Professional Documents

Culture Documents

BS EN 1011 - 8 - 2003 - Draft

Uploaded by

Michael AndrewsOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BS EN 1011 - 8 - 2003 - Draft

Uploaded by

Michael AndrewsCopyright:

Available Formats

L

i

c

e

n

s

e

d

C

o

p

y

:

T

o

m

M

a

g

e

e

,

H

o

w

d

e

n

P

o

w

e

r

,

1

8

J

u

n

e

2

0

0

3

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

British Standard

A single copy of this British Standard is licensed to

Tom Magee

18 June 2003

This is an uncontrolled copy. Ensure use of the most

current version of this document by searching British

Standards Online at bsonline.techindex.co.uk

a

Date: 8 March 2002

Origin: European

Latest date for receipt of comments: 31.05.2002 Project no.: 1994/01384

Responsible committee: ISE/35 Cast Iron

Interested committees: WEE/35, WEE/-/1

Title: Draft British Standard BS EN 1011-8 Welding - Recommendations for welding of metallic materials - Part 8:

Welding of cast irons

Supersession information: If this document is published as a standard, the UK implementation of it will supersede

BS4570 : 1985 . If you are aware of a current national standard which may be affected, please notify the secretary

(contact details below).

WARNING: THIS IS A DRAFT AND MUST NOT BE REGARDED OR USED AS A BRITISH STANDARD.

THIS DRAFT IS NOT CURRENT BEYOND 31.05.2002.

This draft is issued to allow comments from interested parties; all comments will be given consideration prior to

publication. No acknowledgement will normally be sent. See overleaf for information on commenting.

No copying is allowed, in any form, without prior written permission from BSI except as permitted under the Copyright,

Designs and Patent Act 1988 or for circulation within a nominating organization for briefing purposes. Electronic

circulation is limited to dissemination by e-mail within such an organization by committee members.

Further copies of this draft may be purchased from BSI Customer Services, Tel: +44(0) 20 8996 9001 or email

orders@bsi-global.com. British, International and foreign standards are also available from BSI Customer Services.

British Standards on CD or Online are available from British Standards Publishing Sales Limited.

Tel: 01344 404409 or email bsonline@techindex.co.uk.

Information on the co-operating organizations represented on the committees referenced above may be obtained from

the responsible committee secretary.

Cross-references

The British Standards which implement International or European publications referred to in this draft may be found via

the British Standards Online Service on the BSI web site http://www.bsi-global.com.

Direct tel: 020 8996 7140 Responsible Committee Secretary: Mr R Turpin (BSI)

E-mail: robert.turpin@bsi-global.com

Draft for Public Comment

*+

Head Office

389 Chiswick High Road

London W4 4AL

Telephone: +44(0)20 8996 9000

Fax: +44(0)20 8996 7001

www.bsi-global.com

Form 36

Version 6.0

DPC: 02/704031

L

i

c

e

n

s

e

d

C

o

p

y

:

T

o

m

M

a

g

e

e

,

H

o

w

d

e

n

P

o

w

e

r

,

1

8

J

u

n

e

2

0

0

3

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

b

Introduction

This draft standard is based on European discussions in which the UK took an active part. Your comments on this

draft are welcome and will assist in the preparation of the consequent British Standard. If no comments are received

to the contrary, then the UK will approve this draft and implement it as a British Standard. Comment is particularly

welcome on national, legislative or similar deviations that may be necessary.

Even if this draft standard is not approved by the UK, if it receives the necessary support in Europe, the UK will be

obliged to publish the official English Language text unchanged as a British Standard and to withdraw any conflicting

standard.

UK Vote

Please indicate whether you consider the UK should submit a negative (with reasons) or positive vote on this draft.

Submission

The guidance given below is intended to ensure that all comments receive efficient and appropriate attention by the

responsible BSI committee. Annotated drafts are not acceptable and will be rejected.

All comments must be submitted, preferably electronically, to the Responsible Committee Secretary at the address

given on the front cover. Comments should be compatible with Version 6.0 or Version 97 of Microsoft Word for

Windows, if possible; otherwise comments in ASCII text format are acceptable. Any comments not submitted

electronically should still adhere to these format requirements.

