Professional Documents

Culture Documents

h2 Detector

Uploaded by

rombertiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

h2 Detector

Uploaded by

rombertiCopyright:

Available Formats

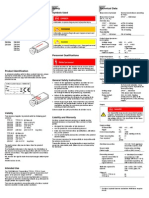

DET-TRONICS

SPECIFICATION DATA

Catalytic Combustible Gas Sensor

DESCRIPTION

F E AT U R E S A N D B E N E F I T S

The new family of Det-Tronics catalytic combustible gas sensors provides unmatched flammable gas detection performance in harsh environments and challenging conditions. The heart of the catalytic sensor consists of a pair of computer matched pellistors (beads) that provide identical electrical resistance in clean air. When flammable gas is present, the active bead catalyzes the combustible gas molecules, while the inactive (reference) bead balances the reaction and compensates for normal changes in the ambient environment. The sophisticated design and construction of Det-Tronics catalytic sensors provides excellent sensitivity, response time, and resistance to physical shock and vibration. All Det-Tronics catalytic gas sensors are now poison-resistant, and are constructed with a new, one-piece 316 stainless steel housing. Other new features include an integral thermal barrier to prevent bead interaction, and a new sinter bonding technique to ensure superior protection against electromagnetic interference. All sensors are provided with a chemically etched identification and approvals label that will withstand exposure to harsh outdoor industrial environments. Det-Tronics catalytic sensors can be used for detection of virtually all combustible and flammable gases, including hydrogen, and are compatible with the entire line of Det-tronics combustible gas transmitters and controllers.

New one piece design with integral thermal barrier New sinter bonded flame arrestor provides superior EMI protection 316 stainless steel housing Excellent impact and vibration resistance Standard poison-resistant performance rating Chemically etched identification and approvals label on sensor FMR/CSA/CENELEC Approvals Extended operating temperature range Complete electrical and mechanical compatibility with existing gas products Comprehensive list of conversion K factors for proper calibration available Full two year warranty 3/4 inch NPT or 20 mm thread types Six inch or optional 30 inch wire lead lengths Constant voltage or constant current sensor types available.

5.1

Detector Electronics Corporation 2002

Printed in USA (6/02)

90-1041

S P E C I F I C AT I O N S Temperature Range* Humidity Range Response Time 67F to +302F (55C to + 150C). 0 to 99% RH, non-condensing. 50% full scale in < 10 seconds with 100% LFL applied. 90% full scale in < 30 seconds with 100% LFL applied. 60% full scale in < 10 seconds with 100% methane by volume in air (CSA flooding test). Recovery Time Linearity < 30 seconds after exposure to pure methane. 0 to 50% LFL: 51 to 99% LFL: 1% LFL. Zero: < 1% LFL per month. Span: < 1% LFL per month in clean air. 3% LFL. 5% LFL. Certification

S P E C I F I C AT I O N S (continued) FMR /CSA: Class I, Div. 1, Groups B, C & D. Explosion-proof verified: 40F to +257F (40C to +125C). Performance verified: 40F to +167F (40C to +75C). CE 0539 II 2 G EEx d IIC T3, T5 DEMKO 02 ATEX 131323 X T5 (Tamb = 40C To +75C) T3 (Tamb = 55C to +125C). Special conditions for safe use (X): Performance Tamb rating = 40C to +75C. Must be used in conjunction with CENELEC certified Det-Tronics combustible gas detector control unit for compliance with EN61779 Series Standards. CGS must be mounted to EEx d (Pref 20 bar) or EEx e enclosure. Intermittent exposure to 125C (500 hours). NOTE: Ensure sensor hazardous (classified) location rating is applicable for the intended use.

CENELEC:

Repeatability Long Term Stability

Temperature Stability

< 5% LFL: 13F to +167F (25C to +75C). < 10% LFL: 40F to 13F (40C to 25C). 3 to 5 years, when environment is free of substances and conditions known to be detrimental to catalytic sensing elements. Indefinite, when stored in unopened original packaging. 90 days typical. Refer to selected transmitter specification. L = 2.0 inches (5.1 cm) W = 1.7 inches (4.3 cm).

