Professional Documents

Culture Documents

50 Kva Distribution Transformer New

Uploaded by

Trip LangOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

50 Kva Distribution Transformer New

Uploaded by

Trip LangCopyright:

Available Formats

A Proposed 37.

5KVA, 1, Distribution Transformer

Design a Transformer to meet the following Specification:

Type of Distribution : CORE

Output in KVA : 37.5kVA

Primary (HT) Volts : 2400 V

Secondary (LT) Volts : 240/120 V (multi-tap)

Frequency : 60 Cycle

Efficiency at Unity Power Factor

Full Load : 98.4 %

Load : 97.8 %

Temperature rise not to exceed to 55c

CALCULATIONS:

Guaranteed Losses:

Total Loss at Full Load

Total Loss at Full Load

Full Load Copper Loss

Core Loss

y Item 1. Voltage Per Turn use c = 62(core type distribution transformer)

= 3.1233 volts

y Item 2 to 4. Primary and Secondary Turns. It is desirable to use Two coils on the High

Tension Side and Four coils of the Low Tension Side.

Total Secondary Turns =

= 76 turns

Turns per Secondary coils =

= 19 turn/coil

Total Primary Turns = =760 turns

Turns per Primary coils =

= 384 turn/coil

y Item 5. Full Load Current

High Tension Low Tension

y Item 6 to 15. Before deciding upon the sizes of wire in the windings, it would be advisable to

the probable dimensions of the opening or window, which must accommodate both primary

and secondary windings. (assume Current Density = 1500 amp/sq. inch)

o Space factor =

o H x D=

inch

o D 4.5 inch

o inch

y the flux in the iron is

y From art 130. We select 70000 lines per sq. in as a trial density in the limbs under windings.

Hence the proportion S = 1.5L and stacking factor of 0.9

inch

inch inch

y Assuming M=L, the same cross section of iron and the same flux density in the end of the core

as in the limbs under windings M= 3.5 inch

y Weight of iron

Weight of iion

y Total core loss watts per pound of B= 70000 be 0.75 from fig. 154

Size of Wires And Winding Particulars

y Thickness CSA / Width

Length of winding space in the Layer = 11.25-0.5 = 10.75 (from fig.)

Width of one Conductor including insulation =

Cotton Coverings = 0.02 in (20 mils)

Width of Copper = 0.56579-0.02 = 0.54579 inch

Thickness =

= 0.285 inch

y For rectangular conductor

y For high tension side select the size of wire at the table on page 431 use size No.7 DCC wire

Length of winding Layer = 10.5 (from fig.)

Number of Wires per Layer = 10.5 x 6.36 = 66.78

where 6.35 is obtained from the wire table on page 431.

y Total Number of Layers of Wire

(for each 2 limbs)

y Volts (RMS)

y It is usual to limit the potential difference between layers which can generally be accomplish the

number of windings in the sufficient number of separate coils providing adequate insulation

between coils with core dimension. Thickness of copper and insulation is computed as follows.

y Item 16 to 23.

Materials Radial Thickness

Cotton tape binding assembled laminations

Varnished cambric

Pressboard

Clearance

0.018

0.010

0.030

0.067

t = 0.125

Inner L.T. coil (one layer) including cotton on wire

Parchment paper (0.010) between coils; allow

Outer L.T. coil (one layer)

0.305

0.015

0.305

s = 0.625

Pressboard around outer L.T. coil

Spacers of treated wood to form oil ducts

Pressboard

Two layers cotton tape

Parchment paper w/ crimped edges on w/c primary and

secondary coil will be wound

0.020

0.125

0.020

0.018

0.005

g = 0.188

6 layers of No. 7 dcc round wire

Two thickness of 0.005 papers between layers

Cotton tape, half lapped

Allowance for bulging (0.02 x 3.05)

0.936

0.080

0.018

0.090

p = 1.124

Total 2.062

Space available to accomodate this total thickness of copper and insulation =

=2.25 in.

CALCULATION OF COPPER LOSS

y The mean length per turn (MLT) of the windings

y Total Length of Wire

Primary Winding = 760 x 2.145 = 1630.2 ft

Secondary Winding = 76 x 1.69 = 128.44 ft

y Weight of Copper Loss

Primary Coils (No.7), 63 x 1.6302 = 102.70 lb

Secondary Coils = 0.32(.285 x 0.55 x 128.44 x 12) = 77.31lb

Since the resistance of No.7 DCC wire is 0.5790 ,

y Total Resistance

(Primary)

RT = 0.61 x 1.6302 = 0.99

IR = 15.625 x 0.99 = 15.497 volts

(Secondary)

RT=

IR = 156.25 x = 1.17 volts

Total Copper Loss = 242.23 + 183.11 = 425.34 watts

y Items 24 32.

