Professional Documents

Culture Documents

G77XK Series Installation and Operation Instruction: Electrohydraulic Servovalve Intrinsic Safety Protected

Uploaded by

Rene GonzalezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

G77XK Series Installation and Operation Instruction: Electrohydraulic Servovalve Intrinsic Safety Protected

Uploaded by

Rene GonzalezCopyright:

Available Formats

1.

INTRODUCTION

This manual provides instructions and procedures necessary to install, operate and troubleshoot the Moog Inc. Series G771K/G772K/G773K (simplified as G77XK) intrinsic safety protected industrial servovalve. It can also be used for Moog Series 77XK servovalves. The G77XK series valves are electrical equipment for hazardous areas requiring intrinsic safety or non-incendive protection.The identification is II 1G Ex ia IIC/IIB T4 KEMA 02ATEX1015 X, or II 3G Ex nA II T3 KEMA 02ATEX1016 X, 0344 per ATEX directive 94/9/EC.They are intended for directional, position, velocity, pressure and force control in hydraulic control systems that operate with mineral oil based fluids. Others on request.

G77XK Series Installation and Operation Instruction Electrohydraulic Servovalve Intrinsic Safety Protected

2. OPERATION

The Moog G77XK series industrial servovalve consists of a polarized electrical torque motor and two stages of hydraulic power amplification.The motor armature extends into the air gaps of the magnetic flux circuit and is supported in this position by a flexure tube member.The flexure tube acts as a seal between the electromagnetic and hydraulic sections of the valve.The two motor coils surround the armature, one on each side of the flexure tube. The flapper of the first stage hydraulic amplifier is rigidly attached to the midpoint of the armature.The flapper extends through the flexure tube and passes between two nozzles, creating two variable orifices between the nozzle tips and the flapper.The pressure controlled by the flapper and nozzle variable orifice is fed to the end areas of the second stage spool. The second stage is a conventional four-way spool design in which output flow from the valve, at a fixed valve pressure drop, is proportional to spool displacement from the null position.A cantilever feedback spring is fixed to the flapper and engages a slot at the center of the spool. Displacement of the spool deflects the feedback spring which creates a force on the armature/flapper assembly.

ELECTROHYDRAULIC VALVE CUT-AWAY

Magnet (not shown) Coil Armature Nozzle Spool Filter Upper Polepiece Flexure Sleeve Lower Polepiece Flapper Feedback Wire

DISASSEMBLY, MAINTENANCE, OR REPAIR OTHER THAN IN ACCORDANCE WITH THE INSTRUCTIONS HEREIN OR OTHER SPECIFIC WRITTEN DIRECTIONS FROM MOOG WILL INVALIDATE MOOGS OBLIGATIONS UNDER ITS WARRANTY AND YIELD THE INTRINSICALLY SAFE PROTECTION PERMIT NULL AND VOID.

CAUTION

P Figure 1 Moog Series G77XK

Inlet Orifice

Input signal induces a magnetic charge in the armature and causes a deflection of the armature and flapper. This assembly pivots about the flexure tube and increases the size of one nozzle orifice and decreases the size of the other. This action creates a differential pressure from one end of the spool to the other and results in spool displacement. The spool displacement transmits a force to the feedback wire which opposes the original input signal torque. Spool movement continues until the feedback wire force equals the input signal force.

5. HYDRAULIC SYSTEM PREPARATION

To prolong servovalve operational life and to reduce hydraulic system maintenance, it is recommended that the hydraulic fluid be kept at a cleanliness level of ISO DIS 4406 Code 16/13 maximum, 14/11 recommended. The most effective filtration scheme incorporates the use of a kidney loop or off-line filtration as one of the major filtration components. The filter for the off-line filtration scheme should be a 375 filter for maximum effectiveness. Upon system startup and prior to mounting the servovalve, the entire hydraulic system should be purged of built-in contaminating particles by an adequate flushing. The servovalve should be replaced by a flushing manifold and the hydraulic circuit powered up under conditions of fluid temperature and fluid velocity, reasonably simulating normal operating conditions. New system filters are installed during the flushing process whenever the pressure drop across the filter element becomes excessive. The flushing processes should turn over the fluid in the reservoir between fifty to one hundred times. To maintain a clean hydraulic system, the filters must be replaced on a periodic basis. It is best to monitor the pressure drop across the filter assembly and replace the filter element when the pressure drop becomes excessive. In addition to other filters that are installed in the hydraulic circuit, it is recommended that a large capacity, low pressure 375 filter be installed in the return line. This filter will increase the interval between filter element replacements and greatly reduce the system contamination level.