Sensor Life

O R D E R I N G I N F O R M AT I O N When ordering, please specify: Model CGSS1A6V2R1XX CGSS1A6C2R1XX CGSS1A3V2R1X CGSS1A3C2R1X CGSS1C6V2R1X CGSS1C6C2R1X CGSS1C3V2R1X CGSS1C3C2R1X Description 3/4 inch, 6 inch leads, constant voltage 3/4 inch, 6 inch leads, constant current 3/4 inch, 30 inch leads, constant voltage 3/4 inch, 30 inch leads, constant current M20, 6 inch leads, constant voltage M20, 6 inch leads, constant current M20, 30 inch leads, constant voltage M20, 30 inch leads, constant current

Storage Life

Calibration Cycle RFI/EMI Immunity Dimensions

* Materials suitable for installation in this range

FM

APPROVED

RE

RED BY UL AN D STE B GI

Detector Electronics Corporation

6901 West 110th Street Minneapolis, Minnesota 55438 USA (612) 941-5665 or (800) 765-FIRE Fax (612) 829-8750 http://www.detronics.com E-mail: detronics@detronics.com

ISO 9001

REG

SI

IR M

.A

230

5 N O.

25

ST

E RE D F

T E ED R

FI

RM

I R EG

82

Specifications subject to change without notice.

You might also like

- Herbs MedicineDocument237 pagesHerbs MedicineSih Kir Nugroho100% (13)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- 8.2 (111 Marks) : MarkschemeDocument47 pages8.2 (111 Marks) : MarkschemeSemwezi Enock0% (1)

- Subsea Sensor BrochureDocument16 pagesSubsea Sensor Brochurealkhwarizmi1968100% (1)

- Section 5 - Concrete PavementDocument18 pagesSection 5 - Concrete PavementLipSingCheong100% (2)

- Winding Temperature IndicatorDocument9 pagesWinding Temperature IndicatorTruong Van Quang100% (2)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Fire Fighting SystemDocument17 pagesFire Fighting SystemAshutosh NayakNo ratings yet

- Basics of Instrumentation Fire GasDocument20 pagesBasics of Instrumentation Fire Gasabdullah100% (1)

- RTD TutorialsDocument11 pagesRTD TutorialsjaigodaraNo ratings yet

- TR-62-Technical Information PDFDocument10 pagesTR-62-Technical Information PDFAlaa RamadanNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- High Temperature Ultrasonic TestingDocument3 pagesHigh Temperature Ultrasonic TestingCarlos Bustamante100% (1)

- (Faringita Streptococica:copii: 250 MG de 2-3 Ori Pe Zi Adolescenţi Şi Adulţi: 250 MG de 4 Ori Pe Zi Sau 500 MG de 2 Ori Pe Zi Timp de 10 ZileDocument5 pages(Faringita Streptococica:copii: 250 MG de 2-3 Ori Pe Zi Adolescenţi Şi Adulţi: 250 MG de 4 Ori Pe Zi Sau 500 MG de 2 Ori Pe Zi Timp de 10 ZileAlina C100% (1)

- Topic: Concrete Paver Block Reinforced With Mature Coconut Fiber As An AdditiveDocument10 pagesTopic: Concrete Paver Block Reinforced With Mature Coconut Fiber As An AdditiveXcyl Myrrh PreciosoNo ratings yet

- Sensores Toxicos ElectroquimicosDocument4 pagesSensores Toxicos Electroquimicostrukcor_1No ratings yet

- 90-1074-03 (Pir9400)Document2 pages90-1074-03 (Pir9400)Donny FitradiNo ratings yet

- CGS SpecificationsDocument2 pagesCGS Specificationsnassir.guellilNo ratings yet

- Combustible Gas Sensor Selection GuideDocument4 pagesCombustible Gas Sensor Selection GuideAjish Rajan TNo ratings yet

- Field Devices - Analytical: Product SpecificationsDocument32 pagesField Devices - Analytical: Product Specificationssalmo83:18No ratings yet

- Foxboro RTDDocument12 pagesFoxboro RTDJonathanGonzalezDiazNo ratings yet

- TPS2500SDocument4 pagesTPS2500SRamy RaafatNo ratings yet

- 90-1074-03 (PIR9400) - Specs Sheet PDFDocument2 pages90-1074-03 (PIR9400) - Specs Sheet PDFKasinathan MuniandiNo ratings yet

- IP66 ATEX certified flow switch for pipes 15-250mmDocument4 pagesIP66 ATEX certified flow switch for pipes 15-250mmthotalnNo ratings yet

- Newchrom 6700 Gas ChromatographDocument2 pagesNewchrom 6700 Gas ChromatographUMA NSTRUMENTNo ratings yet

- Ds Tbx5-En eDocument24 pagesDs Tbx5-En evdaNo ratings yet

- Multispectrum IR Flame Detector for Harsh EnvironmentsDocument2 pagesMultispectrum IR Flame Detector for Harsh EnvironmentsAngela FasuyiNo ratings yet

- TC906D Eclipse™ Series: Intelligent Duct Smoke Detector and DNRECL HousingDocument2 pagesTC906D Eclipse™ Series: Intelligent Duct Smoke Detector and DNRECL HousingsureshNo ratings yet

