Professional Documents

Culture Documents

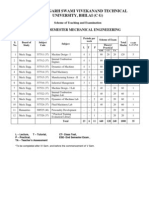

8th Semester Mechanical Engineering Syllabus (MG University)

Uploaded by

Jinu MadhavanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8th Semester Mechanical Engineering Syllabus (MG University)

Uploaded by

Jinu MadhavanCopyright:

Available Formats

8th Semester Mechanical Engineering Syllabus

MU 801 PRODUCTION ENGINEERING Module 1 Theory of metal cutting: Review of deformation of metals-Tool nomenclature and geometry-Oblique & orthogonal cutting Mechanism of chip formation, types, chip curl, chip control Mechanism of orthogonal cutting: Merchants circle diagram shear angle relationship Velocity relationships Effect of rake angle, cutting angle, nose radius etc. on cutting force and surface finish friction process in metal cutting: nature of sliding friction, effect of increasing normal load apparent to real area of contact. Module 2 Machineability of metals:-Factors affecting machineability Evaluation of machineability, significance of tool life-factors affecting tool lifemeasurement of tool life-Economics of machining Machineability indexTool wear: flank & crater (KT) wear types of wear measurements. Tool materials: carbon steel, HSS, coated HSS, ceramics, diamond etc.- Cutting fluids: types, selection of liquids, properties and functions. Module 3 Metal powder-preparation of metal powder Powder characteristics: properties of fine powder, size, size distribution, shape, compressibility, purity, etc Mixing Compaction techniques hot pressing- powder rolling and sintering- Sintering atmosphere Finishing operations: heat treatment, surface treatment, impregnation treatment, etc examples of articles produced and their applications. Module 4 Advanced materials and ceramics: Advanced materials Super alloysTitanium & titanium alloys-shape memory alloys-smart materials-properties and applications. Ceramics: structure- Mechanical, physical properties &

applications common types of ceramic materials ceramic fabrication process like slip casting, pressure forming, hot pressing, plastic forming and ceramic joining glass ceramics Module 5 Advanced manufacturing techniques: Introduction to rapid prototyping:methods. Abrasive water jet machining, LIGA process- principle, types, process parameters, surface finish, applications etc. References 1. Armargeo and Brown, The machining of metals, Prentice Hall. 2. Berman, Barlow and Bourell, Solid free Foam fabrication: A new direction in manufacturing. Kulwer Academic publications. 3. Brophy, Rose & Wulf, the structure and properties of Metals Vol. 2, Wiley Eastern. 4. Dixon and Clayton, Powder metallurgy for Engineers, Machinery Publishing Co. London. 5. HMT, Production Technology, Tata McGrawHill. 6. Kalpakjain, Manufacturing Engineering and Technology, Addison Wesley, 4 rth edition. 7. Lal G. K., Introduction to machining science, New Age Publishers. 8. Metcut research, Machinability Data Centre Vol. 1 & 2. Metcut research associates, Cincinnati. 9. Paul. H. Black, Theory of Metal Cutting, McGraw Hill. U 802 VEHICLE DYNAMICS Module 1 Introduction to synthesis: Graphical methods applied to four bar mechanisms for given input output relation, relative pole method and inversions method. Solutions of velocity and acceleration in mechanisms by special methods Hall and Aults auxiliary point method. Dynamic force analysis: Inertia force, Inertia torque, determination of inertia forces Engine mechanism, four bar mechanism, engine force analysis, dynamically

equivalent masses, equiline output torque. Performance of road vehicles: Tractive resistance, tractive effort, power required for propulsion, grade ability, drawbar pull and the problems related to these terms. Module 2 Suspension: Requirements, spring mass frequency, wheel hop, wheel wobble, wheel shimmy, choice of suspension spring rate, vehicle suspension in force and apt directions, hydraulic dampers and choice of damper, characteristics, suspension systems like independent suspensions, compensated suspension system, rubber and air suspension systems. Module 3 Tyres: Types, relative merits and demerits. Ride characteristics of tyres, behaviour while cornering, slip angle, cornering force, power consumed by a tyre, effect of driving, braking torque, effect of camber, camber thrust. Module 4 Vehicle handling: Oversteer, understeer, steady state cornering, effect of braking, driving torques on steering, effect of camber, transient effects in cornering, directional stability of vehicles. Module 5 Stability of vehicles: Load distribution, stability on a curved track, stability on a slope, Gyroscopic effects, weight transfer during acceleration and braking, over turning and sliding, stability of a rigid vehicle and equations of motion of a rigid vehicle, cross wind handling. References 1. W. Steeds Mechanics of road vehicles Wildlife book Ltd, London 1990. 2. J. G. Giles steering, suspension and tyres, Wildlife books Ltd, London 1968. 3. P. M. Heldt Automotive chassis, Chilton Co, New York, 1952. 4. J. Y. Wong Theory of ground vehicles, Johnwiley and sons Inc., New York.

