Professional Documents

Culture Documents

Concrete Coring (Eng)

Uploaded by

crescentmooonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Coring (Eng)

Uploaded by

crescentmooonCopyright:

Available Formats

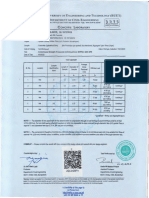

CONCRETE CORE TESTING

Cylinder Core Sampling & Compression Testing

Introduction Condition of concrete in the structure after construction can be assessed directly by core drilling at required location or at suspected location. The core samples obtained are then taken for visual inspection and compression test to determine maximum compressive strength. Test Method Standard The core drilling and compression testing shall be done in accordance with ASTM Method C 4287. Equipments and Apparatus 1. Core drilling machine, rotary drilling type 2. Diamond coring bit, single-tube core barrel type 3. Compression machine, ELE Compact 1500 1.2 Install single-tube core barrel to the drilling machine in 1.1. Select the proper size of core diameter. In general, core diameter should be greater than diameter of coarse aggregate and not below 2 inches. However, outside diameter of core barrel should allow penetration without cutting the reinforcing steel. 1.3 Drill to take core samples at approximately 0.50 m to 1.00 m interval until reaching the required depth. 2. Core Sample Preparation 2.1 Cut the drilled core for compression test using the cutting disc. The lengthto-diameter ratio (L:D Ratio) of the cut sample should be 2:1. 2.2 Measure diameter, length, and determine the weight of samples. 2.3 Cap both ends of sample with capping compound. 3. Compression Test Place the core sample in the compression machine and carry out the compression test in accordance with ASTM Method C 42-87 until reaching ultimate point. Record the maximum load and inspect the failure mode of sample.

Fig.1 Rotary drilling machine for diamond core drill Sampling and Testing Procedures 1. Core Sampling At least 3 core samples should be obtained according to the following procedure 1.1 Install rotary drilling machine at the required location

Version 1.0 Copyright 2004 by STS

Fig. 2 Compression machine

Concrete Core Testing

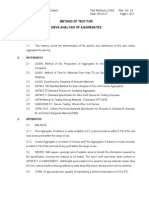

4. Correction of Test Result Compressive strength obtained from core sample has to be corrected before it can be used due to the size of sample is smaller than standard cylinder (6dia.x12). The test result may also subject to correction in case the length-to-diameter ratio is not 2:1. The correction can be done using graphs in Fig.3 and Fig. 4 accordingly. 5. Backfilling the Drilled Hole After drilling is completed and good core samples are obtained, drilled hole should be grouted using non-shrink cement.

CORRECTION CHART FOR EFFECT OF CYLINDER S IZE ON COM PRESS IV E S TRENGTH OF CONCRETE

110

105 STRENGTH IN PERCENT OF 6 - BY 12 - INCH CY LINDERS 100

.

PERCENT

95

90

85

80

75 0 4 8 12 16 20 24 28 32 36 40

DIAM ETER OF CYLINDER, INCHES REFERENCE : CONCRETE MA NUA L NOT E : HEIGHT OF CY LINDER 2.0 DIA METERS MA XIMUM SIZE OF A GGREGA TE 1/4 DIA METER OR LESS

Fig. 3 Graph to correct compressive strength to standard sample 6 x 12

CORRECTION CHART FOR EFFECT OF L/D RATIO ON COM P RES S IV E S TRENGTH OF CONCRETE

200 PERCENT OF STRENGT H OF CYL INDER WITH L /D = 2.0

180

A V ERA GE FROM TESTS BY G.W.HUTCHINSON A ND OTHERS, REPORTED IN BULLELIN 16, LEWIS INSTITUTE, CHICA GOA GE OF SPECIMENS, 28 DA Y S

160

140

120

100

80 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

L/D, RATIO OF LENGT H OF CYL INDER TO DIAM ETER

REFERENCE : CONCRETE MA NUA L

Fig. 4 Graph to normalize L:D ratio

Criteria For Test Result Determination Determination of test result should conform with ACI Standard guidelines as follow. Compressive strength of each core sample should exceed 75 percent of required ultimate strength and the average of three samples should exceed 85 percent.

