Professional Documents

Culture Documents

Hsse and Pipe Check List

Uploaded by

Sandip PalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hsse and Pipe Check List

Uploaded by

Sandip PalCopyright:

Available Formats

Preventive Maintenance Schedule 8 ZIL pipeline Month:

S. No. Job Description Visual inspection on the way of the pipeline to check for any structures coming on its way Visual inspection on the way of the pipeline to check for any excavation or digging on its way Check all indication markers of the line are in place and having proper display Check the ROW is maintained free of over growth and encroachment Check the valves on the pipeline are protected from unauthorized operation and vandalism Check all CP test stations are properly maintained all along the line Check CP readings within limits Check for pressure testing of the pipeline Schedule Date: Date: Observation / Action Date: Date:

01

Weekly

02

Weekly

03

Weekly

04

Weekly

05

Weekly

06 07 08

Monthly Bimonthly Yearly

Preventive Maintenance Schedule Portable water overhead tank

S. No. Job Description Schedule June-11 July-11 Observation / Action Aug-11

Sept-11

01 02 03 04 05 06

Check the condition of water in the tank Clean the tank from inside by cleaning the walls of the tank Check for any algae formation and suspended solids, clean the same Check for any leaks in the tank, rectify if any Check the valves and associated pipes of the tank Check the manholes of the tank are properly closed

Monthly Monthly Monthly Monthly Monthly Monthly

Checked by/Reviewed by Any major observations/ actions

Preventive Maintenance Schedule OWS TPI TANK

S. No. Job Description Schedule Observation / Action

01 02 03 04 05 06 07

Check the condition of TPI plate pack Clean and flush the TPI plates with clean water Check for any algae formation and suspended solids, clean the same Clean the tank secondary chambers internally with clean water Check the valves and associated pipes of the tank Check for any leaks from the tank Check the condition of skimmed oil collection tank, empty if full

Monthly Monthly Monthly Monthly Monthly Monthly Monthly

Checked by/Reviewed by Any major observations/ actions

Zuari Indian Oiltanking Limited

Contractor HSSE Requirements

1. Company Registration: The Contractor shall have valid registrations under the statutory requirements for carrying out the job mentioned in the work order and other enclosures. 2. Regular employees: All the employees of the contractor shall be regular employees on his rolls. 3. Insurance: The contractor shall insure all his employees who will be working in ZIOL premises. 4. Education & Training: All the employees of the contractor shall meet the minimum education criteria pertaining to the job and must be trained for carrying out the job. They should have also undergone training for carrying out the job efficiently and safely. 5. Safety Induction Training: The Contractor shall ensure that all his employees undergo safety induction training conducted by the ZIOL HSSE Dept prior to the start of the job. 6. Personal Protective Equipment (PPE s): The Contractor shall provide his employees with the required PPE s for carrying out the job. It is the duty of the Contractor to ensure that the PPE s are in good condition. All damaged PPE s should be immediately replaced. 7. Water/ Food/Accommodation /Transport: The contractor will be responsible for providing his employees with Water, Food Accommodation, Tea, Coffee, & Transport to the site at his cost. 8. Safety of ZIOL equipment: The contractor shall ensure, that his employees while employed in the premises of ZIOL do not tamper with equipment of ZIOL. 9. Terminal Safety Rules: At all given time the contractor must ensure that he and his employees follow the Terminal Safety Rules very strictly. In case of any doubts the contractor shall contact the Terminal HSSE coordinator. 10. Reporting of Incidents: The contractor shall ensure that all the minor/ major incidents /accidents/ near misses are reported to the HSSE dept or to the control room of ZIOL. 11. Permit to work: The Contractor shall adopt the ZIOL permit to work System.The permit to work is required in all ZIOL restricted and unrestricted area. ZIOL has got different work permits like. Hot Work permit Cold Work permit Confined Space permit Vehicle permit 12. Contractor Vehicles: The contractor can use only diesel vehicles fitted with Spark Arrestor in the licensed area of the terminal after receiving necessary permits from the control Room. The vehicle will be allowed in the licensed area only to supply material etc. No vehicle should be overloaded, the vehicle should be driven by the driver holding valid license issued by the transport department. The driving speed inside the terminal should not exceed 15 KMPH. The Height of the vehicle or goods