- Sae Technical Paper Series: C. Scott Nelson, David Chen, Joseph Ralph and Eric D'HerdeDocument11 pagesSae Technical Paper Series: C. Scott Nelson, David Chen, Joseph Ralph and Eric D'HerderuchikasaxenaNo ratings yet

- Field Devices - Analytical: Product SpecificationsDocument16 pagesField Devices - Analytical: Product SpecificationsPhaniNo ratings yet

- Product Data Sheet ch88 in Situ Flue Gas Oxygen Transmitter Rosemount en 1508434Document12 pagesProduct Data Sheet ch88 in Situ Flue Gas Oxygen Transmitter Rosemount en 1508434cocot 666No ratings yet

- CP 060 en PenningvacDocument8 pagesCP 060 en PenningvacMayur ChauhanNo ratings yet

- Testo 310.: Fully Featured. Priced RightDocument4 pagesTesto 310.: Fully Featured. Priced RightmarkostojanovicNo ratings yet

- CO2 Olikis PDFDocument8 pagesCO2 Olikis PDFAli OsmanNo ratings yet

- Master Thermocouples for Industrial Temperature MeasurementDocument1 pageMaster Thermocouples for Industrial Temperature MeasurementAnonymous HFIQgANMQNo ratings yet

- DS Sensor For M300 Thornton Jul2012Document16 pagesDS Sensor For M300 Thornton Jul2012Edwin Azmiramdhan SulaimanNo ratings yet

- Cromatografo de Gas NaturalDocument8 pagesCromatografo de Gas NaturalJinhichi Molero RodriguezNo ratings yet

- Detector de Gas IR Eclipse PDFDocument2 pagesDetector de Gas IR Eclipse PDFElvio M100% (1)

- Ap B14 02L 01e - Akm - 38750 PDFDocument4 pagesAp B14 02L 01e - Akm - 38750 PDFsamsungloverNo ratings yet

- CP 060 en ThermovacDocument14 pagesCP 060 en ThermovacMayur ChauhanNo ratings yet

- PTC Thermistors As Limit Temperature Sensors PDFDocument11 pagesPTC Thermistors As Limit Temperature Sensors PDFmarckalhiNo ratings yet

- Sensor de Oxigeno Mercury MerdicalDocument2 pagesSensor de Oxigeno Mercury MerdicalIrving MontesNo ratings yet

- Jhonson Control HumidityDocument2 pagesJhonson Control HumidityMad HouseNo ratings yet

- Sensor de PH PDFDocument24 pagesSensor de PH PDFthiagofilipiniNo ratings yet

- Atex Ii 3 G Wdg-Hpii SeriesDocument4 pagesAtex Ii 3 G Wdg-Hpii SeriesEsteban Alejandro CatrilNo ratings yet

- SC 103Document8 pagesSC 103prihartono_diasNo ratings yet

- Pt100 PDFDocument19 pagesPt100 PDFCristi CalotaNo ratings yet

- Lluisma Pressure and Temperature ExamDocument11 pagesLluisma Pressure and Temperature ExamMaxine GarcesNo ratings yet

- THERMOVAC Transmitter: TTR 91, TTR 91 S TTR 96 SDocument4 pagesTHERMOVAC Transmitter: TTR 91, TTR 91 S TTR 96 Smayito12093120No ratings yet

- TI266ten 0409Document12 pagesTI266ten 0409Keren ArteagaNo ratings yet

- Detcon - TP-524D-H2S - Datasheet 965-015420-100Document2 pagesDetcon - TP-524D-H2S - Datasheet 965-015420-100PSC RFQNo ratings yet

- FM CODEL GCEM40xx Ap12 PDFDocument6 pagesFM CODEL GCEM40xx Ap12 PDFCandi.nntppNo ratings yet

- WDG IV O2 AnalyserDocument4 pagesWDG IV O2 Analyserabdul rehmanNo ratings yet

- RTD pt100Document6 pagesRTD pt100jyotiblossomsNo ratings yet

- Olympus Thickness GagesDocument8 pagesOlympus Thickness GagessukimeNo ratings yet

- Product Data: Immersion Sensor W/ Plastic Junction BoxDocument2 pagesProduct Data: Immersion Sensor W/ Plastic Junction BoxAbhishek HJ MallavaNo ratings yet

- Model P155: Stainless SteelDocument2 pagesModel P155: Stainless SteelJavi KatzNo ratings yet

- NETZSCH Analyzing and Testing Product OverviewDocument4 pagesNETZSCH Analyzing and Testing Product OverviewNETZSCH - Leading Thermal Analysis100% (1)

