Professional Documents

Culture Documents

Annex.3 Apron Feeder

Uploaded by

surachsOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Annex.3 Apron Feeder

Uploaded by

surachsCopyright:

Available Formats

URANIUM CORPORATION OF INDIA LIMITED P.

O: JADUGUDA MINES, JHARKHAND 832102

Public Tender no. PUR/2/19/9456/456 Annexure-3 Item : Apron Feeder (Page 1 of 4) ----------------------------------------------------------------------------------------------------------------------------TECHNICAL SPECIFICATION Mainframe, hopper & skirt: These shall be of heavy steel (MS) welded construction to suit the duty condition. The skier will be provided with replaceable liners at wear points. Pan: The pans will be made of SAILMA 350. The pans are attached to heavy-duty conveyor chains. Feed rollers: The feed rollers mitigate falling impact load through apron and are arranged at regular intervals to ensure smooth running of Apron. The rollers will be forged type complete with shaft and ball bearing. Apron chain: The conveyor chain (Crawler type, Berco/equal make) is high precision link chain having sufficient strength. Sprocket wheels: The sprocket wheels are of forged / fabricated steel, with hardened teeth to give a long life (Berco/equal make). Start: The apron feeder should be able to start with hopper full with ore

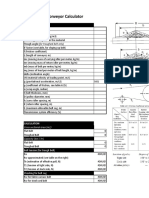

OTHER TECHNICAL DETAILS ARE GIVEN BELOW : APRON FEEDER 1 Material to be handled 2 Ore size 3 Angle of Repose 4 Bulk Density 5 Moisture 6 Method of speed variation 7 8 9 10 11 12 13 14 15 16 17 Make of VVF Maximum height of fall of ore Maximum deck speed Type of Apron Feeder Size of Feeder Quantity Capacity Type of bearing Make of bearing Lubrication arrangement Material of construction Main frame Head shaft Pulley and counter shaft Apron pan (20mm thk. X 1500mm wide)

Uranium Ore 100% passing 700 mm 35 degree 1.8 10% By VVF drive (Rating of VVF drive shall be higher than drive motor) Kirloskar,ABB,Siemens 5500 mm To be given by party Extra Heavy duty 1.5M wide x 10.5 M long One no. 350 to 500TPH Spherical roller bearing SKF / FAG / equivalent Manual MS 42 Cr4 Mo2, IS-1570 45 C8, IS-2004 SAILMA-350

URANIUM CORPORATION OF INDIA LIMITED P.O: JADUGUDA MINES, JHARKHAND 832102

Public Tender no. PUR/2/19/9456/456 Annexure-3 Item : Apron Feeder (Page 2 of 4) ----------------------------------------------------------------------------------------------------------------------------Apron chain (Berco / equal make) Head, tail, counter Plummer block shaft 45C8, IS-1570

& Cast steel

Fed roller assembly Forged steel IS:2004, Cl4/ IS:2062 Head chute, skirt board, drive MS base frame Head chute liner, skirt board liner 18 40C8 / SAILHRD

Details of conveyor with nylon cord ( 4 ply) Drive Through gear box Motor Rating to be given by party (preferably 1000 rpm) Type AC squirrel cage induction motor suitable for 440 V, 3 phase, 50 Hz, foot mounted Gear box Radicon make Type Heavy duty Bevel helical gear box Size One Size higher than designed requirement Conveyor top cover thickness 6 mm Bottom cover thickness 3 mm Ply 4 ply Total thickness Type of HS & LS coupling Counter shaft Return rail Maximum weight of ore above apron when hopper is full 14.3 mm (min.) Geared coupling 42 Cr4 Mo2 IS:1570 45C8 IS:1570 / IS:2062 200 MT

19 20 21 22

NOTE:- The layout drawing of ground hopper of existing & proposed is enclosed here with.

