Professional Documents

Culture Documents

Me Liebherr t282b Din

Uploaded by

zimschoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Me Liebherr t282b Din

Uploaded by

zimschoCopyright:

Available Formats

Mining Truck T 282 B

Maximum Operating Weight 592 t / 652 ton

Payload Class 363 t / 400 ton

Photo shows optional equipment

NTB_T282B_DIN.indd 1 10.04.2007 10:44:46 Uhr

The T 282 B

The Liebherr T 282 B combines a high horsepower diesel engine with an extremely efficient Liebherr-

Siemens AC drive system to maximize productivity and reduce downtime. The AC alternator and

traction motors are virtually maintenance free, since their rotors are the only moving parts. The drive

system is controlled via electronic solid state controllers, which are small, extremely fast and have no

moving components to wear out. Lighter than both a DC drive system or a mechanical drive train, an

AC drive system allows for greater payload to empty vehicle weight ratios, faster acceleration and

higher travel speeds. This results in faster cycle times and lower cost per ton productivity.

Photo shows optional equipment and paint

2 T 282 B

NTB_T282B_DIN.indd 2 10.04.2007 10:44:51 Uhr

T 282 B 3

NTB_T282B_DIN.indd 3 10.04.2007 10:44:55 Uhr

Front Wheel and Brakes

When stopping, electric retarding will

slow the truck to a virtual stand still, at

which time the service brakes are au-

tomatically applied by the control sys-

tem while the operator is applying the

retarder pedal. The service brakes are

also automatically applied by the anti

roll back function at very low speeds.

4 T 282 B

NTB_T282B_DIN.indd 4 10.04.2007 10:44:58 Uhr

AC Drive Performance

The Liebherr-Siemens AC drive system has been tested and proven extensively

in mining applications and other industries. It is dependable, easy to service and

maintain and offers a long life expectancy. When coupled to a high horsepower

diesel engine, the continuous acceleration and retard performance without

having to shift gears provides the mine operator with fuel efficiency and high

productivity to reduce cost per ton.

Main Features

Steering support the system will automatically send more power to the outside

rear wheel or reduce power to the inside rear wheel to help reduce tire wear.

Anti Rollback When facing uphill with the travel lever in forward or when facing

downhill with the travel lever in reverse, the truck will not roll down hill when

propulsion is started.

Two speed over speed Automatically limits the truck speed to the pre-set limit.

One setting for a loaded truck and one setting for an empty truck. Overrides the

cruise control setting

Cruise control Two modes are available, retard only cruise and full cruise.

Slip / Slide control Propel power as well as retarding power are automatically

corrected individually for each set of rear wheels to minimize wheel spin or sliding

in adverse road conditions.

SIBAS Monitoring Program

Siemens electronics provide:

- Real time information during operation can be displayed for the operator or be

remotely sent to a centralized management system.

- Snap shots taken during fault events are easily retrievable.

- Load Boxing, to test-check the electric travel drive system at full diesel engine

power, while the truck is parked.

AC drive main components

1. Diesel engine

2. Alternator and rectifier

3. Control box with integrated main blower

4. Traction motors and planetary gears

5. Grid box mounted on the deck

Rear Brakes Differential Wheel Torque Control

The dry disc service brakes When traveling through a curve, the drive

on the front and rear wheels system will automatically adjust the torque

are used to bring the truck to and speed of the rear traction motors in

a safe stop and are designed order to maximize traction and minimize

and tested to comply with tire wear during low speed handling.

ISO 3450.

The rear service brakes

are cooled by forced air,

eliminating the need for an

additional hydraulic cooling

and circulation system.

T 282 B 5

NTB_T282B_DIN.indd 5 10.04.2007 10:45:04 Uhr

Front Suspension

The T 282 B features a Double A-frame Front Suspension.

This unique geometry allows the tire contact point to move

up and down in a straight line during travel and loading.

Immediate and accurate payload weighing is possible since

there are no side loads on the struts.

Due to the A-frames lever action design there is longer

vertical wheel travel than strut travel, resulting in reduced

tire deflection.

6 T 282 B

NTB_T282B_DIN.indd 6 10.04.2007 10:45:05 Uhr

Chassis

Utilizing the latest in software and durability information, Liebherr is able to

focus on a more modernized approach to equipment design by combining

advanced analysis and test validation to produce a product which is truly fit

for purpose.

