofsilasNo ratings yet

- R Nine T (K21) - Engine, Gearbox & Bevel Gear Oil Change V1.0Document44 pagesR Nine T (K21) - Engine, Gearbox & Bevel Gear Oil Change V1.0Jonathan TelferNo ratings yet

- Welding Technology Steelconstr - EngDocument32 pagesWelding Technology Steelconstr - EngLukman Tarigan SumatraNo ratings yet

- HSK DIN 69893 enDocument29 pagesHSK DIN 69893 enalphatoolsNo ratings yet

- Arc Welding ElectrodesDocument6 pagesArc Welding ElectrodeswaleedyossefNo ratings yet

- CROSS To Mann 2016Document94 pagesCROSS To Mann 2016Sebastian Ganci0% (1)

- Inner Cover For Langstroth HiveDocument0 pagesInner Cover For Langstroth Hivejlcastro693No ratings yet

- Hydraulic system components manualDocument29 pagesHydraulic system components manualWahyu HermantoNo ratings yet

- Welding Consumables For The Offshore IndustryDocument24 pagesWelding Consumables For The Offshore IndustryLuis DuarteNo ratings yet

- Ductile Iron PipesDocument8 pagesDuctile Iron Pipesᕨᖆᕢᘙᖱ ᒸᕢᖽᐸᓎNo ratings yet

- SAGE International, LTD EBR DMDocument4 pagesSAGE International, LTD EBR DMNickchiosNo ratings yet

- Master FOPI Dan DAKSPI (Kode OSS) 15072021Document856 pagesMaster FOPI Dan DAKSPI (Kode OSS) 15072021fennyrahmaNo ratings yet

- S20x2 Deckel enDocument9 pagesS20x2 Deckel enalphatools100% (1)

- MAS-BT enDocument62 pagesMAS-BT enalphatoolsNo ratings yet

- DIN 69871 enDocument69 pagesDIN 69871 enalphatoolsNo ratings yet

- Tightening torques for Silumin and ferrous screw connectionsDocument2 pagesTightening torques for Silumin and ferrous screw connectionsLetacio OliveiraNo ratings yet

- E-Catalogue of IKING GROUP Shear Stud and ARC WelderDocument4 pagesE-Catalogue of IKING GROUP Shear Stud and ARC WelderJohnNo ratings yet

- Vautid100 EnglDocument1 pageVautid100 EnglRamona CrangasNo ratings yet

- Shear StudDocument7 pagesShear StudcongtubatdaNo ratings yet

- Avk Fabricated Flange Adaptor, Pn16 260: Features: OptionsDocument2 pagesAvk Fabricated Flange Adaptor, Pn16 260: Features: Optionskhai ruleNo ratings yet

- Cu CR 1 ZRDocument38 pagesCu CR 1 ZRDaško MedenjaškoNo ratings yet

- Ea IiDocument3 pagesEa IimohattounNo ratings yet

- Wear Resistant Steel: Product DescriptionDocument6 pagesWear Resistant Steel: Product DescriptionoomoomNo ratings yet

- EJ Handbook.A5Document261 pagesEJ Handbook.A5ElMacheteDelHuesoNo ratings yet

- Hardfacing Electrodes: Brand ISDocument13 pagesHardfacing Electrodes: Brand ISashwini shuklaNo ratings yet

- Campaign: Solid Carbide End MillsDocument8 pagesCampaign: Solid Carbide End Mills2dex1adwief2m1a6No ratings yet

- ICS 5000 Flue System: High Positive PressureDocument28 pagesICS 5000 Flue System: High Positive PressureSebastian StefanescuNo ratings yet

- Wear Resistant Steel Sheet Material DataDocument6 pagesWear Resistant Steel Sheet Material DataJuan LeonNo ratings yet