OTHER TECHNICAL REQUIREMENT:

URANIUM CORPORATION OF INDIA LIMITED P.O: JADUGUDA MINES, JHARKHAND 832102

Public Tender no. PUR/2/19/9456/456 Annexure-3 Item : Apron Feeder (Page 3 of 4) ----------------------------------------------------------------------------------------------------------------------------1. Party shall submit details of spillage collecting chutes & conveyor installed below the apron feeder. Detail must include size of conveyor (Length, width, thickness etc.), chutes, plate thickness, cross sectional details of chute, etc. Supply, erection & commissioning of the above facility will be under the scope of the bidder. Party shall submit detail drawing of head chute, particularly the discharge end of head chute above apron feeder for onward transfer of ore after the discharge from the apron feeder to existing conveyor 1 BC-1. Party shall mention the guarantee life of apron feeder. The party shall also enclose details of similar apron feeder supplied, if any, during last 5 years along with their performance report from the users. The design & layout drawing of the proposed belt conveyor below the offered apron feeder which will feed to existing to 1BC-1 conveyor shall be submitted along with the offer. The apron feeder & conveyor belt shall have facility to start from local & remote. Facility of speed control shall also be available both in the local & remote mode. The apron feeder shall discharge the content of hopper into the spillage collecting conveyor belt, which in turn will discharge the material to existing 1BC-1 conveyor. The party shall provide facility of electrical siren before start of the apron feeder. There shall be interlock of sequential operation of spillage conveyor belt & apron feeder.

2.

3. 4. 5. 6. 7. 8.

Party shall submit details in the following format also

URANIUM CORPORATION OF INDIA LIMITED P.O: JADUGUDA MINES, JHARKHAND 832102

Public Tender no. PUR/2/19/9456/456 Annexure-3 Item : Apron Feeder (Page 4 of 4) -----------------------------------------------------------------------------------------------------------------------------

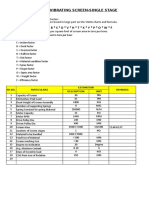

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 a b 16 17 18 19 a b 20 21 22 a b c d e f g h i j k l 23

Model No C/C length x width Speed of apron (high & low) Capacity (high & low) Apron pan size / nos Apron chain type/nos Type of tensioning (screw take up) G.A. drawing of Apron feeder to be provided G.A. drawing of Head chute in details from hopper to apron G.A. drawing of dicharge chute in details from apron to conveyor Cleaning provided between the edge of the head chute & centre of head pulley Fall height from Apron feeder to belt conveyor below Number of carrying Rollers & sketch of the same Number of return Rollers & sketch of the same. Type of coupling & Model no H.S L.S Type & size of G.B Make G.B Reduction ratio Motor Details KW & RPM V.V.F rating & other details like make, starting torque etc. Calculation of motor H.P in Hopper full position Calculation of G.B. Proposed conveyor suitable for Apron feeder discharge Conveyor length Conveyor width Distance Details of rubber lining of head pulley / tail pulley No of carrier idlers & no of return idlers No of impact idlers (carrier as well as return) No of self aligning idler Troughing angle of belt Conveyor belt speed Gear box details Motor details (kw & rpm) Constructional details of conveyor belt Belt safety considered (ZSS, BSS & Pull cord)

You might also like

- United States Naval Aviation 1919-1941Document353 pagesUnited States Naval Aviation 1919-1941Saniyaz Manas100% (14)

- Diesel Engine Compression Tester GuideDocument374 pagesDiesel Engine Compression Tester GuideRusu Alina IoanaNo ratings yet

- Furuno Ais Fa100 Service ManualDocument307 pagesFuruno Ais Fa100 Service ManualRumi Amir92% (13)

- Simultaneous Operations (SIMOPS)Document19 pagesSimultaneous Operations (SIMOPS)Desmond Chang71% (7)

- AA - SPEC - 254001 Stacker Reclaimer SpecDocument28 pagesAA - SPEC - 254001 Stacker Reclaimer SpecJD75% (4)

- Apron FeederDocument12 pagesApron FeederMidDeL'OrmeNo ratings yet

- Calculating The Truss Member ForcesDocument31 pagesCalculating The Truss Member Forcessurachs100% (2)

- Apron Feeder Spare Part ListDocument17 pagesApron Feeder Spare Part ListParmeshwar Nath TripathiNo ratings yet

- Windshield ProtectionDocument3 pagesWindshield ProtectionLjubisa IgnjatovNo ratings yet

- Tape WrappingDocument8 pagesTape WrappingwalitedisonNo ratings yet

- Conveyor StringersDocument9 pagesConveyor StringersAnup DoluiNo ratings yet

- 5.efficient Transfer Chutes-A Case Study PDFDocument6 pages5.efficient Transfer Chutes-A Case Study PDFJaco KotzeNo ratings yet

- SprocketsDocument38 pagesSprocketssurachsNo ratings yet

- Technical Particulars Doc 2119-2120-01 PDFDocument10 pagesTechnical Particulars Doc 2119-2120-01 PDFAnonymous YwlEXh5No ratings yet

