Professional Documents

Culture Documents

CG 3303C MK

Uploaded by

Aminudin ZakariaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CG 3303C MK

Uploaded by

Aminudin ZakariaCopyright:

Available Formats

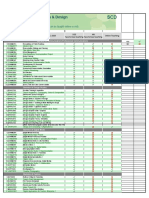

U. S. DEPARTMENT OF HOMELAND SECURITY U.S. COAST GUARD CG-3303C-MK (Rev.

03-2009)

RECORD OF PERFORMANCE QUALIFICATIONS MACHINERY TECHNICIAN (MK)

INSTRUCTIONS

Record of Enlisted Performance Qualifications (EPQ) shall be completed in accordance with the Personnel Manual, COMDTINST M1000.6 (series). Personnel are required to demonstrate proficiency in all performance qualifications for the next higher pay grade to be eligible for advancement. The DATE and INITIALS column shall be completed by a designated supervisor (E-5 or above) at least one pay grade higher than the trainee and of the same occupational specialty whenever possible. Form CG-3303C becomes official documentation to be kept in the members Personnel Data Record (PDR) denoting eligibility for administration of the rating End of Course Test (EOCT) and, if applicable, participation in a Service Wide Exam competition (SWE). Although demonstration and sign-off of any new EPQ at or below the members current pay grade is not required, the EPQ will be used to develop SWE questions. It is the members responsibility to be proficient in all currently published performance qualifications, up to and including those of their present pay grade for their specific rating to facilitate learning of junior personnel. Performance Qualifications numbering system: Example 5.A.01 The number 5 indicates an E-5 level qualification requirement. The letter A indicates the subject section within the qualification requirements. The sequence number 01 indicates the 1st qualification within the subject section. Rating courses are developed using reference material denoting official policy and/or technical standards. Most reference materials are available online through the Coast Guard Directives System at http://www.uscg.mil/directives/. Other reference material may be obtained from the units library, TRACEN course writers, CG Institute, or other government sources. A reference material list is located at the end of this document. If any reference material is found to be in contradiction the cited Coast Guard reference shall take precedence. The Rating Force Master Chief of this occupational specialty is the primary proprietor of these EPQ. The most up to date EPQ revisions are available digitally on the CG Learning Portal at http://learning.uscg.mil. EPQ paper copies are also available from the units Education Services Officer (ESO) or Career Development Advisor (CDA). NOTE: Performance of MK tasks should be dated and initialed by a MK one pay grade or higher in an actual work setting. Signatures from individuals outside of the MK rating are strongly discouraged.

Appendices A. MK Guiding Principles B. Terminology C. Reference List

RATING

ABBREVIATION

MACHINERY TECHNICIAN (Effective beginning with the October 2010 Reserve and November 2010 Active Duty SWE.)

DATE COMPLETED ALL PERFORMANCE QUALIFICATIONS FOR RATE LEVEL

MK

E-4

E-5

E-6

E-7

NAME (Last, First, Middle Initial)

E-8

E-9

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 1 of 30

CG-3303C-MK

(Rev. 03-2009)

SIGNATURE OF SUPERVISOR

DATE NAME/SIGNATURE INITIALS RATE UNIT

REMARKS

Date: ____________ I certify that the person named below has satisfactorily completed all rate related course work and Enlisted Performance Qualifications (EPQ) for pay grade E-_____ and is eligible to take the end of course test (EOCT).

________________________ Shop Chief / Division Officer (Printed Name & Signature)

NAME (Last, First, Middle Initial) EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 2 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

A.

ADMINISTRATION

4.A.01 RETRIEVE the following information from a CG computer-based logistics system IAW Configuration Management Plus (CMPlus) or equivalent application user manual and Federal Logistics System (FedLog). Engineering Parts Inventory Engineering Preventive Maintenance Schedule (PMS) Data Machinery History

SupGuide: The member will demonstrate the ability to navigate the databases, enter data, view and print data. 4.A.02 PERFORM a complete Tag-Out procedure IAW Equipment Tag-Out Procedure, COMDTINST 9077.1 (series), using Engineer Officer (EO)/Engineering Petty Officer (EPO) and Engineering Department Standing Orders to identify components required to tag-out the system. 5.A.01 DEVELOP engineering department Preventive Maintenance Schedules (PMS) IAW Naval Engineering Manual, COMDTINST 9000.6 (series), chapter 081, CMPlus user manual or equivalent CG computer-based logistics application, and Manufacturer's technical manual. SupGuide: The member will initialize, develop and/or prepare amendments to PMS. The member will develop PMS requirements for non-standard local equipment and make PMS entries in CMPlus database or equivalent CG computer-based logistics application. 6.A.01 REVIEW unit engineering technical drawing library IAW Directives, Publications and Reports Index (DPRI), COMDTNOTE 5600 and Naval Engineering Manual, COMDTINST M9000.6 (series), chapter 085 and Naval Engineering Technical Information Management System (NETIMS). SupGuide: The member will ensure unit has the appropriate publications by comparing equipment inventory to publications/drawing inventory. Member should be able to enter updates and changes when required.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 3 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

6.A.02 COMPLETE the following reports/documents IAW Naval Engineering Manual, COMDTINST M9000.6 (series), chapters 090, and Forms for Cutters including Vessel Availability Coast Guard Inspector Daily Inspection Report:

http://cgweb.lant.uscg.mil/vdiv/Availabilities/Availability%20Forms/Cutters/

Boat Inspection Report (Form CG-3022) Drydocking and Underwater Body Inspection Worksheet (Form CG2926) Vessel Availability Coast Guard Inspector Daily Inspection Report Cutter Ships Maintenance Project (CSMP Form CG-2920) Shore Station Maintenance Record (SSMR Form CG-4094) Engineering Change Request (ECR Form CG-5682)

6.A.03 PREPARE entries for the following engineering department files IAW Naval Engineering Manual, COMDTINST M9000.6 (series), chapters 090 and CMPLUS User Manual or equivalent CG computer-based logistics application. Engineering Work Requests Machinery History Boat Record (Form CG-2580)

SupGuide: The engineering work requests includes work orders, PMS, and corrective/casualty maintenance actions submitted to NESUs, Maintenance Augmentation Teams (MAT), and contractors for all bi-level maintenance (i.e., O and D maintenance). 6.A.04 PREPARE the following casualty report messages IAW Casualty Reporting (CASREP) Procedures (Materiel), COMDTINST M3501.3 (series), Operational Reports, NWP 1-03-1 (series), MLC Standard Operating Procedures (SOP), and CMPlus User Manual or equivalent CG computer-based logistics application. Initial Update Correction Cancellation

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 4 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