5. N. K. Giri Automobile mechanics, Khanna Publishers, Delhi 1986. U 803 ENGINE AND DRIVE LINE DESIGN Module 1 Design of IC engine components: Design of cylinder, piston, connecting rod, design of fly wheel turning moment diagram, functions of flywheel, fluctuations of energy and speed in flywheel, size of the flywheel. Springs: Types of springs, design of helical springs, deflection of coil spring, spring rate, energy stored by spring, design of torsion bar, leaf spring design, standard sizes of automobile suspension springs. Module 2 Clutches and Brakes: Design of single plate, multiplate, centrifugal and cone clutches, design factors for brakes, heat rejected during braking, torque transmitted by leading and trailing shoes during braking, braking force, stopping distance, braking efficiency, weight shifted during braking, simple problems. Module 3 Steering systems: Condition for true rolling, Turning circle radius of wheels, angle of inside lock and outside lock problems. Module 4 Design of gears: Nomenclature, Lewis equation and Lewis form factor, working stresses in gear teeth, dynamic load on gear teeth, design of spur gear, helical gear, bevel gear and worm gear, Lewis equation for strength and design dynamic load, endurance load, wear load, AGMA standards. Module 5

Bearings: Classification of bearings, journal bearings, mechanisms of film lubrication, Theories of lubrication, viscosity, bearing modules, coefficient of friction, minimum oil film thickeners, heat dissipation bearings, bearing materials, bearing design, ball and roller bearings, mechanics of rolling friction, bearing life, static and dynamic load rating, equivalent bearing load, bearing selection. References 1. N. K. Giri Automobile mechanics, Khanna Publishers,New Delhi. 2. P. M. Heldt Torque converters, Chillon Book Co, 1952. 3. P. M. Heldt Automotive Chassis, Chillon Book Co, 1952. 4. Shigley Machine Design, McGraw Hill Book Co, New York, 1956. 5. R. S. Khurmi Machine Design. 6. Dr. Sadhu Singh Machine Design, Khanna Publishers, New Delhi, 1997. Note: Use of Design Data Hand Book is permitted for solving the problems. U 804 VEHICLE TRANSPORT MANAGEMENT Module 1 Infrastructure: Types of roads, traffic condition, relief of congestion pedestrian, bus stops, shelters, bus stations, garages layout of premises, equipments, use of machinery. Organization and management: Forms of ownership, principle of transport. Management Internal organization, centralized condition, decentralized condition (Engineering, traffic and administration), administration, recruitment and training, welfare, health and safety. Prevention of accidents: Emphasis of safe driving, Annual awards, bonus encouragement, vehicle design, platform layout, location of stops, scheduled speed, route hazard records, elimination of accident prone drivers. Module 2 Public relations work: Dissemination of information, maintaining good will, handling complaints, traffic advisory committee, local contacts, co-operation with the press news and articles, forms of publicity, importance of quality,

inter departmental liaison, advertisement, general appearance of premises, specialized publicity. Module 3 Route Planning and Scheduling: Sources of traffic, town planning, turning points, stopping places, survey of route, factors affecting frequency, direction of traffic flow, estimated traffic possibility, time table layout, use of flat graph method, preparation of vehicle efficiency, checking efficiency of crew, duty arrangements, duty of drivers and conductors. Module 4 Fare collection system: Principles of fare collection, way bill, bell punch system, will brew system, T. I. M. and straight machines, box system, personal and common stock, flat fare basis. Fare structure: Basis of fares, effect of competition and control, calculating average charge, zone systems, straight and tapered scales, co-ordination of tables, anomalies, double booking, private hire charges. Module 5 Motor vehicle act: Importance of motor vehicle act: VIII, IX, X & XI schedules, types of driving licenses, procedure for obtaining driving license, registration of vehicle, types of permits, procedure for obtaining permits, third party insurance. References U 805 A ENGINEERING ECONOMICS AND AUTOMOTIVE COST ESTIMATION Module 1 Introduction: Definition of various economic terms such as economic goods, utility, value, wealth, wants, capital, rent and profit, loss and returns.

Money and exchange: Theory of exchange, stock exchange, speculation, money, qualities of a good money, functions of money, classification of money, value of money, index number, appreciation and depreciation of money value, Grahams laws and its limitations. Wages: Nominal and real wages, factors affecting real wages, theory of wages, difference in wages, methods of wage payment. Module 2 Interest and Depreciation: Introduction, theory of interest rates, simple and compound interest, nominal and effective interest rates, interest formulae, annual compounding, annual payments and continuous compounding, annual payment, need for depreciation, obsolescence, simple problems. Module 3 Costs: Standard costs, estimated costs, first cost, fixed cost, variable costs, incremental cost, differential cost, sink and marginal cost, breakeven and minimum cost analysis, simple numerical problems. Cost accounting: Introduction, objectives of cost accounting, elements of cost, materials cost, labour cost and expenses, allocation of overheads by different methods, simple numerical problems. Module 4 Cost Estimation: Introduction, importance, objective and functions of estimating. Principal factors in estimating, functions and qualities of an estimator estimating procedure. Module 5 Specification of automobiles: Specifications types, specifications of some important two wheelers, light motor vehicles and heavy duty vehicles (Indian makes). References 1. Grant Etal Engineering Economics. 2. Banga and Sharma Mechanical Estimating and Costing. 3. Tara Sing Engineering Economics.