Engineered to be strong, durable, rugged and yet lightweight, the main frame of

the Liebherr T 282 B continues to evolve while maximizing the payload to empty

vehicle weight ratio ensuring greater productivity and efficiency, reducing the

cost per ton of the mining operation.

Durable Steel Structure

Hollow box frame rails with internal stiffeners fully welded inside and out.

Torque tube connections to absorb warping stresses in the frame rails.

Independent Cross Carriage transfers forces from rear axle and dump cylinders

directly into the frame rails.

Stress flow designed cast steel components are used in high stress areas.

Quality

High strength steel is used throughout the main frame

Ultrasonic inspection aligned with AWS D1.1

Close attention to weld fatigue details

Designed to IIW (International Institute of Welding) weld fatigue guidelines.

Rear Suspension

The unique Rear Wheel Suspension replaces

the traditional nose cone with two Drag Links

and a triangular Rear Control Arm. All forces

from the rear axle are transferred into the truck

frame in straight lines.

Two Suspension Struts transfer all loads from

the frame via the top of the axle box directly

into the wheels. This allows for a shorter, lighter

frame and does not create any torque within the

axle box, saving weight.

T 282 B 7

NTB_T282B_DIN.indd 7 10.04.2007 10:45:12 Uhr

Operator Cab

Featuring integrated ROPS and a fully

insulated double shell construction,

the operator cabin of the Liebherr

T 282 B is ergonomically designed to

allow excellent visibility of the working

environment as well as maximizing

operator comfort and safety.

Visibility is further enhanced with the

aid of mirrors and optional closed

circuit television to assist the operator

in safely operating the truck when in

close proximity to people and smaller

equipment.

8 T 282 B

NTB_T282B_DIN.indd 8 10.04.2007 10:45:17 Uhr

Operator Comfort

The Liebherr T 282 B features a comfortable and safe environment for the operator

enabling efficient equipment control, to achieve excellent performance.

Operator Feedback

Real time digital and analog information is displayed, on a LCD monitor including;

- Vital machine information

- Secondary information and alarms

- Fault event messages.

Three Communications Ports for information sent and received from;

- Engine Control System

- Drive System

- Payload System

Safety

Integrated ROPS (Roll Over Protective Structure) for the cab.

Fully insulated double shell construction.

Two ladders with dual hand rails leading to the deck with

an optional diagonal stairway for safe operator access.

Recessed bolt heads and toe kick plates.

Comfort

Six-way adjustable air suspended driver seat with double

lumbar support, with a full size trainer seat.

Spacious interior with plenty of storage space.

Insulated against sounds, vibration and dust.

Heavy duty heater and air conditioner to maintain a pleasant

environment for the operator.

Access and Egress Deck

Operator comfort and safety is paramount The large and spacious deck of the

to having a productive fleet of equipment. Liebherr T 282 B allows for additional

There are a number of options available installation of optional safety equipment

in regards to access and egress ladders such as fire suppression systems or

designed to ensure three point contact with mine communication systems. The

the equipment and to reduce the stresses standard truck is fitted with two means

and strains on operators and maintenance of egress from the deck.

personnel when climbing on and off the

equipment.

T 282 B 9

NTB_T282B_DIN.indd 9 10.04.2007 10:45:23 Uhr

F

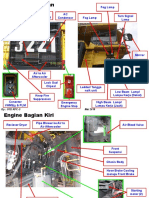

Maintenance Friendly

The Liebherr-Siemens AC drive system of

the T 282 B has few service requirements,

reducing downtime ensuring maximum

productivity of the truck.

Scheduled servicing can be carried out in a

safe manner due to the spacious design and

excellent ground level access to key service

locations.

10 T 282 B

NTB_T282B_DIN.indd 10 10.04.2007 10:45:32 Uhr

Safety and Accessibility

Safety is a key focus in the design of the Liebherr T 282 B. Liebherr recognizes

that the equipment will be more productive if the operator and the service

personnel feel safe in their daily working environment. Some of these safety

features are highlighted below.

Operational Safety

Automatic brake application to bring the truck to a final stop when depressing the

retard pedal.

High capacity retard capability with a virtually immediate response time.

Full retarding capability with a dead engine.