3. ELECTRICAL INFORMATION AND INTRINSICALLY SAFE CIRCUIT SAFETY PARAMETERS

a. A wide choice of coils is available for a variety of rated current requirements. The torque motor coil leads are attached to the connector so external connections can provide series, parallel or single coil operation. The valves are equipped either with an MS type connector or with pigtail leads for electrical wiring. Refer to installation drawings of the specific model for details. Servovalve coils should be driven with current to provide consistency throughout the temperature range. The G77XK valves are approved for intrinsically safe protection per EN 60079-11. The approved safety parameters are listed in the following table for all the coils used by G77XK series. Coil number is marked on the valve nameplate.

b.

6. INSTALLATION

Coil Configuration EX Marking Ui (MAX) Ii (MAX)

G4220-031 (single, series, parallel) G4220-051/098 (single, series, parallel) G4221-001 G4220-042 (single) G4221-001 G4220-042 (single) G4220-031 (single, parallel) G4220-031 (series) G4220-051/098 (single, parallel) G4220-051/098 (series)

Ex ia IIB T4 Ex ia IIB T4 Ex ia IIC T4 Ex ia IIC T4 Ex ia IIC T4 Ex ia IIC T4 Ex ia IIC T4 Ex ia IIC T4

12 V 12 V 16 V 24.4 V 30 V 30 V 30 V 30 V

120 mA 240 mA 160 mA 85 mA 26 mA 18 mA 19 mA 12.7 mA

The Moog G77XK Series Industrial Servovalve may be mounted in any position, provided the servovalve pressure, piston and return ports match respective manifold ports. The mounting pattern, port location and mounting bolts of the servovalve are shown on Figure 4. Apply a light film of oil to the screw threads and torque to 57 inch-pounds. Wire mating connector for desired coil configuration and polarity. Thread connector to valve.

7. MECHANICAL NULL ADJUSTMENT

It is often desirable to adjust the flow null of a servovalve independent of other system parameters. The mechanical null adjustment on the Moog G77XK Series servovalve allows at least 20% adjustment of flow null. The mechanical null adjustor is an eccentric bushing retainer pin located above the port designation on the valve body (see Figure 2) which, when rotated, provides control of the bushing position. Mechanical feedback elements position the spool relative to the valve body for a given input signal. Therefore, a movement of the bushing relative to the body changes the flow null.

c.

The G77XK valves are approved for non-incendive operation for supply current not to exceed 50 mA dc. When making electric connections to the valve, appropriate measures must be taken to ensure that locally different earth potential do not result in excessive ground currents. When barriers are required for the hazardous location, hazardous area (field) wiring must meet the requirements of the barrier manufacturer. All barriers must be mounted and installed in compliance with the barrier manufacturers requirements. Twisted pairs of 18-20 gage wire are recommended. If shielded wire is used, connect shield wire to earth ground only at the barrier strip.

d.

4. SPECIAL CONDITIONS FOR SAFE USE

Because the enclosure of the apparatus is made of aluminum, if it is mounted in an area where the use of category 1 G apparatus is required, it must be installed such that even in the event of rare incidents, ignition sources due to impact and friction sparks are excluded. When the electrohydraulic servovalve is used in an application for type of explosion protection intrinsic safety i, the appropriate box on the data label must be scored. When the electrohydraulic servovalve is used in an application for type of explosion protection n, the appropriate box on the data label must be scored. After use in an application for type of explosion protection n, the servovalve cannot abe safely used in a intrinsically safe application. The screwed cable connector may only be disconnected when the circuit is de-energized or when the location is known to be non-hazardous. When used at an ambient temperature 70C, heat resistant cable must be used with a continuous operating temperature in accordance with the application.