4. Indian make two wheelers, light motor vehicles and heavy vehicles Hand book of Automobiles. U 805 B PROJECT MANAGEMENT (ELECTIVE 2) Module 1 Project feasibility Analysis: Marketing, Technical, and financial feasibilities report preparation case studies. Module 2 Project Management nature and scope PERT and CPM techniques, Estimates time, cost, resources (man, material, tool). Module 3 Fore casting methods Time series analysis method of least square, moving average, curvilinear, correlation analysis. Module 4 Risk analysis risk in economic analysis measuring risk in investment, risk profiles, decision trees, formulation of discounted decision trees, simulation. Module 5. MS Project: (Software Practice) Creation of task, sequencing of task, assignment of resources, finding critical path, ABC activities (discuss), breaking the activities, colouring techniques, resource balancing, allocating overtime, using different calendars (Like 8 or 12 hours shift, Friday/ Sunday holiday, Special public holidays, etc), cost estimates, assignment of blank fields, creation of different views on screen. Reports: Daily reports for completed activity, lagging activities, overall progress review, Management high level reports, individual Departmental reports. References

1. Corter, Mastering MS Project 2000, BPB Publishers. 2. Harvey Maylor, Project Management, Pearson Education. 3. Prasanna Chandra, Project Management, Tata McGraw Hill. 4. Prasanna Chandra, Projects, Tata Mc Graw Hill. MU 805 C COMBUSTION (ELECTIVE 2) Module 1 Thermodynamics of reactive mixtures: Bond energy Heat of formation Heat of reaction adiabatic flames temperatures entropy changes for reacting mixtures chemical equilibrium criteria evaluation of equilibrium constant and equilibrium composition simple numerical problems. Module 2 Elements of chemical kinetics: law of mass action order and molecularity of reaction rate equation Arrheniuss law activation energy collision theory of reaction rates Transition state theory collision theory of reaction rates Transition state theory General theory of chain reactions combustion of carbon monoxide and hydrogen. Module 3 Ignition and flammability: methods of ignition self ignition thermal theory of ignition limits of flammability factors affecting flammability limits flame quenching flame propagation flame velocity measurement of flame velocity factors affecting flame speed premixed and diffusion flames physical structures and comparison characteristics of laminar and turbulent flames theory of laminar flame propagation. Module 4 Flame stabilization: Stability diagrams for open flames mechanisms of flame stabilization critical boundary velocity gradient stabilization by eddies bluff body stabilization effects of variables on stability limits.

Module 5 Combustion in solid and liquid propellant: Reactant motors Classification and types of propellants desirable properties of grain shapes burning rates and combustion model of solid propellants injection of liquid propellants ignition and ignitors. Miscellaneous topics droplet combustion fluidized bed combustion classification of coal air pollution. References Fuels and combustion 1. S. P. Sharma. 2. Some fundamentals of combustion Spalding. D. B. 3. Fundamentals of combustion Strehlow. R. A. 4. Elementary reaction kinetics Lathan. J. L. 5. Flames Gaydan and Wolfhard. MU 805 D AEROSPACE ENGINEERING (ELECTIVE 2) Module 1 The atmosphere: Characteristics of troposphere, stratosphere, mesosphere and ionosphere International Standard Atmosphere Pressure, Temperature and Density variations in the International Standard Atmosphere Review of basic fluid dynamics continuity, momentum and energy for incompressible and compressible flows static, dynamic and stagnation pressures phenomena in supersonic flows. Module 2 Application of dimensional analysis to 2D viscous flow over bodies Reynolds number Mach number similarity Aerofoil characteristics Pressure distribution Centre of Pressure and Aerodynamic centre Horse shoe vertex. Module 3

Momentum and Blade Element Theories Propeller co-efficients and charts Aircraft engines Turbojet, turbo fan and Ram jet engines Bypass and Afterburners. Module 4 Straight and level flight Stalling speed Minimum drag and Minimum power conditions Performance curves Gliding Gliding angle and speed of flattest glide Climbing Rate of climb Service and Absolute ceilings take off and Landing Performance Length of Runway required Circling flight Banked flight High lift devices Range and endurance of air lanes. Module 5 Air speed indicators calculation of true air speed Altimeters Rate of Climb meter Gyro compass Principles of wind tunnel testing Open and closed type Wind tunnels Pressure and velocity measurements Supersonic Wind tunnels (description only) Rocket motors Solid and liquid propellant rockets Calculation of earth orbiting and escape velocities ignoring air resistance and assuming circular orbit. References 1. Mechanics of flight Kermode. A. C. 2. Aerodynamics for Engineering Students Houghton and Brock. 3. Air plane Aerodynamic Dommasch. U 806 A VEHICLE MAINTENANCE (ELECTIVE) Module 1 Maintenance, Records and schedules: Importance of maintenance, types of maintenance, inspection, schedule, maintenance, log sheets, servicing, requirements of service station, layout and personnel for service station. Module 2