- Arme y Desarme Bloque de Control de La Transmision 928GDocument10 pagesArme y Desarme Bloque de Control de La Transmision 928GAlex Consuegra Medina100% (1)

- Flowsheet 130TPH II Stage Wheel Mounted Plant-0-22mm&GSBDocument1 pageFlowsheet 130TPH II Stage Wheel Mounted Plant-0-22mm&GSBMukesh BharatNo ratings yet

- Belt Feeder Calc. Pns Line 1Document4 pagesBelt Feeder Calc. Pns Line 1Waris La Joi Wakatobi67% (3)

- Feeder BreakerDocument10 pagesFeeder BreakerAmit BhaduriNo ratings yet

- HMA-36509 - Reclaim Feeder Manual RevcDocument111 pagesHMA-36509 - Reclaim Feeder Manual RevcAbdul HamidNo ratings yet

- Jaw Crusher Sizing GuideDocument5 pagesJaw Crusher Sizing GuideTerence Jhon TabonNo ratings yet

- F175 (M) 018-Apron Feeder BZ2300×12000 With Scraper Conveyer B2500×10800-User ManualsDocument60 pagesF175 (M) 018-Apron Feeder BZ2300×12000 With Scraper Conveyer B2500×10800-User ManualssuhardiantoNo ratings yet

- Is 12592 2002Document17 pagesIs 12592 2002sharmak_anil0% (1)

- Apron Feeder Application Datasheet enDocument1 pageApron Feeder Application Datasheet enVaijayanti JoshiNo ratings yet

- Apron Feeder 7Document1 pageApron Feeder 7cumpio425428100% (1)

- Feeder-Breaker BrochureDocument4 pagesFeeder-Breaker BrochurekrisezhilNo ratings yet

- Diemme 2500x2500Document8 pagesDiemme 2500x2500Cristian Mena HidalgoNo ratings yet

- CP6 Chain FeederDocument119 pagesCP6 Chain Feederdeddy ariyantoNo ratings yet

- Conveyor BrochureDocument6 pagesConveyor BrochuresurachsNo ratings yet

- Site Installation PROJECT NO. G017 & G087 Stacker Cum ReclaimerDocument27 pagesSite Installation PROJECT NO. G017 & G087 Stacker Cum ReclaimerRamanujam Rathinampillai RNo ratings yet

- Conveyor CalculatorDocument3 pagesConveyor CalculatorBayuNo ratings yet

- R0 ModelDocument1 pageR0 ModeltylerdurdaneNo ratings yet

- 20.312 D02 Rev 01 Design BriefDocument17 pages20.312 D02 Rev 01 Design BriefSarah PerezNo ratings yet

- Espesadores Caserones, Enero 2014Document12 pagesEspesadores Caserones, Enero 2014Juan MichaudNo ratings yet

- AUMUND Chain Conveyors 2Document12 pagesAUMUND Chain Conveyors 2NavidJalalianNo ratings yet

- Troughed Belt ConveyorsDocument18 pagesTroughed Belt Conveyorsjyoti ranjan nayak75% (4)

- Coal Handling System Operation ManualDocument16 pagesCoal Handling System Operation Manualseni cahyonoNo ratings yet

- Capacities and performance characteristics of jaw crushersDocument7 pagesCapacities and performance characteristics of jaw crushersvaper123No ratings yet

- 4 Eng PDFDocument31 pages4 Eng PDFZaYnab IbrahimNo ratings yet

- Apron FeederDocument7 pagesApron FeederEDUARDO0% (1)

- Vibrating ScreensDocument3 pagesVibrating ScreensvinodsnNo ratings yet

- Slurry Pumps MCU Introduction (English)Document33 pagesSlurry Pumps MCU Introduction (English)Jose Antonio RojasNo ratings yet

- Chute Calculation ExampleDocument1 pageChute Calculation ExampleBimal DeyNo ratings yet

- 5720 D E DWG 0201 - RevADocument4 pages5720 D E DWG 0201 - RevAEDUARDONo ratings yet

- Pan ConveyorsDocument24 pagesPan ConveyorswereerNo ratings yet

- Raw Material Conveyor Tunnel DrawingDocument1 pageRaw Material Conveyor Tunnel DrawingHritika PatelNo ratings yet

- Apron Feeder Shaft Design Forces LayoutDocument2 pagesApron Feeder Shaft Design Forces LayoutarsanioseNo ratings yet

- Apron Feeder - TerexDocument12 pagesApron Feeder - TerexRyan R CunninghamNo ratings yet

