Professional Documents

Culture Documents

004

Uploaded by

Partha Pratim MitraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

004

Uploaded by

Partha Pratim MitraCopyright:

Available Formats

SAENumber2008280103

EffectofNonMetallicFuelAdditivesonEmissionsandEconomy

S.O.Hayat

ChemEcol(UK)Limitedchemecoluk@chemecol.net

S.H.Ahmed

ChemAddLimiteddra@chemadd.com Copyright2008SaeInternational

ABSTRACT

The instantaneous and time duration effect of non metallic ashless diesel and gasoline additives in light andheavydutyenginesareevaluated. For the diesel additives, emission tests confirmed PM reduction of up to 19% from both light duty vehicles testedunderMVEGandR49orFiGEcycle. Worldwidefleettestsofthedieseladditivesperformed in a crosssection of light and heavyduty vehicles showed no detrimental effects but did measure a statistically significant improvement in fuel economy andreductioninsmoke. Ascanningmobilityparticlesizerinstrumentwasused to determine the effect of the diesel additive on fine particle number emissions below 500 nanometres. Reductions of between 45% 70% in particle number emissions with no significant shift in the particle size distributionweremeasured. Polyaromatic hydrocarbons emissions revealed a largereductioninthesixteenUSpriorityPAHswiththe additivetreatedfuels.ThereductionsinPAHandultra fine particulate also gave rise to a reduction in the oil viscosity and soot loading of the oil and this was measured.Thesereductionsalsoindicatedapossible reactionpathfortheactionofthenonmetallicadditive. The gasoline additive was tested in a Euro III vehicle with emission standards close to Euro IV specifications. Emission tests confirmed significant reductionsinallengineoutgaseousemissionsaswell as post catalyst emissions. There was also a measurableinstantaneousfueleconomyimprovement duringeachtest.

engines as transportation remains one of the few segments in which overall emissions are increasing. Carbondioxideemissionsfromthetransportsectorare also increasing and adding to climate change. Ultra fine particulate emissions, especially from diesel vehicles, are of growing concern to medical researchers[1]. Fuel composition changes can significantly improve emissions but such compositional changes are expensive and cannot always be achieved at a cost advantage.Therefore,thereisconsiderableinterestin any effective approach that can minimise these costs without severely compromising the overall objectives ofreducingemissions. An increasingly preferred approach to satisfying this requirement is through the use of fuel additives that aredesignedtoenhancethecombustionprocessand are often called "Combustion Improvers". However, metallic combustion enhancers are increasingly been rejected due to their intrinsic carcinogenic nature and potentialdamagetovehiclesystems[2]. Thispaperpresentsextensivemeasurementresultsof emissions from light duty vehicles and heavyduty diesel engines using a novel nonmetallic combustion enhancer.

2.EXPERIMENTAL

Light and heavy duty diesel and gasoline vehicles weretestedtostudytheeffectofnonmetallicadditive technologies on reduction of particulate matter, gaseous regulated emissions, PAH and particle numberemission.

2.1INSTRUMENTATION

The measurement of emissions was carried out according to the ECE15+EUDC cycle for light duty vehicles and ECE R49 or FiGE cycle for the heavy duty engines. Based on standard constant volume sampling technique, pollutants were measured using NonDispersiveInfraRed(NDIR)analysersforCOand CO2 readings, Chemiluminscent technique for NOx (NO+NO2) and Hydrocarbon (HC) emissions are also determined by use of a Flame Ionisation Detector (FID)analyser.

KEYWORDS

Non Metallic Additives, UltraFine Particulate, Poly Aromatic Hydrocarbons, Fleet Trials, Chemecol, Smps, Particulate Reduction, Mpg Improvement, Diesel Additives, Gasoline Additives, Emission Reduction,CombustionImprovers

1.INTRODUCTION

There is concern over the growing health effects of emissionsfromdieselandgasolinecombustion

2.2METHODOLOGY

The following test sequence was employed for gaseousemissionmeasurements:

was added after each sample, to replace that removed.

