Professional Documents

Culture Documents

49 360 (49NDTP) - R03 27 02

Uploaded by

mullanjiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

49 360 (49NDTP) - R03 27 02

Uploaded by

mullanjiCopyright:

Available Formats

NONDESTRUCTIVE TESTING FOR STEEL PIPE PILING Steel pipe piling at shall receive nondestructive testing (NDT) in conformance

with these special provisions. Nondestructive Testing of Welds made at a Permanent Facility Nondestructive testing of welding performed in conformance with the requirements of API 5L shall conform to the following criteria: A. The manufacturer shall provide to the Engineer a VHS videocassette recording of the actual product testing, when radiological testing is utilized, or the actual radiographic film when film radiography is utilized. This videocassette or film submittal shall be provided to the Engineer for review prior to shipment of the product from the manufacturing facility. B. Ultrasonic testing of seam welds produced by the electric resistance welding process (ERW) shall comply with API 5L, SR17 utilizing a type V10 notch, N10 notch, or a 3.2 mm drilled hole. C. The ultrasonic equipment shall utilize transducers oscillating at frequencies between 2 and 5 megahertz. D. When the pipe ends of seam welds produced by the submerged arc welding process (SAW) are inspected by ultrasonic methods in accordance with API 5L Paragraph 9.7.4, the acceptance criteria shall be based on a type N5 notch or a 1.6 mm drilled hole. E. When film radiography is utilized to inspect pipe ends or repairs, the transmitted film density shall be 2.0 to 4.0 in the area of interest (weld, base metal, and IQI). F. Repaired defects shall be re-inspected utilizing the NDT method that originally detected the defect, except that film radiography may be utilized for inspection of repairs when the defect was originally detected utilizing real time imaging or radiological testing. Nondestructive testing of welding performed in conformance with AWS D1.1 shall be in conformance with the following criteria: A. Twenty-five percent of each longitudinal, circumferential, or spiral weld made at a permanent fabrication facility shall receive NDT. If repairs are required in a portion of the tested weld, the repaired portion shall receive NDT, and additional NDT shall be performed on untested portions of the weld. The additional NDT shall be made on both sides of the repair area for a length equal to 10 percent of the length of the pipe's outside circumference. After this additional 20 percent of NDT is performed, and if more repairs are required, the total cumulative repair lengths from all NDT shall be determined and documented. If the cumulative weld repair length is determined to be equal to or more than 10 percent of the length of the pipe outside circumference, then the entire weld shall receive NDT. B. Circumferential or longitudinal welds shall receive NDT by either radiographic, real time imaging systems, or ultrasonic methods that are in conformance with the requirements in AWS D1.1. C. The acceptance and repair criteria for ultrasonic testing (UT) shall conform to the requirements in AWS D1.1, Section 6, Table 6.3 for cyclically loaded nontubular connections. The acceptance and repair criteria for radiographic or real time image testing shall conform to the requirements of AWS D1.1 for tensile stress welds.

Nondestructive Testing of Field Welds Nondestructive testing of field welds shall be in conformance with these special provisions. Personnel performing ultrasonic testing (UT) for field welds will be required to verify their qualifications prior to performing nondestructive testing by both written and practical exams. Information regarding these exams is available at the Transportation Laboratory. At the option of the Contractor, either ultrasonic testing (UT) or radiographic testing (RT) shall be used as the method of NDT for splices made by field welding steel pipe piling. This NDT shall be used for each field weld, including welds that are made onto a portion of the steel pipe piling that has been installed and any repair made to a splice weld. Testing shall be done at locations selected by the Engineer. The length of a splice weld, not including repairs, where NDT is to be performed, shall have a cumulative weld length that is equal to 25 percent of the pipe outside circumference. The Engineer may select several locations on a given splice for NDT. The cover pass shall be ground smooth at the locations to be tested. The acceptance and repair criteria for UT shall conform to the requirements in AWS D1.1, Section 6, Table 6.3 for cyclically loaded nontubular connections. The acceptance and repair criteria for radiographic or real time image testing shall conform to the requirements of AWS D1.1 for tensile stress welds. If repairs are required in a portion of the tested weld, the repaired portion shall receive NDT, and additional NDT shall be performed on untested portions of the weld. The additional NDT shall be made on both sides of the repair area for a length equal to 10 percent of the length of the pipe's outside circumference. After this additional 20 percent of NDT is performed, and if more repairs are required, the total cumulative repair lengths from all NDT shall be determined and documented. If the cumulative weld repair length is determined to be equal to or more than 10 percent of the length of the pipe outside circumference, then the entire weld shall receive NDT. When backing rings are used, the backing ring complete joint penetration splice welds shall be inspected by RT or UT for material of thickness equal to or greater than 8 mm, or by RT for material of thickness less than 8 mm. The acceptance criteria for splice welds in backing rings shall be AWS D1.1, Section 6 and Figure 6.5 for RT, or Table 6.3 for UT.