- Westermann Table 8Document1 pageWestermann Table 8muhd.qasimNo ratings yet

- Heat Treatment Equipment and Services GuideDocument4 pagesHeat Treatment Equipment and Services GuideVinod KumarNo ratings yet

- PIC Wire & Cable: For S22089Document1 pagePIC Wire & Cable: For S22089Vidhu SrikumaranNo ratings yet

- Bahra Cables & Busbars IntroductionDocument4 pagesBahra Cables & Busbars IntroductionSalmanNo ratings yet

- Inconel 112-DatasheetDocument1 pageInconel 112-DatasheetrobertNo ratings yet

- Self-Drilling Dowel: Steel and AluminumDocument6 pagesSelf-Drilling Dowel: Steel and AluminumLucas SeñaNo ratings yet

- Eo Weld Fitting 4100e001Document11 pagesEo Weld Fitting 4100e001sandeepNo ratings yet

- A Study of The Grouped Arrangements of Stud Connectors On Shear StrengthDocument15 pagesA Study of The Grouped Arrangements of Stud Connectors On Shear Strengthfs jiNo ratings yet

- Hollo BoltDocument5 pagesHollo Boltikirby77No ratings yet

- Pan Head Self-Drill Drywall Screw: Product DatasheetDocument1 pagePan Head Self-Drill Drywall Screw: Product DatasheetRobNo ratings yet

- ZP00707 GB 2Document40 pagesZP00707 GB 2grandtrading.egNo ratings yet

- Web+Presentation+12+July+2016 EA+-+Scott+MunterDocument44 pagesWeb+Presentation+12+July+2016 EA+-+Scott+MunterDesika RaniNo ratings yet

- Cylindrical Fuse ProtectionDocument3 pagesCylindrical Fuse ProtectionHendra AwanNo ratings yet

- Firecel SR 124 E 30 / E 90: in Accordance With DIN 4102-12 AND DIN VDE 0815Document2 pagesFirecel SR 124 E 30 / E 90: in Accordance With DIN 4102-12 AND DIN VDE 0815Denis BuonoNo ratings yet

- 77e5-B005 (Hydraulic Cylinder)Document4 pages77e5-B005 (Hydraulic Cylinder)Sandeep JoshiNo ratings yet

- Spec Sheet Alphajoint Classic 4010 v5.1Document3 pagesSpec Sheet Alphajoint Classic 4010 v5.1Bucalae IzvorelNo ratings yet

- Hercules Generic CylinderDocument92 pagesHercules Generic CylinderALEXSANDRONo ratings yet

- Ka 8000 M PDFDocument9 pagesKa 8000 M PDFluis fernando veraNo ratings yet

- Ball and Socket Joints: Thread (Hand) D D L D D L Min. X GDocument2 pagesBall and Socket Joints: Thread (Hand) D D L D D L Min. X GGembonz Crew Gon'z SpeedNo ratings yet

- 2200226e Enquiry and PQR 1594289715Document5 pages2200226e Enquiry and PQR 1594289715loganathanNo ratings yet

- 08122018steel Cord Splicing enDocument22 pages08122018steel Cord Splicing ensivaNo ratings yet

- Dismantling Joint - AVKDocument2 pagesDismantling Joint - AVKtecnoturbines ttNo ratings yet

- Parts List 23 262 06 00: Adapter AM80, AM90 Backstop For Mounting IEC Motors Version With Dog ClutchDocument2 pagesParts List 23 262 06 00: Adapter AM80, AM90 Backstop For Mounting IEC Motors Version With Dog ClutchKleiber OrtegaNo ratings yet

- Product Data Sheet: USG Boral SHEETROCK® Standard PlasterboardDocument2 pagesProduct Data Sheet: USG Boral SHEETROCK® Standard Plasterboardkaval chhabraNo ratings yet