2.21LIGHTDUTYVEHICLES

Fiat Ducato 2.2 + EGR+ oxycat Mileage AccumulationProgram Service vehicle, triplicate MVEG (w/o 40 sec idle) on base fuel, switch to base fuel + additive triplicate MVEG, run vehicle for 1000 km, triplicate MVEG, run vehiclefor1000kmonbasefuelplusadditive,triplicate MVEG, run vehicle for 1000km on base fuel plus additive,triplicateMVEG,switchtobasefuel,triplicate MVEGonbasefuelplusadditive.

2.26FLEETTRIALS

Single blind studies to determine the effect of the ashless non metallic diesel additive in fleet trials was conducted in a crosssection of light and heavy duty public transportvehicles. The aim ofthe study was to verifythereductionsinsmoke,gaseousemissionsand specific fuel consumption under standard fleet operating conditions and observe if any field related problemsoccurredwiththeuseoftheadditive.These trials were conducted on a large number of fleet vehicles in Europe, South America, Middle East and Africa.ThevehiclesrangedfrompreEurostandardsto EuroIVvehicles.Resultsreportedinthispaperarefor fleets operatingin Europe and South America but are representativeoffleetsintheotherterritories.

2.22HEAVYDUTYENGINES

Iveco8360 The engine was mounted on to the test bed and instrumented to measure emission parameters. The engine was run on base 500ppm sulphur fuel corresponding to EN590 specification and three consecutive R49 emission measurement and fuel consumptiontestswereconducted.

2.26.1FLEETTRIAL1

Fromthethirtytwoadditivetreatedvehiclesinthetest group, 6 vehicles were specifically monitored for emissions.Initialemissionreadings weremeasuredto obtainbaseresultsandthenbimonthlyreadingswere also taken after the introduction of the additive. For further comparison the 6 vehicles were also paired specificallyforemissiontestingwithanother6vehicles of similar make and age and running condition that were not dosed with the additive treatment. The total numbersoftestvehiclesusingtheadditivewas32and thesewerepairedwithafurther32vehiclesthatranon base diesel only but operated in very similar conditions. The fuel consumption figures for all these vehicles were automatically electronicallylogged on a dailybasis.Havingthepairedvehiclesallowedbotha historical comparison for the additive treated vehicles and a month to month direct comparison with the pairedvehicles.

2.23VWTDI1.9LI,DIPARTICLENUMBERAND SIZINGTESTPROGRAM

The Scanning Mobility Particle Sizer was used to determine particle size distribution and number concentration in the nominal range 10 to 450 nm. Further details may be found in earlier published papers[3].

2.24PARTICULATEBOUNDPAH

Two filter papers each from base fuel, base fuel + additiveweretakenfromtheVWTDitestprogramfor PAH analysis. The particulate filters were soxhlet extracted in ~185ml. of toluene for a minimum of six hours under photo protective conditions. The sample wasthenrotaryevaporatedfiltered,passedthrougha Seppak silica cartridge to remove polar compounds and solvent exchanged, ultimately to methanol. The final volume typically being 2ml. Analysis was performed by High Performance Liquid Chromatography (HPLC) with fluorescence detection. The PAH were detected at their optimum excitation and emission wavelengths using two solvent runs per sample.

2.26.2FLEETTRIAL2

A one year monitoring program was conducted to determinetheeffectoftheadditivetechnologyonfuel consumption. Historical data for the vehicles were extracted to enable pre and post additive treatment performance to be evaluated. A total of 265 vehicles were additive treated. The vehicles ranged from light duty vans of 1.5li cylinder volume to heavy duty vehiclesof12livolume.Thevehiclesalsorangedfrom Euro I to Euro III vehicle emission standard. 52 vehicleswerediscardedfromtheanalysisduetoeither erroneous data or no like for like data. The analysis shownthereforerepresents213vehicles.