Figure 2 Mechanical Null Adjustment

Adjustment Procedure

Using a 3/8 inch offset box wrench, loosen the self-locking fitting until the null adjustor pin can be rotated. (This should usually be less than 1/2 turn). DO NOT remove self-locking fitting. Insert a 3/32 inch allen wrench in null adjustor pin. Use the 3/32 inch Allen wrench to rotate the mechanical null adjustor pin to obtain desired flow null. Torque self-locking fitting to 57 inch lbs. Note:

Clockwise rotation of null adjustor pin produces flow from port P to port B.

8. GENERAL SERVICING RECOMMENDATIONS

a. b. c. Disconnect electrical lead to servovalve. Relieve hydraulic system of residual pressure. Remove servovalve.

9. TROUBLESHOOTING CHART

The following troubleshooting chart list potential troubles encountered, probable causes, and remedies.

Potential Trouble

Servovalve does not follow input command signal. (Actuator or components are stationary or creeping slowly.) High threshold. (Jerky, possible oscillatory or hunting motion in closed loop system.) Poor response. (Servovalve output lags electrical command signal). High Null Bias. (High input current required to maintain hydraulic cylinder or motor stationary.)

Probable Cause

Plugged inlet filter element.

Remedy

Replace filter element.

Plugged filter element.

Replace filter element.

Partially plugged filter element.

Replace filter element and check for dirty hydraulic fluid in system. 1. Readjust null 2. Replace filter element and check for dirty hydraulic fluid in system.

1. Incorrect null adjustment 2. Partially plugged filter element.

Figure 3 End cap

Table 1. Replacement Parts

Part Description Qty. Part Number

Filter End Cap O-Rings Inlet Orifice O-Rings (two at each end cap)

G77XK Series Filter Replacement Kit Inlet Orifice O-Rings (1) Inlet Orifice O-Rings (1) End Cap O-Rings (1) Filter Tube (1) End Cap O-Rings (1) Base O-Rings G771K G772K G773K

(1) Included in Filter Replacement Kit.

1 2 2 2 1 2 4 4 4

B52555RK054K001 -42082-001 -42082-189 -42082-042 C39486-005-060 -42082-001 -42082-007 -42082-013 -42082-022

10. FILTER ASSEMBLY REPLACEMENT

Tools and Equipment

a. Blade screwdriver b. 3/16 Allen wrench c. Torque wrench d. Tweezers a. b. c. Remove four socket head cap screws and lockwashers using a 3/16 inch Allen wrench. Remove end caps. Remove o-rings from end caps. Remove inlet orifice assembly from both sides of body. Note: 2-56 screw threads into the inlet orifice assembly. Remove filter. The inlet orifice assemblies are matched to each other and are therefore interchangeable. Note: These assemblies seat in body and cannot go through bore during removal. Remove o-rings from inlet orifice assemblies. Visually inspect orifice assemblies for damage or foreign material. Discard o-rings and filter. Install o-rings on inlet orifices. Install filter and inlet orifice assembly in body. Inlet orifice assembly pilots into filter. Install the other inlet orifice assembly into other end of filter. Install o-rings on end caps. Install end caps on body and install four socket head cap screws and lockwashers. Torque the screws to 85 inch-pounds.

11. FUNCTIONAL CHECKOUT AND CENTERING

a. b. Install servovalve on hydraulic system or test fixture, but do not connect electrical lead. Apply required system pressure to servovalve and visually examine for evidence of external leakage. If leakage is present and cannot be rectified by replacing o-rings, remove the discrepant component and return for repair or replacement. Note: If the system components are drifting or hardover, adjust the mechanical null of the servovalve. Connect electrical lead to servovalve and check phasing in accordance with system requirements.

c.

12. AUTHORIZED REPAIR FACILITIES

If servovalve continues to malfunction after all recommended corrective action procedures are performed, defective valve should be returned to Moog for repair. Moog does not authorize any facilities other than Moog or Moog subsidiaries to repair its servovalves. It is recommended you contact Moog at (716) 652-2000 to locate your closest Moog repair facility. Repair by an independent (unauthorized) repair house will result in voiding the Moog warranty and could lead to performance degradation or safety problems.

d. e. f. g. h. i. j.

