Professional Documents

Culture Documents

Cabletec

Uploaded by

Liang ZhangOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cabletec

Uploaded by

Liang ZhangCopyright:

Available Formats

Atlas Copco Bolting rigs

Cabletec LC

Technical specification

www.atlascopco.com

LC

LC

Illustration shows rig with optional equipment mounted.

Fully mechanized rig for long hole drilling and cable bolting. Features automatic drilling and cement handling system, which together with the high capacity steel strand reel gives top performance and high quality bolt installations.

Standard features

Rock drill

Atlas Copco COP-series high performance rock drills

Cement handling unit

Fully automatic cement handling unit On board silo for cement storage RCS-controlled water/cement ratio Cement dust collector Semi-automatic cement hose control

Drilling unit

Accurate and fully adjustable feed control Sturdy and reliable carousel, 17 + 1 rods Drill steel support and cutting deflector Stinger support during drilling

Cable bolting head

Cable and cement hose feeding system Cable bending mechanism Strand cutter Cable pusher for installation of twin cables

Control system

Rig Control System (RCS) Advanced Boom Control (ABC) Regular Automatic functions such as one hole automatics Optimized regulation of the drilling process Logging system

Carrier

Sturdy articulated carrier with four-wheel drive Powered by a 4-cylinder, EPA III/COM III (Tier 3/Stage IIIA) approved diesel engine Cable reel

Drilling boom

Hydraulic heavy-duty boom with proportional movements

Cable bolting boom

Telescopic boom with proportional movements Turning actuators enables full coverage in the working area Cement grouting separated from the drilling unit

Cabletec LC

Specifications

ROCK DRILL

COP 1638

Shank adapter Height over drill centre Length without shank Impact power Impact rate Hydraulic pressure Rotation system Rotation speed Rotation torque, max Water consumption Weight Sound level R32/ TC35/T38 88 mm 1 008 mm 16 kW 60 Hz 200 bar Separate rotation 0340 rpm 4401 000Nm 35120 l/min 173 kg <106 dB(A)

Control System

COP 1838ME

R32/ TC35/T38 88 mm 1 008 mm 18 kW 60 Hz 230 bar Separate rotation 0340 rpm 6401 000 Nm 5 l/s 40120 l/min 170 kg <106 dB(A)

COP 1838MUX

TC35/T38 122 mm 1 206 mm 18 kW 60 Hz 220 bar Separate rotation 0340 rpm 1 000 Nm 5 l/s 55120 l/min 225 kg <106 dB(A)

Rig Control System (RCS) versatile and upgradeable to a higher degree of automation ABC Regular Two electronic control panels with colour display USB-port for transfer of data Integrated diagnostic system

Electrical system

Total installed power ...................................................105 kW Main motor ....................................................................95 kW Voltage/frequency.............................. 4001 000 V/5060 Hz Starting method ..................................... star/delta, 400690 V Electronic overload protection Digital volt/amperage meter in electric cabinet Phase sequence indicator Earth fault indicator Working lights, halogen ...................................... 2 x 1 000 W Isolation switch lockout

Lub. air consump. at 2 bar 57 l/s

Feed

Feed BMH 200 series including BSH55 drill steel support and BSC55 cutting deflector RHS 17 for 1.2, 1.5 or 1.8 m rods

Air/Water system

Water booster pump, max capacity at 15 bar ........... 250 l/min Hydraulic drive, axial piston motor ................................ 10 cc Atlas Copco screw compressor .................................... GAR 5 Maximum capacity at 7 bar and 5 400 rpm.....................20 l/s Air/water pressure/flow gauge Hole blowing kit Rig washing kit Joystick controlled water-jet canon for cleaning

Positioning system

Feed extension, 4'/ 5', 6' drill steel ................... 900/1 200 mm Boom extension, BUT 35 BS .................................. 1 600 mm Rotary actuator for 360 ring drilling ......................... BHR 30 Positioning system tilt ............................................. +90/-10 Boom lift .......................................................................... +45 Stinger, backward on feed holder ............................BSJ 8-200 Stinger, forward on feed .......................................... BSJ 8-115