2.25OILVISCOSITYANALYSISVWTDI

Theenginewasfilledwith4.0kgofCECRL148batch 3referenceoilandwarmeduptotestconditionsusing base fuel. A 50ml oil sample was removed after 30 minutes running time. At the end of one hour the engine was stopped and the fuel changed to the additive test fuel. After these initial base line measurements the engine was restarted for the 50 hourviscositytestrun.Oilsamplesof50mlweretaken after 30minutes and every 5 hours, 50ml of fresh oil

2.26.3FLEETTRIAL3

A major program was conducted to determine the effect of the additive on a large bus fleet. The fleet comprised of over 1,000 buses of different make and age and therefore results would indicate the effect of the additive on differentmakes and design as well as onconsumptionprofile.

Historical datafor thefleet was available and 3 years ofbasedata wasusedtodetermineanaveragebase figurepermonth.Thedatawaspresentedinlitresper hour of driving to negate idling effects. The data was also corrected for passenger number differences i.e. passenger loading effect and so the final data represented the consumption per hour without any interferencefromvaryingpassengerloads. The fuel economy program lasted for six months during the southern hemispheres summer months which represents for this particular bus fleet the most stable period of operation. Although, this initial monitored program was for six months of additive treatment the buses are still continuing to use the additive after 1 year as part of their own commercial rational.

lowestnumberofultrafineparticleswithoutchangesto the distribution profile.The MFP being presentmainly to ensure that the engine condition is maintained in termsofkeepcleanandthatproblemsassociatedwith lubricitydonotarise.

3.30PARTICULATEBOUNDPAH

From the VWTDi program, a limited number of particulate filter papers were tested to determine the effect of fuel specification and additive treatment on PAH and NPAH formation. Although, the repeatability of this PAH data set is good the lighter PAH from naphthalene to fluoranthene are normally less repeatable, due to variation in particulate collection temperatures and ambient conditions. These compounds exist in the vapour phase rather than the liquid or gas phase, therefore small temperature variations can have a significant effect on their collection. Compounds between benz (a) anthracene and benzo (a) pyrene are those which show the greatest repeatability in this type of testing and therefore have the highest confidence in terms of significance of result. Figure 4 shows the reduction in comparison with the average of the base EN590 results.

2.27GASOLINETEST

A light duty Opel Astra CDX vehicle was used to determine the effect of the non metallic gasoline additive on pre and post catalyst emission and fuel consumption.Thevehiclewasinstrumentedandthree ECE15 + EUDC cycles were conducted one cold cyclefollowedbytwohotcycles.Duringeachphaseof thetests3repeatswereperformed.

3.RESULTS 3.1PARTICULATEMASS&GASEOUS EMISSIONS

Representative results of the light and heavy duty testing on particulate mass and gaseous emissions underregulatedEuropeanemissionstandardtestsare shown in figures 1 and 2. Figure 1 also reflects the timeeffectoftheadditivetreatment.

3.40OILVISCOSITY

Thethreedifferentmethodsoftestingtheconditionof the oil all measured an improvement with the use of theadditive.Viscosityincrease wasreduced by2.3%, Figure 5, the soot loading was reduced by 21% and mostimportantlytheoveralloilconsumptionduringthe testwasreducedby16%.

3.50FLEETTRIALS

During the fuel economy trials the vehicles were run according to the normal operating schedule of the respective operators. Each vehicle always ran a specifiedroutewithmultipledriverswhowereunaware oftheadditivetrial.Fueleconomymeasurementswere recordedforupto3yearspriortoadditivetreatmentof the fuel and then measured for up to 15 months in somecases.Insometrials,controlfleetswerealsorun according to the same schedule. Each vehicle was individually analyzed and thefuel economy calculated on a daily basis. Ifthefuel economyfigure calculated varied significantly from the median value then it was eliminated from further analysis. This ensured that outliers did not have a significant contribution to the finalfuel economyvalues. No adverse of the effect of the non metallic combustion enhancer fuel additive was noted from any test vehicle. In fact, there was indicativeevidencethatthetreatmenthadabeneficial impactonparticulatefiltersandinjectorsthiswillform partofalaterstudy.