stacked on it shall not exceed 4.5 mts inside the terminal. The driver shall wear Safety Belt at all given time when driving inside the ter minal. 13. Inspection of Equipments and Tools: It will be the responsibility of the contractor to provide his employees with proper tools and tackles. The contractor shall periodically check the equipment and if found defective shall replace the same so as to eliminate the risk of dangers. The HSSE dept of ZIOL shall have the right to reject all the equipment or some part of it, which he finds may jeopardize the safety 14. Safe Handling of Tools: The contractor shall ensure that all the safety devices of the equipment to be used are in place and are not bypassed, e.g. guard of the hand grinding machine should be in place, flash back arrestor should be provided for gas welding machine etc. 15. Supervisor: The contractor shall provide a trained supervisor at all time. No work will be allowed inside the ZIOL premises in the absence of the supervisor. 16. Security: The contractor shall ensure that the names of his employees are entered at the security gate register at the time of entry everyday. The contractor shall also make all his employees available for frisking at the time of entry and exit from the terminal. 17. House Keeping: The contractor shall ensure that the site of work is kept free of surplus waste and shall maintain a clean and tidy site through out the duration of work. 18. Lifting Equipments: All the lifting equipments of the contractor like cranes, Chain pulley block, slings etc should be regularly tested and certified by a competent person. The copy of the certificate should be made available to the ZIOL HSSE dept. 19. Scaffoldings: All scaffolds and staging shall comply with recognized standards. Prior to using any scaffolding, it shall be approved by ZIOLL. A SCAF-TAG indicating ZIOL acceptance will be attached to the scaffolding, the scaffolding is not to be used until the approval is given.

You might also like

- W-2 Wage and Tax Statement: Copy B-To Be Filed With Employee's FEDERAL Tax ReturnDocument1 pageW-2 Wage and Tax Statement: Copy B-To Be Filed With Employee's FEDERAL Tax ReturnjeminaNo ratings yet

- The Berenstain Bears Blessed Are The PeacemakersDocument10 pagesThe Berenstain Bears Blessed Are The PeacemakersZondervan45% (20)

- 44.0 - Traffic Management and Logistics v3.0 EnglishDocument14 pages44.0 - Traffic Management and Logistics v3.0 EnglishEyob Yimer100% (1)

- Completion Equipment ChecklistDocument3 pagesCompletion Equipment ChecklistYougchu LuanNo ratings yet

- OISD STD 2015 OISD STD 132 Pressure Relieving DevicesDocument60 pagesOISD STD 2015 OISD STD 132 Pressure Relieving DevicesÏÂm ÂvïRâjNo ratings yet

- Spill Prevention Control and Countermeasure PlanDocument56 pagesSpill Prevention Control and Countermeasure PlanPhilip ColeNo ratings yet

- LPG StandardsDocument115 pagesLPG StandardsKatie RamirezNo ratings yet

- Lifting Equipment Controller NotesDocument5 pagesLifting Equipment Controller NotesHitesh GuptaNo ratings yet

- RP 122Document14 pagesRP 122Niraj Srivastava100% (1)

- SOP-015-Testing of H2S, CO2 & H2O in Sales GasDocument9 pagesSOP-015-Testing of H2S, CO2 & H2O in Sales GasAmnaKamranNo ratings yet

- GDN 197Document21 pagesGDN 197Arvind BharadwajNo ratings yet

- Bottom-And Top Loading Arms For Liquefied GasesDocument4 pagesBottom-And Top Loading Arms For Liquefied GasesprabhuarunkumarNo ratings yet

- STD 135Document26 pagesSTD 135Mathan Selva Kumar ANo ratings yet

- Installing an ESGI 2 LPG Supply SystemDocument27 pagesInstalling an ESGI 2 LPG Supply SystemKhateeb RehmanNo ratings yet

- OISD RP-124 Predictive Maintenance Practices GuideDocument22 pagesOISD RP-124 Predictive Maintenance Practices GuideNanu PatelNo ratings yet

- Marquard Bahls Annual Report 2018 en WebDocument72 pagesMarquard Bahls Annual Report 2018 en WebMercury ManNo ratings yet

- Rules and Regulations for Contractors at Oil FacilitiesDocument60 pagesRules and Regulations for Contractors at Oil FacilitiesanggaNo ratings yet

- C.02 - Gas-Freeing and Cleaning of TanksDocument7 pagesC.02 - Gas-Freeing and Cleaning of TanksmkkamarajNo ratings yet

- Sop-003-Rvp of Crude Oil LPG and NGLDocument8 pagesSop-003-Rvp of Crude Oil LPG and NGLAmnaKamranNo ratings yet

- Work Permit RequirementsDocument1 pageWork Permit RequirementsBenedito Cossa FelicianoNo ratings yet

- OISD GDN-203 Guide on Operation, Maintenance and Inspection of Hoisting EquipmentDocument9 pagesOISD GDN-203 Guide on Operation, Maintenance and Inspection of Hoisting EquipmentRajesh Suthar100% (1)

- SOP-017-Testing of Specific Gravity of CondensateDocument9 pagesSOP-017-Testing of Specific Gravity of CondensateAmnaKamranNo ratings yet