Carrier

Deutz TCD 2013 L04 2Vwater-cooled turbo-charged engine Power rating at 2 300 rpm ............................ 120 kW (163 hp) FOPS-approved protective roof Fixed seat for tramming, including safety belt Articulated steering ...................................38 steering angle Hydrostatic power steering system Hydrostatic transmission ...................................... Dana 24000 Front axle ................................................................. Dana 114 Rear axle.......................................... Dana 114, 8 oscillation Automatic differential lock on front axle, limited slip Tires ......................................................................14.00 x R24 Clearance outside axles ...................................................... 13 Hydraulic jacks, front .............2 extendable, with large plates Hydraulic jacks, rear ..............................................................2 Service brakes .............................................2 separate circuits Emergency and parking brakes .....................................SAHR Fuel tank, volume ............................................................ 100 l Electric system .................................................................24 V Batteries..................................................................2 x 125 Ah Tramming lights ........................................................ 8 x 70 W Illuminated stairs for platform .................................. 2 x 70 W Spotlight ...........................................................1 x 70 W, 24 V Control panel for roof, jacks and cable reel Central lubrication system Fire extinguisher Shelf for drill bits and tools Gradeability at max load on drive wheels .......................... 1:4 Beacon, horn and reverse alarm Reversing camera with monitor Manual lubrication kit

Bolting system

Grout hose diameter, inner/outer ............................. 20/29 mm Grout hose reel, max hole length .................................... 25 m Steel strand cable reel load, max ................................1 700 kg Cable and hose feeder with cable cutter and bending unit Logging of accumulated cable consumption Cable feeding depth measurement

Cement grouting system

Cement mixer, volume .....................................................114 l Cement silo, max load dry cement .............................1 000 kg Preprogrammed cleaning sequences Water/cement ratio preprogrammed recipes Logging of accumulated cement consumption Cement hose feeding depth measurement Form oil kit

Hydraulic system

Hydraulic pump................ 3 variable pumps and 1 gear pump Pumps unloaded at start System pressure................................................... 150240 bar Hydraulic oil tank, volume max/min ....................... 250/200 l Low oil level indicator and shut down Oil temperature gauge on oil tank Filtration ........................................................................ 16 m Oil filter indicator Water cooled oil cooler Electric oil filling pump Oil leakage shut down system

Cabletec LC

Specifications

sHanK aDaPtERs

thread mm

R32 TC35 T38/T38*

*Extractor

RECOMMEnDED CaBLE sIzE anD LEngtH

Diameter

38 38 38/59.5

Hole dimension

4876 5176 6489

Voltage

400V 400V 440500V 440500V

type

H07RN-F Buflex H07RN-F Buflex H07RN-F Buflex H07RN-F Buflex Buflex

Dimension, mm2

4G70 3x95 + 3G25 4G70 3x95 + 3G16 4G50 3x70 + 3G16 4G35 3x50 + 3G10 3x25 + 3G6

Diameter, mm

55 46 49 42 44 39 38 33 26

Length, m

90 135 110 155 150 165 160 275 275

EXtEnsIOn RODs FOR PRODUCtIOn DRILLIng

Dimension mm

R32 Speedrod TC35 Speedrod T38 Speedrod

500550V 500550V 660700V 660700V 1000V

Min. hole diameter

48 51 64

G= Protection yellow/green. Valid for temperature below 40 C

FEEDs

Recommended drift size Feed type BMH 214 BMH 215 BMH 216 BMH 214X BMH 215X BMH 216X Length

3200 3500 3800 3400 3700 4000

Min. width

3400 3700 4000 3600 3800 4200

Min. height

3400 3700 4000 3600 3900 4200

Efficient height

6100 6200 6300 6100 6200 6300

Max. height

8300 8400 8500 8300 8400 8500

Optional equipment

Rock drill

Extractor unit COP 1838MUX Lubrication surveillance kit Thread lubrication kit Full Drill Data Handling Boom Alignment Laser Radio Text Message System Automatic Parallel Holding Void Detection Remote Cradle Control Remote Feed Control Fire suppression system FORREX Automatic fire suppression system Particle filter UNIKAT Brake lights Hot climate tramming kit Rig Alignment Laser