6.A.05 COMPARE Shore Station Maintenance Record (SSMR) with the associated Scope of Work IAW Naval Engineering Manual, COMDTINST M9000.6 (series) and Civil Engineering Manual, COMDTINST M11000.11 (series). SupGuide: The member will review Specifications for any technical shortcomings. Review will include matching SSMR to the statement of work and ensuring that the entire scope of the project is addressed. If changes are needed, member will submit change recommendations to the appropriate authority. 6.A.06 AUDIT the Unit Engineering Tag-Out Log IAW Equipment Tag-Out Procedure, COMDTINST 9077.1 (series). 6.A.07 CONDUCT a basic engineering casualty control exercise (BECCE) IAW Naval Engineering Manual, COMDTINST M9000.6 (series), chapter 079, Naval Ships Technical Manual (NSTM) chapter 079, Volume 3, Damage Control Engineering Casualty Control, U.S. Coast Guard Boat Operations and Training (BOAT) Manual, Volume II, COMDTINST M16114.33 (series), and Cutter Training and Qualification Manual, COMDTINST 3502.4 (series). SupGuide: The member will coordinate the drill event on either a CG Cutter or CG Standard Boat to include: planning, preparing the drill card, conducting the drill, evaluating the drill, conducting both the pre/post briefing of the watch section. 7.A.01 COMPLETE a Cutter Engineering Report (Form CG-4874) IAW Naval Engineering Manual, COMDTINST M9000.6 (series), Chapter 090. 7.A.02 REVIEW the following engineering logs IAW Naval Engineering Manual, COMDTINST M9000.6 (series). Machinery Log (Form CG-2616G) Zinc Log Flexible Joint Log Flexible Hose Log

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 5 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

7.A.03 SUPERVISE the administration of the following programs IAW Naval Engineering Manual, COMDTINST M9000.6 (series), NSTM Chapter 533 Potable Water Systems, and Water Supply and Waste Disposal Manual, COMDTINST M6240.5 (series), and CMPlus User Manual or equivalent CG computer-based logistics application. Lube Oil Analysis Program Diesel Engine Condition Monitoring Program Potable Water Management Program Jacket Water Treatment Program Preventive Maintenance Program

7.A.04 REVIEW a dockside/drydock maintenance availability specifications for any technical shortcomings IAW Maintenance and Logistics Command Atlantic (MLCA) Standard Operating Procedure (SOP)/Maintenance and Logistics Command Pacific (MLCP) instruction/MLC standard specifications, Naval Engineering Manual, COMDTINST M9000.6 (series), Current Ships Maintenance Project (CSMP) and Engineering Change Request (ECR) file. SupGuide: The member will review specifications for any technical shortcomings and cutter/boat class maintenance plans. Review will include matching CSMPs to the statement of work and ensuring all interferences are identified within the specifications. If changes are needed, member will submit change recommendations to the appropriate authority. Member will verify specs by utilizing the CSMP/ECR file and MLC standard specifications.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 6 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

B.

ELECTRICAL AND ELECTRONIC

4.B.01 INSTALL starter/storage batteries IAW NSTM, chapter 313, Portable Storage and Dry Batteries and Manufacturer's Instructions. SupGuide: The member will demonstrate the ability to connect batteries in series and parallel. Member will understand what happens to amperage/voltage when batteries are connected in either parallel or series operation. 4.B.02 MAINTAIN starter/storage batteries IAW NSTM, chapter 313, Portable Storage and Dry Batteries and Manufacturer's Instructions. SupGuide: Member will place battery on a charger and understand the differences between initial, boost, normal and floating charge. Member will load test battery. Member will wear all required safety equipment.

4.B.03 TROUBLESHOOT common faults such as opens and grounds (i.e., buses, fuses, breakers) in the following alternating current electrical circuits IAW the Manufacturer's Technical Manuals, NSTM Chapter 491, and Appendix III, Schematic Symbols of the Navy Electricity and Electronics Training Series Module 3Introduction to Circuit Protection, Control, and Measurement NAVEDTRA 14175. Hotstart Motors

SupGuide: The member will demonstrate proper usage of the following tools; multi meter, ammeter and megger. The member will understand basic electrical theory as it applies to alternating current (AC) circuits. The member will have a basic understanding of electrical wiring diagrams. The member will conduct basic system checks to include 110 volts circuits and understand how to safely isolate electronics in order to prevent damage to those components.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 7 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

4.B.04 TROUBLESHOOT common faults such as opens and grounds (i.e., buses, fuses, breakers) in one of the following direct current electrical circuits IAW the Manufacturer's Technical Manuals and NSTM Chapter 491, Appendix III, Schematic Symbols of the Navy Electricity and Electronics Training Series Module 3Introduction to Circuit Protection, Control, and Measurement NAVEDTRA 14175. Starting Circuits Charging Circuits Lighting Circuits Engine Alarm Circuits Steering Circuits

SupGuide: The member will demonstrate proper usage of the following tools; multi meter, ammeter and megger. The member will understand basic electrical theory as it applies to direct current (DC) circuits. The member will have a basic understanding of electrical wiring diagrams. The member will conduct basic system checks and understand how to safely isolate electronics in order to prevent damage to those components. 4.B.05 RENEW electric wire and connectors as part of a maintenance or repair procedure IAW American Wire Gage (AWG) standards, NSTM Chapter 320, Electric Power Distribution Systems, and Manufacturer's Technical Manuals. SupGuide: The member will know how to select the proper replacement wire and connectors for electrical systems. Member will demonstrate selecting the proper wire then strip and install common compression connectors.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 8 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

5.B.01 TROUBLESHOOT an electronic circuit to the card level IAW NSTM Chapter 300, Electric Plant- General, NSTM Chapter 330, Lighting, NSTM Chapter 400, Electronics, NSTM Chapter 491, Appendix III, Schematic Symbols of the Navy Electricity and Electronics Training Series Module 3Introduction to Circuit Protection, Control, and Measurement NAVEDTRA 14175, Manufacturer's Technical Manuals. SupGuide: Member will troubleshoot an electronic circuit such as a starting, engine alarm, or steering circuit. The member will understand safety precautions associated with electronics. Member will use electronic wiring diagrams and identify components within the diagram for one of the above circuits. Member will use a multi meter or appropriate diagnostic tool to isolate a fault to the card level. Member will remove/renew faulty card. 5.B.02 TROUBLESHOOT switches IAW NSTM Chapter 300, Electric PlantGeneral, NSTM Chapter 302, Electric Motors & Controllers, NSTM Chapter 330, Lighting, NSTM Chapter 400, Electronics, NSTM Chapter 491, Electrical Measuring and Test Instruments, NSTM Chapter 504, Pressure Temperature and Electromechanical Measuring, Naval , Appendix III, Schematic Symbols of the Navy Electricity and Electronics Training Series Module 3Introduction to Circuit Protection, Control, and Measurement NAVEDTRA 14175, and Manufacturer's Technical Manuals. SupGuide: The member will renew, test, and adjust switches such as flow, pressure, temperature. The member will select the proper replacement components by comparing nameplate data. The member will then install the component using the proper connectors then place system back into operation. Member will demonstrate applicable safety precautions.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 9 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

6.B.01 TROUBLESHOOT an electronic system IAW NSTM Chapter 320, Electric Power Distribution Systems, NSTM Chapter 491, Electrical Measuring and Test Instruments, Appendix III, Schematic Symbols of the Navy Electricity and Electronics Training Series Module 3 Introduction to Circuit Protection, Control, and Measurement NAVEDTRA 14175, and Manufacturer's Technical Manuals. SupGuide: Member will troubleshoot an electronic system such as Monitoring Control Systems (MCS), Remote Control Systems (RCS), Controller Area Network (CAN) communication circuits, Peripheral Interface Modules (PIM), starting, charging, programmable logic controllers (PLC), or engine alarm. The member will understand safety precautions associated with electronics. Member will use electronic wiring diagrams and identify components within the diagram for one of the above systems. Member will use a multi meter or appropriate diagnostic tool to troubleshoot the system.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 10 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

C.