You might also like

- Ex StickersDocument3 pagesEx StickersmullanjiNo ratings yet

- ANSI Pipe Lengths: Size Standard LengthDocument2 pagesANSI Pipe Lengths: Size Standard LengthmullanjiNo ratings yet

- Tainjin Haigang Steel Co. Ltd. (Made in China)Document2 pagesTainjin Haigang Steel Co. Ltd. (Made in China)mullanjiNo ratings yet

- Hindi English Masala TranslationDocument10 pagesHindi English Masala TranslationmullanjiNo ratings yet

- Inspection Check ListDocument3 pagesInspection Check ListmullanjiNo ratings yet

- Product Details ASTM A53Document4 pagesProduct Details ASTM A53mullanjiNo ratings yet

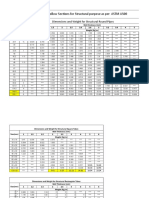

- Pre-Galvanized (Round Pipes) NPS Wall Thickness (MM) 1.5 1.8 2 3 3.2 Weight (KG/M) Outside DiameterDocument1 pagePre-Galvanized (Round Pipes) NPS Wall Thickness (MM) 1.5 1.8 2 3 3.2 Weight (KG/M) Outside DiametermullanjiNo ratings yet

- Product Specification Levels for PipesDocument14 pagesProduct Specification Levels for PipesmullanjiNo ratings yet

- Astm 500Document4 pagesAstm 500mullanjiNo ratings yet

- Zinc MTC PDFDocument1 pageZinc MTC PDFmullanjiNo ratings yet

- NPT Thread DetailsDocument1 pageNPT Thread DetailsmullanjiNo ratings yet

- API 5l Details From My SideDocument14 pagesAPI 5l Details From My SidemullanjiNo ratings yet

- BPV Stencil MarkingDocument2 pagesBPV Stencil MarkingmullanjiNo ratings yet

- ANSI Coupling Weight Chart by SizeDocument1 pageANSI Coupling Weight Chart by SizemullanjiNo ratings yet

- Inspection Check ListDocument3 pagesInspection Check ListmullanjiNo ratings yet

- Employee training recordsDocument10 pagesEmployee training recordsmullanjiNo ratings yet

- Al-Jazera Steel Factories API 5L Pipe SpecificationsDocument22 pagesAl-Jazera Steel Factories API 5L Pipe Specificationsmullanji50% (2)

- CSWIP-WI-6-92 14th Edition April 2017Document17 pagesCSWIP-WI-6-92 14th Edition April 2017mullanjiNo ratings yet

- Standard Analysis UpdatedDocument15 pagesStandard Analysis UpdatedmullanjiNo ratings yet

- Zinc MTCDocument1 pageZinc MTCmullanjiNo ratings yet

- NoiceDocument2 pagesNoicemullanjiNo ratings yet

- Supplier List: Supplier Name & Address Vendor Code Product / Services StatusDocument2 pagesSupplier List: Supplier Name & Address Vendor Code Product / Services StatusmullanjiNo ratings yet

- Hydro Test Pressure As Per UL 852 (Sprinkler Pipes) IsDocument1 pageHydro Test Pressure As Per UL 852 (Sprinkler Pipes) IsmullanjiNo ratings yet

- Performance of Galvanized Steel ProductsDocument16 pagesPerformance of Galvanized Steel ProductsAndy ChongNo ratings yet

- 46 RegionalMaterialsDocument8 pages46 RegionalMaterialsmullanjiNo ratings yet

- Pipe ThreadsDocument11 pagesPipe Threadsanac_mathNo ratings yet

- Oznake ČelikaDocument8 pagesOznake ČelikaSamra DukićNo ratings yet

- BS 1387/1985 Standard for Black and Galvanized Steel TubesDocument2 pagesBS 1387/1985 Standard for Black and Galvanized Steel TubesmullanjiNo ratings yet

- Work at Height Safety GuideDocument1 pageWork at Height Safety GuidemullanjiNo ratings yet

- M1 - 2 Welding Symbols and DrawingsDocument13 pagesM1 - 2 Welding Symbols and DrawingsmullanjiNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Wps For Akbtpl E-6013 - ModifiedDocument13 pagesWps For Akbtpl E-6013 - ModifiedvinayNo ratings yet

- Temper Designations of Magnesium Alloys, Cast and Wrought: Standard Practice ForDocument3 pagesTemper Designations of Magnesium Alloys, Cast and Wrought: Standard Practice Foramlandas08No ratings yet