Anti rollback in forward and reverse.

Slip / Slide control both uphill and in downhill modes.

Fire Prevention By Design

Fuel and hydraulic lines are separated from electrical lines and heat sources

Critical hydraulic hose are encased in non permeable hose sleeves

Turbochargers and exhaust piping are shielded by insulated pre shaped covers

and side exhausts are standard.

Access ladders are fabricated with solid steel backs and fire aprons are fitted

between the ladders and the engine compartment.

Legend:

A Spacious, high visibility operator cabin with integrated ROPS

and low sound levels for the operator

B Optional engine air filter platforms for better maintenance access

C Optional drop down access ladder for safer access and egress

D Diagonal access ladder with dual hand rails to maintain a three

point contact at all times

E High intensity discharge headlights for optimum visibility

C F Optional fire suppression systems

G Optional off driver side and rear view closed circuit telemetry

for increased visibility

Accessibility Service Points

Ladders to access the engine and alternator The automatic lubrication system

are located on both sides of the main chassis reduces downtime.

with excellent walk around access via service

Sampling points located at or near

platforms.

ground level.

Engine and hydraulic system filters accessible

Centralized service station located

either from the ground level or from the catwalks

conveniently at ground level for fast

around the engine installation.

and efficient refilling.

Drop down door and steps to access the rear axle

Air cleaner restriction gauges mounted

boxs electrical and mechanical components.

in the cab for optimum visibility.

Tie off points where access is limited.

T 282 B 11

NTB_T282B_DIN.indd 11 10.04.2007 10:45:39 Uhr

Technical Data

Engine Braking Systems

Model ______________________________ MTU DD 20V4000 Electric dynamic retard with continuously rated, fan forced air over stainless steel

Gross horsepower @ 1800 rpm ________ 2,722 kW (3,650 hp) resistor grids with a dry disc secondary braking system

No. of cylinders ______________________ 20 Electric dynamic retard _______________ Max: 4,480 kW (6,030 hp)

Displacement ________________________ 90 L (5,490 in) Extended speed range ________________ Full retarding down to 0.8 km/h

(0.5 mph). Automatic brake blending

Wet weight __________________________ 10,480 kg (23,100 lbs) with service brakes down to zero.

Crankcase __________________________ 390 L (103 gal) Cruise control _______________________ Operator adjustable and will auto

Cooling system ______________________ 758 L (200 gal) retard truck on downhill grade

Two speed over speed ________________ Automatic speed settings for empty

Model ______________________________ Cummins QSK 78 and loaded truck adjustable for site

Gross horsepower @ 1900 rpm ________ 2,610 kW (3,500 hp) requirements

No. of cylinders ______________________ 18 Slip slide traction control ______________ Computer controlled, propel and retard,

Displacement ________________________ 78 L (4,735 in) forward and reverse, fully independent

left and right.

Wet weight __________________________ 11,300 kg (24,912 lbs)

Service brakes front __________________ Single disc, wheel speed, five calipers

Crankcase __________________________ 281 L (74 gal) per wheel

Cooling system ______________________ 721 L (191 gal) Service brakes rear ___________________ Dual discs per side, one caliper per

Fan clutch ___________________________ Rockford variable speed, temperature disc, armature speed

controlled Hydraulic accumulators _______________ 2 x 7.6 L (2 x 2 gal), Separate

Air cleaners _________________________ Two units with 2 elements per unit accumulator for front and rear axle.

with restriction gauges in the cab Park brakes _________________________ Spring applied, pressure released, one

Radiator ____________________________ Mesabi caliper per each rear disc.

Starter ______________________________ Electric Filtration ____________________________ Cleanliness level ISO 18/16/13

Roll out power module ________________ Radiator, engine and alternator,

mounted on roll out sub frame

Batteries ____________________________ 6 x 12 Volt, (3 series of 2), 1200 CCA

each at -18 C (0 F), 1475 CCA at

0 C (32 F)

Steering

Ackermann center point lever system. Full hydraulic power steering with accu-

mulator safety backup. Fully separate from dump hydraulic system. Two double

Electric Drive System acting hydraulic cylinders.