- D.09 - Vehicle Entry Permit FormDocument1 pageD.09 - Vehicle Entry Permit FormBenedito Cossa FelicianoNo ratings yet

- Tank Lorry Filling GantryDocument21 pagesTank Lorry Filling GantrySiddharth BarmanNo ratings yet

- Terminal Booklet Vopak Worldwide 2008Document102 pagesTerminal Booklet Vopak Worldwide 2008Fabu Lous CeeNo ratings yet

- Basic Mechanical-ReqrmntDocument14 pagesBasic Mechanical-Reqrmntadel rihanaNo ratings yet

- TDW Pipeline Pigging CatalogDocument135 pagesTDW Pipeline Pigging CatalogShaho Abdulqader Mohamedali100% (1)

- T&C Air BalancingDocument4 pagesT&C Air BalancingAzwan SunlineNo ratings yet

- OISD-RP-182 Guidelines Workover StimulationDocument46 pagesOISD-RP-182 Guidelines Workover StimulationArvind Bharadwaj100% (1)

- OISD Guidelines for Environmental Audit in Oil & GasDocument32 pagesOISD Guidelines for Environmental Audit in Oil & Gasmasoud132No ratings yet

- Work Permit System Standard RevisionDocument27 pagesWork Permit System Standard Revisionakv9005100% (1)

- Cold Work Permit Safety ChecklistDocument1 pageCold Work Permit Safety ChecklistBenedito Cossa FelicianoNo ratings yet

- Ibn Mujahid and Seven Established Reading of The Quran PDFDocument19 pagesIbn Mujahid and Seven Established Reading of The Quran PDFMoNo ratings yet

- The Influence of Leadership and Organizational Commitment On Employee Performance Through Working Disciplines As Intervening VariablesDocument22 pagesThe Influence of Leadership and Organizational Commitment On Employee Performance Through Working Disciplines As Intervening VariablesHendra SaputraNo ratings yet

- Port Operations Manual 2002Document67 pagesPort Operations Manual 2002markie supieNo ratings yet

- Ibañez v. People: GR No. 190798. January 27, 2016Document2 pagesIbañez v. People: GR No. 190798. January 27, 2016Tootsie GuzmaNo ratings yet

- Landman Training ManualDocument34 pagesLandman Training Manualflashanon100% (2)

- Oisd 161Document20 pagesOisd 161Arvind BharadwajNo ratings yet

- Opentext Vendor Invoice Management For Sap: Product Released: 2020-10-30 Release Notes RevisedDocument46 pagesOpentext Vendor Invoice Management For Sap: Product Released: 2020-10-30 Release Notes RevisedkunalsapNo ratings yet

- Oisd STD 127Document23 pagesOisd STD 127Priyank SutariyaNo ratings yet

- D.06 - Hot Work Permit FormDocument1 pageD.06 - Hot Work Permit FormBenedito Cossa FelicianoNo ratings yet

- Non-Aviation Fuel Quality ManualDocument142 pagesNon-Aviation Fuel Quality Manualraj dasNo ratings yet

- Chopin SongsDocument8 pagesChopin Songsgstewart_pianoNo ratings yet

- Oisd 161Document37 pagesOisd 161poojaupesNo ratings yet

- 351-2 English Prose - UsagesDocument171 pages351-2 English Prose - UsagesKritika 12No ratings yet

- Field Inspection and Handling Guidelines for Casing and TubingDocument23 pagesField Inspection and Handling Guidelines for Casing and TubingMitul PatelNo ratings yet

- Application Format For Seeking Certified CopiesDocument1 pageApplication Format For Seeking Certified CopiessinghcybercafeNo ratings yet

- Fas 13Document6 pagesFas 13LPG Equipment Consulting and ServicesNo ratings yet

- Oisd STD-225Document43 pagesOisd STD-225Manoj SharmaNo ratings yet

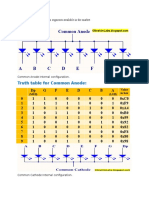

- Truth Table For Common AnodeDocument3 pagesTruth Table For Common AnodeSisay ADNo ratings yet

- LPG Cylinder Filling Machine MK17-2.Document4 pagesLPG Cylinder Filling Machine MK17-2.mohsin mohammadNo ratings yet

- SHE Training For Exploration & Production PersonnelDocument1 pageSHE Training For Exploration & Production PersonnelArun Bhati0% (2)

- IS2808 Storage Tank Capacity TablesDocument28 pagesIS2808 Storage Tank Capacity TablesKatie RamirezNo ratings yet

- Salient Features and Revival of Polluted Powai Lake in MumbaiDocument24 pagesSalient Features and Revival of Polluted Powai Lake in MumbaiShamika Ayre0% (1)