3.20PARTICLESIZING.

Results are presented on a purely comparative basis with effects illustrated as graphical differences. Data are presented in terms of number concentration vs. electrical mobility diameter on a logarithmic scale for the SMPS. These data reflect the effect of the additives in physical terms, on the number weighted particlesizedistribution.Henceiftheadditivereduces the number of ultra fine particles in the submicron region, this will be observed as a reduction in magnitude of the mode of the SMPS generated distribution. Changes in particle size distribution can be related to changes in the number distributions and arelikelytoresultinmassshifts. Resultsarepresentedinrawformati.e.correctedfor dilution. Hence, the test points at which the greatest magnitudes of particles are observed would be expected to produce the greatest tailpipe out concentration. Figure 3 shows the integrated distribution profile over allthe key points and shows the effect of the ashless combustion enhancer. It is apparent that the combustion enhancer is consistently producing the

3.51FLEETTRIAL1:UKLOCAL GOVERNMENTALFLEET

The analysis of the raw data measured an improvement in fuel economy of 3.5%, in line with

expectation,Table1.Duringthetrialperiodthecontrol vehiclesmeasuredaslightincreaseinconsumptionof approximately 2%, possibly reflecting a drop in weathertemperature. Emission readings on six of the additive treated fleet were conducted and compared with the original base readings. Although, such emission readings are not underlegislatedconditionstheyneverthelesscangive indication of the general trend of the emission. These readings when taken in context with the legislated drivecycleemissionreadingsrevealadefinitetrendin hydrocarbon and nitrogen oxides emissions. Carbon Monoxideemissionsalsoshowedageneraldownward trend during the course of the trial but values were more erratic, possibly reflecting the temperature changes,Figure6.

engine condition. This is an important result as changes to the distribution profile could have significant implications to both the catalyst/trap manufacturers and to human health i.e. if larger particles are made smaller. It is evident from these resultsthatthecombustionenhancerhasa significant effectinreducingultrafineparticlenumberemissions. Although, the MFP does reduce particle number emissions the magnitude of the reduction is rather limited as when compared to the non metallic combustion enhancer. The reduction in ultra fine particles will also improve the ageing profile of the oil as these fine particles with very larges surface areas aretransportedtotheoilsumpcausinganincreasein soot loading. Any reduction in the formation of ultra fineparticlesmaybemanifestedinanimprovementin theoilviscosity[4] . ThereductioninPAH mayofferamechanismbywhich theadditiveactswithinthecombustionchamber.Ithas been postulated that ultra fine particles are formed fromPAH.PAHgrowthbyreplicationleadstoparticle nucleation and particle growth by coagulation. If PAH removal can be achieved by the oxidation of the aromatic intermediaries, this in turn will lead to a reduction in particle nucleation and formation. It is believed that the combustion enhancer provides radicals that react with these intermediaries in the initial and subsequent ring formation steps. The radicals also provide early kinetic initiation thereby allowing oxygencontaining radicals to react with the initial soot precursors furtherminimising theformation ofsoot. The extensive fleet trial program in several fleet and countriesclearlydemonstratesthepracticalbenefitsof the non metallic combustion enhancer fuel additives. There were no reported problems with its use and significant emission and fuel economy benefits. The additive treatment was applicable to a wide range of enginesfrompreEurostandardstoEuroIVstandards. The higher consumption vehicles tended to have a greaterdegreeofbenefitfromadditivetreatment.This may be due to the larger combustion chamber and slowerenginespeedsofthesevehicles. The non metallic gasoline additive treatment also demonstrated both pre and post catalyst emission benefitsandfueleconomyimprovementswhentested under the European ECE15 + EUDC test cycle. This test clearly demonstrated the instantaneous emission and fuel economy benefits. It is postulated that the post catalyst benefits were derived from the fact that the additive treatment was able to partially oxidize compounds reaching the catalyst and therefore these compoundsweremorereadilyoxidizedbythecatalyst.