PUMPS AND VALVES

4.C.01 MAINTAIN the following valves found in common Coast Guard systems (e.g., Firemain, Raw Water, Potable Water, Chill Water, Fuel Oil, Sewage and Hydraulic oil) IAW NSTM Chapter 505, Piping Systems, Manufacturer's Technical Manuals, and MLC Standard Specifications. Check Pressure regulating/relief Ball Butterfly Gate Globe Needle Petcock Temperature control Duplex strainer (plug) Solenoid

SupGuide: The member will understand the functional characteristics and perform basic maintenance associated with each type of valve to include lubrication, cycling, visual inspection, testing and understand how to perform lapping procedures. Member will identify safety procedures with removing/installing valves. Demonstrate use and nomenclature of common tools. 4.C.02 OVERHAUL centrifugal pumps IAW NSTM Chapter 503, Pumps, NSTM Chapter 505, Piping Systems and Manufacturer's Technical Manuals. SupGuide: The member will understand centrifugal pump theory. Member will know all safety precautions associated with performing maintenance. Member will disassemble, inspect, and reassemble to include replacing/renewing seals, bearings, impellers, and place back in service.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 11 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

4.C.03 ALIGN a Pump Shaft IAW NSTM, Chapter 503, Pumps, Preventive Maintenance Schedule Manual (PMS), and Manufacturer's Technical Manuals. SupGuide: The member will understand the importance of proper pump shaft alignment. Member will understand the different techniques used to align common pump couplings. The member will demonstrate the proper usage of applicable tools such as: dial indicator, machinist rule, thickness gauges and optical alignment tools.

D.

TUBING, PIPING AND HOSES

4.D.01 RENEW copper/stainless steel tubing using the following techniques IAW NSTM Chapter 505, Piping Systems. Silver Soldering/brazing Soft Soldering Flare fittings Compression fittings SupGuide: The member will understand how to select the proper materials and assembly technique for application. Member will safely operate the oxy/acetylene torch, cut, size, bend, flare tubing and solder tubing. Demonstrate use and nomenclature of common tools. 4.D.02 RENEW a flexible hose as part of a maintenance or repair procedure IAW Naval Engineering Manual, COMDTINST M9000.6.(series), chapter 505, NSTM Chapters 505, Piping Systems, NSTM Chapter 556, Hydraulic Equipment, and Manufacturer's Technical Manuals. SupGuide: The member will select proper tools and replacement materials to include; flexible hose, reusable fittings, gaskets, and thread sealers prior to conducting the job. Member will understand how to size, assemble, install, and test flexible hose. 4.D.03 INSTALL spray/flange shielding to a piping system using proper tools and materials IAW Naval Engineering Manual, COMDTINST M9000.6 (series) Chapter 077, NSTM Chapter 505, Piping Systems, and NSTM 635, Thermal Fire, and Acoustic Insulation. SupGuide: The member will demonstrate proper installation techniques and demonstrate the proper usage of lockwire pliers.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 12 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

4.D.04 INSTALL piping systems as part of a maintenance or repair procedure IAW NSTM Chapter 505, Piping Systems and Manufacturer's Technical Manuals. SupGuide: The member will demonstrate the proper usage of the following tools when performing this qualification: bench grinder, drill press, taps dies, thread files. Member will select replacement materials to include; PVC, copper/nickel, and steel piping, fittings, gaskets, glue, primer and thread sealers prior to conducting the job. Member will cut, size, and thread piping. Identify sizes of pipe and threads, U.S. and metric.

E.

AUXILIARY EQUIPMENT

4.E.01 PERFORM maintenance on air compressors as part of a pneumatic system IAW NSTM, Chapter 551, Compressed Air Plants and Systems, and Manufacturer's Technical Manuals. SupGuide: The member will understand the basic safety and principles of operation of either a start air compressor; ships service air compressor or a fixed shop air compressor. Member will adjust drive belt tension, clean cooling fins, replace air filters add and change oil. Demonstrate use and nomenclature of common tools. 4.E.02 MAINTAIN strainers and filters in the following systems IAW NSTM Chapter 262, Lubricating Oils, Greases, Specialty Lubricants, and Lubrication Systems, NSTM Chapter 505, Piping Systems, NSTM Chapter 541, Ship Fuel and Fuel System, NSTM Chapter 542, Gasoline and JP-5 Fuel Systems, NSTM Chapter 551, Compressed Air Plants and Systems, Unit PMS Procedures, and Manufacturer's Technical Manuals. Raw Water (Sea or Fresh Water) Air (LP/MP) Fuel Oil

SupGuide: The member will understand the functional characteristics of simplex and duplex strainers. Member must know associated safety precautions. Member will know how to clean/replace strainers/filters in R/W, LP/MP ships service, shore service, control, and start air, Fuel and Oil systems.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 13 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

4.E.03 RENEW the following gauges as part of a maintenance or repair procedure IAW NSTM Chapter 504, Pressure, Temperature and other Mechanical and Electromechanical Measuring Instruments, and Manufacturer's Technical Manuals. Temperature Duplex Compound Manometer Vacuum

SupGuide: The member will select the appropriate gauge and identify the operating characteristics of the above gauges. 5.E.01 TROUBLESHOOT common casualties in a Pneumatic system IAW NSTM Chapter 551, Compressed Air Plants and Systems, and Manufacturer's Technical Manuals SupGuide: The member must understand major components of a ships service, control air, start air, or shop fixed air system. Member will systematically troubleshoot a non-functioning system to determine what component or components have failed, to include; pressure regulating, pressure relief valves, air water separators, and isolation valves. Member will renew defective components, and/or adjust components to restore the system to proper operation. 6.E.01 OVERHAUL one of the following types of heat exchangers found in MDEs, SSDGs, AC&R, ASW, and MGTs IAW Unit PMS Procedures, NSTM Chapter 254, Condensers, Heat Exchangers and Air Ejectors, and Manufacturer's Technical Manuals. Tube & Shell Fin & Tube Plate Type

SupGuide: The member will clean and overhaul a heat exchanger from one of the above systems.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 14 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

F.

OILY WATER SEPARATORS

5.F.01 MAINTAIN an oily water separator IAW the Manufacturer's Technical Manuals, Unit PMS Procedures and NSTM Chapter 593, Pollution Control. SupGuide: The member will understand the principals of operation. Member will align system, adjust the Oil Content Monitor (OCM), monitor PPM, inspect and replace coalescing elements and maintain safety devices. 6.F.01 TROUBLESHOOT an oily water separator IAW Manufacturers Technical Manuals and NSTM Chapter 593, Pollution Control. SupGuide: The member will systematically troubleshoot an inoperative OWS, identify faults such as loss of power, loss of pump suction, and system stuck in a constant re-circulation cycle. Member will take corrective actions to bring system up to full operation.

G.