Comments should be submitted wherever possible as presented in the example table below. A blank electronic

version of this table is available from the Committee Secretary or it can be downloaded from the BSI web site at:

http://www.bsi-global.com/Standards+Development/05_Drafts+For+Public+Comment_Drafts/index.xhtml

Draft no: Project no.: 1998/XXXXX DPC no.: 98/XXXXXX

Short title: Commentator: Date:

Clause/

subclause

Paragraph/

Figure/ Table

Type of comment

(General/

technical/editorial)

Comment (with rationale) Proposed change

3.1 1st definition Editorial Definition is ambiguous and needs

clarifying.

Amend to read ... so that the mains

connector to which no connection ...

6.4 2nd paragraph Technical The use of the UV photometer as an

alternative cannot be supported as

serious problems have been

encountered in its use in the UK.

Delete reference to UV photometer.

Microsoft and MS-DOS are registered trademarks, and Windows is a trademark of Microsoft Corporation.

L

i

c

e

n

s

e

d

C

o

p

y

:

T

o

m

M

a

g

e

e

,

H

o

w

d

e

n

P

o

w

e

r

,

1

8

J

u

n

e

2

0

0

3

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

EUROPEAN STANDARD

NORME EUROPENNE

EUROPISCHE NORM

DRAFT

prEN 1011-8

March 2002

ICS

English version

Welding - Recommendations for welding of metallic materials -

Part 8: Welding of cast irons

Soudage - Recommandations pour le soudage des

matriaux mtalliques - Partie 8: Soudage des fontes

Schweien - Empfehlungen zum Schweien metallischer

Werkstoffe - Teil 8: Schweien von Gusseisen

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee CEN/TC 190.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations which

stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other language

made by translation under the responsibility of a CEN member into its own language and notified to the Management Centre has the same

status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,

Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without notice and

shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMI T EUROPEN DE NORMALI SATI ON

EUROPI SCHES KOMI TEE FR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

2002 CEN All rights of exploitation in any form and by any means reserved

worldwide for CEN national Members.

Ref. No. prEN 1011-8:2002 E

L

i

c

e

n

s

e

d

C

o

p

y

:

T

o

m

M

a

g

e

e

,

H

o

w

d

e

n

P

o

w

e

r

,

1

8

J

u

n

e

2

0

0

3

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

prEN 1011-8:2002 (E)

2

Contents

Foreword......................................................................................................................................................................3

1 Scope ..............................................................................................................................................................4

2 Normative references ....................................................................................................................................4

3 Terms and definitions....................................................................................................................................4

4 Abbreviations and symbols..........................................................................................................................5

5 Provision for quality assurance requirements ...........................................................................................5

6 Storage, handling and identification of parent metal.................................................................................5

7 Fusion welding processes............................................................................................................................5

8 Welding consumables...................................................................................................................................6

8.1 General ............................................................................................................................................................6

8.2 Supply, storage and handling.......................................................................................................................6

9 Equipment.......................................................................................................................................................6

9.1 General ............................................................................................................................................................6

9.2 Ancillary equipment.......................................................................................................................................6

10 Fabrication......................................................................................................................................................7

10.1 General ............................................................................................................................................................7

10.2 Butt welding ...................................................................................................................................................7

10.3 Fillet welding ..................................................................................................................................................7

11 Weld preparation............................................................................................................................................7

11.1 Joint welds......................................................................................................................................................7

11.2 Finishing welds and repair welds.................................................................................................................7

12 Positioning of parts to be welded ................................................................................................................7

13 Pre-heat temperature and interpass temperature ......................................................................................8

14 Tack welds......................................................................................................................................................8

15 Temporary attachments ................................................................................................................................8

16 Run-on plates and run-off plates..................................................................................................................8

17 Arcing..............................................................................................................................................................8

18 Inter-run cleaning and inter-run treatment..................................................................................................8

19 Heat input........................................................................................................................................................8

20 Welding procedure specification (WPS)......................................................................................................8

21 Traceability .....................................................................................................................................................8

22 Peening ...........................................................................................................................................................8

23 Inspection and testing...................................................................................................................................9

24 Quality requirements.....................................................................................................................................9

25 Correction of non-conformity.......................................................................................................................9

26 Distortion ........................................................................................................................................................9

27 Post weld heat treatment ..............................................................................................................................9

28 Post weld cleaning.........................................................................................................................................9

Annex A (normative) Quality assurance requirements .........................................................................................10

Annex B (informative) Welding technology for cast iron castings ......................................................................15

Bibliography ..............................................................................................................................................................19

L

i

c

e

n

s

e

d

C

o

p

y

:

T

o

m

M

a

g

e

e

,

H

o

w

d

e

n

P

o

w

e

r

,

1

8

J

u

n

e

2

0

0

3

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

prEN 1011-8:2002 (E)

3

Foreword

This document (prEN 1011-8) has been prepared by Technical Committee CEN/TC 190 "Foundry Technology", the

secretariat of which is held by DIN.