13. DECLARATION OF MANUFACTURER

An EC Declaration of Conformity according to Council Directive 94/9/EC is supplied with each servovalve.

G77XK SERIES INSTALLATION AND OPERATION INSTRUCTION

1.88 47.8 2.550 64.77 1.275 32.39 1.88 47.8

NOTES

1 Fluid: Industrial type petroleum base hydraulic fluid, maintained to ISO DIS 4406 Code 14/11 recommended. 2 Operating Temperature Range: -20F [-29C] to +275F [+135C] unless otherwise specified on nameplate.

1.343 34.11

1.12 MAX [28.4] (OPTION) 1.39 MAX 35.3

4X .221(5.61) THRU (G771 AND G772) .014 OR 4X .265(6.73) THRU (G773) .007

1.06 26.9 1.00 25.4 .671 17.04

.844 21.44 1.688 42.88 ELECTRICAL CONNECTOR PIN D PIN C PIN A PIN B 2.12 53.8

3 Valve Phasing: Flow out port B results when Series coils: B & C connected,A+, D-; Parallel coils:A & C connected, B & D connected; Single coil:A+, B-, or C+, D-. 4 Ports: See table below left. 5 Surface: Surface to which valve is mounted requires 32 [ ] finish, flat within 0.002 [0.05] TIR. 6 Null Adjust: Flow out port B results with clockwise rotation of null adjust screw (3/32 hex key). Flow bias is continually varied for a given port as the null adjust is rotated.

2.81 71.4 1.03 26.2 LOCATING PIN EXTERNAL NULL ADJUST 3/32 IN. HEX SOCKET

2.18 55.4 P

1.56 39.6

1.75 44.5 MTG HGT

X F1 Y A G F2 P B

.062 1.57

.12 MAX 3.0

TYPICAL WIRING SCHEMATIC

TT

F4

G771K

P X Y 0.84 0.36

F3

A B 3 C D METRIC

U.S.

A 0.53 0.67 B 1.16 0.67 T 0.84 0.98 G 0.45 0.17 F1 0 0 F2 1.69 0 F3 1.69 1.34 F4 0 1.34

P 4.85 X Y 21.3 9.1

A 4.85 13.5 17.0

B 4.85 29.5 17.0

T 4.85 21.3 24.9

G 2.39 11.4 4.3

F1 M5 0 0

F2 M5 42.9 0

F3 M5 42.9 34.0

F4 M5 0 34.0

.191 .191 .191 .191 .094 .190-32 .190-32 .190-32 .190-32

G772K

P X Y 0.84 0.28

U.S.

A 0.45 0.67 B 1.23 0.67 T 0.84 1.06 G 0.45 0.17 F1 0 0 F2 1.69 0 F3 1.69 1.34 F4 0 1.34

METRIC

P 6.6 X Y 21.3 7.2 A 6.6 11.4 17.0 B 6.6 31.2 17.0 T 6.6 21.3 27.0 G 2.39 11.4 4.3 F1 M5 0 0 F2 M5 42.9 0 F3 M5 42.9 34.0 F4 M5 0 34.0

.260 .260 .260 .260 .094 .190-32 .190-32 .190-32 .190-32

G773K

P X Y 0.84 0.20

U.S.

A 0.38 0.67 B 1.31 0.67 T 0.84 1.14 G 0.45 0.17 F1 0 0 F2 1.69 0 F3 1.69 1.34 F4 0 1.34

METRIC

P 7.92 X Y 21.3 5.1 A 7.92 9.7 17.0 B 7.92 33.3 17.0 T 7.92 21.3 29.0 G 2.39 11.4 4.3 F1 M6 0 0 F2 M6 42.9 0 F3 M6 42.9 34.0 F4 M6 0 34.0

.312 .312 .312 .312 .094 .250-20 .250-20 .250-20 .250-20

Figure 4 4 Three standard designs are available. Model Number G771K G772K G773K Port Circle Diameter in mm .625 .780 .937 15.8 19.8 23.8 Port Diameter in mm .191 .260 .312 4.85 6.60 7.93 Manifold O-Rings Moog MS -007 -013 -022 -010 -012 -013 Mounting Bolt Size (socket head cap screws) .190-32 NF .190-32 NF .250-28 NF

The products described herein are subject to change at any time without notice, including, but not limited to, product features, specifications, and designs.