LUBE OIL AND FUEL OIL SYSTEMS

4.G.01 COMPARE the Lube Oil Viscosity of oil from an engine with the viscosity of new oil using a viscosity gage (VISGAGE) or falling ball comparator IAW Naval Engineer Manual, COMDTINST M9000.6 (series), NSTM Chapter 233 Diesel Engines, NSTM Chapter 262, Lubricating Oils, Greases, Specialty Lubricants and Lubrication Systems, and Manufacturer's Technical Manuals. SupGuide: The member will understand the safety precautions associated with drawing lube oil samples from running equipment. Member will understand the causes and effects of viscosity changes. Member will know what operating hour intervals to pull oil samples. Demonstrate use and nomenclature of common tools. 4.G.02 PREPARE Lube Oil Sample for Spectro analysis IAW Naval Engineering Manual, COMDTINST M9000.6 (series) and NSTM Chapter 262, Lubricating Oils, Greases, Specialty Lubricants and Lubrication Systems. SupGuide: The member will follow all safety precautions. Member will draw sample, label, package and mail lube oil samples to the testing facility.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 15 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

4.G.03 PERFORM a clear and bright fuel oil test prior to fueling a CG Standard Boat or Cutter IAW Naval Engineering Manual, COMDTINST M9000.6 (series), Chapter 541, NSTM Chapter 541, Ship Fuel and Fuel Systems, and Units Engineering Standing Orders. SupGuide: The member will draw a fuel sample prior to refueling and check for water sediment and report finding to the Fueling Officer. 5.G.01 MAINTAIN fuel and oil systems installed on CG Standard Boat or Cutter IAW Naval Engineering Manual, COMDTINST M9000.6 (series) Chapters 541 & 542, NSTM Chapter 541, Ship Fuel and Fuel Systems, NSTM Chapter 542, Gasoline and JP-5 Fuel Systems, Manufacturer's Technical Manuals, and Shipboard Helicopter Operations Procedure Manual, M3710.2 (series) SupGuide: Includes: storage, transfer, and service systems, treatment of tanks, purifiers and aviation fuel systems. 5.G.02 MAINTAIN lube oil systems installed on CG Standard Boat or Cutter IAW Naval Engineering Manual, COMDTINST M9000.6 (series) Chapter 262, NSTM Chapter 262, Lubricating Oils, Greases, Specialty Lubricants and Lubrication Systems, and Manufacturer's Technical Manuals. SupGuide: Includes: storage, transfer, service and purifier lube oil systems. 6.G.01 SUPERVISE shipboard fueling operations IAW Naval Engineering Manual, COMDTINST M9000.6 (series), Chapter 541, NSTM Chapter 541, Ship Fuel and Fuel Systems, NSTM Chapter 542, Gasoline and JP5 Fuel Systems, and Units Engineering Standing Orders. SupGuide: Following all safety procedures the member will oversee setup, treatment, receipt and transfer of fuel.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 16 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

H.

BEARINGS AND SEALS

4.H.01 RENEW gaskets, seals, packing, and O-rings IAW NSTM Chapter 078 Volume 1, Seals, NSTM Chapter 078 Volume 1 & 2, Seals/Gaskets and Packing and Manufacturer's Technical Manuals. SupGuide: The member will select the proper materials and applicable tools. The member will cut new gaskets and packing and make an o-ring. The member will then install new gaskets/seals/packing/O-rings used in Coast Guard machinery. Demonstrate use and nomenclature of common tools. The member will make inspections and adjustments to any of the common shaft packing glands, seals found on CG Cutters and Small Boats. In addition, using a packing puller tool, remove worn packing. The member will then select the proper replacement packing/seals and install. 5.H.01 TROUBLESHOOT bearings found in common Coast Guard systems (e.g.: diesel engines, pumps, air compressors) IAW NSTM Chapter 233, Diesel Engines, NSTM Chapter 503, Pumps, NSTM Chapter 551, Compressed Air Plants and Systems and Manufacturer's Technical Manuals. SupGuide: The member will understand the principals of operation for the following bearing types; ball, roller, precision inserts, thrust bearings, bushings, collars and needle bearings. Member will perform basic maintenance to include lubrication, cleaning and inspecting bearings. Member will know common causes of bearing failure how to replace failed bearings. 5.H.02 ADJUST shaft seals and propulsion bearings IAW NSTM Chapter 244, Propulsion Bearings and Seals, PMS Manual and Manufacturer's Technical Manual. SupGuide: The member will understand the importance of proper shaft alignment. Member will understand the different techniques used to align common propulsion shafts and couplings. The member will demonstrate the proper usage of applicable tools such as: dial indicator, machinist rule, thickness gauges and optical alignment tools.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 17 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

I. 4.I.01

SMALL BOATS MAINTAIN a CG Standard Boat propulsion system IAW Preventive Maintenance Schedule Manual (PMS), and Manufacturer's Technical Manual. SupGuide: The member will understand the mechanical and electrical components of an outboard motor including lower unit and fuel injection system, and conduct Preventative Maintenance. Member will change lower unit oil, tune up, change zincs, and replace water pumps. Member will conduct common corrective maintenance associated with outboard motors such as prop replacement, ignition system and charging system component replacement. Member will identify components of, and describe operating principles of jet propulsion units. Demonstrate use and nomenclature of common tools.

4.I.02

MAINTAIN a standard boat trailer electrical and mechanical components IAW PMS Manual and Manufacturer's Technical Manual. Axle assembly Braking system Bunks/Rollers Lighting system Suspension system Tires Wheel bearings

5.I.01

TROUBLESHOOT a CG Standard Boat outboard engine IAW PMS Manual and Manufactures Technical Manual. SupGuide: Member will conduct systematic checks of all electrical/electronic and mechanical components (including lower unit and trim tilt unit) utilizing manufactures electronic diagnostic tools. Member will make recommendations; take corrective actions, and document repairs.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 18 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

J.

INTERNAL COMBUSTION ENGINES

4.J.01 OVERHAUL an internal combustion engine listed in Naval Engineering Manual, COMDTINST M9000. 6 (series), chapter 233, table 233-1 IAW Naval Engineering Manual, COMDTINST M9000.6 (series), NSTM Chapter 233, Diesel Engines, the Manufacturer's Technical Manuals, PMS Procedure Cards and NAVEDTRA 14104 Fireman. SupGuide: The member will overhaul under supervision one of the engines listed in the Naval Engineering Manual, COMDTINST M9000.6 (series), and identify the general operating principles of gasoline & diesel two-stroke and four-stroke engines and gas turbine engines. The member will demonstrate the proper usage of the following tools: inside and outside micrometers, dial indicator, calipers, thickness gages, depth gages, bearing pullers, snap ring pliers, machinist rule, torque wrench, gasket cutter, hydraulic press, lock wire pliers, compression tester, and thread repair kit. Identify different grades, thread count, sizes and materials of machine screws used commonly in the Coast Guard. Identify threads, national fine, national coarse, and metric. Member will record system operating temperatures, pressures, differentials, measurements and tolerances in U.S. and metric units. Demonstrate converting temperatures and pressures from U.S. to metric. Member will renew/replace components worn beyond Manufacturer's tolerances. Emphasis will be placed on the engines external attachments. Member will make all required adjustments and place engine back in operation. 5.J.01 TROUBLESHOOT an internal combustion engine listed in Naval Engineering Manual, COMDTINST M9000. 6 (series), chapter 233, table 233-1 IAW Naval Engineering Manual, COMDTINST M9000.6 (series), NSTM Chapter 233, Diesel Engines, the Manufacturer's Technical Manuals and PMS procedures. SupGuide: The member will systematically troubleshoot a diesel engine using DEMPS, DECM, ODR, PAR, round sheets, and Technical Manuals then make recommendations for repairs.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 19 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