This document is currently submitted to the CEN Enquiry.

Within its programme of work, Technical Committee CEN/TC 190 requested CEN/TC 190/WG 5 "Welding of cast

iron" to prepare the following standard:

prEN 1011-8, Welding Recommendations for welding of metallic materials Part 8: Welding of cast irons.

This is one of a series of European Standards for requirements for fusion welding of metallic materials.

According to CEN/CENELEC Internal Regulations, the following countries are bound to implement this European

Standard:

L

i

c

e

n

s

e

d

C

o

p

y

:

T

o

m

M

a

g

e

e

,

H

o

w

d

e

n

P

o

w

e

r

,

1

8

J

u

n

e

2

0

0

3

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

prEN 1011-8:2002 (E)

4

1 Scope

This draft European Standard specifies the requirements for fusion welding of unalloyed and low-alloy cast iron

castings produced in accordance with

EN 1561, Founding Grey cast irons;

EN 1562, Founding Malleable cast irons;

EN 1563, Founding Spheroidal graphite cast irons.

2 Normative references

This European Standard incorporates by dated or undated reference, provisions from other publications. These

normative references are cited at the appropriate places in the text and the publications are listed hereafter. For

dated references, subsequent amendments to or revisions of any of these publications apply to this European

Standard only when incorporated in it by amendment or revision. For undated references the latest edition of the

publication referred to applies (including amendments).

EN 288-2, Specification and approval of welding procedures for metallic materials Part 2: Welding procedure

specification for arc welding.

EN 729-1, Quality requirements for welding Fusion welding of metallic materials Part 1: Guidelines for selec-

tion and use.

EN 1011-1, Welding Recommendations for welding of metallic materials Part 1: General guidance for arc

welding.

EN 12536, Welding consumables Rods for gas welding of non alloy and creep-resisting steels Classification.

EN 25817, Arc-welded joints in steel Guidance on quality levels for imperfections (ISO 5817:1992).

EN ISO 4063, Welding and allied processes Nomenclature of processes and reference numbers

(ISO 4063:1998).

NOTE Informative references to documents used in the preparation of this standard, and cited at the appropriate places in

the text, are listed in the bibliography.

3 Terms and definitions

For the purposes of this standard, the following terms and definitions apply:

3.1

production welding

any welding carried out during manufacturing before final delivery to the end user

NOTE It includes joint welding and finishing welding (see 3.2 and 3.3).

3.2

joint welding

production welding used to assemble components together to obtain an integral unit

3.3

finishing welding

production welding carried out in order to ensure the agreed quality of the casting

3.4

repair welding

any welding carried out after final delivery of the casting to the end user

L

i

c

e

n

s

e

d

C

o

p

y

:

T

o

m

M

a

g

e

e

,

H

o

w

d

e

n

P

o

w

e

r

,

1

8

J

u

n

e

2

0

0

3

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

prEN 1011-8:2002 (E)

5

3.5

homogeneous filler metal

any filler metal which results in a deposited metal with the same type of microstructure as the parent metal

3.6

semi-homogeneous filler metal

any filler metal which results in a deposited metal with a steel-type microstructure

3.7

non-homogeneous filler metal

any filler metal which results in a deposited metal with a microstructure that differs from the parent metal

3.8

cast welding

welding by pouring liquid metal into a specially prepared groove in a casting

3.9

liquid metal welding

cast welding with additional use of a metal arc welding process

4 Abbreviations and symbols

For the purposes of this standard, the abbreviations and symbols given in EN 1011-1 shall apply.

5 Provision for quality assurance requirements

For the purposes of this standard, the provisions for quality assurance requirements given in annex A shall apply.

6 Storage, handling and identification of parent metal

Storage and handling shall be carried out in such a manner that the parent metal is not adversely affected.

Provision shall be made for correct identification, e.g. grade and storage.