- Crack VibDocument4 pagesCrack VibIshu VohraNo ratings yet

- HC-300PL-Infrared Hydrocarbon Gas DetectorDocument2 pagesHC-300PL-Infrared Hydrocarbon Gas DetectorIrlan LeiteNo ratings yet

- ST51 Data Sheet RevCDocument2 pagesST51 Data Sheet RevCjakkyjeryNo ratings yet

- AI Tek Tachometer OverviewDocument1 pageAI Tek Tachometer OverviewM Irfan MaulanaNo ratings yet

- 34 Xy 03 51 PDFDocument10 pages34 Xy 03 51 PDFAnonymous 8edbEtNo ratings yet

- CERGAS Deteccion de Gases ExplosivosDocument4 pagesCERGAS Deteccion de Gases ExplosivosdanilokaralejicNo ratings yet

- Stainless Steel Cable Tie GuideDocument8 pagesStainless Steel Cable Tie GuideSathorn TumNo ratings yet

- The Ultimate GHS Hazard Classification Guide - ERA Software SolutionsDocument32 pagesThe Ultimate GHS Hazard Classification Guide - ERA Software SolutionsDina AzizNo ratings yet

- Is 248-1987 Ra 2021Document14 pagesIs 248-1987 Ra 2021Aadarsh Kumar ShitalNo ratings yet

- Paducah Gaseous Diffusion Plant CleanupDocument1 pagePaducah Gaseous Diffusion Plant CleanupJames BruggersNo ratings yet

- Super Dilac VA 4Document2 pagesSuper Dilac VA 4Bhavesh PatelNo ratings yet

- Spredox D 364 For Solvent Based InkjetDocument9 pagesSpredox D 364 For Solvent Based InkjetPravin TandelNo ratings yet

- Cracks in ConcreteDocument45 pagesCracks in ConcreteRanjeet SinghNo ratings yet

- Report Filed by The APPCBDocument30 pagesReport Filed by The APPCBhcbbNo ratings yet

- Philippines Pharmacy Act PenaltiesDocument6 pagesPhilippines Pharmacy Act PenaltiesOdyNo ratings yet

- Dental Unit CS 300B Chair MountedDocument3 pagesDental Unit CS 300B Chair MountedCatrin AfriliaNo ratings yet

- GSE CertificatesDocument1 pageGSE CertificatesOkan KalendarNo ratings yet

- LWAASHJSPLANGULDocument5 pagesLWAASHJSPLANGULAmiy SrivastavaNo ratings yet

- 10 Science Imp Ch3 1Document8 pages10 Science Imp Ch3 1rajkumar trivediNo ratings yet

- Sweet Flag Acorus Calamus Linn An Incredible Medicinal HerbDocument9 pagesSweet Flag Acorus Calamus Linn An Incredible Medicinal HerbaquiladimareNo ratings yet

- FE Thermodynamics 7th Appendices: Water Property TablesDocument71 pagesFE Thermodynamics 7th Appendices: Water Property TableshollegansNo ratings yet

- Concrete Repair and Structure StrengtheningDocument5 pagesConcrete Repair and Structure StrengtheningAidaJalaluddinNo ratings yet

- Polymers: Chitosan: An Overview of Its Properties and ApplicationsDocument27 pagesPolymers: Chitosan: An Overview of Its Properties and Applicationsjuan esteban MonroyNo ratings yet

- Christian Pfeiffer Maschinenfabrik GMBHDocument5 pagesChristian Pfeiffer Maschinenfabrik GMBHPeyman KhNo ratings yet

- 5052 Aluminum Sheet SuppliersDocument13 pages5052 Aluminum Sheet Supplierssanghvi overseas incNo ratings yet

- Btu Analysis Using A Gas ChromatographDocument5 pagesBtu Analysis Using A Gas Chromatographlutfi awnNo ratings yet

- SECTION 15081: Duct Insulation 15081Document5 pagesSECTION 15081: Duct Insulation 15081fatREVITNo ratings yet

- Routes of Drug Delivery To The LungsDocument4 pagesRoutes of Drug Delivery To The LungsAquiles VaestoNo ratings yet

- Crystal Appearance/Characteristics Clinical SignificanceDocument4 pagesCrystal Appearance/Characteristics Clinical SignificanceAngela LaglivaNo ratings yet

- Viruses & Bacteria: Biology 11Document28 pagesViruses & Bacteria: Biology 11Adnan Bhisma RizaldyNo ratings yet

- Celavive All Products OverviewDocument11 pagesCelavive All Products OverviewQuila Gonzales ReyesNo ratings yet