Boom

Automatic boom lubrication kit Central boom lubrication kit Automatic lubrication kit, drilling unit/boom Stinger extensions

Cabin

FOPS-approved cabin, noise level < 80 dB(A), including: - Air conditioning unit - Fixed seat - CD-changer - Boot washing kit Alternative mounting height (-200/+250 mm) Cabin body made of stainless steel Front window, 24 mm Protection bars, front window Swingable seat for drilling/tramming Cabin lift and tilt system Low-designed cabin, for seated operator cabin height 2 953 mm

Electrical system

Soft start for electrical motors Electric cable Dual controls for cable reel Limit switch for cable reel Electric plugs, socket and switch gear Connector Electric outlet for accessories Extra transformer CSA/Australian approved electrics Metal halogen working lights

Air/Water System

Water hose reel Water hose Dual controls for hose reel

Hydraulic system

Heater kit for hydraulic oil tank, diesel engine and electric motors

Miscellaneous

Hose/cable guide at water/cable reel EPB on CD-CAT B Remote operating kit Special paint Boots washing arrangement (canopy) Ni-Cr plated piston rods Area guards

Software

Rig Remote Access Breakthrough Automatic System Drill Plan Handling Drill Plan Handling with raise view

Carrier

Fire suppression system ANSUL (manual or Checkfire)

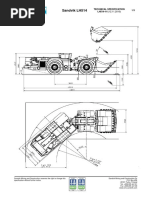

Cabletec LC

Dimensions

2203

3586

1426

3640

2450

www.atlascopco.com

LC

LC

10 2105 1576 2000 2200 14333 925

19

160

sIDE VIEw

Illustration shows rig with optional equipment mounted.

12 m

10

3360 4100

Plattform in outer position 500 400

4

2140

3931

2 8 6 4 2 0 2 4 6 8m

200 300 1328 Rear 1125 Min 1520 Max

4100

1730

Reel in outer position

COVERagE aREa DRILLIng anD BOLtIng

Illustration shows equipment with 6 feet rod. Efficient working height 6 metres.

FROnt VIEw

DIMEnsIOns

mm

Width, transport Cabin height Length Ground clearance 2 750 3 093 14 333 265

wEIgHt

gross weight kg

Total Boom side Engine side 30 000 18 000 12 000

tURnIng RaDIUs

depending on surface mm

Outer Inner 7 400 4 500

tRaMMIng sPEED

km/h

On flat ground (rolling resistance 0.05) On incline 1:8 >15 >5

9851 2367 01c

06/2009

Copyright 2009, Atlas Copco Rock Drills AB, rebro, Sweden. All product names in this publication are trademarks of Atlas Copco. Any unauthorized use or copying of the contents or any part thereof is prohibited. Illustrations and photos in this brochure may show equipment with optional extras. No warranty is made regarding specifications or otherwise. Specifications and equipment are subject to change without notice. Consult your Atlas Copco Customer Center for specific information.

643

840

225

You might also like

- Inverted Jigsaw TableDocument6 pagesInverted Jigsaw Tableboon1961100% (1)

- PonyPlansMv2Document17 pagesPonyPlansMv2anon-822633100% (2)

- Minetruck MT42 - Technical Specification - English - High ResDocument8 pagesMinetruck MT42 - Technical Specification - English - High Resd86299878No ratings yet

- FlexiRoc T35 EpirocDocument5 pagesFlexiRoc T35 EpirocDaniel Páez100% (2)

- BoomDocument67 pagesBoomBruno Almeida Carvalho100% (1)

- Minetruck MT436B 9851 2249 01N tcm835 1540890 PDFDocument4 pagesMinetruck MT436B 9851 2249 01N tcm835 1540890 PDFbenjamin100% (1)