Engine overhauling and repair: Reconditioning of engine, specific tools used for overhauling, de-carbonizing and degreasing, engine tune up, valve reconditioning, use of automobile stethoscope, troubles and trouble shooting related to engines. Module 3 Maintenance and repair of chassis: Servicing of clutch assembly, gearbox and propeller shaft, troubles and trouble shooting on transmission, differential maintenance and repair, backlash adjustment, servicing of braking system, identification and rectification of brake faults, brake testing steering system, maintenance, tyre rotation, tyre rethreading, checking and adjusting, suspension, wheel balancing, wheel alignment. Module 4 Vehicle body repair and maintenance, minor panel beating, dolly blocks, tinkering, body painting, maintenance of body trim, specific tools for body repair, methods of towing a vehicle. Module 5 Maintenance of auxiliaries: Maintenance of starter motor and dynamo or alternator, battery maintenance, methods of testing various electrical accessories and other accessories, radiator service, anticorrosion additives, engine oil change, preventive maintenance. References 1. Boyce Dwiggins Automobile Repair guide, Theodor Audel and Co., Indiana 1978. 2. A. W. Judge Maintenance of high speed diesel engine, Chapmann Hall Ltd. 3. A. W. Judge Motor vehicle engine servicing 3rd edition, Pitman paper mark, London, 1969. 4. Vehicle service manuals and reputed manufacturers. U 806 B VEHICLE PERFORMANCE AND TESTING

Module 1 Laboratory testing: Engine testing on dynamometers, different types, engine analysis for petrol and diesel engines, F.I.P. calibrating and testing, exhaust gas analyzers, various types. Module 2 Vehicle testing on chassis dynamometers, wheel alignment testing, wheel balancing, testing, brake testers, head light alignment testing. Module 3 Noise production and control: Noise inside and outside the vehicle, sources of vehicle noise, intake and exhaust noise, combustion noise, mechanical noise, noise from auxiliaries, wind noises, transmission noises, brake squeal, structure noise, noise control methods. Module 4 Vehicle performance: Operation of full load and part conditions, fuel economy, effect of vehicle condition, tyre and road condition and traffic condition and driving habits on fuel economy. Module 5 Road and track testing: Initial inspection, running in and durability, intensive driving, maximum speed and acceleration, brake testing on the road, hill climbing, handling and ride characteristics, safety, corrosion, testing, wind tunnel testing and test tracks. References 1. J. G. Giles Vehicle operation and performance, Wildlife Publications, London, 1969. 2. W. H. Crouse and L. Anglin Motor vehicle inspection, McGraw Hill Book Co. 1978. 3. SAE Transaction papers 831814, 820346, 820367, 820371, 820375.

U 806 C ALTERNATIVE ENERGY SOURCES/ FUELS FOR AUTOMOBILES Module 1 Introduction: Need for non-conventional energy sources, energy conservation in transportation sector, alternative energy, alcohol, hydrogen, biomass and electric. Alcohol: Methanol and Ethanol production methods, properties of methanol and ethanol as engine fuels, use of alcohols in SI engines, performance of methanol and gasoline blends. Combustion characteristics of alcohols in engine, use of alcohols in CI engines, different method of use, Alcohol diesel emulsions, dual fuel systems. Module 2 Hydrogen energy: Properties of hydrogen, sources of hydrogen, production of hydrogen, electrolysis of water, thermal decomposition of water, thermo chemical production and biochemical production, storage and methods, applications to engines, modifications necessary, precautions and safety for use performance characteristics in engines. Module 3 Gaseous fuels: Biogas production, description of biogas plant, application of biogas as a single fuel and double fuel performance, LPG property use in SI engines, fuel metering system, performance in engines natural gas and producer gas use in engines general view. Vegetable oil: Vegetable oil properties, esterification of vegetable oil, bio diesel, diesel and vegetable oil blends, engine performance with vegetable oil. Module 4 Solar power: Collection and storage of solar energy, collection devices, flat plate collectors, concentrating type collectors, principle and working of photovoltaic conversion, application to automobiles. Module 5

Electric vehicles: Design considerations, limitations, opportunities for improvement, batteries, problems, future possibilities, capacities, types, material requirement, driving requirements, applicability of electric cars, cost of electric car, comparative use of fuel and energy recharging. References 1. T. K. Garrett: Automotive fuel system, SAE INC, Warrendale, 1991. 2. J. David Powell and Richard. P. Brennan The Automobile Technology and society Printice Hall. 3. SAE Papers: 73802, 750121, 750118, 741008. 4. Energy research group Alternate liquid fuels Willey Eastern Ltd, New Delhi, 1990. 5. T. N. Vezgiriglu Alternative energy sources. 6. Mathur and Sharma IC Engines, Dhanpat Rai and Sons. 7. William Hamilton Electric Automobile. MU 806 D CRYOGENICS (ELECTIVE 3) Module 1 Introduction: Historical development present areas involving cryogenic engineering, Basic thermodynamics applied to liquefaction and refrigeration process isothermal, adiabatic and Joule Thomson expansion process adiabatic demagnetization efficiency to liquefaction and coefficient of performances irreversibility and losses. Module 2 Low temperature properties of engineering materials: mechanical properties thermal properties electrical and magnetic properties. Properties of cryogenic fluids materials of constructions for cryogenic applications. Module 3 Gas liquefaction systems: production of low temperatures general liquefaction systems liquefaction systems for neon, hydrogen, nitrogen and helium.