Moog Inc., East Aurora, NY 14052-0018 Telephone: 716/652-2000 Fax: 716/687-7910 Toll Free: 1-800-272-MOOG www.moog.com/industrial

CDS6768 RevB 500-427 0509

You might also like

- MoogDocument4 pagesMoogHamzaKadNo ratings yet

- Operation and Maintenance Manual: Maxp Series AnsiDocument40 pagesOperation and Maintenance Manual: Maxp Series AnsiCarlos GomezNo ratings yet

- RH Broschuere FNPM enDocument8 pagesRH Broschuere FNPM enTim KuNo ratings yet

- G761 CDS6673 D Moog Trubleshooting ManualDocument4 pagesG761 CDS6673 D Moog Trubleshooting ManualRamesh BabuNo ratings yet

- MD10 1 FLENDER Standard Couplings en 2011Document280 pagesMD10 1 FLENDER Standard Couplings en 2011hasanalmazbasanalir100% (1)

- Material Turbina A GásDocument47 pagesMaterial Turbina A GásGetúlio RibeiroNo ratings yet

- Final Report - NTPCDocument31 pagesFinal Report - NTPCVibhor MishraNo ratings yet

- 131-110 - Falk A-Plus Parallel and Right Angle Gear Drives - CatalogDocument118 pages131-110 - Falk A-Plus Parallel and Right Angle Gear Drives - CatalogDanilo NóbregaNo ratings yet

- F 0077 e 55Document6 pagesF 0077 e 55Bùi Cảnh TrungNo ratings yet

- February 2003 Subject: Troubleshooting Hydraulic Ratchet ProblemsDocument4 pagesFebruary 2003 Subject: Troubleshooting Hydraulic Ratchet ProblemsKarim MuhammedNo ratings yet

- Electric Barring GearDocument4 pagesElectric Barring Gearhardani100% (1)

- Proportional Control Valves ISO 4401 Size 05Document8 pagesProportional Control Valves ISO 4401 Size 05Devendra BangarNo ratings yet

- N61 1591 000 002 - CTS800 - LHTEC - Final BroDocument4 pagesN61 1591 000 002 - CTS800 - LHTEC - Final Broalper bmcNo ratings yet

- CNV 03 BDocument4 pagesCNV 03 BMaitry ShahNo ratings yet

- Compressed Gas Regulators v2 0Document12 pagesCompressed Gas Regulators v2 0RajanbabuNo ratings yet

- Operating and maintenance norms for hydraulic cylindersDocument4 pagesOperating and maintenance norms for hydraulic cylinderszsmithNo ratings yet

- Air Driven, High Pressure Liquid Pumps: Product CatalogDocument24 pagesAir Driven, High Pressure Liquid Pumps: Product CatalogCantora Franciely Viana officialNo ratings yet

- Reciprocating Diaphragm Pumps PDFDocument16 pagesReciprocating Diaphragm Pumps PDFSushil GoswamiNo ratings yet

- GT24/GT26 Operation Training Module: Jacking Oil SystemDocument15 pagesGT24/GT26 Operation Training Module: Jacking Oil SystemAli HegaigNo ratings yet

- Past and Future of Electrohydraulic ServovalvesDocument20 pagesPast and Future of Electrohydraulic Servovalves1sympatyaga100% (1)

- Pump Wear RingsDocument1 pagePump Wear RingsLaxman Singh Sankhla100% (1)

- Coupling PDFDocument68 pagesCoupling PDFmmkattaNo ratings yet

- Turbine Control Solution Parameter Reference Guide EP-DPCX18 PDFDocument352 pagesTurbine Control Solution Parameter Reference Guide EP-DPCX18 PDFMahesh DivakarNo ratings yet

- المستندDocument5 pagesالمستندMahdi HassanNo ratings yet

- Shafer™ RV-Series Rotary Vane Valve ActuatorsDocument8 pagesShafer™ RV-Series Rotary Vane Valve ActuatorsarseneNo ratings yet