5.J.02 MAINTAIN the following internal combustion engine systems and components IAW Naval Engineering Manual, COMDTINST M9000.6 (series), NSTM Chapter 233, Diesel Engines, the Manufacturer's Technical Manuals and PMS procedures. Air induction system Cooling systems Fuel systems Lube Oil Fuel control (electronic, mechanical, hydraulic governor) system

SupGuide: The member will tune-up and adjust governor settings (i.e., overspeed, overload, and topping), fuel control, valves, injectors, and linkages to any engine listed in the Naval Engineering Manual, COMDTINST M9000.6 (series), table 233-1. 5.J.03 TROUBLESHOOT the following internal combustion engine systems and components IAW Naval Engineering Manual, COMDTINST M9000.6 (series), NSTM Chapter 233, Diesel Engines, the Manufacturer's Technical Manuals and PMS procedures. Air induction system Cooling systems Fuel systems Lube oil systems Fuel control (electronic, mechanical, hydraulic governor) system

SupGuide: The member will troubleshoot overspeed trips, fuel control, valves, injectors, and linkages to any engine listed in the Naval Engineering Manual, COMDTINST M9000.6 (series), table 233-1 and effect necessary repairs to restore system to full operational condition. 6.J.01 SUPERVISE the overhaul of an internal combustion engine listed in Naval Engineering Manual, COMDTINST M9000.6 (series), chapter 233 table 233-1 IAW Naval Engineering Manual, COMDTINST M9000.6 (series), NSTM Chapter 233, Diesel Engines, the Manufacturer's Technical Manuals and PMS procedures. SupGuide: The member will supervise the overhaul of one of the engines referenced in the Naval Engineering Manual, COMDTINST M9000.6 (series). Member will ensure all safety procedures are followed and all tools and parts are staged for overhaul.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 20 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

K.

MECHANICAL POWER TRANSMISSION EQUIPMENT

5.K.01 MAINTAIN propulsion transmission equipment IAW Manufacturer's Technical Manual, Naval Engineering Manual, COMDTINST M9000.6 (series), NSTM Chapter 241, Propulsion Reduction Gears, Couplings, Clutches and Associated Components, and Unit PMS schedule. SupGuide: The member will understand functional characteristics of commonly found reduction gears in the Coast Guard. Member will ensure quality and quantity of lube oil. Member will clean/change filters/strainers. 5.K.02 INSPECT rudders IAW Manufacturer's Technical Manual, NSTM Chapter 562, Surface Ship Steering, and Unit PMS Schedule. SupGuide: The member will take rudder bearing clearance readings on a Coast Guard Cutter or Standard Boat. Member will make recommendations concerning the condition found, then enter readings in the boat or cutter records. 6.K.01 ALIGN a propulsion shaft found on a Coast Guard Cutter or Standard Small Boat IAW NSTM Chapter 243, Propulsion Shafting, and Manufacturer's Technical Manual. SupGuide: The member will understand how the raising, lowering, and lateral adjustment of foundation mounts changes the alignment relationship to the shaft. Member will align a propulsion shaft to an output coupling and ensure parallel and angular alignment and optical alignment tools. 6.K.02 TROUBLESHOOT a propulsion transmission found on either a Cutter or Standard Small Boat IAW Manufacturer's Technical Manual, Naval Engineering Manual, COMDTINST M9000.6 (series), NSTM Chapter 241, Propulsion Reduction Gears, Couplings, Clutches and Associated Components, and Unit PMS schedule. SupGuide: The member will have knowledge of shafting, gears, clutches, seals, and bearings. Member will make repairs/adjustments to any of the following components: selector valves, control linkages, seals, coolers, thermostats, and clutches. The member will recommend and take applicable corrective action for common casualties.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 21 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

L.

POTABLE WATER SYSTEMS

5.L.01 MAINTAIN potable water tanks and systems IAW Naval Engineering Manual, COMDTINST 9000.6 (series), Water Supply and Waterwaste Disposal Manual, COMDTINST M6240.5 (series), NSTM Chapter 533, Potable Water Systems, Medical Manual, COMDTINST M5000.1 (series) and Standards for Potable Water, NAVMEDCOMINST 6240.1 (series), SupGuide: The member will complete P/W testing and treatment (Bromine and Chlorine) procedures. 5.L.02 MAINTAIN a reverse osmosis system IAW NSTM Chapter 531 Volume 3, Desalination, Reverse Osmosis Desalination Plants and Manufacturer's Technical Manuals. SupGuide: The member will understand the principals of operation. Member will be capable of changing oil in the high PSI pump, changing the filters, both membrane and sand. 5.L.03 TROUBLESHOOT a reverse osmosis system IAW NSTM Chapter 531 Volume 3, Desalination, Reverse Osmosis Desalination Plants and Manufacturer's Technical Manuals SupGuide: The member will complete systematic checks of all electrical/electronic and mechanical components. Member will make recommendations to supervisor for repair and take corrective action.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 22 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

M.

HEATING, VENTILATION, AIR CONDITIONING AND REFRIGERATION (HVAC&R)

4.M.01 OPERATE an AC&R system IAW Goodheart & Wilcox Modern Refrigeration Book, NSTM Chapter 516 Refrigeration Systems, and Manufacturer's Technical Manuals. SupGuide: The member will understand theory of operation, component function and be capable of system component identification. Given a secured AC&R system, member will properly place system on line and then secure. Demonstrate use and nomenclature of common tools. 4.M.02 MAINTAIN heating and ventilation systems IAW Unit PMS Procedures, NSTM Chapter 510, Heating, Ventilating, and Air Conditioning Systems For Surface Ships, and Manufacturer's Technical Manuals. SupGuide: The member will understand the functional characteristics of heating and ventilation. Member must know associated safety precautions and know how to clean heating and cooling coils, clean condensate drains, and replace filters. 5.M.01 TROUBLESHOOT AC&R and air handler systems IAW Goodheart & Wilcox Modern Refrigeration Book and Manufacturer's Technical Manuals, and Naval Engineering Manual, COMDTINST M9000.6 (series). SupGuide: The member will complete systematic checks of all electrical/electronic and mechanical components with the guidance of a certified technician. Member will make recommendations and take appropriate corrective action.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 23 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

N.