Module 4 Cryogenic refrigeration systems: Ideal refrigeration systems refrigerators using liquids and gases as refrigerators refrigerators using solids as working media. Module 5 Cryogenic storage and transfer systems Cryogenic fluid storage vessels cryogenic fluid transfer systems. Application of cryogenics cryo pumping superconductivity and superfluidity cryogenics in space technology cryogenics in biology and medicine. References 1 .Cryogenic Systems Barron. R. F. 2. Cryogenic Engineering Scot. R. W. 3. Cryogenic Engineering Bell. J. H. MU 807 MECHANICAL MEASUREMENTS LABORATORY 1. Study of use of laser interferometer for caliberation of linear measurements. 2. Measurement of temperature: Caliberation of thermometers and pyrometers, Preparation and caliberation of thermocouple and resistance temperature detectors (TTD & RTD). 3. Measurement of pressure: Caliberation and use of pressure measuring instruments Pressure Gauge, Micro manometer, Pressure Transducers, Dead Weight pressure gauge caliberator. 4. Measurement of speed: Caliberation and use of tachometers & stroboscope. 5. Measurement of linear and angular dimensions: Micrometer, Vernier caliper, dial gauge, feeler gauge, comparator, interferometer, angle gauge, sine bar, plug gauge and wire gauge. 6. Measurement of flow: Rotameter, watermeter, anemometer, caliberation and use. 7. Measurement of surface roughness using subtonic tester.

8. Measurement of gear and screw thread profiles gear tooth calilpers, screw thread calipers. 9. Measurement of strain and force calibration of strain gauges and load cells. 10. Measurement of vibration use of vibration pick ups, accelerometer and vibration indicator. 11. Acoustic measurements sound level meter preparation of noise contours. 12. Measurement of PH value. 13. Measurement of psychometric properties of air. 14. Analysis of Automobile exhaust gas and Flue gas Use of instruments like oxygen analyzer. Orsat gas analyzer, Gas chromatography. MU 808 PROJECT & SEMINAR At the beginning of the seventh semester, students must submit an abstract of their undergraduate project. They must submit a preliminary report at the end of the semester. They will complete the project in the eight-th semester. Sessional marks for seminar will be out of 25. Sessional marks for project will be out of 75, in which 35 marks will be based on day to day performance assessed by the guide. Balance 40 marks will be awarded based on the presentation of the project by the students before an evaluation board consisting of minimum 3 faculty members including the guide. MU 809 VIVA VOCE A comprehensive Viva-voce examination will be conducted to assess the students overall knowledge in the specified field of engineering. At the time of viva voce, certified reports of seminar and project work are to be presented for evaluation.

You might also like

- Production Engineering M 801 2+1+ 0Document5 pagesProduction Engineering M 801 2+1+ 0roinbanerjiNo ratings yet

- Mech 6th Sem SyllabusDocument14 pagesMech 6th Sem SyllabusArun ManoNo ratings yet

- Transverse Loads, Vibrations of Beams With Concentrated and Distributed Loads. Dunkerly's Methods, Raleigh's MethodDocument7 pagesTransverse Loads, Vibrations of Beams With Concentrated and Distributed Loads. Dunkerly's Methods, Raleigh's Methodsanyasirao1No ratings yet

- Ms 481 Management Concepts & Industrial Relations L T P CDocument8 pagesMs 481 Management Concepts & Industrial Relations L T P CNarayanan ShrikanthNo ratings yet

- 6 THDocument19 pages6 THyoyotoyoNo ratings yet

- 6th Semester Mechanical Engineering Syllabus (MG University)Document9 pages6th Semester Mechanical Engineering Syllabus (MG University)Jinu MadhavanNo ratings yet

- MPSC Mechanical Engineering Main SyllabusDocument6 pagesMPSC Mechanical Engineering Main SyllabusD JNo ratings yet

- The Benefits and Drawbacks of eDocument5 pagesThe Benefits and Drawbacks of esaikumarNo ratings yet

- 66 Handbook Me V SemDocument62 pages66 Handbook Me V Semkanishkakhurana240% (1)

- 6th Sem Auto. Engg. SyllabusDocument22 pages6th Sem Auto. Engg. Syllabusrudey18No ratings yet

- Auto Engine Course Document SummaryDocument13 pagesAuto Engine Course Document SummaryDineshNewalkarNo ratings yet

- MPSC Non Gazetted Services Syllabus of Group C Mains Exam 2023 UpdatedDocument4 pagesMPSC Non Gazetted Services Syllabus of Group C Mains Exam 2023 UpdatedPRATIK MALAVENo ratings yet

- 5th Semester Mechanical Engineering Syllabus (MG University)Document9 pages5th Semester Mechanical Engineering Syllabus (MG University)Jinu MadhavanNo ratings yet

- Chhattisgarh Technical University B.E. Mechanical 5th Sem Subject SchemeDocument14 pagesChhattisgarh Technical University B.E. Mechanical 5th Sem Subject Schemeveer_sNo ratings yet