3.52FLEETTRIAL2:UKLOCAL GOVERNMENTALFLEET

The improvement in fuel economy with additive treatmentfortheoverallfleetrangedbetween2%and 5% as shown in Figure 7. This is in line with expectation and closely resembles the improvement measuredinothercouncilfleetsacrossLondon.

3.53FLEETTRIAL3:BUSFLEET

There was an immediate improvement of approximately 3.5% which remained constant for the duration of the test program. This reflects the improvement achieved by the use of the combustion enhancer additive as well as the mild detergency associated with the formulation. Table 2 shows the results of trial with passenger correction factors included.Thefleetcomprisedofanumberofdifferent makesofvehiclesandTable3showstheimpactofthe additivetreatmentoneachtype.Itwasalsodecidedto establish the impact of the additive technology on vehicles with different consumption profiles to determineiftherewereanydifferences.Table4shows that the additive technology has a larger impact on higherconsumptionvehicles.

3.60GASOLINEVEHICLETEST

Pre and Post catalyst effect of the non metallic gasoline fuel treatment are shown in table 4. Fuel economy figures ranged between 1.5% and 2.8% for the two cycles. It is apparent from the table that the fuel additive treatment technology had an impact on both pre and post emissions. It is postulated that as the fuel technology acts as combustion enhancer it may partially oxygenate compounds reaching the catalystandhenceimprovethecatalystperformance.

4.DISCUSSION

The results confirm that reduction in particulate mass emissions can be achieved with the use of non metallicadditives. Particle number emission distribution profile between the base and treated fuels are similar within each

5.CONCLUSION

Asignificantprogramofworkonanonmetallicdiesel additive including extensive fleet trials has documented the beneficial effect of the additive on emissions and fuel consumption/ CO2.The additiveis applicable to both advanced engines systems and older vehicle technologies. There is an apparent

greater benefit in larger slower diesel engines. The additives seem to be operating at a fundamental nature by interfering in the initial cyclization reactions in diesel combustion. A non metallic gasoline additive has also shown significant emission and fuel consumptionbenefit.Therearestrongindicationsthat the additive treatment also improves catalyst conversion rates but not through direct catalyst enhancement.

2. 3.

4.

REFERENCE

1. Air Pollution and Cardiovascular Disease A statement for healthcare professionals from the expert panel on pollution and prevention science of the American Heart

Association Robert D Brook et. al 2004109:26552671 Worldwide Fuel Charter, September 2006ACEA,AAM,EMA,JAMA Effect of a NonMetallic Combustion Enhancer Diesel Additive on Mass and Number Particulate Emissions from Light DutyVehiclesandHeavyDutyEnginesS. O.Hayatet.alSAE2000011910 C.A.Morewood&R.P.GregoryfifthCEC International Symposium on the Performance Evaluation of automotive fuels and Lubricants 1315 May 1997 Goteborg, Sweden Soot levels & Structures from a range of diesel passengercars.PaperNo.CEC97EL15.

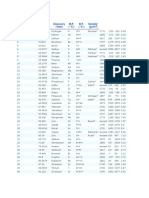

Table1.FleetTrial1:UKLocalGovernmentalFleet:Effectofadditivetreatmentonfuelconsumption FleetSector AdditiveTreatedVehicles %Change Refuse 1.70 Recycling 5.90 StreetCleaning 4.40 Highways 2.30 Total 3.50 NB: vevaluesdenoteanincreaseinconsumption PairedControlVehicles %Change 2.25 1.70 4.40 0.50#limiteddata 1.90

