Professional Documents

Culture Documents

JHA Civil Works

Uploaded by

ethelchudiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JHA Civil Works

Uploaded by

ethelchudiCopyright:

Available Formats

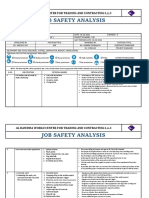

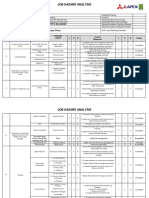

OKOLOMA GAS PLANT PROJECT - RIVERS STATE

JOB HAZARD ANALYSIS

JHA No. AFM-ALC-OKL-F18-00002 Title/JOB DESCRIPTION Company Site Number of Persons Supervisor

Yamah Mathias

NEW OR REVISED Civil Works - OKL Gas Plant ALCON NIGERIA LIMITED Okoloma 6

New Date: 22nd JUNE, 2006 Revison No: Author/ANALYSIS Revised By Reviewed By

Revised

Ikenna O./I. O Egwero

Kevin Doyle

Flavio Grosso/M. Yamah

Department SPDC HSE REFERENCE MANUAL MODULE Equipment / Location PERMIT REQUIRED YES/NO if yes number of PTW PPE Required (put Requirements in BOLD ITALICS)

Civil Works

Approved By

K. Doyle./F. Onyekpe

(14 - Material handling, 03 - PPE, 02 - PTW) Survey instrument, Cutlass,Hammer,Radios, Measurement Contract No: tape / OKL GAS Plant Site 0073474 TOOL BOX Meeting Held/Location

E-17937

Okoloma site Hard Hat/Safety Clear Glasses/Safety Tinted glasses/Goggles/Dust Mask/Welding Mask/Power Respirator/SCBA/Half Mask Respirator/Ear plugs/Ear Defenders/Cotton Coveralls/Fire Proof Coveralls/HI Viz Jacket/Gloves/Gauntlets/Safety Shoes/Wellington boots/Safety Harness/Life jacket Potential hazards 1. Equipment failure and exposure to reptiles. Effect/Consequence 1. Injury to personnel and material damage Hazard Rating Recommended Safe Job Controls 1. All equipment for work to be fit for purpose. 2 Use of flagman to safely direct equipment movement. 3 Use appropriate PPE. 4 Strict access control area, Ensure good journey management, Stop work during poor weather 1. Use of appropriateTBT as a minimum for all workers condition, Recorded PPE. 2. Use fit for purpose probe meter

Job Sequence Mobilization of equipment to site

2. Check work site for U/G metals, pipes and live cable routes.

1. Personnel may trip or fall. 2. Contact with sharp objects

1. Injury to personnel, M

3. Clearing ground with earth moving equipment.

1. Exposure to dust. 2. Personnel contact with equipment moving part. 3. Equipment failure

1 Injury to personnel 2 Damage to materials M

1. 2. 3. 4.

Use appropriate PPE. Strict access control Use of fit for purpose equipment. Use of flagmen to safely direct equipment movement.

4. Remove scraped-out waste to approved dump site

1. Exposure to dust particles. 2 Equipment failure. 3. Exposure to community 1 Exposure to dust particles. 2 Equipment failure.

1. Injury to personnel 2. Damage to materials

1. Use appropriate PPE. 2 Use of fit for purpose equipment. 3 Strict adherence to journey management 1. Use appropriate PPE. 2 Use of fit for purpose equipment. 3 Use of dedicated flagmen to safely direct equipment movement

5. Sand Filling and compacting earth materials.

1 Injury to personnel. 2 Damage to materials.

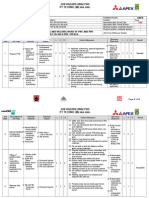

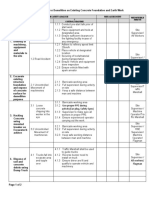

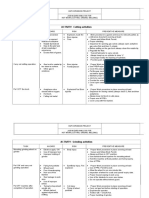

Job Sequence 6. Setting out works

Potential hazards .1 Exposure to underground live cable. 2 Personnel may fall 1. Exposure to dust 2 Personnel contact with equipment moving part. 3. Equipment failure. 4. Exposure to underground utilities 1. Exposure to cement dust. 2 Personnel contact with equipment moving part. 3 Equipment failure. 4 Trip and fall. 1. Personnel may trip or fall. 2 Contact with sharp objects. 3. Equipment failure. 1. Personnel may trip or fall. 2 Contact with sharp objects. 3. Contact with concrete 1. Personnel may trip or fall. 2 Contact with sharp objects. 3. Equipment failure. 4. Rigging accessories failure 1 Exposure to dust particles. 2 Equipment failure. 1 Slip, trip and fall