Hydraulic accumulator ________________ 174 L (46 gal) SAE J53

Manufacturer ________________________ Siemens-Liebherr Filtration ____________________________ Cleanliness level ISO 18/16/13

Alternator ___________________________ AC brushless, direct drive with top Turning radius (SAE) Tire centerline* ___ 18.6 m (61 ft)

mounted rectifier Vehicle clearance Radius ______________ Depends on options fitted

Traction motors ______________________ AC induction motors * This is a theoretical calculation and depends on the ground surface, the strut

Gear ratio ___________________________ Standard 37.33 to 1 length and tie rod length

Optional 43.7 to 1

Max speed __________________________ 64 km/h / 40 mph

Cooling fan __________________________ AC drive, two impeller radial fan,

control box mounted. Dump System

Two double stage, double acting hoist cylinders with inter stage and end cush-

ioning in both directions. Electronic joystick with full modulating control in both

extend and retract.

Tires Dump angle _________________________ 45

Rims _______________________________ 41 inch wide with 5.5 x 5 inch flanges Cycle times __________________________ Raise - 34 sec

Power Down - 22 sec

Tires ________________________________ Michelin 56/80 R63 or Bridgestone

59/80 R63 Remote dump _______________________ Quick disconnects for external power

dumping (buddy dump) accessible

from ground level

Filtration ____________________________ Cleanliness level ISO 18/16/13

Suspensions

Front suspension _____________________ Double A-frame with inclined king pin

design pivot and spindle

Body

Rear suspension _____________________ Three bar linkage comprised of Two double stage, double acting hoist cylinders with inter stage and end cus-

triangular upper link plus two bottom hioning in both directions. Electronic joystick with full modulating control in both

drag links extend and retract.

Suspension struts ____________________ Nitrogen over oil with integral

damping.

12 T 282 B

NTB_T282B_DIN.indd 12 10.04.2007 10:45:42 Uhr

Technical Data

Frame Weights

Design ______________________________ Closed box structure with multiple Payload class ________________________ 363 t / 400 ton

torque tube cross members, internal Max operating weight _________________ 592 t / 652.5 ton

stiffeners and integrated front

bumper. Steel castings are used in Chassis weight * _____________________ 189 t / 208 ton

stress concentration areas. Body weight _________________________ Custom for each mine site

Welding _____________________________ Frame girders welded inside and out Frame capacity ** ____________________ 404 t / 445 ton

with ultrasonic inspection aligned Weight distribution ___________________ Empty front 46 % / Rear 54 %

with AWS D1.1 Loaded front 33 % / rear 67 %

* depends on options fitted

** total weight of body and payload, subject to chassis weight.

Operator Cab

Deluxe operator cabin with integrated ROPS and double wall design for

optimum insulation. Fully adjustable air suspension operator seat with double

Fluid Capacities

lumbar support and full size second seat for training requirements. Operator

comfort controls include a tilt and telescoping steering wheel, heater, defroster Fuel tank ____________________________ 4,732 L / 1,250 gal

and standard AC. Real time vital truck information is easily displayed to the Hydraulic dump circuit

operator and also recorded for download. - Tank ______________________________ 1,302 L / 344 gal

- System ____________________________ 1,514 L / 400 gal

Hydraulic brake and steering

- Tank ______________________________ 924 L / 244 gal

Sound - System ____________________________ 1,060 L / 280 gal

Final drives, each (2) __________________ 280 L / 74 gal

Designed to meet OSHA and MSHA occupational noise criteria for truck opera- Front wheels, each (2) ________________ 60 L / 16 gal

tor weighted sound exposure Grease tank _________________________ 90 kg / 200 lbs

Dimensions

T 282 B 13

NTB_T282B_DIN.indd 13 10.04.2007 10:45:42 Uhr

Performance Curves

Performance Chart Parameters

Gross power _________________________ 2,722 kW (3,650 hp)

Net power ___________________________ 2,558 kW (3,430 hp)

Tire size _____________________________ 56/80 R63

Gear ratio ___________________________ 37.33 to 1

Reference curves ____________________ A: Propulsion

B: Retard

C: Trolley (see note 1)

Note 1. Trolley performance shown is augmented with engine power if the line

voltage is below 2600 VDC.

The propulsion curve is calculated using net horsepower therefore site specific

and climatic variables will have an effect on the parasitic losses.

Optional performance charts are available on request.