Core and Copper Losses 158 + 425.34= 583.34 watts

Flux density in core under windings =

Cross section of iron core under winding =

Weight of two limbs =

y Items 33. Efficiency at unity power factor

@

Full Load :

@ Full load :

@ Half Full load :

@ Three quarter full load :

@ 25% over load :

Maximum Efficiency:

0.9864

y Items 34. Basis of 4 hour full load and 20 hour no load.

All Day Efficiency:

y Item 35. For the two limbs under the winding with mean length

B =

Mean Length = 2 x (3.5 + 5.25 + 4.5) = 26.5

For the two limbs outside the winding with mean length

x

Total (T x I) = + = 222.6 amp. turns

y Item 36 to 39. Regulation

Biop

% Regulation @ 0.80 power factor

y Item 40 to 42. The temperature rise of the windings as measured by the resistance method

must not exceed the specified 55.

For the dimension of tank total area

Dimension are 18.25 x 14.75 x 28.25 in high

Cooling Effective Surface

For temperature

Item No.

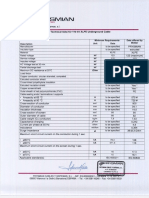

SUMMARY OF CALCULATIONS

1 Volts per turn : From formula = 3.1233 v

Windings High Tension Low Tension

2 Total numbers of turns 760 76

3 Numbers of coils 2 4

4 Turns per coil 384 19

5 Full Load Current (Amp) 15.625 156.25

6 Current Density(

) 955 997

7 Cross Section of Conductor 0.01635 0.15675

8 Dimension of Conductors No. 7 0.55 x 0.285

9 No. of Turns per Layer per Coil 69 19

10 No. of Layer per Coil 6 1

11 No. of Taps None 2

12 Volts per Coil 1200 60

13 Volts Between Layers 486.75

14 Length of Winding Layers 10.5

15 Length of Layer Including Insulation

16 Insulation Between Layers 0.02

17 Insulation on Wire dcc dcc

18 Length per Turn 2.145 1.69

19 Total Length, all Turn in series, ft 1630.2 128.44

20 Weight in Copper(lbs) 102.70 77.31

21 Resistance a 75 c All Coils 0.99 0.0075

22 IR Drop Volts 15.497 1.17

23 Full Load Copper Loss(Compare to Guaranteed)242.23 183.11

THE MAGNETIC CIRCUIT

24 Dimension of Windows 11.25 x 4.5

25 Total Flux, Maxwells 1185395.922

26 Flux Density in Core Under Windings 64500

27 Cross Section of Iron in Core Under Windings 18.375

28 Width of Stampings in Core Under Windings 3.5

29 Gross Thickness of Core 5.25

30 Total Weight of Iron in Core, lbs. 231.525

31 Watts Loss in Iron (compare to guaranteed) 158

32 Total Full Load Losses, watts 425.34

EFFICIENCY AND EXCITING CURRENT

33 Efficiency at Unity Power Factor

At Full Load 0.9847

At Load 0.9861

At Load 0.9806

At Load 0.9860

At 25% Over Load 0.9828

34 All Day Efficiency (4Hr Full Load) 0.9647

35 Primary Exciting Current, Amp. 0.2173

REGULATION

36 Total Equivalent IR Drop Percent 1.56

37 Total Reactive Drop Percent 3.56

38 Regulation on Unity Power Factor 1.56

39 Regulation on 0.80 Power Factor 3.384

DESIGN OF TANK TEMPERATURE RISE

40 Effective Cooling Surface of Tank, sq. inch. 2122.28

41 Watts per square inch of Tank 0.275

42 Approximate Temperature Rise, 67

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Test2 Resistance Safety Electrontheory Ohmslaw Version2Document9 pagesTest2 Resistance Safety Electrontheory Ohmslaw Version2Pierre-jai LakeNo ratings yet

- Sheet 2 - Solution - EE218Document10 pagesSheet 2 - Solution - EE218NouraNo ratings yet

- 8712 enDocument2 pages8712 enalpegambarliNo ratings yet

- NG CalculationDocument9 pagesNG CalculationAhmedNo ratings yet

- Universal Analog Converters CAL30IG and CAL35IG Technical SpecificationsDocument2 pagesUniversal Analog Converters CAL30IG and CAL35IG Technical SpecificationsMargaret DaughertyNo ratings yet