Version 1.0 Copyright 2004 by STS

For more information, please contact: STS Engineering Consultants Co., Ltd. Quality Assurance Division 196/10-12 Soi Pradipat 14, Pradipat Road, Samsennai, Phayathai, Bangkok 10400 Tel. : 0-2618-4288 (10 lines) ext. 265 Fax : 0-2279-8507, 0-2618-6373 http://www.sts.co.th

You might also like

- Core Tests:: Easy To Perform, Not Easy To InterpretDocument10 pagesCore Tests:: Easy To Perform, Not Easy To InterpretEngr Shofiul AlamNo ratings yet

- Trial MixDocument4 pagesTrial MixShesha Shayan0% (1)

- Schmidt Hammer TestDocument7 pagesSchmidt Hammer TestJas DhillonNo ratings yet

- Rebound Hammer-RH (Schmidt) TestDocument2 pagesRebound Hammer-RH (Schmidt) TestmandregomesNo ratings yet

- Evaluation of Modulus of Elasticity and Modulus of Subgrade Reaction of Soils Using CBR TestDocument7 pagesEvaluation of Modulus of Elasticity and Modulus of Subgrade Reaction of Soils Using CBR TestMyzael ValdiviaNo ratings yet

- Load Testing SetupDocument23 pagesLoad Testing SetupWalid TahhanNo ratings yet

- Point Load Test 2Document12 pagesPoint Load Test 2Rajitha ShehanNo ratings yet

- Modulus of Subgrade ReactionDocument4 pagesModulus of Subgrade ReactionDennis SagaoNo ratings yet

- CBR Test Procedure Determination of California Bearing Ratio For Road Design PDFDocument5 pagesCBR Test Procedure Determination of California Bearing Ratio For Road Design PDFMohamed AdelNo ratings yet

- Pre-Excavation GroutingDocument7 pagesPre-Excavation GroutingDavid marpaungNo ratings yet

- C 0) C' and ' C' and ' C' ' C C' Effective Undrained Cohesion C' Undrained Angle of Friction ' Effective Undrained Angle of Friction 'Document6 pagesC 0) C' and ' C' and ' C' ' C C' Effective Undrained Cohesion C' Undrained Angle of Friction ' Effective Undrained Angle of Friction 'Dr Wong Kim YuenNo ratings yet

- Ultra-High Capacity Micropiles, Drilled Displacement Steel Piles & Expanded Base PilesDocument1 pageUltra-High Capacity Micropiles, Drilled Displacement Steel Piles & Expanded Base PilesAnonymous JZFSB3D0% (1)

- Direct Shear TestDocument2 pagesDirect Shear TestUtkarsh KumarNo ratings yet

- Hiley Formula - Bruce Piling Hammer Pile HammerDocument1 pageHiley Formula - Bruce Piling Hammer Pile HammertanujaayerNo ratings yet

- Geotechnical Checklist-Geocon - Runwal PinncleDocument5 pagesGeotechnical Checklist-Geocon - Runwal PinncleKOMAL JOSHINo ratings yet

- 2 Soil Test Result at ParoleumDocument10 pages2 Soil Test Result at ParoleumWinNo ratings yet

- Plate Load Test SpecificationDocument4 pagesPlate Load Test Specificationgowtham87No ratings yet

- Splash Works Water Parks Core Test Report PDFDocument1 pageSplash Works Water Parks Core Test Report PDFJahid HasanNo ratings yet

- SOP - Standard Penetration TestDocument5 pagesSOP - Standard Penetration TestGajendra PandeyNo ratings yet

- Sieve Analysis ProcedureDocument0 pagesSieve Analysis ProcedureAbdul Raheem U LNo ratings yet

- Particle Size DistributionDocument106 pagesParticle Size DistributionRajeshkumar ElangoNo ratings yet

- Schmidt Hammer AbbeyDocument4 pagesSchmidt Hammer AbbeyStephen OgaloNo ratings yet

- Method Statement Concrete Coring (ASTM C 142)Document2 pagesMethod Statement Concrete Coring (ASTM C 142)Twin Bulls100% (1)

- PDA CheckDocument2 pagesPDA ChecksinambeladavidNo ratings yet

- Jisg 3112.2010Document2 pagesJisg 3112.2010Mani MaNo ratings yet

- Concrete Quality Non-Destructive TestsDocument5 pagesConcrete Quality Non-Destructive TestsNadhirah LnfNo ratings yet

- Standard Test Method For Measurement of Collapse Potential of Soils - ASTM D 5333-92Document3 pagesStandard Test Method For Measurement of Collapse Potential of Soils - ASTM D 5333-92Gusti PaganiniNo ratings yet

- Proctor TestDocument3 pagesProctor TestAzrizal EzlianaNo ratings yet

- Safe Bearing Capacity of Soil at SiteDocument3 pagesSafe Bearing Capacity of Soil at SiteTravel With EvonNo ratings yet

- Hydraulic Injection Piles-KL - 2Document6 pagesHydraulic Injection Piles-KL - 2Ferdi AparatNo ratings yet