Performance Chart Parameters

Gross power _________________________ 2,722 kW (3,650 hp)

Net power ___________________________ 2,558 kW (3,430 hp)

Tire size _____________________________ 56/80 R63

Gear ratio ___________________________ 43.7 to 1

Reference curves ____________________ A: Propulsion

B: Retard

C: Trolley (see note 1)

Note 1. Trolley performance shown is augmented with engine power if the line

voltage is below 2600 VDC.

The propulsion curve is calculated using net horsepower therefore site specific

and climatic variables will have an effect on the parasitic losses.

Optional performance charts are available on request.

14 T 282 B

NTB_T282B_DIN.indd 14 10.04.2007 10:45:42 Uhr

Standard/Optional Equipment

Truck Standard Equipment Truck Optional Equipment

Automatic air cleaner dust ejectors Air Starter

Side exhaust with insulated exhaust pipes Gear ratio of 43.7 to 1

Mufflers Cold climate kits

L&M (Mesabi) radiator Retractable access ladder

Large diameter, low rpm engine fan Special language decals

Rockford fan clutch Additional headlights

Electric starter Fog lights

6 x HD 12 V Batteries Hub-odometer

Engine shutdown and disconnect at ground level Additional mud flaps

Bolted rims on front and rear Fire suppression systems

Spring applied pressure released park brake Heated dump body

Accumulator backup on steering and hydraulic brake system Body liner packages

Dual access ladders plus diagonal ladder Tailgate for coal body

Catwalks and platforms on both sides of the engine Trolley drive

Automatic lubrication system Custom paint specification

Centralized service station (driver side) Side and rear video camera

Back up warning alarm Air cleaner access platforms

Service lights in engine compartment and axle box Belly pan skid plates

Ladder access lights Air ride passenger seat

Auxiliary dump, brake and steering connectors

Second fuel gauge on centralized service station Please contact your local representative for further information.

Sight gauge on hydraulic tank

Sight gauge on radiator header tank

Mud flaps on both sides of hydraulic and fuel tanks

Rear wheel rock ejectors

Hand held fire extinguishers (2) mine to install

External digital payload system display on left and right

Liebherr white standard color for chassis.

Integrated ROPS

Fully adjustable operator seat with air suspension

Passenger seat with mechanical suspension

2 point seat belt

Tempered front cab glass with laminated safety glass on other windows

Power windows

Dual blade windshield wipers, electric

Side mirrors, left and right

Tilt and telescopic steering wheel with horn

3 x sun visors

Pressurized cab with filtered heater and defroster and standard Red Dot AC System

12 VDC and 115VAC power supply in cab

Computerized dash display

Air cleaner restriction indicators

37.33 to 1 gear ratio

T 282 B 15

NTB_T282B_DIN.indd 15 10.04.2007 10:45:43 Uhr

The Liebherr Group of Companies

Wide product range State-of-the-art technology

The Liebherr Group is one of the largest earthmoving and To provide consistent, top quality products, Liebherr

construction equipment manufacturers in the world. attaches great importance to each product area, its

Liebherrs high-value products and services enjoy a high components and core technologies. Important modules

reputation in many other fields, too. The wide range and components are developed and manufactured in-

includes domestic appliances, aerospace and transporta- house, for instance the entire drive and control techno-

tion systems, machine tools and maritime cranes. logy for construction equipment.

Exceptional customer benefit Worldwide and independent

Every product line provides a complete range of models Hans Liebherr founded the Liebherr family company in

in many different versions. With both its technical excel- 1949. Since that time, the enterprise has steadily grown to

lence and acknowledged quality, Liebherr products offer a Group of 100 companies with over 26,000 employees

a maximum of customer benefits in practical application. located on all continents. The corporate headquarters of the

Group is Liebherr-International AG in Bulle, Switzerland.

The Liebherr family is the sole owner of the company.

www.liebherr.com

Printed in Germany by Eberl BK-RP LME 10100385-2-04.07 Subject to change without notice.

Liebherr Mining Equipment Co.