Effect/Consequence 1. Injury to personnel.

Hazard Rating

Recommended Safe Job Controls 1. Use fit for purpose probe meter to check for U/G utilities 2 Ensure good housekeeping 3. Use as built drawing (if available) 1. Use fit for purpose probe meter to check for U/G utilities 2 Ensure good housekeeping 3. Use as built drawing (if available) 4. Manual trial digging before mechanical digging 1. 2 3 4. 1. 2 3 4. Use appropriate PPE. Use of fit for purpose equipment. Use of dedicated flagmen to safely direct equipment movement. Strict access control. Use appropriate PPE. Use of fit for purpose equipment. Use of dedicated flagmen to safely direct equipment movement. Strict access control

M 1. Injury to personnel 2 Damage to materials. 3. Electrical shock. 4. Fire/explosion 1. Injury to personnel. 2 Damage to materials.

7. Mechanical/manual Excavation works

8. Concrete mixing

9. Concrete transfer (Mechanical/manual)

1. Injury to personnel. 2 Damage to materials. . 1. Injury to personnel.

10 Blinding of foundation

M 1 Injury to personnel 2 Damage to portacabin/ pre cast pipe supports 1 Injury to personnel. 2 Damage to materials 1 Injury to personnel L

1. Use appropriate PPE. 2 Good housekeeping. 3. Strict access control 1. Use of fit for purpose equipment. 2. Use of experienced riggers 3. Use of appropriate PPE. 4. Use of certified rigging accessories. 5. Strict access control 1. Use appropriate PPE. 2 Use of fit for purpose equipment. 3 Use of dedicated flagmen to safely direct equipment movement 1 Practice good house keeping. 2 Use of appropriate PPE. 1. Ensure work permit is signed off. (Copies given to appropriate departments).).

11 Installation of portacabin/ precast Concrete supports.

12. Sand filling of area with sharp sand

13 Clean up work site

14 Close out permit 1. Lack of understanding

1. Non-compliance L

CREW ACKNOWLEDGEMENT: This JHA was explained and discussed with us by our foreman / supervisor at the site toolbox meeting. I have been briefed on the hazards and necessary control measures including the correct PPE. I have received instructions on the need to work safe in order not to harm myself, fellow team workers and other workers nearby. I have also been briefed on the nearby work activities and the associated hazards on my work. I am aware of the guidelines to follow in case of an emegency. DATE:....... JHA NO: AFM-ALC-OKL-F18-00002 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

You might also like

- Jsa For Arc WeldingDocument3 pagesJsa For Arc Weldingtnssbhaskar100% (4)

- Excavations: Job Safety AnalysisDocument5 pagesExcavations: Job Safety AnalysisJICKNo ratings yet

- Risk AssessmentDocument10 pagesRisk Assessmentalamdar321100% (2)

- Concreting and ShutteringDocument3 pagesConcreting and ShutteringAnuj Kjoy0% (1)

- Jha Tree Cutting, Felling, Balling v. 2Document10 pagesJha Tree Cutting, Felling, Balling v. 2arsenio100% (1)

- Jsa CraneDocument3 pagesJsa Cranenattwa201075% (24)

- JSA G17 Lift Container With CraneDocument4 pagesJSA G17 Lift Container With CraneYosep Sapto Rahyudi100% (3)

- Jha For RoadworksDocument15 pagesJha For RoadworksHenry RajahNo ratings yet

- (JSA) For Cast-In-place Reinforced ConcreteDocument1 page(JSA) For Cast-In-place Reinforced ConcreteNazir Hussain100% (4)