- JBL Charge4 ManualDocument5 pagesJBL Charge4 ManualFerdy LainsamputtyNo ratings yet

- Operator's Manual: Original InstructionsDocument240 pagesOperator's Manual: Original InstructionsDmitriyNo ratings yet

- Especificaciones Boomer l2dDocument4 pagesEspecificaciones Boomer l2dJuan RodriguezNo ratings yet

- Manual Elevador Challenger c10Document18 pagesManual Elevador Challenger c10Pedro GonzalezNo ratings yet

- Jumbo Perfuracao - Atlas Copco - Boomer L3C, XL3C, WL3C (Intervalos de Manutencao) (En)Document50 pagesJumbo Perfuracao - Atlas Copco - Boomer L3C, XL3C, WL3C (Intervalos de Manutencao) (En)Augusto Oliveira100% (3)

- Technical Specifications: HC 95 LMDocument1 pageTechnical Specifications: HC 95 LMJuan Enrique Perez VillanuevaNo ratings yet

- Simba 1354Document4 pagesSimba 1354Manuel Uturunco AguilarNo ratings yet

- TLE 7 8 Carpentry Module 3Document24 pagesTLE 7 8 Carpentry Module 3Marycon Lao NacitoNo ratings yet

- Simba L6 CDocument4 pagesSimba L6 CKoko ElrNo ratings yet

- Atlas Wb42 ManualDocument31 pagesAtlas Wb42 ManualLeGumNo ratings yet

- Boltec Boltec MC, LC MK 7BDocument180 pagesBoltec Boltec MC, LC MK 7BHector Vergara MirandaNo ratings yet

- Roller Reamer PresentationDocument18 pagesRoller Reamer Presentationmbhadel0% (1)

- Technical Specification Cabletec LC - 9851 2367 01d - tcm795-1533088Document4 pagesTechnical Specification Cabletec LC - 9851 2367 01d - tcm795-1533088Mark Edowai100% (1)

- Lower Drive - 24" Assy: Item Part Number Description QtyDocument6 pagesLower Drive - 24" Assy: Item Part Number Description QtyFreddy Martínez Avendaño100% (1)

- TransmisioDocument34 pagesTransmisioWilliams ArayaNo ratings yet

- Minetruck mt42Document4 pagesMinetruck mt42Miguel Angel Cortes Quintrel100% (1)

- Brochure Tamrock Axera D05Document4 pagesBrochure Tamrock Axera D05Esteban Fernando Meza IbacetaNo ratings yet

- Technical Specification Boomer m2 C With Cop 3038 9851 2774 01 Web tcm821-1533267 PDFDocument4 pagesTechnical Specification Boomer m2 C With Cop 3038 9851 2774 01 Web tcm821-1533267 PDFTamara Monsalve100% (1)

- Masonry Lesson PlanDocument4 pagesMasonry Lesson Planwiljone90% (10)

- Instrucciones y Funcionamiento de Seguridad SB 302 Gama SBDocument36 pagesInstrucciones y Funcionamiento de Seguridad SB 302 Gama SBJean MoralesNo ratings yet

- Trakker Motor 2 Motor f3bDocument102 pagesTrakker Motor 2 Motor f3bLuis Pastor Alayo100% (1)

- Boomer E2C FTDocument8 pagesBoomer E2C FTCami FC100% (3)

- Simba Atlas Copco PDFDocument4 pagesSimba Atlas Copco PDFdiego0% (1)

- Simba M4 C PDFDocument4 pagesSimba M4 C PDFTamara MonsalveNo ratings yet

- SimbaDocument4 pagesSimbaCesar Sarmiento100% (1)

- 13.atlas Copco ROCKET BOOMER E1-E2 SerijaDocument8 pages13.atlas Copco ROCKET BOOMER E1-E2 Serijaadamajaks1985No ratings yet

- Preforadoras DS311Document1 pagePreforadoras DS311Gerardo RiosNo ratings yet

- Spec ST2D 9851 2251 01f - tcm795-1539250 PDFDocument4 pagesSpec ST2D 9851 2251 01f - tcm795-1539250 PDFRizky AsharyNo ratings yet