4100 Chestnut Avenue, Newport News, VA 23607, USA

+1 757 245 5251, Fax +1 757 928-8755

www.liebherr.com, E-Mail: info.lme@liebherr.com

NTB_T282B_DIN.indd 16 10.04.2007 10:45:43 Uhr

You might also like

- Mobil Renault-K-380-824006Document16 pagesMobil Renault-K-380-824006Joko PurwodadiNo ratings yet

- Arocs 4042 K 6x4 Euro 5Document2 pagesArocs 4042 K 6x4 Euro 5Yessa FitraNo ratings yet

- Drive Lines, Differentials, and Power TrainsDocument44 pagesDrive Lines, Differentials, and Power TrainsAnonymous QiMB2lBCJLNo ratings yet

- Belaz 75137 Usa and CanadaDocument2 pagesBelaz 75137 Usa and CanadabasNo ratings yet

- Series TF350 180Document2 pagesSeries TF350 180Eka Sugiantoro0% (1)

- HarisDocument28 pagesHarisZen PNo ratings yet

- 385C Cat Vs PC8007 KomatsuDocument78 pages385C Cat Vs PC8007 KomatsuKolo BenduNo ratings yet

- P410CB 8x4 PDFDocument2 pagesP410CB 8x4 PDFAgustinus Yosef100% (1)

- HD465-7Document6 pagesHD465-7hebert131No ratings yet

- Hydraulic Excavator: Engine WeightsDocument28 pagesHydraulic Excavator: Engine WeightsAkhmad SebehNo ratings yet

- Brochure PV-311 High Res A4 Tcm835-3508041Document4 pagesBrochure PV-311 High Res A4 Tcm835-3508041David SantoNo ratings yet

- 730E (AC) Spec Sheet PDFDocument16 pages730E (AC) Spec Sheet PDFsoufiane OkNo ratings yet

- SuspensionDocument2 pagesSuspensionSandeep MeenaNo ratings yet

- P410CB 8x4 PDFDocument2 pagesP410CB 8x4 PDFAgustinus YosefNo ratings yet

- Final Drive ChecklistDocument2 pagesFinal Drive Checklistkathir drayNo ratings yet

- Kertas PeneranganDocument11 pagesKertas Peneranganamir akmalNo ratings yet

- 3 Axles Side Tipper Semi-TrailerDocument1 page3 Axles Side Tipper Semi-TrailerAndy WangNo ratings yet

- ISO Sovereign Parts ListDocument17 pagesISO Sovereign Parts ListTiago PortanskyNo ratings yet

- Operation & Maintenance Manual For End Suction Type Pumps: Patterson Pump CompanyDocument25 pagesOperation & Maintenance Manual For End Suction Type Pumps: Patterson Pump CompanyvaisakhpillaiNo ratings yet

- Swedish hypercar maker KoenigseggDocument11 pagesSwedish hypercar maker KoenigseggAzizul Anwar0% (1)

- 777 BrochureDocument36 pages777 BrochureAlexandra Ioana IoanaNo ratings yet

- Komatsu Dump Truck HD785-5 SpecsDocument8 pagesKomatsu Dump Truck HD785-5 SpecsSatria SpaNo ratings yet

- Spesifications of Hino ZY1EWPD Series (8X4)Document2 pagesSpesifications of Hino ZY1EWPD Series (8X4)MuhaiminNo ratings yet

- Adt Cat 740/745 40T (40 Ton)Document5 pagesAdt Cat 740/745 40T (40 Ton)Wildan Anrian100% (1)

- Wheel Dozers & Soil CompactorsDocument19 pagesWheel Dozers & Soil CompactorsJorge Gutierrez100% (1)

- Balancer HW 113 (Eng)Document40 pagesBalancer HW 113 (Eng)Suresh Naidu100% (2)

- CAT775GDocument32 pagesCAT775GAndy Chan100% (1)

- Spesifications of Hino Ranger FL 235,260 Series (6X2)Document4 pagesSpesifications of Hino Ranger FL 235,260 Series (6X2)MuhaiminNo ratings yet

- A64 Service Lube Datasheet PDFDocument8 pagesA64 Service Lube Datasheet PDFCruzado Vilca AmesquitaNo ratings yet

- Elektrim Techtop CatalogueDocument20 pagesElektrim Techtop CatalogueCao Trang PhamNo ratings yet

- HTTP WWW - Etftrucks.eu Downloads Etf BrochureDocument20 pagesHTTP WWW - Etftrucks.eu Downloads Etf Brochuregamarus7771372No ratings yet