- JOB HAZARD ANALYSIS (Pipe Laying)Document9 pagesJOB HAZARD ANALYSIS (Pipe Laying)jay R100% (3)

- NWC Corporate Projects Risk Assessment Forms: Job / TaskDocument3 pagesNWC Corporate Projects Risk Assessment Forms: Job / TaskNowfal HabeebNo ratings yet

- JSA Fitting and Welding Work For Pipe Trench InstalationDocument6 pagesJSA Fitting and Welding Work For Pipe Trench InstalationAzmi Fauzi78% (9)

- Oil & Gas Rig Inspection ChecklistDocument34 pagesOil & Gas Rig Inspection ChecklistlukevNo ratings yet

- JSA For Demobilization WorksDocument2 pagesJSA For Demobilization WorksIanne Dee85% (13)

- OSHA 1926-Subpart QDocument7 pagesOSHA 1926-Subpart QSteven HalewskiNo ratings yet

- JSA For Welding GrindingDocument7 pagesJSA For Welding GrindingBabar78% (9)

- Job Safety Analysis for Concrete WorksDocument8 pagesJob Safety Analysis for Concrete Worksfrancis_e_tan93% (27)

- Aboveground Piping Installation Works 2016Document7 pagesAboveground Piping Installation Works 2016Aldrin75% (4)

- 2020 Safety Strategy - Training SlidesDocument28 pages2020 Safety Strategy - Training SlidesThaís Felipe GermanoNo ratings yet

- 001 - JHA Survey Setting Out - REV000Document5 pages001 - JHA Survey Setting Out - REV000Venkadesh Periathambi100% (2)

- 7 - Civil WorkDocument12 pages7 - Civil WorkPerwez21100% (1)

- Draft JSA Levelling & GradingDocument9 pagesDraft JSA Levelling & GradingAzeem Khan33% (3)

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDocument9 pagesHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- Jha For Earth WorkDocument6 pagesJha For Earth Worknik100% (13)

- Job Safety Analysis for Relay ConfigurationDocument4 pagesJob Safety Analysis for Relay Configurationfrancis_e_tan100% (2)

- JSA For Cutting, Grinding and WeldingDocument4 pagesJSA For Cutting, Grinding and Weldingyc safety100% (3)

- Jsa ExcavatorDocument1 pageJsa Excavatorbladeliger22No ratings yet

- ULSADO-JSA-Demolation Existing Concrete FoundationDocument2 pagesULSADO-JSA-Demolation Existing Concrete FoundationKelvin Tan75% (4)

- JHA-011 (Power Brush & Touch-Up Painting Activities 1)Document1 pageJHA-011 (Power Brush & Touch-Up Painting Activities 1)shaiful annuar50% (2)

- AHPI Standard For Green & Clean HospitalDocument31 pagesAHPI Standard For Green & Clean HospitalAgita Ayu KusumahNo ratings yet

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDocument4 pagesJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- Chilled Water Pipe Installation - ACMVDocument4 pagesChilled Water Pipe Installation - ACMVbinhjuki100% (2)

- JHA - Civil Work - Excavation (Manual & Mechanical), Form Work & Concreting For Marlin ProjectDocument9 pagesJHA - Civil Work - Excavation (Manual & Mechanical), Form Work & Concreting For Marlin ProjectKelvin TanNo ratings yet

- JHA - Survey WorksDocument3 pagesJHA - Survey WorksNazirul Syazwan100% (3)

- Safe Work Method Statement FormDocument7 pagesSafe Work Method Statement FormSokha RunNo ratings yet

- Jsa For Piping and Erection RevisedDocument1 pageJsa For Piping and Erection RevisedDr AnwarNo ratings yet

- JHA For Excavation Backfilling and Compaction R 01Document6 pagesJHA For Excavation Backfilling and Compaction R 01Sreekumar100% (2)

- Jsa Installation of Supports and Cable Racks1Document16 pagesJsa Installation of Supports and Cable Racks1loveson709100% (3)

- JSA Shut Down and Tie in Work PDFDocument6 pagesJSA Shut Down and Tie in Work PDFpjosesm80% (5)