- TeleStacker® ConveyorDocument4 pagesTeleStacker® ConveyorSuperior IndustriesNo ratings yet

- Spread Sheet Bucket ElevatorDocument1 pageSpread Sheet Bucket ElevatorBayu Pramana PutraNo ratings yet

- Determination of Maximum Span Between Pipe Support Using Bending Stress TheoryDocument4 pagesDetermination of Maximum Span Between Pipe Support Using Bending Stress TheoryMannattil Krishna KumarNo ratings yet

- 2010 - Telescopic ChuteDocument29 pages2010 - Telescopic ChutesteelageNo ratings yet

- Uranium Corporation of India Limited P.O: Jaduguda Mines, Jharkhand - 832102Document4 pagesUranium Corporation of India Limited P.O: Jaduguda Mines, Jharkhand - 832102arsanioseNo ratings yet

- I Feeder Application Design CalculationsDocument2 pagesI Feeder Application Design Calculationsarsaniose100% (1)

- Feeder Breaker 1200mtph Project01!08!08Document3 pagesFeeder Breaker 1200mtph Project01!08!08Herman AbdullahNo ratings yet

- Apron Feeder PDFDocument3 pagesApron Feeder PDFabdulloh_99100% (1)

- Apron Feeder Data Sheet Material Handling SystemsDocument1 pageApron Feeder Data Sheet Material Handling SystemsPat AuffretNo ratings yet

- VibratingEquipmentBrochure PDFDocument10 pagesVibratingEquipmentBrochure PDFWilliam VillamizarNo ratings yet

- Energy & Data Transmission Systems For StockyardsDocument12 pagesEnergy & Data Transmission Systems For StockyardsNos GoteNo ratings yet

- Dunlop Conveyor Belt Design Manual - HTMLDocument38 pagesDunlop Conveyor Belt Design Manual - HTMLForbes KambaNo ratings yet

- Smalis Radial Stacker ManualDocument61 pagesSmalis Radial Stacker Manualmacross086100% (1)

- Technical Specification Reclaim FeederDocument1 pageTechnical Specification Reclaim FeederTeguh Yuliardi Putra100% (1)

- BHG - Transfer Chute Data SheetDocument2 pagesBHG - Transfer Chute Data Sheetacas35No ratings yet

- PEF500X750 Jaw CrusherDocument21 pagesPEF500X750 Jaw CrushersanjeevarorahsrNo ratings yet

- Pipe Conveyor Belts: With Steel Cord and Fabric ReinforcementDocument5 pagesPipe Conveyor Belts: With Steel Cord and Fabric ReinforcementEugenepaccelli Kolandai SamyNo ratings yet

- Apron FeederDocument4 pagesApron FeederMineria28No ratings yet

- Conveyorchains HitachiDocument173 pagesConveyorchains HitachiLLNo ratings yet

- Helix Delta-T6 Sample Report01Document29 pagesHelix Delta-T6 Sample Report01Khaleel PashaNo ratings yet

- DTS - Belt Bucket Elevator - DatasheetDocument3 pagesDTS - Belt Bucket Elevator - DatasheetBRUNA NASCIMENTONo ratings yet

- Gentle Single Roll Crusher for Soft to Medium MaterialsDocument3 pagesGentle Single Roll Crusher for Soft to Medium MaterialsBobby A. Palem100% (1)

- Joy Underground Feeder Breakers Brochure PDFDocument5 pagesJoy Underground Feeder Breakers Brochure PDFSabahNo ratings yet

- FLS Apron Feeder BrochureDocument4 pagesFLS Apron Feeder BrochureMilan SjausNo ratings yet

- PHQ Long Tom Manual 2012Document42 pagesPHQ Long Tom Manual 2012Miroslav PenevicNo ratings yet

- Bosch Conveyor SystemDocument32 pagesBosch Conveyor Systemjd1schroederNo ratings yet

- Hindustan Petroleum CorporationDocument39 pagesHindustan Petroleum CorporationSrinivasan RajenderanNo ratings yet

- 6 Restrained Beams HandoutDocument2 pages6 Restrained Beams HandoutHakan EzcanNo ratings yet

- 1968 - Guthrie - The Design of BeltDocument10 pages1968 - Guthrie - The Design of BeltsurachsNo ratings yet