- Tokyu Low Bed Trailer - Sleading 50TDocument1 pageTokyu Low Bed Trailer - Sleading 50TRiyanto RiyantoNo ratings yet

- HD Premium 50 Pre-Diluted PDFDocument2 pagesHD Premium 50 Pre-Diluted PDFereresrdfNo ratings yet

- CAT 777G FiltersDocument3 pagesCAT 777G FiltersettoscarNo ratings yet

- Every Ton.: Non-Certified Engines For Mining ApplicationsDocument4 pagesEvery Ton.: Non-Certified Engines For Mining ApplicationsCarlos andres Revelo gomezNo ratings yet

- Duratray TraysDocument6 pagesDuratray TraysAlejandroZappaNo ratings yet

- HONDA ADV Brochure F.A 13DEC19 PDFDocument4 pagesHONDA ADV Brochure F.A 13DEC19 PDFFrey NazNo ratings yet

- Chubb ExtinguisherDocument14 pagesChubb Extinguisherprsiva2420034066No ratings yet

- Remove & Install RadiatorDocument4 pagesRemove & Install RadiatorIndah Widya PutriNo ratings yet

- SANY TRUCK CRANE STC 250 SPECS AND LIFTING RANGEDocument8 pagesSANY TRUCK CRANE STC 250 SPECS AND LIFTING RANGEfajarNo ratings yet

- SCN0046 P410 MSZDocument2 pagesSCN0046 P410 MSZCristian ChiruNo ratings yet

- FM400 - 8x4 Tipper - 18.7cum PDFDocument12 pagesFM400 - 8x4 Tipper - 18.7cum PDFavinawsh100% (1)

- Rawler Ozer: With Steering Clutch/Brake SystemDocument10 pagesRawler Ozer: With Steering Clutch/Brake SystemDinh Phu LeNo ratings yet

- Komponen HD 785-7Document23 pagesKomponen HD 785-7Wahyu IskandarNo ratings yet

- TONLY Vs SINOTRUCK - Main Assembly & Performance Comparison - Richie - 20160902Document4 pagesTONLY Vs SINOTRUCK - Main Assembly & Performance Comparison - Richie - 20160902Sumitomo Laos Sumitomo LaosNo ratings yet

- MB 4054 S TRACKTOR 6x4 (Full Spec.)Document18 pagesMB 4054 S TRACKTOR 6x4 (Full Spec.)Mar Dha ZudyanNo ratings yet

- United Tractors Machines & EnginesDocument17 pagesUnited Tractors Machines & EnginesAkbar WijayaNo ratings yet

- P410 B6X4 Coal 01 130122 1 1Document4 pagesP410 B6X4 Coal 01 130122 1 1mickel santoniNo ratings yet

- ETF Truck Presentation April 2011 PDFDocument43 pagesETF Truck Presentation April 2011 PDFwilledworkerNo ratings yet

- LTM1120 Technical DataDocument18 pagesLTM1120 Technical DataVinodh Palanichamy0% (1)

- Power Train Components and FunctionsDocument70 pagesPower Train Components and FunctionsJang UziNo ratings yet

- Pluma Reforzada AK-912Document19 pagesPluma Reforzada AK-912William Espinoza OrellanaNo ratings yet

- TVS115 engine parts listDocument5 pagesTVS115 engine parts listmcswain99No ratings yet

- Dual Ignition PDFDocument3 pagesDual Ignition PDFSiddharth SharmaNo ratings yet

- CAT Forklift Spec SheetDocument3 pagesCAT Forklift Spec SheetJuan Carlos100% (1)

- Amco Veba Marine - Brochure - LRDocument24 pagesAmco Veba Marine - Brochure - LRHươngTpuNo ratings yet

- Electric Truck Variable Speed Drive Current OscillationsDocument12 pagesElectric Truck Variable Speed Drive Current OscillationsLiebherr100% (1)

- Liebherr T282B GB NTB PDFDocument12 pagesLiebherr T282B GB NTB PDFJulio100% (1)

- CAT D6R2-Brochure PDFDocument24 pagesCAT D6R2-Brochure PDFalvaro gavrielNo ratings yet

- Volvo Trucks I-Shift AT2412F 12-Speed Automatic TransmissionDocument3 pagesVolvo Trucks I-Shift AT2412F 12-Speed Automatic TransmissionMohammad Saleh AbbasiNo ratings yet