- JSA Steel Erection ManliftsDocument1 pageJSA Steel Erection Manliftsrudygoot100% (1)

- Job Safety Analysis PlumbersDocument5 pagesJob Safety Analysis Plumbersallen2912100% (1)

- Tie in Hot Work JHADocument4 pagesTie in Hot Work JHAmalik jahan100% (2)

- Jha Lin FillingDocument6 pagesJha Lin FillingLuqman OsmanNo ratings yet

- JSA Template 5 - Plumbing and Wastewater System InspectionsDocument13 pagesJSA Template 5 - Plumbing and Wastewater System InspectionsSayed Darwish100% (2)

- JRA Exxon Format - Insulation Removal and ReinstatementDocument3 pagesJRA Exxon Format - Insulation Removal and ReinstatementJayesh J PillaiNo ratings yet

- Civil Works Construction Laydown AreaDocument4 pagesCivil Works Construction Laydown AreaMohammed MinhajNo ratings yet

- Civil JSA Form Block WorkDocument3 pagesCivil JSA Form Block Workdrmuhsin86% (7)

- Job Safety Analysis Lifting and RiggingDocument17 pagesJob Safety Analysis Lifting and RiggingSam Seed100% (1)

- JHA Scaffolding ErectionDocument12 pagesJHA Scaffolding ErectionChayank TiwariNo ratings yet

- Part-A: Jsa Date: 23.11.16 Work Permit No: HW-: Civil Works Inside The Tank DykeDocument4 pagesPart-A: Jsa Date: 23.11.16 Work Permit No: HW-: Civil Works Inside The Tank DykevivekaramanaNo ratings yet

- Civil JSA Form Application of Protective Coating On Sump PitsDocument1 pageCivil JSA Form Application of Protective Coating On Sump PitsdrmuhsinNo ratings yet

- Jsa ExcavationDocument33 pagesJsa Excavationlal5012002390782% (17)

- JHA - Handrails and GratingsDocument10 pagesJHA - Handrails and GratingsVidyesh Nair67% (3)

- Job Safety AnalysisDocument2 pagesJob Safety AnalysisQin Qin63% (8)

- JSA-010 Excavation Sampling PDFDocument5 pagesJSA-010 Excavation Sampling PDFArgaYurIstiawanNo ratings yet

- JSA For Rebar Works Includes Working in ScaffoldingDocument4 pagesJSA For Rebar Works Includes Working in Scaffoldingyc safetyNo ratings yet

- Rmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)Document2 pagesRmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)myn maliQueNo ratings yet

- Sspc-Pa Guide 3 PDFDocument16 pagesSspc-Pa Guide 3 PDFvricardol100% (1)

- JHA Scaffolding - ApprovedDocument15 pagesJHA Scaffolding - ApprovedLuqman OsmanNo ratings yet

- Barbending HiracDocument2 pagesBarbending HiracJohn Ha71% (7)

- 5X5 Matrix RA For Installation Fo CHC-2A Conveyor SystemDocument16 pages5X5 Matrix RA For Installation Fo CHC-2A Conveyor SystemSandeep Jain100% (2)

- JSA-10 Excavation and SamplingDocument5 pagesJSA-10 Excavation and SamplingMuhammadHaziqHaiqalNo ratings yet

- Refueling JSA 4 08 2019 Rev.03 Near WaterDocument9 pagesRefueling JSA 4 08 2019 Rev.03 Near Waterrisky indra antariNo ratings yet

- Guidance For Hazard Determination For Compliance With The OSHA Hazard Communication StandardDocument29 pagesGuidance For Hazard Determination For Compliance With The OSHA Hazard Communication Standardbatorn@mac.comNo ratings yet

- Jsa R B 6 ForkliftDocument3 pagesJsa R B 6 ForkliftsinghajitbNo ratings yet

- Pipeline Construction Toolbox TalkDocument1 pagePipeline Construction Toolbox TalkShafie ZubierNo ratings yet

- Building De-Dusting JSADocument3 pagesBuilding De-Dusting JSAJayesh J PillaiNo ratings yet