Table2.FleetTrial3:BusFleet:Effectofadditivetreatmentonoverallfleetfuelconsumption Oct03 Oct06 Oct06Nov06 Oct06Dec06 Oct06Jan07 Oct06Feb07 Sep06 56,371,655 2,489,811 4,948,963 7,343,877 9,600,222 11,729,806 9,085,480 411,539 817,469 1,215,815 1,602,397 1,962,278 6.20 6.05 2.56% 6.05 2.49% 6.04 2.72% 5.99 3.56% 5.98 3.80%

Consumption(litres) DrivingDuration(hour) SpecificConsumption (li/h) %changefromBase

Table3.FleetTrial3:BusFleet:Effectofadditivetreatmentwithrespecttodifferentenginetypes Leyland Base Additive Consumption(litres) DrivingDuration(hour) SpecificConsumption (li/h) %changefromBase %oftotalconsumption

5,826, 530 896,7 91 809,757 129,676

MercedesBenz Base Additive

41,460,704 7,499,426 5,752,335 1,062,962

Scania Base Additive

2,453,296 371,227 333,573 51,895

Base

Volvo Additive

4,834,141 717,745

35,711,011 5,072,213

6.50

6.24

5.53 49%

5.41 2.16%

6.61 3%

6.43 2.81%

7.04 42%

6.74 4.53%

4.05% 7%

Table4.FleetTrial3:Effectofadditivetreatmentwithrespecttodifferentfuelconsumptionrates SpecificConsumption (li/h) Consumption(litres) DrivingDuration (hours) SpecificConsumption (li/h) %ChangefromBase %ofFleet <=5 Base 6,930,626 1,514,459 4.58 8% Additive 969,063 214,840 4.51 1.46% 66% >5y<=7 Base 56,160,086 9,343,751 6.01 Additive 7,772,873 1,330,531 5.84 2.88% 26% >7 Base 22,360,829 2,981,447 7.50 Additive 2,987,870 416,907 7.17 4.65%

Table5.GasolineECE15+EUDCtestcycle Cumulative EmissionResults BaselineTests AdditiveTests Difference HC (g/km) PRE POST 11.5 0.004 11.1 0.003 3.5% 25% CO (g/km) PRE POST 60.6 0.582 55.3 0.415 8.8% 28.7% NOx (g/km) PRE POST 23.5 0.004 22.8 0.003 2.9% 25% CO2 (g/km) PRE POST 1830.61 1775.0 1787.45 1753.0 2.4% 1.2%

Figure1.LightDutyECE15+EUDCtestwithnonmetallicdieseladditive

Figure2.HeavyDutyECER49testwithnonmetallicdieseladditive

Figure3.Integrateddistributionprofileoverallthekeypoints

Figure4.ReductioninPAHincomparisonwiththeaverageofthebaseEN590

Figure5.Changeintherateofoilviscosityincrease

Figure6.Fleettrial1:Gaseousemissionreduction

Figure7.Fleettrial2:Fueleconomybenefitsinarangeofpublicsectorvehicles

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Symbol Hebrew תירבע Trans-literation* Discovery (Year) M.P. (°C) B.P. (°C) Density* (g/cm)Document79 pagesSymbol Hebrew תירבע Trans-literation* Discovery (Year) M.P. (°C) B.P. (°C) Density* (g/cm)Kameswar MandhataNo ratings yet

- Lower and Higher Heating Values of Gas Liquid and Solid FuelsDocument2 pagesLower and Higher Heating Values of Gas Liquid and Solid FuelsElwathig BakhietNo ratings yet

- Applications of Protein Sericin From The SilkglandDocument5 pagesApplications of Protein Sericin From The SilkglandMadiha AshrafNo ratings yet

- Aqa Mechanisms A Level SummaryDocument5 pagesAqa Mechanisms A Level SummaryRS JNo ratings yet

- Pitting-Acceptance or Rejection Pitting-Acceptance or RejectionDocument24 pagesPitting-Acceptance or Rejection Pitting-Acceptance or Rejectionmohammed harrisNo ratings yet

- Synthesis of PetrochemicalsDocument9 pagesSynthesis of PetrochemicalsAnoop UchagawkarNo ratings yet