- DNFT A-6348 Led-Ps PDFDocument4 pagesDNFT A-6348 Led-Ps PDFhugoheloNo ratings yet

- RCE Brochure 05 - 15Document10 pagesRCE Brochure 05 - 15Javier Alejandro Rodriguez MelgozaNo ratings yet

- Metastream TSC Coupling Iom PDFDocument4 pagesMetastream TSC Coupling Iom PDFVíctor Hugo Morales Curay100% (1)

- 218 e Cr228 en Voith-Torque-converterDocument22 pages218 e Cr228 en Voith-Torque-converterlubangjarum100% (1)

- Nireco Servojet Sj2: GeneralDocument8 pagesNireco Servojet Sj2: GeneralKen JunNo ratings yet

- Axial Comp On OffDocument4 pagesAxial Comp On OffMohamed OmarNo ratings yet

- Top Guide Control ValveDocument32 pagesTop Guide Control Valveachari_swapnilNo ratings yet

- Technical Information Letter: Excessive Gas Fuel Flow at Start-Up (F-Class)Document5 pagesTechnical Information Letter: Excessive Gas Fuel Flow at Start-Up (F-Class)Chidiebere Samuel Okogwu100% (1)

- Compressor CT Valve E 02Document2 pagesCompressor CT Valve E 02Liaqat AliNo ratings yet

- Moog Controllers MotionControllers Catalog enDocument68 pagesMoog Controllers MotionControllers Catalog enKamillAL-akhras100% (1)

- ESD White Paper From NorgrenDocument24 pagesESD White Paper From NorgrenArun BalajiNo ratings yet

- Booster PumpDocument5 pagesBooster Pumpbryesanggalang0% (1)

- Bombas Parker Pvp16Document10 pagesBombas Parker Pvp16Gustavo HuertasNo ratings yet

- Moog Pumps RKP Catalog enDocument75 pagesMoog Pumps RKP Catalog enSantiago Bonilla RiveraNo ratings yet

- Bombas Pistões, Out 07Document68 pagesBombas Pistões, Out 07edimar santanaNo ratings yet

- VH60-100 Presentation Philippe ChabinDocument46 pagesVH60-100 Presentation Philippe ChabinMohamedMansour50% (2)

- Dosing Pump (Lmi-Metering Pump)Document44 pagesDosing Pump (Lmi-Metering Pump)Arifuddin NurdinNo ratings yet

- JC-364-TSKS IOM EN Final HiRes NoCropsDocument12 pagesJC-364-TSKS IOM EN Final HiRes NoCropsFabio StuiNo ratings yet

- Guidelines For Preventing Torsional Vibration Problems in Reciprocating MachineryDocument48 pagesGuidelines For Preventing Torsional Vibration Problems in Reciprocating MachineryFabbrox100% (2)

- 9964 MFHB07343 MFHD02744 EngbDocument2 pages9964 MFHB07343 MFHD02744 Engbnvkjayanth0% (1)

- Catalogo Bomba DiafragmaDocument19 pagesCatalogo Bomba DiafragmaMaria Jose Araya CortesNo ratings yet

- Ebara Horizontal Multistage PumpDocument27 pagesEbara Horizontal Multistage PumpYohanes KrisNo ratings yet

- Fluid Couplings - Installation, Operation and MaintenanceDocument15 pagesFluid Couplings - Installation, Operation and Maintenanceatee_hua66No ratings yet

- U.V. Flame Detectors HoneywellDocument12 pagesU.V. Flame Detectors HoneywellgabNo ratings yet

- Null Bias ControlDocument44 pagesNull Bias ControlAbderrahmane AyounNo ratings yet

- Design For Analysis of A Welded Hydraulic CylinderDocument3 pagesDesign For Analysis of A Welded Hydraulic CylindertahirNo ratings yet

- Moog ServoValves G761and761Series InstallationInstructions enDocument4 pagesMoog ServoValves G761and761Series InstallationInstructions entetsa zangetsuNo ratings yet

- Maintain & Recharge Fire ExtinguishersDocument6 pagesMaintain & Recharge Fire ExtinguishersKamal Jit DhimanNo ratings yet

- General Instruction For ApplicantsDocument32 pagesGeneral Instruction For ApplicantstomiNo ratings yet