HYDRAULICS

4.N.01 MAINTAIN a hydraulic system IAW Naval Engineering Manual, COMDTINST M9000.6 (series), NSTM Chapter 556, Hydraulic Equipment, Eaton Fluid Power Industrial Hydraulics Manual, Manufacturer's Technical Manuals and Unit PMS Procedures. SupGuide: The member will understand the functional characteristics of a hydraulic system and the following components; Reservoirs, positive displacement pumps (vane, piston & gear), Motors (vane, piston & gear), cylinders (single, double acting), and directional control valves. Member will change filters, clean strainers and inspect for leaks. Record system operating temperature and pressures in U.S. and metric. Demonstrate converting temperatures and pressures from U.S. to metric. Demonstrate use and nomenclature of common tools. 6.N.01 TROUBLESHOOT a hydraulic system IAW Naval Engineering Manual, COMDTINST M9000.6 (series), NSTM Chapter 556, Hydraulic Equipment, Eaton Fluid Power Industrial Hydraulics Manual, Manufacturer's Technical Manuals and Unit PMS Procedures. SupGuide: Member will complete systematic checks of the following components to locate malfunctions: positive displacement pumps, motors, reservoirs, cylinders, filters, strainers and control valves. Member will make recommendations for corrective action. Once corrective action is taken, member is to conduct operational test. Demonstrate calculating system volumes, force, and flow in U.S. and metric.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 24 of 30

CG-3303C-MK

(Rev. 03-2009)

INIT DATE

RATING: Machinery Technician

O.

DAMAGE CONTROL

4.O.01 MAINTAIN the Coast Guard standard portable dewatering pump IAW Tech Pub 3942, P-6 Dewatering / Fire Pump Operators Manual, Service Manual, and Owners Manual, Current Maintenance Procedure Cards, or current standard portable dewatering pump Manufacturer's Technical Manual. 4.O.02 OPERATE the Coast Guard standard portable dewatering pump IAW Tech Pub 3942, P-6 Dewatering / Fire Pump Operators Manual, Service Manual, and Owners Manual, Current Maintenance Procedure Cards, or current standard portable dewatering pump Manufacturer's Technical Manual. SupGuide: The member will understand theory of operation, component function and be capable of system component identification. Given a secured portable dewatering pump, member will safely bring pump on line IAW proper procedures, obtain suction, and then secure. Member will also demonstrate proper stowage of pump. 4.O.03 MAINTAIN the Coast Guard standard portable firefighting pump IAW Tech Pub S6226-NM-MMC-010, P-100 Technical Manual, current Maintenance Procedure Cards, or current standard portable firefighting pump Manufacturer's Technical Manual. 4.O.04 OPERATE the Coast Guard standard portable firefighting pump IAW Tech Pub S6226-NM-MMC-010, P-100 Technical Manual, current Maintenance Procedure Cards, or current standard portable firefighting pump Manufacturer's Technical Manual. SupGuide: The member will understand theory of operation, component function and be capable of system component identification. Given a secured portable firefighting pump, member will safely bring pump on line IAW proper procedures and obtain suction and pressure. Member will also demonstrate proper securing and stowage of pump and all peripheral equipment.

-End-

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 25 of 30

Coast Guard Machinery Technician Guiding Principles

I. Stay one step ahead of technology. II. Stand vigilant watches, continue to train, and maintain open lines of communication up and down the Chain of Command. III. From Preventive Maintenance to Center Section Overhauls, complete each task properly the first time, while taking the knowledge and skills youve received and pass them to those individuals that look up to you. IV. Provide the Coast Guard with first-rate quality work. V. Keep Coast Guard Cutters, Boats and Stations Always Ready to perform their mission. VI. Seek out new ways to do our job more efficiently. VII. Present and review engineering evidence, theory and interpretation honestly, accurately and without bias. VIII. Take due account of the limited availability of natural and human resources. IX. In a caring and creative manner, we will embrace the challenge of helping build a community that is environmentally and socially responsible. X. Focus on attention to detail and go above and beyond the minimum to uphold the ratings reputation of dedication to our mission, people, and organizational success.

CG-3303C-MK

(Rev. 03-2009)

RATING: Machinery Technician

Appendix B: TERMINOLOGY AUDIT An official examination and verification of accounts and records. ADJUST To bring parts or equipment into a truer or more effective setting or relationship. ALIGN Place parts in proper position to one another. ASSEMBLY To fit parts of a machine together. COMPARE To examine the character or qualities of, in order to discover resemblances of differences. COMPLETE Follow a process or procedure from initial identification to submission of any required reports or forms. CONDUCT To direct or control, lead, or guide. DEVELOP To set forth or make in detail. INSPECT Examine, test, measure, or evaluate spaces or equipment for installation, operation, and performance in accordance with established industry standards, specifications, drawings, technical manuals, directives, policies, or other requirements. INSTALL To place a new or modified part in a system or equipment IAW established procedures, standards, specifications, drawings, directives and policies. LAP To cut or polish mating surfaces. MAINTAIN To preserve or keep in good repair. OPERATE To cause to function. OVERHAUL To disassemble, inspect, renew defective components, reassemble and place back in service. PERFORM To carry out an action or pattern of behavior. PREPARE Plan, gather, and assemble information to produce a document (i.e. forms and schedules). RECORD To document required information in a record book, database, or other application for later retrieval and review. RENEW To remove a defective component and install a new component with the same specifications in its place. REPAIR To restore a circuit or machinery to an as intended operational state. REPLACE To remove and reinstall same component. REVIEW To examine a document or process for accuracy in content and/or format and report errors or updates to the author or controlling authority. RETRIEVE To obtain data.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 27 of 30

CG-3303C-MK

(Rev. 03-2009)

RATING: Machinery Technician

Appendix B: TERMINOLOGY (Contd) SUBMIT To prepare a report or form following a defined process and forwarding it to the prescribed authority. SUPERVISE To oversee, to critically watch, motivate and direct activities. TROUBLESHOOT The process of locating and diagnosing faults in equipment by means of systemic checking or analysis and then affecting repair. VERIFY To determine the accuracy of recorded information by comparing to physical evidence.

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 28 of 30

CG-3303C-MK

(Rev. 03-2009)

RATING: Machinery Technician

Appendix C: REFERENCE MATERIAL (hyperlinks provided where available) America Boat and Yacht (ABYC) Standards (series) U.S. Coast Guard Boat Operations and Training (BOAT) Manual, Volume II, COMDTINST M16114.33 (series) Casualty Reporting (CASREP) Procedures (Materiel), COMDTINST M3501.3 (series) Civil Engineering Manual, COMDTINST M11000.11 (series) CMPlus User Manual CSMP File Cutter Training and Qualification Manual, COMDTINST 3502.4 (series) Directives, Publications, & Reports Index, COMDTNOTE 5600 Eaton Fluid Power Industrial Hydraulics Manual ECR file Equipment Tag-Out Procedures, COMDTINST 9077.1 (series) Forms for Cutters including Vessel Availability Coast Guard Inspector Daily Inspection Report: http://webapps.mlca.uscg.mil/vdiv/Availabilities/Availability%20Forms/Cutters/ GoodHeart & Wilcox Modern Refrigeration Book Hazardous Waste Management Manual, COMDTINST M16478.1 (series) Manufacturer's Instructions/Technical Manuals Medical Manual, COMDTINST M5000.1 (series) MLC Instructions MLC Specifications (LANT SPECS, PAC SPECS) MLC Standard Operating Procedures (MLCLANT SOP, MLCPAC SOP) National Electric Code Handbook (series)