- Minetruck MT436B 9851 2249 01N tcm833-1540890 PDFDocument4 pagesMinetruck MT436B 9851 2249 01N tcm833-1540890 PDFLuis Hernández BarrazaNo ratings yet

- Boomer104 SpecDocument4 pagesBoomer104 SpecLucho MoraNo ratings yet

- Ajustes HidraulicosDocument58 pagesAjustes Hidraulicosedwin100% (1)

- SCH 5000Document2 pagesSCH 5000Anonymous xxFArUCS100% (3)

- Utimec LF 600 Transmixer engine bonnet parts listDocument73 pagesUtimec LF 600 Transmixer engine bonnet parts listalexis aguirre espejo100% (1)

- Powerroc T35 E: Surface Drill Rig For Construction, Road Construction and Urban DevelopmentDocument5 pagesPowerroc T35 E: Surface Drill Rig For Construction, Road Construction and Urban DevelopmentElgi Alam PangestuNo ratings yet

- Lowres RCS Pit Viper Brochure - tcm835-3271875Document12 pagesLowres RCS Pit Viper Brochure - tcm835-3271875rigoberto otiniano100% (1)

- 08 ST1030 Dump and Hoist - enDocument25 pages08 ST1030 Dump and Hoist - enGerardo HuertaNo ratings yet

- LF 700 Cylinder Rope FeedDocument2 pagesLF 700 Cylinder Rope FeedMax RojasNo ratings yet

- 1 Eurostar EngineeringDocument13 pages1 Eurostar EngineeringriteshreplyNo ratings yet

- Boltec S: Start The EngineDocument2 pagesBoltec S: Start The EngineerwinNo ratings yet

- ST7Document4 pagesST7marcelonieto761No ratings yet

- Utimec LF 600 Agitator 100018506Document7 pagesUtimec LF 600 Agitator 100018506lucas0% (1)

- Mr-hl500 Data SheetDocument1 pageMr-hl500 Data SheetAlmaNo ratings yet

- 9852 1466 01h Safety Boomer 281 - 282 DC15Document47 pages9852 1466 01h Safety Boomer 281 - 282 DC15lidoNo ratings yet

- Brochure Burg 1450Document2 pagesBrochure Burg 1450serge.pungweNo ratings yet

- Spec Pantera Dp1500i t4 2 WebDocument3 pagesSpec Pantera Dp1500i t4 2 WeblenardoangeloNo ratings yet

- ST 710 PDFDocument3 pagesST 710 PDFIvanNo ratings yet

- Atlas Copco Drilling Solutions: Part List Model: Dm50/Lp S/N: US009240Document790 pagesAtlas Copco Drilling Solutions: Part List Model: Dm50/Lp S/N: US009240Nasrul arul100% (1)

- Drill Rigs Safety PowerROC T50Document46 pagesDrill Rigs Safety PowerROC T50Seno AgusNo ratings yet

- Especificaciones DT820Document5 pagesEspecificaciones DT820Jorge Cid BlancoNo ratings yet

- Ficha Tecnica Alpha 30Document7 pagesFicha Tecnica Alpha 30jonathan francisco allende escobarNo ratings yet

- Sandvik LH514 SpecificationDocument3 pagesSandvik LH514 Specificationenriquerojoperez_539100% (2)

- Atlas Copco Blasthole Drills Dm45-SeriesDocument4 pagesAtlas Copco Blasthole Drills Dm45-SeriesfelipeNo ratings yet

- Atlas Copco COP 1838HD+ Drilling Rig SettingsDocument1 pageAtlas Copco COP 1838HD+ Drilling Rig SettingsrodolfoNo ratings yet

- ScopTramp 1030Document89 pagesScopTramp 1030Nelson GonzalezNo ratings yet

- 9852 3243 01 PowerROC T50 Tier 3 Maintenance SchedulesDocument54 pages9852 3243 01 PowerROC T50 Tier 3 Maintenance SchedulesrolandNo ratings yet