- LPG SamplerDocument2 pagesLPG SamplerAibiNo ratings yet

- OISD 225 ROs Oct2010Document17 pagesOISD 225 ROs Oct2010taranakgecNo ratings yet

- Oisd GDN 168Document40 pagesOisd GDN 168sgh135550% (2)

- Codes of Practice For BMDDocument8 pagesCodes of Practice For BMDKuldeep SinghNo ratings yet

- Oisd STD 170Document26 pagesOisd STD 170Nanu PatelNo ratings yet

- High Court Judgment on LPG Distributorship TransfersDocument42 pagesHigh Court Judgment on LPG Distributorship TransfersMahesh RadeNo ratings yet

- Pol Tanklorry Design & Safety: OISD - RP-167 For Restricted CirculationDocument28 pagesPol Tanklorry Design & Safety: OISD - RP-167 For Restricted CirculationKiran KumarNo ratings yet

- MOC FinalDocument40 pagesMOC FinalAvinash MuralaNo ratings yet

- Safe Storage and Dispensing of Fuels at Petrol StationsDocument42 pagesSafe Storage and Dispensing of Fuels at Petrol StationsGyan KumarNo ratings yet

- Oisd STD 175Document59 pagesOisd STD 175yandiNo ratings yet

- CV Daud SitorusDocument8 pagesCV Daud SitorusDaud SitorusNo ratings yet

- Boletim Jig 106Document10 pagesBoletim Jig 106Alexandre SaraNo ratings yet

- Insulation Work TermsDocument5 pagesInsulation Work TermsRishabh VermaNo ratings yet

- Alert Space SOPDocument3 pagesAlert Space SOPAMIT PAWARNo ratings yet

- Contractor safety policy overviewDocument8 pagesContractor safety policy overviewglenn umaliNo ratings yet

- Swing Lift FV500Document24 pagesSwing Lift FV500vladcccNo ratings yet

- Executive Order No. 01-s-2023 (BDC)Document2 pagesExecutive Order No. 01-s-2023 (BDC)kencyrilachasNo ratings yet

- Impact of Pop Culture On PoliticsDocument3 pagesImpact of Pop Culture On PoliticsPradip luitelNo ratings yet

- Mary Rieser "Things That Should Not Be"Document22 pagesMary Rieser "Things That Should Not Be"Tony OrtegaNo ratings yet

- Punishment For Offences Against The StateDocument3 pagesPunishment For Offences Against The StateMOUSOM ROYNo ratings yet

- Khilafat Movement 1919 1924Document4 pagesKhilafat Movement 1919 1924obaidNo ratings yet

- (Rev.00) Offer For Jain Solar 15 HP Ac Pumping System - 03.12.2020Document5 pages(Rev.00) Offer For Jain Solar 15 HP Ac Pumping System - 03.12.2020sagar patoleNo ratings yet

- BANKERS INDEMNITY INSURANCE POLICY WORDING (Com)Document12 pagesBANKERS INDEMNITY INSURANCE POLICY WORDING (Com)maddy honeyNo ratings yet

- Affidavit of Consent-JonaDocument1 pageAffidavit of Consent-Jonajude thaddeus estoquiaNo ratings yet

- AsfsadfasdDocument22 pagesAsfsadfasdJonathan BautistaNo ratings yet

- Education in The Face of Caste: The Indian CaseDocument13 pagesEducation in The Face of Caste: The Indian CaseParnasha Sankalpita BhowmickNo ratings yet

- Socrates vs. Commission On Elections, G.R. No. 154512 - Case DigestDocument2 pagesSocrates vs. Commission On Elections, G.R. No. 154512 - Case DigestAlena Icao-AnotadoNo ratings yet

- Block Class Action LawsuitDocument53 pagesBlock Class Action LawsuitGMG EditorialNo ratings yet

- Latur District JUdge-1 - 37-2015Document32 pagesLatur District JUdge-1 - 37-2015mahendra KambleNo ratings yet

- Prince SmartFit CPVC Piping System Price ListDocument1 pagePrince SmartFit CPVC Piping System Price ListPrince Raja38% (8)

- DAC88094423Document1 pageDAC88094423Heemel D RigelNo ratings yet

- RP-new Light DistrictsDocument16 pagesRP-new Light DistrictsShruti VermaNo ratings yet

- Brief History of PhilippinesDocument6 pagesBrief History of PhilippinesIts Me MGNo ratings yet

- CASE BRIEF Switzerland v. Nigeria San Pedro Pio Case PDFDocument3 pagesCASE BRIEF Switzerland v. Nigeria San Pedro Pio Case PDFDILG STA MARIANo ratings yet

- 14-1 Mcdermott PDFDocument12 pages14-1 Mcdermott PDFDavid SousaNo ratings yet

- FM ReportDocument2 pagesFM Reportcaiden dumpNo ratings yet