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 29 of 30

CG-3303C-MK

(Rev. 03-2009)

RATING: Machinery Technician

Appendix C: REFERENCE MATERIAL (Contd) Naval Engineering Computer Aided Design Standards, COMDTINST M9085.1 (series) Naval Engineering Manual, COMDTINST M9000.6 (series) Fixed Link Naval Engineering Technical Information Management System (NE-TIMS) NAVEDTRA 14104 Fireman NAVMEDCOMINST 6240.1 (series), "Standards for Potable Water." NSTM Chapters, 077, 078, 079, 081, 220, 233, 234, 241, 243, 244, 254, 262, 300, 302, 313, 320, 330, 400, 491, 503, 504, 505, 531, 533, 541, 542, 551, 555, 556, 562, 593 and 635 Operational Reports, NWP 1-03-1 (series) Shipboard Helicopter Operations Procedure manual, M3710.2 Supply and Policy Procedures Manual, COMDTINST M4400.19 (series) Tech Pub 3942, P-6 Dewatering / Fire Pump Operators Manual, Service Manual, and Owners Manual Tech Pub S6226-NM-MMC-010, P-100 Technical Manual Water Supply and Waterwaste Disposal Manual, COMDTINST M6240.5 (series) Unit Instructions/Standing Orders/PMS Schedule

NAME (Last, First, Middle Initial)

EMPLID NUMBER

PREVIOUS EDITION IS OBSOLETE

Page 30 of 30

You might also like

- MC HandbookDocument355 pagesMC HandbookSyahirul Alim100% (5)

- Mccs Presentation Comm & MaintenanceDocument32 pagesMccs Presentation Comm & MaintenanceNur FarahatanNo ratings yet

- Scheduled Maintenance and Inspection Program SummaryDocument10 pagesScheduled Maintenance and Inspection Program SummaryVincent LefeuvreNo ratings yet

- Trailer PMS ManualDocument33 pagesTrailer PMS ManualTharanga Lakmal OpanayakaNo ratings yet

- Audit ManualDocument189 pagesAudit ManualEslam HusseinNo ratings yet

- Wsc2011 Td06 CNC TurningDocument12 pagesWsc2011 Td06 CNC Turningelectro3ergenNo ratings yet

- Company Maintenance Manual (CMM) 1. GeneralDocument7 pagesCompany Maintenance Manual (CMM) 1. GeneralSiti Rizka FauziyahNo ratings yet

- CDCCL PTCDocument82 pagesCDCCL PTCrizcst9759100% (7)

- Atr MPDDocument11 pagesAtr MPD4587560No ratings yet

- Houston Course Catalog - 45Document1 pageHouston Course Catalog - 45AnuranjanNo ratings yet

- SRU Offplot - Process - Phase 3 - Class 3 TIC Estimate (FEED)Document86 pagesSRU Offplot - Process - Phase 3 - Class 3 TIC Estimate (FEED)GPNo ratings yet

- NAVSEA RCM Handbook DTD 18 April 2007 PDFDocument105 pagesNAVSEA RCM Handbook DTD 18 April 2007 PDFTiu TonNo ratings yet

- Boeing 787 8 Genx Gen Fam Syllabus Oct 2011 v1Document15 pagesBoeing 787 8 Genx Gen Fam Syllabus Oct 2011 v1Julio50% (4)

- Paver InglesDocument282 pagesPaver InglesGu VanNo ratings yet

- Deck and Engineering GuideDocument131 pagesDeck and Engineering GuideRaji MN100% (1)

- Operator E-Jets News Rel 82Document25 pagesOperator E-Jets News Rel 82PDDELUCANo ratings yet

- 121114.001 Specification For TCN VCU WebsiteDocument32 pages121114.001 Specification For TCN VCU WebsiteSURJIT SINGH100% (1)

- Load Flow & Short CKT CalculationDocument5 pagesLoad Flow & Short CKT CalculationBert De BorjaNo ratings yet

- Pumps and Motors ManagementDocument80 pagesPumps and Motors ManagementMihai Constantinescu100% (1)

- L1 CHE PRO 031 Engineering Change ProcedureDocument24 pagesL1 CHE PRO 031 Engineering Change Procedure4493464No ratings yet

- Guide 15950Document7 pagesGuide 15950djukalNo ratings yet

- SPC-0804.02-50.91 Rev D2 3D-CAD Model Review SpecificationDocument22 pagesSPC-0804.02-50.91 Rev D2 3D-CAD Model Review SpecificationAroon Kumar100% (1)

- 121114.001 - Specification For - TCN - VCU - Website PDFDocument32 pages121114.001 - Specification For - TCN - VCU - Website PDFSunil JadhavNo ratings yet

- Industrial Motor Controls I: IDSY 1110Document5 pagesIndustrial Motor Controls I: IDSY 1110Ajay SolateNo ratings yet

- F-15 (Final)Document244 pagesF-15 (Final)bdunc100% (3)

- Jakarta Plant Engineering Standard: B. General Rules of PFMEA B.1. ScopeDocument24 pagesJakarta Plant Engineering Standard: B. General Rules of PFMEA B.1. ScopeLeonardoViannaNo ratings yet

- CS 101Document2 pagesCS 101sslbsNo ratings yet

- Potante - Dante@dpwh - Gov.ph: PLEASE EMAIL YOUR ANSWERS (Including Solutions) TODocument1 pagePotante - Dante@dpwh - Gov.ph: PLEASE EMAIL YOUR ANSWERS (Including Solutions) TOdadarwinpopogiNo ratings yet

- k90mcc6 PDFDocument381 pagesk90mcc6 PDFTammy JohnsonNo ratings yet

- Mechanical Completions - WELDINGDocument17 pagesMechanical Completions - WELDINGDinesh RadhakrishnanNo ratings yet

- Training Abb Technical Training Booklet WebDocument98 pagesTraining Abb Technical Training Booklet Webman_y2kNo ratings yet

- 1540Document294 pages1540Joe CoughlinNo ratings yet

- MIl STD 785BDocument88 pagesMIl STD 785BrezaNo ratings yet

- 2021 TSO Workshop - Questions and AnswersDocument5 pages2021 TSO Workshop - Questions and Answersandre_lsaNo ratings yet

- MTD AssignmentsDocument80 pagesMTD AssignmentsAdinath DhamdhereNo ratings yet

- 3m PqsDocument94 pages3m Pqssmbushue100% (1)

- Maint Philsp N Devlp ProgrDocument47 pagesMaint Philsp N Devlp Progrhatach100% (1)

- MSRP-K2 05Document390 pagesMSRP-K2 05Daniel VargasNo ratings yet

- Training Support Package (TSP) : TSP Number Task Number(s) Title(s) Effective Date Supersedes TSP(S) TSP UserDocument16 pagesTraining Support Package (TSP) : TSP Number Task Number(s) Title(s) Effective Date Supersedes TSP(S) TSP UserLo Shun FatNo ratings yet

- 5 Diagnostics As Basis For Condition Based MaintenanceDocument16 pages5 Diagnostics As Basis For Condition Based Maintenanceured cizminNo ratings yet