- ACI Job MixDocument31 pagesACI Job MixIrfan KhanNo ratings yet

- Density and Unit Weight ReportDocument71 pagesDensity and Unit Weight ReportGayan Indunil JayasundaraNo ratings yet

- Method Statement For Grout ColumnDocument1 pageMethod Statement For Grout ColumnAlsonChin100% (1)

- Span DeflectionDocument12 pagesSpan Deflectionnirmala_siva_1100% (1)

- CBR TestDocument4 pagesCBR TestAtish Kumar100% (1)

- Specification For Jack in PileDocument4 pagesSpecification For Jack in Pilekhuanoz100% (1)

- DCP Test Report ExampleDocument4 pagesDCP Test Report Exampledwi istNo ratings yet

- C 1005 - 00 QzewmduDocument3 pagesC 1005 - 00 QzewmduGarcia ManuelNo ratings yet

- Windsor Probe and Quantab TestDocument28 pagesWindsor Probe and Quantab Testsabareesan09No ratings yet

- CBR (California Bearing Ratio) Test: 1. ObjectiveDocument7 pagesCBR (California Bearing Ratio) Test: 1. Objectivesdfsdf100% (1)

- Chapter 1 Site InvestigationDocument42 pagesChapter 1 Site InvestigationAjimu SulaimanNo ratings yet

- How to calculate Fineness Modulus (FM) of aggregateDocument3 pagesHow to calculate Fineness Modulus (FM) of aggregateTahmidur RahmanNo ratings yet

- CE-452 CBR TestDocument15 pagesCE-452 CBR TestNandon RoyNo ratings yet

- Mechanical and Physical Properties of Aggregates Aggregate Crushing Value (Acv)Document10 pagesMechanical and Physical Properties of Aggregates Aggregate Crushing Value (Acv)Kamukwema johnNo ratings yet

- MDD-OMC-compactionDocument7 pagesMDD-OMC-compactionCobbinah MarkNo ratings yet

- 6.rock Testing (DR - Tejas Thaker)Document24 pages6.rock Testing (DR - Tejas Thaker)Rakesh7770No ratings yet

- Job-2 Relative DensityDocument5 pagesJob-2 Relative DensityUmair JuttNo ratings yet

- High Impact Energy Dynamic Compaction applications for ground improvement and earthworksDocument10 pagesHigh Impact Energy Dynamic Compaction applications for ground improvement and earthworkssezaitanyoluNo ratings yet

- CracksDocument10 pagesCracksSyed Mohd MehdiNo ratings yet

- Pile Testing For Driven or Jack-In Pile PDFDocument25 pagesPile Testing For Driven or Jack-In Pile PDFBMZNo ratings yet

- Design MixDocument7 pagesDesign MixMohammad Hafiz MahadzirNo ratings yet

- 2 Ss Unconfined Compression TestDocument10 pages2 Ss Unconfined Compression TestIqi IqahNo ratings yet

- ACI Mix DesignDocument9 pagesACI Mix DesignManuelNo ratings yet

- CORE TESTING FOR CONCRETE STRENGTHDocument13 pagesCORE TESTING FOR CONCRETE STRENGTHvempadareddyNo ratings yet

- Testing Concrete CoresDocument7 pagesTesting Concrete CoresvigneshwarimahamuniNo ratings yet

- ASTM D 1634-00 Standard Test Method For Compressive Strength of Soil-Cement Using Portions of Beams Broken in Flexure (Modified Cube Method)Document3 pagesASTM D 1634-00 Standard Test Method For Compressive Strength of Soil-Cement Using Portions of Beams Broken in Flexure (Modified Cube Method)Pablo Antonio Valcárcel VargasNo ratings yet

- Tensile Stress-Strain of Carbon and Graphite: Standard Test Method ForDocument12 pagesTensile Stress-Strain of Carbon and Graphite: Standard Test Method Forsj19330No ratings yet

- Determine compressive strength of concrete with rebound hammer testDocument6 pagesDetermine compressive strength of concrete with rebound hammer testDira AzmanNo ratings yet

- Split Tensile Strength of ConcreteDocument9 pagesSplit Tensile Strength of Concreteabhineet srivastavaNo ratings yet

- Medical Gas Piping Design-Part1Document4 pagesMedical Gas Piping Design-Part1Gage Floyd Bitayo100% (2)

- Tutorial ETABSDocument60 pagesTutorial ETABSValentin VrabieNo ratings yet

- Design of 6 Storey Building in EtabsDocument51 pagesDesign of 6 Storey Building in EtabsMisqal A Iqbal100% (2)

- Material Engineer Exam Flow Chart DPWHDocument1 pageMaterial Engineer Exam Flow Chart DPWHKiyoshi Jin100% (7)