- BombasDocument8 pagesBombasDiego Fernando GaviriaNo ratings yet

- 16-18 Deburring BladesDocument1 page16-18 Deburring BladesangelNo ratings yet

- Part C-ToolingDocument142 pagesPart C-ToolingSayed qasimNo ratings yet

- Gibault Joint: Ref: RF25Document1 pageGibault Joint: Ref: RF25Glee ZiEoNo ratings yet

- DEMU 4010 Rebar Coupler System DEMUDocument24 pagesDEMU 4010 Rebar Coupler System DEMUTonni KurniawanNo ratings yet

- 32 Koenig 2013Document1 page32 Koenig 2013shashibagewadiNo ratings yet

- JOST Jsk37eDocument2 pagesJOST Jsk37eBryce CarterNo ratings yet

- Cellulosic Electrodes: Brand AWS A/SFA 5.1/5.5 EN 499Document4 pagesCellulosic Electrodes: Brand AWS A/SFA 5.1/5.5 EN 499ashwini shuklaNo ratings yet

- 70cuni TigDocument3 pages70cuni TigGiannhs SeitaridhsNo ratings yet

- DELFERDocument81 pagesDELFERalphatoolsNo ratings yet

- SAITDocument166 pagesSAITalphatoolsNo ratings yet

- BondhusDocument52 pagesBondhusalphatoolsNo ratings yet

- SINTCOMDocument58 pagesSINTCOMalphatoolsNo ratings yet

- Z-Carb Corner Radius SpeedFeedDocument2 pagesZ-Carb Corner Radius SpeedFeedalphatoolsNo ratings yet

- Z-Carb JetStreamDocument4 pagesZ-Carb JetStreamalphatoolsNo ratings yet

- Z-Carb JetStream SpeedFeedDocument2 pagesZ-Carb JetStream SpeedFeedalphatoolsNo ratings yet

- Z-CARB MD SpeedFeedDocument1 pageZ-CARB MD SpeedFeedalphatoolsNo ratings yet

- Z-Carb HTADocument2 pagesZ-Carb HTAalphatoolsNo ratings yet

- Z Carb MDDocument4 pagesZ Carb MDalphatoolsNo ratings yet

- Z-Carb Original End Mills: Revolutionizes MillingDocument4 pagesZ-Carb Original End Mills: Revolutionizes MillingalphatoolsNo ratings yet

- Z-Carb Corner Radius SpeedFeedDocument2 pagesZ-Carb Corner Radius SpeedFeedalphatoolsNo ratings yet

- Z-Carb Corner RadiusDocument4 pagesZ-Carb Corner RadiusalphatoolsNo ratings yet

- Ti NAMITEDocument2 pagesTi NAMITEalphatoolsNo ratings yet

- Turbo CarbDocument2 pagesTurbo CarbalphatoolsNo ratings yet

- Tri CarbDocument2 pagesTri CarbalphatoolsNo ratings yet

- Osborn Load Runners CatalogueDocument1 pageOsborn Load Runners CataloguealphatoolsNo ratings yet

- The Finishing Touch: Expect More From A Finishing MillDocument4 pagesThe Finishing Touch: Expect More From A Finishing MillalphatoolsNo ratings yet

- Ice-Carb High Performance Internal Coolant Drills For Drilling Depths Up To 7XdDocument4 pagesIce-Carb High Performance Internal Coolant Drills For Drilling Depths Up To 7XdalphatoolsNo ratings yet

- SCarb 012004Document12 pagesSCarb 012004alphatoolsNo ratings yet

- Ski CarbDocument4 pagesSki CarbalphatoolsNo ratings yet

- Osborn Novoflex-B CatalogueDocument1 pageOsborn Novoflex-B CataloguealphatoolsNo ratings yet

- Osborn EZ-Flex CatalogueDocument1 pageOsborn EZ-Flex CataloguealphatoolsNo ratings yet

