Professional Documents

Culture Documents

Air Hardened Alloys

Uploaded by

Ananda RahaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Hardened Alloys

Uploaded by

Ananda RahaCopyright:

Available Formats

Air Hardened Alloys

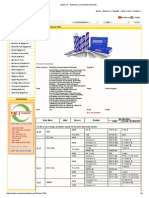

The C S ranges of welding consumables are based on carbon, manganese, chromium and Detailed & Technical Information molybdenum alloys with a lime-fluorspar flux fill, and are easy to in either an open-arc or a Please register / login to view detailed self-shielded format. As no shielding gas is required the C S wires are as suitable for remote, technical information on-site work as they are for workshop procedures. BS11B is an open arc, self-shielded, wire developed with Railtrack in the UK specifically for repair welding on normal and 'A' grade rail steels. CS70 ...suitable for single- and multi-pass welding of mild steel in flat, horizontal or vertical positions. C S70 is also ideal for non-critical welding of general and structural steel work, and for building-up a surface prior to applying hardfacing.

Typical Weld Metal Analysis C 0.28

Diameters available

Approximate AS Welded Hardness 190-210 Hv

Weld Metal Machinability

Abrasion Resistance

Impact Resistance

Air Hardened Alloys Chrome Carbide Alloys

1.2mm

Good

Work Hardening Alloys Welding Consumables Welding Machines Forge Die W elding

CS300 ...gives a machinable deposit that is ideal for building-up substantial a thickness, or as a base onto which harder metals can be applied. Suitable applications include caterpillar tracks, roller guides and slide-ways & track wheels.

Typical Weld Metal Analysis C Mn Si 0.25 2.00 010

Diameters available

Approximate AS Welded Hardness 25-34 Rc

Weld Metal Machinability

Abrasion Resistance

Impact Resistance

1.2mm 1.6mm 2.1mm

Good

CS400 ...produces a machinable weld metal that is resistant to compressive wear, impacts and abrasion. Typical applications include punches, shear blades, tractor rollers and idlers.

Typical Weld Metal Analysis C Mn Si Cr Mo 0.35 2.00 0.15 1.50 0.20

Diameters available

Approximate AS Welded Hardness 32-45 Rc

Weld Metal Machinability

Abrasion Resistance

Impact Resistance

1.2mm 1.6mm 2.4mm 3.2mm

Moderate

CS600 ...an air-hardening deposit with a high resistance to abrasive media such as soil, sand and crushed minerals. C S600 is ideally suited to scraper blades, chutes and buckets.

Typical Weld Metal Analysis C Mn Si 0.80 2.00 0.80

Diameters available

Approximate AS Welded Hardness 52-58 Rc

Weld Metal Machinability

Abrasion Resistance

Impact Resistance

1.2mm 1.6mm 2.4mm

Grinding Only

BS11B ...a crack free, and wear resistant weld metal that was approved by Railtrack and SNC F for repairing normal and ?A? grade rails. BS11B is particularly suited to remote, on-site work.

Typical Weld Metal Analysis C Mn Si Cr Ni Mo Al 0.15 1.10 0.30 1.00 2.25 0.40 1.60

Diameters available

Approximate AS Welded Hardness 31-36 Rc

Weld Metal Machinability

Abrasion Resistance

Impact Resistance

1.2mm 1.6mm

Moderate

tel: +44 (0) 1252 517 766 email: info@corewire.com Stite Map

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hse Plan - Kaia Project - SBGDocument164 pagesHse Plan - Kaia Project - SBGMehmet Alper Sahin75% (4)

- GU-611 - PDO Guide To Engineering Standards and ProceduresDocument1 pageGU-611 - PDO Guide To Engineering Standards and ProceduressameerpecNo ratings yet

- Asme Sec 5 QuestionsDocument13 pagesAsme Sec 5 Questionsanasseeksscribd100% (1)