- Casing CalculationsDocument10 pagesCasing CalculationsKimiko ShopNo ratings yet

- Aland Wilson - SI CONVERSIONSDocument9 pagesAland Wilson - SI CONVERSIONSAland WilsonNo ratings yet

- Super X/Xi Series VRF: Variable Refrigerant Flow SystemsDocument104 pagesSuper X/Xi Series VRF: Variable Refrigerant Flow SystemsIván CovarrubiasNo ratings yet

- Smart GridDocument35 pagesSmart GridSanjana Ganesh100% (2)

- Loop Cheking ProcedureDocument5 pagesLoop Cheking ProcedureMd Omar FaruqueNo ratings yet

- Δ XYZ: x=29m, y=15m, ∠Z=122°: Law Of Cosines WorksheetDocument3 pagesΔ XYZ: x=29m, y=15m, ∠Z=122°: Law Of Cosines WorksheetHannah CenaNo ratings yet

- Borehole No.: ABH 39 Water Table For Calculation: 6.15 M Zone Factor (Zone-III) 0.16Document4 pagesBorehole No.: ABH 39 Water Table For Calculation: 6.15 M Zone Factor (Zone-III) 0.16debapriyoNo ratings yet

- Journal Pre-Proofs: Applied Thermal EngineeringDocument40 pagesJournal Pre-Proofs: Applied Thermal EngineeringDedi AfandiNo ratings yet

- Bamboo Calculation SheetDocument3 pagesBamboo Calculation Sheetangdutta2No ratings yet

- Generator Synchronizing ParametersDocument14 pagesGenerator Synchronizing ParametersRam SinghNo ratings yet

- CVFDDDocument126 pagesCVFDDKaran Sharma100% (1)

- Problem Set 5 - Engineering Mechanics-PhysicsDocument2 pagesProblem Set 5 - Engineering Mechanics-Physicsdaryl malolosNo ratings yet

- Unisonic Technologies Co., LTD: 2 Amps, 650 Volts N-CHANNEL Power MosfetDocument6 pagesUnisonic Technologies Co., LTD: 2 Amps, 650 Volts N-CHANNEL Power MosfetMarquinhosCostaNo ratings yet

- Distance Relays Protect Power LinesDocument2 pagesDistance Relays Protect Power Linesuadikema01No ratings yet

- VE Bus BMS Example With 3KW 12V MultiPlus 230 Volt Revision BDocument1 pageVE Bus BMS Example With 3KW 12V MultiPlus 230 Volt Revision BAlba Car MarNo ratings yet

- FINAL. Electronics (SSCE - Grade 10) - Q1. Week 5. Module 5Document28 pagesFINAL. Electronics (SSCE - Grade 10) - Q1. Week 5. Module 5Buenavides P. Gerundio Jr.No ratings yet

- Plane Motion of Rigid Bodies: Energy and Momentum Methods: 2 - 1 Dr. Mohammad Abuhaiba, PEDocument53 pagesPlane Motion of Rigid Bodies: Energy and Momentum Methods: 2 - 1 Dr. Mohammad Abuhaiba, PEAnonymous A100% (1)

- Experimental Investigation of A Lysholm Turbine Operating WithDocument8 pagesExperimental Investigation of A Lysholm Turbine Operating WithmehmacarNo ratings yet

- Ginder 1996Document9 pagesGinder 1996bluedolphin7No ratings yet

- Robert A. Millikan - Atomic Theory ProjectDocument14 pagesRobert A. Millikan - Atomic Theory Projectjade_murray93No ratings yet

- Analytical Model of An Ultrasonic Cross-Correlation Flow Meter, Part 1 - ..Document7 pagesAnalytical Model of An Ultrasonic Cross-Correlation Flow Meter, Part 1 - ..Thiago TavaresNo ratings yet

- Entrpy and Second Law of ThermodynamicsDocument12 pagesEntrpy and Second Law of ThermodynamicsMarion AlyssaNo ratings yet

- Design Differences Between Salient Pole and Non-Salient Pole Synchronous MachinesDocument25 pagesDesign Differences Between Salient Pole and Non-Salient Pole Synchronous MachinesHiren KapadiaNo ratings yet

- 110kv Ehv Cable - GtpsDocument2 pages110kv Ehv Cable - GtpsBijaya Kumar MohantyNo ratings yet

- BOIL OFF GAS ANALYSISDocument8 pagesBOIL OFF GAS ANALYSISJetul PatelNo ratings yet