- Syl Lab Us of Mechanical EngineeringDocument4 pagesSyl Lab Us of Mechanical Engineeringavinash_k007No ratings yet

- Btech Viii Sem Syallbus 21-22030622124052Document16 pagesBtech Viii Sem Syallbus 21-22030622124052Manish NayakNo ratings yet

- SylabDocument2 pagesSylabEmma PunnooseNo ratings yet

- ME123 Machine Design - IIDocument1 pageME123 Machine Design - IIArun KumarNo ratings yet

- VEHICLE TECH BODY, CHASSIS, STEERING, BRAKES & SUSPENSIONDocument2 pagesVEHICLE TECH BODY, CHASSIS, STEERING, BRAKES & SUSPENSIONyashvantNo ratings yet

- Mech Engg Syllabus Modified (R10) 11.3.2012Document57 pagesMech Engg Syllabus Modified (R10) 11.3.2012Srimanthula SrikanthNo ratings yet

- B.Tech. Mechanical Engineering IV Semester S.No Subject Name and CodeDocument8 pagesB.Tech. Mechanical Engineering IV Semester S.No Subject Name and CodeGuru MaheshNo ratings yet

- Course ContentsDocument5 pagesCourse ContentsJitesh NikamNo ratings yet

- 073 - ME6601 Design of Transmission Systems - Anna University 2013 Regulation SyllabusDocument2 pages073 - ME6601 Design of Transmission Systems - Anna University 2013 Regulation SyllabusM A JomahNo ratings yet

- Syllabus Final YearDocument5 pagesSyllabus Final YearPradeep JangidNo ratings yet

- Mee362 Two-And-three-wheeler TH 1.00 Ac21Document2 pagesMee362 Two-And-three-wheeler TH 1.00 Ac21yashvantNo ratings yet

- Read This First MechanicalDocument5 pagesRead This First MechanicalAnimesh RoyNo ratings yet

- DETAILS OF PROGRAMME NO. 15/2011 (DECEMBER 2011Document7 pagesDETAILS OF PROGRAMME NO. 15/2011 (DECEMBER 2011Ganesh MalayathNo ratings yet

- Automobile VTU Syllabus For 6th SemesterDocument22 pagesAutomobile VTU Syllabus For 6th SemesterprabhuswamygsNo ratings yet

- PH D Syllabus For Entrance Exam 2022 23Document20 pagesPH D Syllabus For Entrance Exam 2022 23Mohammad Reza AlaeiNo ratings yet

- Mechanical EngineeringDocument3 pagesMechanical EngineeringsathishmtNo ratings yet

- 5 1Document13 pages5 1gabrieltinNo ratings yet

- MD 2 SyllabusDocument1 pageMD 2 SyllabusSabir AliNo ratings yet

- DTS Syllabus12122011Document1 pageDTS Syllabus12122011ntsdharmaNo ratings yet

- BME Fifth Semester Theory ModulesDocument5 pagesBME Fifth Semester Theory ModulesDeepak AgrawalNo ratings yet

- Me53 Design of Machine Elements L T P CDocument2 pagesMe53 Design of Machine Elements L T P CajithjkingsNo ratings yet

- Automobile EngineeringDocument4 pagesAutomobile EngineeringRita KalaniNo ratings yet

- Learning Vehicle MaterialsDocument74 pagesLearning Vehicle MaterialsYUCABETHNo ratings yet

- 7th Semester Mechanical Engineering Syllabus (MG University)Document13 pages7th Semester Mechanical Engineering Syllabus (MG University)Amit CherianNo ratings yet

- RTU-Syllabus of (VI Sem.)Document7 pagesRTU-Syllabus of (VI Sem.)mamta1008835366No ratings yet

- Automobile Engineering FundamentalsDocument74 pagesAutomobile Engineering FundamentalsAbhimanyuravi CrNo ratings yet

- Vocational Teacher (Maintenance and Repairs of Automobiles)Document7 pagesVocational Teacher (Maintenance and Repairs of Automobiles)Brandon AllenNo ratings yet

- Scheme and Syllabus For The Post of Lecturers in Government Polytechnics (Engineering & NON Engineering) in A.P. Technical Education ServiceDocument6 pagesScheme and Syllabus For The Post of Lecturers in Government Polytechnics (Engineering & NON Engineering) in A.P. Technical Education ServiceD A KUMARNo ratings yet

- Syllabus Automobile EngineeringDocument54 pagesSyllabus Automobile EngineeringmechanzsNo ratings yet

- Mechanical EngineeringDocument3 pagesMechanical EngineeringVj Vicky'sNo ratings yet

- S4 Mechanical SyllabusDocument8 pagesS4 Mechanical SyllabusJinu MadhavanNo ratings yet

- RGPV Syllabus 5th SemDocument4 pagesRGPV Syllabus 5th SemavantikasankhyainNo ratings yet

- Syllabus of Engineering Service ExaminationDocument5 pagesSyllabus of Engineering Service ExaminationTeiborlin MarngarNo ratings yet

- 06ME61 - DME - 2 SyllabusDocument2 pages06ME61 - DME - 2 SyllabusGirish HanumaiahNo ratings yet