- Conveyor SystemsDocument19 pagesConveyor SystemssurachsNo ratings yet

- Centrifugal PumpDocument254 pagesCentrifugal PumpsurachsNo ratings yet

- Dyna Flight 08Document12 pagesDyna Flight 08surachsNo ratings yet

- Bin and Hopper Design Presentation on Flow Modes, Testing and Stress AnalysisDocument73 pagesBin and Hopper Design Presentation on Flow Modes, Testing and Stress AnalysisGanesh.MahendraNo ratings yet

- Design of Truss BridgesDocument10 pagesDesign of Truss Bridges0808276kNo ratings yet

- 1allegato Power StationsDocument1 page1allegato Power StationssurachsNo ratings yet

- 1994 Gibbon Cad Thrashplate DesignDocument3 pages1994 Gibbon Cad Thrashplate DesignsurachsNo ratings yet

- Drawing Wet Kernel Elevator0001Document3 pagesDrawing Wet Kernel Elevator0001surachsNo ratings yet

- Belt Conveyor Design Optimized: C:/Winbelt/Belthelp - PDF 7/23/2009 8:49 AMDocument113 pagesBelt Conveyor Design Optimized: C:/Winbelt/Belthelp - PDF 7/23/2009 8:49 AMsurachsNo ratings yet

- Belt Bucket SampleDocument1 pageBelt Bucket Samplesurachs100% (2)

- BH 1Document1 pageBH 1surachsNo ratings yet

- 2 Astm D6943Document16 pages2 Astm D6943Boris CardenasNo ratings yet

- Tymco 435 - 435 Cabover FT4 Gen Specs 2019Document2 pagesTymco 435 - 435 Cabover FT4 Gen Specs 2019Yew LimNo ratings yet

- Optical Transceiver Market2016 PDFDocument8 pagesOptical Transceiver Market2016 PDFjim1234u0% (1)

- Operations ManagementjjjDocument29 pagesOperations ManagementjjjHarish AgarwalNo ratings yet

- Ipc06 - 10464Document12 pagesIpc06 - 10464Nestor AmachuyNo ratings yet

- Chapter 1Document40 pagesChapter 1Wia AbdullahNo ratings yet

- Investigation On Magnetorheological Damper For Its Various ApplicationsDocument6 pagesInvestigation On Magnetorheological Damper For Its Various ApplicationsLiyakat KhanNo ratings yet

- Design of Surface Mine Hauage-RoadsDocument49 pagesDesign of Surface Mine Hauage-RoadsLuis Gustavo Flores RondonNo ratings yet

- Hot Product: Supplier Name: AddressDocument16 pagesHot Product: Supplier Name: AddressSander DuqueNo ratings yet

- Automotive (2) Lab: Suspension SystemDocument8 pagesAutomotive (2) Lab: Suspension SystemMohammad YahyaNo ratings yet

- Ramsey Pricing ExplanationDocument46 pagesRamsey Pricing ExplanationYasha DawraNo ratings yet

- Strahlenfolter - Electronic Harassment - Torture DiaryDocument230 pagesStrahlenfolter - Electronic Harassment - Torture Diary-Targeted-Individuals-No ratings yet

- Mariner 202Document28 pagesMariner 202Pat ReynoldsNo ratings yet

- Coast Pilot 5 - 42nd Edition (2014) - Gulf of Mexico, Puerto Rico and Virgin IslandsDocument608 pagesCoast Pilot 5 - 42nd Edition (2014) - Gulf of Mexico, Puerto Rico and Virgin IslandssperlingreichNo ratings yet

- Plan Estratégico de Seguridad Vial - (1-119)Document16 pagesPlan Estratégico de Seguridad Vial - (1-119)karinaNo ratings yet

- BoQ For RFQ 1 2 Culverts Revised PDFDocument2 pagesBoQ For RFQ 1 2 Culverts Revised PDFAbdurezak AbdurehimNo ratings yet

- Design Notes for Box CulvertDocument1 pageDesign Notes for Box CulvertDaniel YitbarekNo ratings yet

- Balanced Cantilever Method of Bridge ConstructionDocument7 pagesBalanced Cantilever Method of Bridge ConstructionyyingmunNo ratings yet

- Review of Literature Job Satisfaction of DriversDocument3 pagesReview of Literature Job Satisfaction of DriversrameshNo ratings yet

- Om Enterprises QuotationDocument4 pagesOm Enterprises Quotationrilhouse2406No ratings yet

- Aluminium Bridges Past Present and FuturDocument8 pagesAluminium Bridges Past Present and FuturСтанислав ПодольскийNo ratings yet