- (G) 72K Series Installation and Operation Instruction: Electrohydraulic ServovalveDocument4 pages(G) 72K Series Installation and Operation Instruction: Electrohydraulic Servovalvephankhoa83-1No ratings yet

- Metrix 5550 Manual M8905Document8 pagesMetrix 5550 Manual M8905manuelNo ratings yet

- BELIMO LMX120-3 ActuadorDocument5 pagesBELIMO LMX120-3 ActuadordcarunchioNo ratings yet

- Chapter 3. Alternator: 1. DescriptionDocument21 pagesChapter 3. Alternator: 1. DescriptionGabriel QuijadaNo ratings yet

- 27CX25BDocument63 pages27CX25BguenardwNo ratings yet

- Globe Valve Type Flow Switch: DescriptionDocument4 pagesGlobe Valve Type Flow Switch: DescriptiongoparsucoNo ratings yet

- 9FB Gas TurbineDocument2 pages9FB Gas TurbineRene GonzalezNo ratings yet

- MOOG SERVO VALVES 771 772 773 SeriesDocument0 pagesMOOG SERVO VALVES 771 772 773 SeriesRene GonzalezNo ratings yet

- Short Circuit and Arc FlashDocument20 pagesShort Circuit and Arc FlashRene GonzalezNo ratings yet

- Turbine Supervisory Instrumentation Selection Guide - RockwellDocument52 pagesTurbine Supervisory Instrumentation Selection Guide - Rockwellhozipek100% (1)

- Gas Turbine Technology Helping TEPCODocument2 pagesGas Turbine Technology Helping TEPCORene GonzalezNo ratings yet

- Partial Oxidation Gas Turbine CycleDocument9 pagesPartial Oxidation Gas Turbine CycleRene GonzalezNo ratings yet

- Hybrid Gas Turbine Fuel Cell SystemsDocument37 pagesHybrid Gas Turbine Fuel Cell SystemsRene Gonzalez100% (1)

- Ger 3952aDocument3 pagesGer 3952aMohamed LabibNo ratings yet

- 6FA Spanish Refinery DGTWW Dec2010Document2 pages6FA Spanish Refinery DGTWW Dec2010Rene GonzalezNo ratings yet

- 1.2.1 - Different Types of Gasifiers and Their Integration With Gas TurbinesDocument11 pages1.2.1 - Different Types of Gasifiers and Their Integration With Gas TurbinesRene GonzalezNo ratings yet

- 1 3 2Document7 pages1 3 2jimi7No ratings yet

- Hydrogen Fueled Power SystemsDocument9 pagesHydrogen Fueled Power SystemsRene GonzalezNo ratings yet

- 1.3.1.2 - Clean Energy SystemsDocument21 pages1.3.1.2 - Clean Energy SystemsRene GonzalezNo ratings yet

- Graz Cycle - A Zero Emission Power Plant of Highest EfficiencyDocument15 pagesGraz Cycle - A Zero Emission Power Plant of Highest EfficiencyRene GonzalezNo ratings yet

- 1.2.2 - Implications of CO2 Sequestration For Gas TurbinesDocument5 pages1.2.2 - Implications of CO2 Sequestration For Gas TurbinesRene GonzalezNo ratings yet

- 1.2 - Integrated Coal Gasification Combined CycleDocument11 pages1.2 - Integrated Coal Gasification Combined CycleRene GonzalezNo ratings yet

- Gas Turbines A Manual PDFDocument74 pagesGas Turbines A Manual PDFHenry Pannell100% (1)

- English LanguageDocument15 pagesEnglish LanguageRene GonzalezNo ratings yet

- Gas Turbines A Manual PDFDocument74 pagesGas Turbines A Manual PDFHenry Pannell100% (1)

- R500 Users GuideDocument94 pagesR500 Users GuideRene GonzalezNo ratings yet

- Protective Gear for SafetyDocument19 pagesProtective Gear for SafetyRene Gonzalez100% (1)

- InfoVista Planet 5G NRDocument32 pagesInfoVista Planet 5G NRDenmark Wilson100% (8)