- VTU Syllabus Analysis and DesignDocument13 pagesVTU Syllabus Analysis and DesignSwamy ManiNo ratings yet

- 6TH SEM SyllabusDocument35 pages6TH SEM Syllabussrujangowdasj2002No ratings yet

- RRB JE Mech-SyllabusDocument2 pagesRRB JE Mech-SyllabusRandhir SinghNo ratings yet

- TNPSC Engineering Services SyllabusDocument4 pagesTNPSC Engineering Services SyllabusGOPALAKRISHNAN RAGOTHAMANNo ratings yet

- Design of High-Speed Railway Turnouts: Theory and ApplicationsFrom EverandDesign of High-Speed Railway Turnouts: Theory and ApplicationsRating: 4.5 out of 5 stars4.5/5 (4)

- Nonlinear Optimization of Vehicle Safety Structures: Modeling of Structures Subjected to Large DeformationsFrom EverandNonlinear Optimization of Vehicle Safety Structures: Modeling of Structures Subjected to Large DeformationsRating: 5 out of 5 stars5/5 (1)

- Multiscale Modeling of Additively Manufactured Metals: Application to Laser Powder Bed Fusion ProcessFrom EverandMultiscale Modeling of Additively Manufactured Metals: Application to Laser Powder Bed Fusion ProcessNo ratings yet

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Essay Writing Service Reviews UKDocument1 pageEssay Writing Service Reviews UKJinu MadhavanNo ratings yet

- TET Solved Question BankDocument16 pagesTET Solved Question BankRajneesh TripathiNo ratings yet

- 2013 Syllabus 12 BiologyDocument4 pages2013 Syllabus 12 BiologyJinu MadhavanNo ratings yet

- 2014 Syllabus 12 EconomicsDocument3 pages2014 Syllabus 12 Economicsabhisheksachan10No ratings yet

- Pages From PC World 2012 01 JanDocument1 pagePages From PC World 2012 01 JanJinu MadhavanNo ratings yet

- Mba SyllabusDocument79 pagesMba SyllabusMichael CaseNo ratings yet

- S4 Mechanical SyllabusDocument8 pagesS4 Mechanical SyllabusJinu MadhavanNo ratings yet

- Tet Aptitude Test Question PaperDocument4 pagesTet Aptitude Test Question PaperJinu MadhavanNo ratings yet

- Class XII (Theory) : One Paper Time: 3 Hours 70 Marks Unit No. Title MarksDocument7 pagesClass XII (Theory) : One Paper Time: 3 Hours 70 Marks Unit No. Title MarksJinu MadhavanNo ratings yet

- 2012 Syllabus 12 PhysicsDocument6 pages2012 Syllabus 12 PhysicsNidhi Puri KumarNo ratings yet

- Evised S3 Mechanical SyllabusDocument11 pagesEvised S3 Mechanical SyllabusJinu MadhavanNo ratings yet

- KANNUR UNIVERSITY Degree B.S.W SyllabusDocument33 pagesKANNUR UNIVERSITY Degree B.S.W SyllabusJinu MadhavanNo ratings yet

- University of Calicut: General and Academic Branch - I E' SectionDocument86 pagesUniversity of Calicut: General and Academic Branch - I E' SectionFarash MuhamedNo ratings yet

- s3 Mechanical SyllabusDocument8 pagess3 Mechanical SyllabusJinu MadhavanNo ratings yet

- S5, s6 Mechanical SyllabusDocument16 pagesS5, s6 Mechanical SyllabusJinu MadhavanNo ratings yet

- Kannur University B.SC Biochemistry PDFDocument51 pagesKannur University B.SC Biochemistry PDFJinu MadhavanNo ratings yet

- Kannur University Scheme and Syllabi of BbaDocument14 pagesKannur University Scheme and Syllabi of BbaJinu Madhavan100% (1)

- Botany Ug SyllabusDocument205 pagesBotany Ug SyllabusJinu MadhavanNo ratings yet

- KANNUR UNIVERSITY COURSE Syllabus FOR B.COM DEGREEDocument17 pagesKANNUR UNIVERSITY COURSE Syllabus FOR B.COM DEGREEJinu Madhavan50% (2)

- Kannur Bse Arabic Syllabi 2009Document131 pagesKannur Bse Arabic Syllabi 2009Jinu MadhavanNo ratings yet

- Kannur Bse Arabic Syllabi 2009Document131 pagesKannur Bse Arabic Syllabi 2009Jinu MadhavanNo ratings yet

- Scheme and Syllabus of B.A. Travel and Tourism ManagementDocument36 pagesScheme and Syllabus of B.A. Travel and Tourism ManagementJinu Madhavan100% (1)

- MG 6th Sem Question PapersDocument13 pagesMG 6th Sem Question PapersJinu Madhavan0% (2)

- Kannur Bse Arabic Syllabi 2009Document131 pagesKannur Bse Arabic Syllabi 2009Jinu MadhavanNo ratings yet

- Agriculture Syllabus (Animal)Document10 pagesAgriculture Syllabus (Animal)Jinu MadhavanNo ratings yet

- Agriculture B.tech SyllabusDocument24 pagesAgriculture B.tech SyllabusJinu MadhavanNo ratings yet