- WWW ManilastandardtodayDocument2 pagesWWW ManilastandardtodaycrescentmooonNo ratings yet

- Computer Engineering Undergraduate HandbookDocument17 pagesComputer Engineering Undergraduate HandbookImranNo ratings yet

- Mutual Fund Operations at Axis Bank: A Study on Investor BehaviourDocument1 pageMutual Fund Operations at Axis Bank: A Study on Investor BehaviourNakul SehgalNo ratings yet

- DPWH Standard Specification for RailingsDocument7 pagesDPWH Standard Specification for Railingsalterego1225No ratings yet

- Technical DraftingDocument22 pagesTechnical DraftingDylan Brhyce Esparagoza100% (1)

- Automation System PSS 4000 - Modules With Approval For The Railway SectorDocument4 pagesAutomation System PSS 4000 - Modules With Approval For The Railway SectorRadu George CristianNo ratings yet

- 5031Document3 pages5031Kat HansenNo ratings yet

- A New Approach to ValidationDocument60 pagesA New Approach to ValidationBhagesh Kumar100% (1)

- ANG BulletinDocument4 pagesANG BulletinRoron WicaksonoNo ratings yet

- Pure Water SumpDocument8 pagesPure Water SumpVarad Sonawadekar100% (1)

- The Renishaw QC20-W Wireless Ballbar For Machine Tool Performance DiagnosisDocument8 pagesThe Renishaw QC20-W Wireless Ballbar For Machine Tool Performance DiagnosisXuan Phuong HuynhNo ratings yet

- Waterproofing101 GMXDocument27 pagesWaterproofing101 GMXJatinder BhatiaNo ratings yet

- IEEE-14764 - Software MaintenanceDocument24 pagesIEEE-14764 - Software MaintenanceSuharman DjajaNo ratings yet

- Meghnad Saha Institute of Technology Central Library New Arrival Book List: September, 2018 - September, 2019Document9 pagesMeghnad Saha Institute of Technology Central Library New Arrival Book List: September, 2018 - September, 2019ChandrilNo ratings yet

- Stockist of Alloy Steel A234 Gr. Wp11 Buttweld Pipe FittingsDocument3 pagesStockist of Alloy Steel A234 Gr. Wp11 Buttweld Pipe FittingsspipingNo ratings yet

- 6 Huma1013 Introduction To The HumanitiesDocument4 pages6 Huma1013 Introduction To The Humanitiesnoli90No ratings yet

- B.Tech Power System Operation and Control Exam QuestionsDocument8 pagesB.Tech Power System Operation and Control Exam QuestionsMedha AravindNo ratings yet

- Balakannan ResumeDocument6 pagesBalakannan Resumesibu_me04085600No ratings yet

- BS en 00040-1-1992 (2006) PDFDocument14 pagesBS en 00040-1-1992 (2006) PDFShan Sandaruwan AbeywardeneNo ratings yet

- Bridge Design To Eurocodes - UK ImplementationDocument11 pagesBridge Design To Eurocodes - UK ImplementationMarekNo ratings yet

- QCF 42 CladdingDocument7 pagesQCF 42 CladdingAnneBricklayerNo ratings yet

- Civil Engg Drawing Pract 1 & 2 Materials & FixturesDocument2 pagesCivil Engg Drawing Pract 1 & 2 Materials & Fixturesmind_mac24302867% (6)

- Protastructure 2018 BrochureDocument8 pagesProtastructure 2018 BrochureIfiokobong AkpanNo ratings yet

- Series V Cooling Towers SpecificationsDocument6 pagesSeries V Cooling Towers SpecificationsGeelissonNo ratings yet

- Effectiveness of The Project Delivery Methods in Construction Management. Lagos State, NigeriaDocument6 pagesEffectiveness of The Project Delivery Methods in Construction Management. Lagos State, NigeriaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Cost estimate for construction of RCC footing and wall shutteringDocument2 pagesCost estimate for construction of RCC footing and wall shutteringAtulJainNo ratings yet

- Community BuildingDocument75 pagesCommunity BuildingMaj M NazzNo ratings yet

- Aecom Brochure PDFDocument23 pagesAecom Brochure PDFAlexandru GateiuNo ratings yet

- CHED Sample OBE Syllabus AT 1 AUTOMOTIVE ENGINEERING SYSTEMDocument6 pagesCHED Sample OBE Syllabus AT 1 AUTOMOTIVE ENGINEERING SYSTEMMarvin Sarmiento TalimonganNo ratings yet

- NDT Report PDFDocument5 pagesNDT Report PDFUmesh Mishra100% (1)

- Henry Berger ResumeDocument1 pageHenry Berger Resumeapi-581806915No ratings yet