- Akasison Siphonic Drainage Downpipe Systems ComponentsDocument1 pageAkasison Siphonic Drainage Downpipe Systems ComponentsebsboliviaNo ratings yet

- 02 Asae 101892Document1 page02 Asae 101892raviteja036No ratings yet

- Catalogo Thyssen PDFDocument8 pagesCatalogo Thyssen PDFbiancogallazzi0% (1)

- Recovery of Gold With Nitric AcidDocument2 pagesRecovery of Gold With Nitric AcidRodney LangleyNo ratings yet

- PE-O-ME-TRE-001-00 Technical Specification For Piping According To EN 13480 PDFDocument53 pagesPE-O-ME-TRE-001-00 Technical Specification For Piping According To EN 13480 PDFmarin cristian100% (1)

- LPS precision fastener manufacturerDocument16 pagesLPS precision fastener manufacturerHiren SonarNo ratings yet

- WeldDecayTesting TechSheet Sfs PDFDocument0 pagesWeldDecayTesting TechSheet Sfs PDFNooruddin SheikNo ratings yet

- Corrosion of Iron Experiment-StudentDocument6 pagesCorrosion of Iron Experiment-StudentKunal Ramnatsing100% (1)

- Santa Fe Symposium: Basic Metallurgy of Precious MetalsDocument33 pagesSanta Fe Symposium: Basic Metallurgy of Precious MetalsaripNo ratings yet

- DS Tri-Clamp Ferrules V1.4 PDFDocument7 pagesDS Tri-Clamp Ferrules V1.4 PDFAgustin CesanNo ratings yet

- Corrosion Glossary PDFDocument5 pagesCorrosion Glossary PDFasif_pisces100% (1)

- Astm B576Document5 pagesAstm B576iyamNo ratings yet

- DIN ISO Equivalent FastenersDocument12 pagesDIN ISO Equivalent FastenersGunnie PandherNo ratings yet

- E155-00 Aluminum & Magnesium CastingsDocument4 pagesE155-00 Aluminum & Magnesium CastingsSander Duque100% (1)

- Astm B209 B209M (2001)Document26 pagesAstm B209 B209M (2001)Asif ChougleNo ratings yet

- Pressure Vessel Plates, Carbon Steel, Manganese-Titanium For Glass or Diffused Metallic CoatingsDocument2 pagesPressure Vessel Plates, Carbon Steel, Manganese-Titanium For Glass or Diffused Metallic CoatingsNagendra KumarNo ratings yet

- Welding Quality and Structural Life Enhancement of High Strength Low Alloy Steel S460Document16 pagesWelding Quality and Structural Life Enhancement of High Strength Low Alloy Steel S460Noridzwan Nordin0% (1)

- WHO - EU Drinking Water Standards Comparative Table PDFDocument3 pagesWHO - EU Drinking Water Standards Comparative Table PDFGopalaKrishnan SivaramanNo ratings yet

- IS-209 For ZN IngotsDocument6 pagesIS-209 For ZN IngotsAnuradhaPatraNo ratings yet

- Specification: Hot Coiled Helical Springs Mainline Coaches, Emu and Freight Stock No. WD-01-HLS-94 (Rev.3)Document43 pagesSpecification: Hot Coiled Helical Springs Mainline Coaches, Emu and Freight Stock No. WD-01-HLS-94 (Rev.3)Anonymous PSNjTGUNo ratings yet

- B.A. Washers - BA Washers - : Specification For Specification ForDocument8 pagesB.A. Washers - BA Washers - : Specification For Specification ForcoolkaisyNo ratings yet

- Some Investigations On The Corrosion of IronDocument6 pagesSome Investigations On The Corrosion of IronHannah MercadoNo ratings yet

- Astm B479 19Document3 pagesAstm B479 19mohamedsamireldeep70No ratings yet

- Material Technology MSQ QuestionDocument2 pagesMaterial Technology MSQ QuestionRupesh KamatNo ratings yet

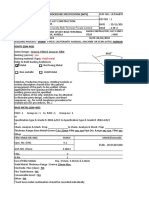

- Curriculam Vitae Ismail TP: Division, Aries Group of Companies Email: Employee ID: AG00002510Document6 pagesCurriculam Vitae Ismail TP: Division, Aries Group of Companies Email: Employee ID: AG00002510Ismail TpNo ratings yet

- Ugiweb 913082Document128 pagesUgiweb 913082psychedelic_lullabyNo ratings yet

- IISCO Steel Plant Daily Cast Analysis ReportsDocument23 pagesIISCO Steel Plant Daily Cast Analysis ReportsBinod Kumar PadhiNo ratings yet

- Martindale SawsDocument64 pagesMartindale SawsMann Sales & MarketingNo ratings yet