7 Fusion welding processes

Fusion welding processes shall be either one or a combination of the following welding processes with their

reference number in accordance with EN ISO 4063:

111 manual metal arc welding (metal arc welding with covered electrode);

114 self-shielded tubular-cored arc welding;

12 submerged arc welding;

13 gas-shielded metal arc welding;

141 tungsten inert gas welding; TIG welding;

15 plasma arc welding;

185 magnetically impelled arc butt welding;

24 flash welding;

311 oxy-acetylene welding;

42 friction welding;

71 aluminothermic welding;

L

i

c

e

n

s

e

d

C

o

p

y

:

T

o

m

M

a

g

e

e

,

H

o

w

d

e

n

P

o

w

e

r

,

1

8

J

u

n

e

2

0

0

3

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

prEN 1011-8:2002 (E)

6

and additionally:

cast welding;

liquid metal welding.

Other fusion welding processes shall be agreed between the manufacturer and the purchaser by the time of

acceptance of the order.

8 Welding consumables

8.1 General

An appropriate filler metal (see 3.5, 3.6 and 3.7) shall be selected in accordance with the requirements of the weld

and the welding process.

Any special recommendations given by the manufacturer and/or supplier of the welding consumables shall be

taken into account.

Welding consumables (e.g. filler metals, gases and fluxes) shall conform to the appropriate European and/or ISO

Standards, as applicable, (see annex B, Tables B.1 and B.2).

It can be necessary to manufacture appropriate filler metals, especially for oxy-acetylene and liquid metal

welding.To avoid confusion, such products shall be identified.

8.2 Supply, storage and handling

For the purposes of this standard, the supply, storage and handling requirements given in EN 1011-1 shall apply.

9 Equipment

9.1 General

For the purposes of this standard, the equipment requirements given in EN 1011-1 shall apply.

9.2 Ancillary equipment

If applicable, the ancillary equipment shall include:

a) power source for welding equipment and additional machinery;

b) facilities for joint preparation;

c) facilities for preheating and post-weld heat treatment including temperature measurement equipment;

d) cranes and other handling equipment;

e) peening equipment;

f) electrode baking ovens, electrode bags etc. for handling filler metals;

g) cleaning equipment;

h) equipment for destructive and non-destructive testing;

i) fixtures and welding jigs;

j) personal protection equipment directly connected with welding.

L

i

c

e

n

s

e

d

C

o

p

y

:

T

o

m

M

a

g

e

e

,

H

o

w

d

e

n

P

o

w

e

r

,

1

8

J

u

n

e

2

0

0

3

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

prEN 1011-8:2002 (E)

7

10 Fabrication

10.1 General

When planning the welding of cast iron castings, consideration shall be given to the:

need for trained and approved welders;

need for a responsible welding coordinator;

casting geometry;

temperature control;

stress conditions caused by welding;

material behaviour;

working conditions;

inspection requirements.

NOTE Selection of the requirement category (see EN 729-1) is recommended and should be carried out with due consid-

eration of any special operating conditions and joint strains together with any economic factors.

Prior to welding, there shall be an agreement made between the parties concerned which includes the require-

ments for finishing welding, joint welding and repair welding, as applicable.

If applicable, finishing and/or repair welding methods to correct casting non-conformities shall be carefully planned

and prepared.

The casting surface to be welded shall be checked by a suitable non-destructive test method, in order to ensure

complete removal of any casting non-conformity.

10.2 Butt welding

Butt welding shall be in accordance with EN 1011-1.

10.3 Fillet welding

Fillet welding shall be in accordance with EN 1011-1.

11 Weld preparation

11.1 Joint welds

Preparation shall be carried out in accordance with EN 1011-1.

NOTE In addition, joint welding should meet the recommendations given in Table B.1 and Table B.2.

11.2 Finishing welds and repair welds

Preparation shall remove any crack, pore, notche and contamination. The area to be welded shall be suitable for

the welding process (see B.1 and B.2).

NOTE Recommendations on weld preparation are given in B.2.

If contamination cannot be removed (e.g. during repair welding), other measures shall be used, such as the

selection of special filler metals.

12 Positioning of parts to be welded

Positioning of parts to be welded shall be carried out in accordance with EN 1011-1.

L

i

c

e

n

s

e

d

C

o

p

y

:

T

o

m

M

a

g

e

e

,

H

o

w

d

e

n

P

o

w

e

r

,

1

8

J

u

n

e

2

0

0

3

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

prEN 1011-8:2002 (E)

8

13 Pre-heat temperature and interpass temperature

The pre-heat temperature T

p

and interpass temperature T

i

shall be within the recommended values given in B.4 and

Tables B.1 and B.2 for the following:

filler metal;

parent material grade;

geometry of the casting;

welding process;

welding parameters.