- Welding TechnologyDocument390 pagesWelding Technologygueess100% (2)

- Shop Manual Pc1100lc-6Document884 pagesShop Manual Pc1100lc-6David InojosaNo ratings yet

- Astm A 497Document5 pagesAstm A 497John Errol Saldevar MarcosNo ratings yet

- Duplex Stainless SteelDocument231 pagesDuplex Stainless Steelponnivalavans_994423No ratings yet

- Pipeline StandardsDocument50 pagesPipeline StandardsSusheel Gupta100% (5)

- Crue Oil 7500bbl API 650 DatasheetDocument16 pagesCrue Oil 7500bbl API 650 DatasheetrobertantoreniNo ratings yet

- 15 API 570 - Open Book Mockup Exam FinalDocument12 pages15 API 570 - Open Book Mockup Exam FinalMichael Albuquerque100% (1)

- The Optimization of Friction Stir Welding Process Parameters To Achievemaximum Tensile Strength in Polyethylene Sheets PDFDocument6 pagesThe Optimization of Friction Stir Welding Process Parameters To Achievemaximum Tensile Strength in Polyethylene Sheets PDFSantiago EscobarNo ratings yet

- Final Report FB-2018-1 PDFDocument75 pagesFinal Report FB-2018-1 PDFRatik GaonkarNo ratings yet

- General Manager UIP Nusra SRM Operasi Dan Konstruksi UIP NUSRA PT. PLN (Persero) UPP Timor ArsipDocument31 pagesGeneral Manager UIP Nusra SRM Operasi Dan Konstruksi UIP NUSRA PT. PLN (Persero) UPP Timor Arsiphastaria mannaNo ratings yet

- Welder MIG160Document15 pagesWelder MIG160MatiasNo ratings yet

- Operator's Manual: For Use With Machines Having Code NumbersDocument200 pagesOperator's Manual: For Use With Machines Having Code NumbersNaye OrtizNo ratings yet

- ATNM Handrail 2277 DPR 30 03 2023Document1 pageATNM Handrail 2277 DPR 30 03 2023vasantha kumarNo ratings yet

- Section 2 QuestionsDocument2 pagesSection 2 QuestionsSameer MohammadNo ratings yet

- Heat Removal: NPTEL Online Course On Analysis and Modelling of WeldingDocument20 pagesHeat Removal: NPTEL Online Course On Analysis and Modelling of Weldinganish tNo ratings yet

- 11th EASN Virtual Conference-Book of AbstractsDocument246 pages11th EASN Virtual Conference-Book of Abstractsthomasconan17No ratings yet

- COLLECTOR INSTRUCTIONS MANUAL. WUNDER CLS 1808 & 2108 & 2510 ModelsDocument19 pagesCOLLECTOR INSTRUCTIONS MANUAL. WUNDER CLS 1808 & 2108 & 2510 ModelsCiprian BalcanNo ratings yet

- Kop DDocument44 pagesKop Dridhwan6339No ratings yet

- A PROJECT REPORT (Souvik Sen)Document94 pagesA PROJECT REPORT (Souvik Sen)Souvik Sen100% (1)

- Aladin SDocument4 pagesAladin SJeffrey BeanNo ratings yet

- Article 5 Ultrasonic Examination Methods For MaterialsDocument10 pagesArticle 5 Ultrasonic Examination Methods For Materialsr_ramiresNo ratings yet

- Plastics WeldingDocument4 pagesPlastics Weldingmehdi7891No ratings yet

- A595Document3 pagesA595rohit kumarNo ratings yet

- Pipeline SlidesDocument14 pagesPipeline Slidesc丽诗No ratings yet

- Internal Convertion 2Document53 pagesInternal Convertion 2MANISH DASNo ratings yet

- 9b. Advanced Forming Research Centre (AFRC)Document24 pages9b. Advanced Forming Research Centre (AFRC)Ivan RinconNo ratings yet