- The Use of Silicone Materials in Close Proximity PDFDocument4 pagesThe Use of Silicone Materials in Close Proximity PDFLBNo ratings yet

- TX-1000 OwnerManualDocument16 pagesTX-1000 OwnerManualPato LankenauNo ratings yet

- Media Queries PDFDocument18 pagesMedia Queries PDFFernando SalazarNo ratings yet

- Indoor & Outdoor Lighting: Better Light ... Better LifeDocument44 pagesIndoor & Outdoor Lighting: Better Light ... Better Lifemorad omr100% (2)

- Model G PressDocument2 pagesModel G Pressbeach_lover_1970No ratings yet

- M7996v1.1 Parte1Document8 pagesM7996v1.1 Parte1lakekosNo ratings yet

- Raindropz Remix - YouTubeDocument3 pagesRaindropz Remix - YouTubeGary DiazNo ratings yet

- Frameless09072012C PampDocument8 pagesFrameless09072012C PampLeandro Francisco da SilvaNo ratings yet

- AgentInstallGuide enDocument56 pagesAgentInstallGuide enshikhanirankariNo ratings yet

- Logarithmic Amplifier: BE o Be Be oDocument1 pageLogarithmic Amplifier: BE o Be Be oJoseGarciaRuizNo ratings yet

- PowerDocument2 pagesPowerraymond baliteNo ratings yet

- Introduction of The ILS, VOR, DMEDocument43 pagesIntroduction of The ILS, VOR, DMEChiranjivi Kuthumi100% (1)

- Ov7670 TestDocument3 pagesOv7670 TestAhmad Arif SaktiNo ratings yet

- Price Miadri Grup 07.02Document158 pagesPrice Miadri Grup 07.02Arteom DobîndăNo ratings yet

- Admissibility of Electronic Evidence in CourtsDocument22 pagesAdmissibility of Electronic Evidence in CourtsNasir ZamanNo ratings yet

- Holmarc Lab EquipmentsDocument24 pagesHolmarc Lab EquipmentsatswallaNo ratings yet

- Panasonic Ag dvx100 Ag Dvx100be Manual Do UtilizadorDocument12 pagesPanasonic Ag dvx100 Ag Dvx100be Manual Do UtilizadorAnderson Assis MansanoNo ratings yet

- Chapter17 Corrosion&DegradationofMaterials PDFDocument84 pagesChapter17 Corrosion&DegradationofMaterials PDFAngelaNo ratings yet

- Earth Station Block Diagram Study: Section 5Document213 pagesEarth Station Block Diagram Study: Section 5Extreme DaysNo ratings yet

- dp120 47ltmiDocument1 pagedp120 47ltmiSandroCezardeAraujoNo ratings yet

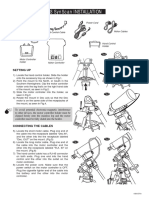

- Aprstracker - SkyTracker-Rev250309Document9 pagesAprstracker - SkyTracker-Rev250309John HaycoxNo ratings yet

- EQ3 SynScan INSTALLATION guideDocument1 pageEQ3 SynScan INSTALLATION guideOscar MalamudNo ratings yet

- Quantum Q-VISION HF Series BrochureDocument6 pagesQuantum Q-VISION HF Series BrochureReverieM100% (1)

- List of Companies Empanelled With UPDESCODocument5 pagesList of Companies Empanelled With UPDESCOriju nairNo ratings yet

- Tnstrument Transformers (CT, PT) TheoryDocument6 pagesTnstrument Transformers (CT, PT) TheorySARAVANANo ratings yet

- Product Sheet: Nibp100D Noninvasive Blood Pressure Monitoring SystemDocument3 pagesProduct Sheet: Nibp100D Noninvasive Blood Pressure Monitoring SystemSadegh ShebaniNo ratings yet

- NVIDIA QuestionsDocument5 pagesNVIDIA QuestionsJibin P John0% (1)

- Fusealloy Fabrication Guidelines 2016Document25 pagesFusealloy Fabrication Guidelines 2016Vitor Rigueira de GodoyNo ratings yet

- List of Scilab CodesDocument68 pagesList of Scilab CodesOscar Sttewe Jaehnig BarriosNo ratings yet