- Power CarbDocument3 pagesPower CarbalphatoolsNo ratings yet

- HPC Flyer UnzippedDocument8 pagesHPC Flyer UnzippedalphatoolsNo ratings yet

- OSBORN Retail & Trading ConceptsDocument1 pageOSBORN Retail & Trading ConceptsalphatoolsNo ratings yet

- AD-Coated End MillsDocument2 pagesAD-Coated End MillsalphatoolsNo ratings yet

- Osborn Top CatalogueDocument1 pageOsborn Top CataloguealphatoolsNo ratings yet

- VDI enDocument110 pagesVDI enalphatoolsNo ratings yet

- Osborn Pro CatalogueDocument1 pageOsborn Pro CataloguealphatoolsNo ratings yet

- Single Acting Hydraulic ActuatorDocument18 pagesSingle Acting Hydraulic ActuatorAbboud KingNo ratings yet

- FC 9160Document7 pagesFC 9160johnNo ratings yet

- Spare Parts List: (1.081-200.0) SE 5.100 EUDocument14 pagesSpare Parts List: (1.081-200.0) SE 5.100 EUgeorge pefanisNo ratings yet

- MECHANICALDocument91 pagesMECHANICALAhsan JunaidNo ratings yet

- Hydraulic Brakes - Parts, Working, Diagram, Advantages and DisadvantagesDocument16 pagesHydraulic Brakes - Parts, Working, Diagram, Advantages and DisadvantagesKishoreChowdaryNalaboluNo ratings yet

- Model PM Series Three Axis Mills Features Setup & OperationDocument8 pagesModel PM Series Three Axis Mills Features Setup & OperationAntonius NataNo ratings yet

- Electric tools and equipment rental guideDocument2 pagesElectric tools and equipment rental guideMphoNhlobaneMAK-gNo ratings yet

- Clamping Units: Kennametal Km4X™Document2 pagesClamping Units: Kennametal Km4X™g1763970No ratings yet

- Internal Normalization Piping Project Specification for Weakly Corrosive HydrocarbonsDocument1 pageInternal Normalization Piping Project Specification for Weakly Corrosive Hydrocarbonsliviu_dovaNo ratings yet

- Hydraulic control diagram schematicDocument1 pageHydraulic control diagram schematicSuresh DNo ratings yet

- gdc-141 - 3 601 CA4 1F0Document3 pagesgdc-141 - 3 601 CA4 1F0Raghav sharmaNo ratings yet

- DIN 2080 enDocument45 pagesDIN 2080 enalphatoolsNo ratings yet

- Meal Preperation: Airpot Chopping BoardDocument4 pagesMeal Preperation: Airpot Chopping BoardJohnlen LaigueNo ratings yet

- 2005 CatalogDocument76 pages2005 CatalogBradley TurnerNo ratings yet

- Pressure Drop Calculation Summary SheetDocument13 pagesPressure Drop Calculation Summary SheetAmol KanadeNo ratings yet

- 7855.n1.80708.04-Otgi 60Document2 pages7855.n1.80708.04-Otgi 60Claudio Valencia MarínNo ratings yet

- 4800E Parts Book: Version 4 For Serial Numbers 1E-109-926 To 1E-169-1770Document153 pages4800E Parts Book: Version 4 For Serial Numbers 1E-109-926 To 1E-169-1770Lucio de SáNo ratings yet

- Tooling For Rifle BarrelsDocument5 pagesTooling For Rifle BarrelsGyörgy MurvaiNo ratings yet

- Guide to Braking Systems Under 40 CharactersDocument14 pagesGuide to Braking Systems Under 40 CharactersVinay SaiNo ratings yet

- Sphere Beam: Non-Demountable Sphere Beam For Monitoring The Accuracy of Medium-Sized Coordinate Measuring MachinesDocument2 pagesSphere Beam: Non-Demountable Sphere Beam For Monitoring The Accuracy of Medium-Sized Coordinate Measuring Machinescmm5477No ratings yet

- 40981Document23 pages40981Verdes CouchNo ratings yet