- B.Tech (Agricultural Engineering) Syllabi (2007-11) : Tamil Nadu Agricultural UniversityDocument4 pagesB.Tech (Agricultural Engineering) Syllabi (2007-11) : Tamil Nadu Agricultural UniversityJinu MadhavanNo ratings yet

- 1st Sem Syllabus For B.SC Agri For MPKVDocument23 pages1st Sem Syllabus For B.SC Agri For MPKVVIKRAM9350% (4)

- PG Syllabus AgriDocument432 pagesPG Syllabus AgriJinu Madhavan100% (1)

- Hons. Agriculture SullabusPart I-IVDocument84 pagesHons. Agriculture SullabusPart I-IVJinu MadhavanNo ratings yet

- Remanufacturing Solutions For Transportation Electronics: WWW - inDocument47 pagesRemanufacturing Solutions For Transportation Electronics: WWW - inAndrey AndrienkoNo ratings yet

- Question Topic WiseDocument5 pagesQuestion Topic WisePagan jatarNo ratings yet

- E16 Starbulk S.A. Diesel Generator Performance Report: M/V For Engine No: 1Document3 pagesE16 Starbulk S.A. Diesel Generator Performance Report: M/V For Engine No: 1joreyvilNo ratings yet

- Apd NG40Document5 pagesApd NG40Magaly PeraltaNo ratings yet

- MPH122Document8 pagesMPH122Hasan BasriNo ratings yet

- Techical Operations: CumminsDocument5 pagesTechical Operations: Cumminsh1977h22No ratings yet

- Etabloc PDFDocument86 pagesEtabloc PDFDoss MartinNo ratings yet

- Hyundai-HiMSEN 20H32/40V Alternative B Engine Specs and Cost AnalysisDocument3 pagesHyundai-HiMSEN 20H32/40V Alternative B Engine Specs and Cost AnalysisMavrix AgustinNo ratings yet

- Lexus - GS300 - GS430 - Service - Manual 8Document88 pagesLexus - GS300 - GS430 - Service - Manual 8seregap8475% (12)

- CSB01 1Document5 pagesCSB01 1stiveNo ratings yet

- MTEE Info Sheet S16R2 T2MPTAW PDFDocument2 pagesMTEE Info Sheet S16R2 T2MPTAW PDFJORGE MONTESNo ratings yet

- C7.1 Generator Set Fuel Purging ProceduresDocument4 pagesC7.1 Generator Set Fuel Purging ProceduresbejoythomasNo ratings yet

- Turboprop Engine Nacelle Optimisation.Document10 pagesTurboprop Engine Nacelle Optimisation.Elena Presura - ChirilescuNo ratings yet

- Tug - ESKORTDocument6 pagesTug - ESKORTudelmark100% (1)

- Ca25 2015Document500 pagesCa25 2015Bruno RibeiroNo ratings yet

- Course Name: Hybrid Electric Vehicle Theory and Design Course Code: HEVTDDocument28 pagesCourse Name: Hybrid Electric Vehicle Theory and Design Course Code: HEVTDAmit Kumar BaghelNo ratings yet

- 01 - Utility Consumption PDFDocument6 pages01 - Utility Consumption PDFVinod Varadan SNo ratings yet

- Moto Guzzi Breva 1100 2005-2007 Manuale RiparazioneDocument155 pagesMoto Guzzi Breva 1100 2005-2007 Manuale RiparazioneAndrea NeriNo ratings yet

- Automotive Diagnostic System GT90 User's Manual v120180622Document84 pagesAutomotive Diagnostic System GT90 User's Manual v120180622CleytonBronoskiNo ratings yet

- SuppressedDocument40 pagesSuppressedJason Youngquist100% (2)

- 2019-09-03 UD Trucks UD-HDE Quester List Error CodeDocument24 pages2019-09-03 UD Trucks UD-HDE Quester List Error Codenanda adisNo ratings yet

- MQM 385 Group Project Honda MotorsDocument31 pagesMQM 385 Group Project Honda Motorsapi-546622986No ratings yet

- DifferenceDocument3 pagesDifferencehp rocksNo ratings yet

- Mechanical Engineer ResumeDocument2 pagesMechanical Engineer Resumerobert carbungcoNo ratings yet

- 100732Document8 pages100732213eknoNo ratings yet

- Marine Diesel Engines 16V 1163 M74 for Fast VesselsDocument3 pagesMarine Diesel Engines 16V 1163 M74 for Fast Vesselsghostt123No ratings yet

- Trend Plus Users ManualDocument102 pagesTrend Plus Users ManualRicardo zafraNo ratings yet

- Selection of PumpDocument39 pagesSelection of PumpM. Nasikhun WahidinNo ratings yet

- PG1000B Generating Set Ratings and Technical DataDocument4 pagesPG1000B Generating Set Ratings and Technical Datamohsen_cumminsNo ratings yet

- Astec Roadtec SX 5 Stabilizer Reclaimer Spec Sheet EnglishDocument2 pagesAstec Roadtec SX 5 Stabilizer Reclaimer Spec Sheet EnglishashutoshpathakcivilNo ratings yet