- NgteanDocument6 pagesNgteanIan MuhammadNo ratings yet

- RAM (Reliability, Availability and Maintainability) Analysis Version1Document5 pagesRAM (Reliability, Availability and Maintainability) Analysis Version1John KingsleyNo ratings yet

- PLE QA QSP 12 Technical AuditDocument6 pagesPLE QA QSP 12 Technical Auditkumarkrishna29No ratings yet

- Mil P 24534Document150 pagesMil P 24534jandroweenNo ratings yet

- Advanced Composites Repair Analysis Tool (Acrat)Document12 pagesAdvanced Composites Repair Analysis Tool (Acrat)BharatiyulamNo ratings yet

- Amc 20 22Document32 pagesAmc 20 22diana_veronicaNo ratings yet

- 3 Note To Spec. Writer Insert Data in BlanksDocument5 pages3 Note To Spec. Writer Insert Data in Blanksakppk1384No ratings yet

- Engine Monitoring System Display Overview: Información de Servicio GeneralDocument17 pagesEngine Monitoring System Display Overview: Información de Servicio GeneralmanuelNo ratings yet

- MCP-Maintenance-Procedures Rev1 - 072019Document91 pagesMCP-Maintenance-Procedures Rev1 - 072019Rodolfo ValençaNo ratings yet

- Lighthouse Modernization ManualDocument49 pagesLighthouse Modernization ManualAnurag ManiNo ratings yet

- 08 - Michael Kennedy PaperDocument7 pages08 - Michael Kennedy PaperManel MontesinosNo ratings yet

- Qurayyah Combined Cycle Power Plant - SATDocument10 pagesQurayyah Combined Cycle Power Plant - SATrenjithv_4100% (1)

- Di PSSS 80991BDocument7 pagesDi PSSS 80991BInaamNo ratings yet

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BFrom EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- Rapid Prototyping Software for Avionics Systems: Model-oriented Approaches for Complex Systems CertificationFrom EverandRapid Prototyping Software for Avionics Systems: Model-oriented Approaches for Complex Systems CertificationNo ratings yet

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- Approvals Management Responsibilities and Setups in AME.B PDFDocument20 pagesApprovals Management Responsibilities and Setups in AME.B PDFAli LoganNo ratings yet

- SCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Document2 pagesSCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Nguyễn Hồng AnhNo ratings yet

- Etag 002 PT 2 PDFDocument13 pagesEtag 002 PT 2 PDFRui RibeiroNo ratings yet

- Kübler 5800-5820 - enDocument5 pagesKübler 5800-5820 - enpomsarexnbNo ratings yet

- Installation Instructions INI Luma Gen2Document21 pagesInstallation Instructions INI Luma Gen2John Kim CarandangNo ratings yet

- Unit 2: Air Intake and Exhaust SystemsDocument10 pagesUnit 2: Air Intake and Exhaust SystemsMahmmod Al-QawasmehNo ratings yet

- Course Outline ENTR401 - Second Sem 2022 - 2023Document6 pagesCourse Outline ENTR401 - Second Sem 2022 - 2023mahdi khunaiziNo ratings yet

- Source:: APJMR-Socio-Economic-Impact-of-Business-Establishments - PDF (Lpubatangas - Edu.ph)Document2 pagesSource:: APJMR-Socio-Economic-Impact-of-Business-Establishments - PDF (Lpubatangas - Edu.ph)Ian EncarnacionNo ratings yet

- SM EFATEX Rev D2 3 1 2018 PDFDocument20 pagesSM EFATEX Rev D2 3 1 2018 PDFGuilhermePlacidoNo ratings yet

- Waste Biorefinery Models Towards Sustainable Circular Bioeconomy Critical Review and Future Perspectives2016bioresource Technology PDFDocument11 pagesWaste Biorefinery Models Towards Sustainable Circular Bioeconomy Critical Review and Future Perspectives2016bioresource Technology PDFdatinov100% (1)

- Viscar Industrial Capacity LTD Company ProfileDocument36 pagesViscar Industrial Capacity LTD Company ProfileTechnician MwangiNo ratings yet

- ME-6501Computer Aided Design (CAD) WITH QB - BY Civildatas - Com 1Document85 pagesME-6501Computer Aided Design (CAD) WITH QB - BY Civildatas - Com 1Nathar ShaNo ratings yet

- Homework 9Document1 pageHomework 9Nat Dabuét0% (1)

- 2014 - Intelligence As A Predictor of Outcome in Short-And Long-Term PsychotherapyDocument9 pages2014 - Intelligence As A Predictor of Outcome in Short-And Long-Term PsychotherapyZayne CarrickNo ratings yet

- (EN 10348) - Steel For The Reinforcement of Concrete. Galvanized Reinforcing SteelDocument24 pages(EN 10348) - Steel For The Reinforcement of Concrete. Galvanized Reinforcing Steelbagusu_6No ratings yet

- Documentation Report On School's Direction SettingDocument24 pagesDocumentation Report On School's Direction SettingSheila May FielNo ratings yet

- Jinivefsiti: Sultan LorisDocument13 pagesJinivefsiti: Sultan LorisSITI HAJAR BINTI MOHD LATEPINo ratings yet

- KRAS QC12K-4X2500 Hydraulic Shearing Machine With E21S ControllerDocument3 pagesKRAS QC12K-4X2500 Hydraulic Shearing Machine With E21S ControllerJohan Sneider100% (1)

- Importance of Porosity - Permeability Relationship in Sandstone Petrophysical PropertiesDocument61 pagesImportance of Porosity - Permeability Relationship in Sandstone Petrophysical PropertiesjrtnNo ratings yet

- AP8 Q4 Ip9 V.02Document7 pagesAP8 Q4 Ip9 V.02nikka suitadoNo ratings yet

- 4. Nguyễn Thị Minh Khai, Sóc TrăngDocument15 pages4. Nguyễn Thị Minh Khai, Sóc TrăngK60 TRẦN MINH QUANGNo ratings yet

- Bone Surface MarkingsDocument2 pagesBone Surface MarkingsNurul Afiqah Fattin AmatNo ratings yet

- Banking Ombudsman 58Document4 pagesBanking Ombudsman 58Sahil GauravNo ratings yet

- Naval TV SystemDocument24 pagesNaval TV Systemsharmasandeep0010No ratings yet

- Point and Figure ChartsDocument5 pagesPoint and Figure ChartsShakti ShivaNo ratings yet

- Supply List & Resource Sheet: Granulation Techniques DemystifiedDocument6 pagesSupply List & Resource Sheet: Granulation Techniques DemystifiedknhartNo ratings yet

- Acoustic Glass - ENDocument2 pagesAcoustic Glass - ENpeterandreaNo ratings yet

- Log and Antilog TableDocument3 pagesLog and Antilog TableDeboshri BhattacharjeeNo ratings yet

- Saflex-Dg - 41 Data SheetDocument5 pagesSaflex-Dg - 41 Data SheetrasheedgotzNo ratings yet

- Sheet-Metal Forming Processes: Group 9 PresentationDocument90 pagesSheet-Metal Forming Processes: Group 9 PresentationjssrikantamurthyNo ratings yet