- Catalogo DTH SandvikDocument49 pagesCatalogo DTH SandvikStevenNo ratings yet

- EDLinked PDFDocument50 pagesEDLinked PDFNilson Cieza ZamoraNo ratings yet

- Spraymec 6050 WPCDocument3 pagesSpraymec 6050 WPCPatop CofréNo ratings yet

- IHT Global CatalogDocument153 pagesIHT Global CatalogIsabel ChoqueNo ratings yet

- Technical Specification Boomer m2 C With Cop 3038 9851 2774 01 Tcm835-1533267Document4 pagesTechnical Specification Boomer m2 C With Cop 3038 9851 2774 01 Tcm835-1533267death666darkNo ratings yet

- Technical Specification Boomer E1 C - 9851 3137 01 - tcm835-3515820Document4 pagesTechnical Specification Boomer E1 C - 9851 3137 01 - tcm835-3515820VVyldher UghoNo ratings yet

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.From EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.No ratings yet

- Power Pack & Tools-1Document14 pagesPower Pack & Tools-1Dodi Julianto فاصلNo ratings yet

- 029 Mechanized Bolting and ScreeningDocument4 pages029 Mechanized Bolting and ScreeningKenny CasillaNo ratings yet

- Threading Wood For Machine Screws PDFDocument1 pageThreading Wood For Machine Screws PDFBen Gerez100% (1)

- Alfra Manuals 3462Document28 pagesAlfra Manuals 3462januszekNo ratings yet

- MasonryDocument115 pagesMasonryTitiliaNo ratings yet

- Meaker VI's Mark8Document13 pagesMeaker VI's Mark8zhonghua shiNo ratings yet

- Lists of Laboratory EquipmentDocument7 pagesLists of Laboratory EquipmentjansenrosesNo ratings yet

- 3HH-07197-AAAA-RJZZA-11-7302 FD HW Installation Manual R4 - XDocument386 pages3HH-07197-AAAA-RJZZA-11-7302 FD HW Installation Manual R4 - XStavros SotiriadisNo ratings yet

- Made in Germany: Powerful solutions and passionate peopleDocument25 pagesMade in Germany: Powerful solutions and passionate peopleuripssgmailNo ratings yet

- Drilling MachineDocument79 pagesDrilling MachineMunem ShahriarNo ratings yet

- ITW Buildex Catalogue 2010-2011Document48 pagesITW Buildex Catalogue 2010-2011Nugraha BintangNo ratings yet

- AutoCad 2022 Make A Custom Tilt-Top Tool CaddyDocument59 pagesAutoCad 2022 Make A Custom Tilt-Top Tool CaddyRicardo Sage2 HarrisNo ratings yet

- Cylinder Liner - Production Recommendation 0742048 3Document17 pagesCylinder Liner - Production Recommendation 0742048 3thiha aungNo ratings yet

- Alignment Test DrillingDocument4 pagesAlignment Test DrillingVivek Fegade33% (3)

- Econ 6Document7 pagesEcon 6ceejay RedondiezNo ratings yet

- High-Torque, All-Hydraulic Auger DrillDocument2 pagesHigh-Torque, All-Hydraulic Auger DrillAsif KhanzadaNo ratings yet

- DRILL JIG DESIGNS GUIDEDocument43 pagesDRILL JIG DESIGNS GUIDEAkeju AyodeleNo ratings yet

- Carport UniversalDocument19 pagesCarport UniversalRobert BNo ratings yet

- Drilling Machine Definition, Parts, Operation, TypesDocument19 pagesDrilling Machine Definition, Parts, Operation, TypesMunem Shahriar100% (2)

- Sandvik Ds210l VDocument4 pagesSandvik Ds210l Vlorenzo henerNo ratings yet

- Thread Check PDFDocument51 pagesThread Check PDFAsghar AliNo ratings yet

- Onyx 90 Instruction ManualDocument19 pagesOnyx 90 Instruction ManualnomuseNo ratings yet