- OHS Policies and ProceduresDocument2 pagesOHS Policies and ProceduresDja FilesNo ratings yet

- Environmental Engineer EHS in Charlotte NC Resume Diana KooserDocument2 pagesEnvironmental Engineer EHS in Charlotte NC Resume Diana KooserDianaKooserNo ratings yet

- She Strategy DocumentDocument30 pagesShe Strategy DocumentEarnest A. Bartlett100% (2)

- Internship Report - of - OGDCLby - Hakim - Ali - Shar PDFDocument50 pagesInternship Report - of - OGDCLby - Hakim - Ali - Shar PDFbureaucrat315No ratings yet

- Accidents Preventive Practice for High-Rise ConstructionDocument6 pagesAccidents Preventive Practice for High-Rise ConstructionNur MajNo ratings yet

- Awareness of Workers To Health, Safety & Welfare Provisions Under Factories Act, 1948Document5 pagesAwareness of Workers To Health, Safety & Welfare Provisions Under Factories Act, 1948inventionjournalsNo ratings yet

- B-711 Purpose: Agency Name Chapter No./Name Part No./Name Section No./Name Document No./Name Dates Issue EffectiveDocument3 pagesB-711 Purpose: Agency Name Chapter No./Name Part No./Name Section No./Name Document No./Name Dates Issue EffectiveJoyjoy C LbanezNo ratings yet

- Notice: Meetings: Maritime Advisory Committee For Occupational Safety and HealthDocument2 pagesNotice: Meetings: Maritime Advisory Committee For Occupational Safety and HealthJustia.comNo ratings yet

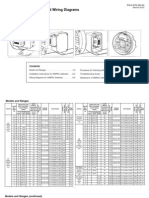

- Installation Instructions and Wiring Diagrams For All Models and RangesDocument8 pagesInstallation Instructions and Wiring Diagrams For All Models and RangesMaria MusyNo ratings yet

- A Study On The Safety and Welfare Measures Provided To The Employees at Cochin Port Trust, CochinDocument61 pagesA Study On The Safety and Welfare Measures Provided To The Employees at Cochin Port Trust, CochinSavitha Sree50% (2)

- Construction Phase Plan Church Field Primary SchoolDocument72 pagesConstruction Phase Plan Church Field Primary SchoolGregor SchwarbNo ratings yet

- MSDS BeeswaxDocument6 pagesMSDS BeeswaxBhavin ShahNo ratings yet

- IELTS Sample of General Training Reading PaperDocument5 pagesIELTS Sample of General Training Reading Papermarusha8100% (1)

- What is Hexane and Where Can it Be Found? - The Complete Guide to Hexane Uses, Hazards and SafetyDocument11 pagesWhat is Hexane and Where Can it Be Found? - The Complete Guide to Hexane Uses, Hazards and SafetyvivekNo ratings yet

- Hand WinchesDocument24 pagesHand WinchesnalakasaNo ratings yet

- Elias - PX - BDA - 1 - 1Document36 pagesElias - PX - BDA - 1 - 1soundman11No ratings yet

- MEM05052A Apply Safe Welding Practices - Learner GuideDocument14 pagesMEM05052A Apply Safe Welding Practices - Learner Guidequestionbank.com.au100% (1)

- DR Kshitij ResumeDocument3 pagesDR Kshitij ResumeBarney StinsonNo ratings yet

- Job Safe Practices for Overhead Crane Operation (JSP 08Document4 pagesJob Safe Practices for Overhead Crane Operation (JSP 08Farooq MohammadNo ratings yet

- 2.4 WP-XXX XX-XX PPE Policy (Final)Document5 pages2.4 WP-XXX XX-XX PPE Policy (Final)MarwotoNo ratings yet

- Hearing Conservation Resources LLWeb Feb 08Document4 pagesHearing Conservation Resources LLWeb Feb 08Joao Carlos RibeiroNo ratings yet

- Pentane Msds Praxair p6229Document8 pagesPentane Msds Praxair p6229Michael SchreiberNo ratings yet

- MK 1 SDS PDFDocument11 pagesMK 1 SDS PDFBennyNo ratings yet