- Gas Exchange in Plants and AnimalsDocument7 pagesGas Exchange in Plants and AnimalsMarvin MelisNo ratings yet

- Spectrophotometric Determination of Triclosan Based On Diazotization Reaction: Response Surface Optimization Using Box - Behnken DesignDocument1 pageSpectrophotometric Determination of Triclosan Based On Diazotization Reaction: Response Surface Optimization Using Box - Behnken DesignFitra NugrahaNo ratings yet

- 0580 w15 QP 42Document16 pages0580 w15 QP 42Shahrizan Noor100% (1)

- Mic ProjectDocument12 pagesMic Projectsarthakjoshi012No ratings yet

- Vectors FoundationDocument8 pagesVectors FoundationNaning RarasNo ratings yet

- Production of Natural Bamboo Fibers-1: Experimental Approaches To Different Processes and AnalysesDocument13 pagesProduction of Natural Bamboo Fibers-1: Experimental Approaches To Different Processes and AnalysesrabiulfNo ratings yet

- Shri Durga Chalisa 1Document25 pagesShri Durga Chalisa 1gsameeriitdNo ratings yet

- Experimental Design and Optimization MethodsDocument38 pagesExperimental Design and Optimization MethodssudalaiyandiNo ratings yet

- PCB Table of Contents GuideDocument3 pagesPCB Table of Contents GuidePreet ChahalNo ratings yet

- 32776Document6 pages32776Muqtar KhanNo ratings yet

- Pancreatic NekrosisDocument8 pagesPancreatic Nekrosisrisyda_mkhNo ratings yet

- Scheme of Valuation and Key for Transportation Engineering ExamDocument3 pagesScheme of Valuation and Key for Transportation Engineering ExamSivakumarNo ratings yet

- Project Cash FlowsDocument2 pagesProject Cash FlowsAdarsh Chhajed20% (5)

- Medulla Oblongata Nucleus (Final)Document7 pagesMedulla Oblongata Nucleus (Final)Hassan.shehri100% (3)

- A Kitchen in The Corner of The HouseDocument2 pagesA Kitchen in The Corner of The HousedanielrubarajNo ratings yet

- March 17, 2016 Strathmore TimesDocument24 pagesMarch 17, 2016 Strathmore TimesStrathmore TimesNo ratings yet

- Bentone LTDocument2 pagesBentone LTdamiendamNo ratings yet

- Contemporary Philippine Arts From The Regions: Quarter 3Document15 pagesContemporary Philippine Arts From The Regions: Quarter 3Ackie Inacay RosarioNo ratings yet

- Chefs at HomeDocument4 pagesChefs at Homezbdv2kyzv7No ratings yet

- DigiMasterIII Car Model ListDocument72 pagesDigiMasterIII Car Model ListRAGB1989No ratings yet

- 03-Mechanical Seal &seal System Basics-REV01Document39 pages03-Mechanical Seal &seal System Basics-REV01Fayez Al-ahmadiNo ratings yet

- EAPP w2Document13 pagesEAPP w2Elijah AquinoNo ratings yet

- MR 20 Nissan PDFDocument1,639 pagesMR 20 Nissan PDFFREDYRUFO AZA MORALES83% (6)

- Blower Selection For Wastewater Aeration PDFDocument10 pagesBlower Selection For Wastewater Aeration PDFRobert MontoyaNo ratings yet

- Da Memorandum Order No 6 Implementation Guidelines of The Kadiwa Ni Ani at Kita ProjectDocument17 pagesDa Memorandum Order No 6 Implementation Guidelines of The Kadiwa Ni Ani at Kita ProjectMildred VillanuevaNo ratings yet

- Kinematics Problem SetDocument1 pageKinematics Problem SetMohammad JubranNo ratings yet

- Final Project Proposal Digital Stopwatch-1Document6 pagesFinal Project Proposal Digital Stopwatch-1Shahid AbbasNo ratings yet

- ElectrochemistryDocument24 pagesElectrochemistryZainul AbedeenNo ratings yet

- Automatic Transaxle PDFDocument50 pagesAutomatic Transaxle PDFdemos70100% (1)

- Copeland CompressorDocument135 pagesCopeland CompressorsugirinNo ratings yet