- How to Prevent Sulfate Attack on ConcreteDocument19 pagesHow to Prevent Sulfate Attack on ConcreteIrvebry Ayu WulandaryNo ratings yet

- The Effectiveness of Cassava Starch As A Component of Biodegradable PlasticDocument43 pagesThe Effectiveness of Cassava Starch As A Component of Biodegradable PlasticRhea Danica AngusNo ratings yet

- ASTM D6224 Eksploataciono Praćenje UljaDocument14 pagesASTM D6224 Eksploataciono Praćenje UljaDejan DejanovicNo ratings yet

- Stability of Phases The Si-C-N-0 System: Harue Wada, Ming-Jong Wang, and Tseng-Ying Tien"Document4 pagesStability of Phases The Si-C-N-0 System: Harue Wada, Ming-Jong Wang, and Tseng-Ying Tien"radoslavoffNo ratings yet

- Assignment-5 Enmt610029 Welding ANDARADHI NARARYA/1206291992Document8 pagesAssignment-5 Enmt610029 Welding ANDARADHI NARARYA/1206291992Andaradhi NararyaNo ratings yet

- Welder Qp3Document12 pagesWelder Qp3Lekshmanan PadmanabhanNo ratings yet

- PhysicalDocument70 pagesPhysicalGadde Gopala KrishnaNo ratings yet

- A333 - 18 PDFDocument8 pagesA333 - 18 PDFRamyMoustafaNo ratings yet

- Effective Approaches To Improve The Electrical Conductivity of PEDOT:PSS: A ReviewDocument16 pagesEffective Approaches To Improve The Electrical Conductivity of PEDOT:PSS: A ReviewSasa PetrovicNo ratings yet

- Chapter - Vii: Moringa Oleifera Seed PowderDocument18 pagesChapter - Vii: Moringa Oleifera Seed PowderDrVishwanatha HNNo ratings yet

- Atp InvetigationDocument6 pagesAtp InvetigationHussain IbrahimNo ratings yet

- Complete Immersion Phosphating LineDocument8 pagesComplete Immersion Phosphating LineStay AwayNo ratings yet

- NganalDocument19 pagesNganalWaleed El-azabNo ratings yet

- Aims03 22 002Document7 pagesAims03 22 002Jorge OrtegaNo ratings yet

- Specification Data: Starquick® Self-Locking Pipe ClampDocument6 pagesSpecification Data: Starquick® Self-Locking Pipe ClampأبومحمدالزياتNo ratings yet

- CBSE Class-12 Chemistry Quick Revision Notes on AminesDocument8 pagesCBSE Class-12 Chemistry Quick Revision Notes on AminesAryan MeenaNo ratings yet

- Mil DTL 81706BDocument20 pagesMil DTL 81706BwcwtnuiNo ratings yet

- Test 2 - Carbohydrates, Lipids, Proteins and Nucleic AcidsDocument7 pagesTest 2 - Carbohydrates, Lipids, Proteins and Nucleic AcidsChrisNo ratings yet

- A Study On The Compressive Strength and Water Absorption of Fired Soda Ash Infused Clay BricksDocument30 pagesA Study On The Compressive Strength and Water Absorption of Fired Soda Ash Infused Clay BricksNicole Andrei BaldozaNo ratings yet

- Introduction To BiopharmaceuticsDocument106 pagesIntroduction To BiopharmaceuticsHely Patel100% (1)

- Molarity and DilutionsDocument21 pagesMolarity and DilutionsRebecca Putri LimbardoNo ratings yet

- Rancidity in FoodDocument3 pagesRancidity in FoodNur Ain Nadiah AbahaNo ratings yet

- Gen Chem 3Document15 pagesGen Chem 3Marco SarmientoNo ratings yet

- 1.7 Batch Cell Culture 2Document36 pages1.7 Batch Cell Culture 2Astra BeckettNo ratings yet