14 Tack welds

Tack welds shall be in accordance with EN 1011-1.

15 Temporary attachments

Temporary attachments shall be in accordance with EN 1011-1.

16 Run-on plates and run-off plates

Run-on and run-off plates shall be in accordance with EN 1011-1.

17 Arcing

Arcing shall be in accordance with EN 1011-1.

18 Inter-run cleaning and inter-run treatment

Inter-run cleaning and inter-run treatment shall be in accordance with EN 1011-1.

19 Heat input

If applicable, heat input can be estimated in accordance with EN 1011-1.

20 Welding procedure specification (WPS)

If a wleding procedure specification is required:

for arc welding its content shall be in accordance with EN 288-2;

for other welding methods, its content may be modified. In this case, its content shall be agreed in writing be-

tween the parties concerned.

21 Traceability

Traceability shall be in accordance with EN 1011-1.

22 Peening

Peening shall be in accordance with EN 1011-1.

L

i

c

e

n

s

e

d

C

o

p

y

:

T

o

m

M

a

g

e

e

,

H

o

w

d

e

n

P

o

w

e

r

,

1

8

J

u

n

e

2

0

0

3

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

prEN 1011-8:2002 (E)

9

NOTE To minimize residual stress, when using non-homogeneous filler metal, peening is recommended immediately after

welding. For further information, see the instructions of the filler metal manufacturer.

23 Inspection and testing

Inspection and testing shall be carried out in accordance with the contract.

24 Quality requirements

Quality requirements shall be in accordance with EN 1011-1.

The requirement class and/or the quality level shall be agreed between the manufacturer and the purchaser prior to

welding. Joint welds shall conform to the requirement class given in Table A.1, and/or the quality level given in

Table A.2.

25 Correction of non-conformity

Correction of non-conformity shall be carried out in accordance with EN 1011-1.

26 Distortion

If necessary, the method of correction of castings unacceptably distorted by the welding process shall be agreed

between the manufacturer and the purchaser.

NOTE Any method used to correct distortion should not be deleterious to the casting structure.

27 Post weld heat treatment

The details of any post weld heat treatment shall be agreed between the manufacturer and the purchaser prior to

welding (see recommendations in Table B.1 and B.2).

NOTE Post weld heat treatment can be necessary because of the need to reduce residual stresses in welded castings

and/or to adjust the mechanical properties of the material.

28 Post weld cleaning

Post weld cleaning shall be in accordance with EN 1011-1.

L

i

c

e

n

s

e

d

C

o

p

y

:

T

o

m

M

a

g

e

e

,

H

o

w

d

e

n

P

o

w

e

r

,

1

8

J

u

n

e

2

0

0

3

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

prEN 1011-8:2002 (E)

10

Annex A

(normative)

Quality assurance requirements

A.1 General

This annex gives information on the quality assurance requirements that need to be met. The requirement class,

quality level and corresponding tests shall be chosen so as to achieve the mechanical properties of the casting.

Test frequencies and test methods are not given in this annex.

The test requirements shall be agreed between the manufacturer and the purchaser by the time of acceptance of the

order.

A.2 Requirements for fusion welding

A.2.1 Agreement

In planning the welding procedure for the particular cast iron casting, the following shall be considered:

stresses caused by the welding process;

the weldability of the material;

the operating conditions;

the test procedures.

For each welded casting, only the requirements concerning the necessary conditions of use of the component shall

be defined. These requirements and the quality levels shall be agreed between the manufacturer and the purchaser

by the time of acceptance of the order (see Tables A.1 and A.2). This agreement shall be recorded.

A.2.2 Requirements

The three requirement classes and eleven criteria for fusion welding are given in table A.1.

The requirement class for weld workmanship criterion shall be selected from Table A.1. The weld workmanship (No. 1

in Table A.1) requirement class limits for external and internal imperfections shall be chosen by reference to

Table A.2.

1) excess weld metal

2) excessive convexity

3) incompletely filled groove

4) fillet weld having a throat thickness smaller than the nominal value

5) excessively asymmetric fillet weld

especially for joint welding

6) undercut and root concavity

7) end-crater pipe

8) surface pore

9) visible slag inclusions

10) spatter

11) stray arcing

12) visible cracks

13) crater cracks

L

i

c

e

n

s

e

d

C

o

p

y

:

T

o

m

M

a

g

e

e

,

H

o

w

d

e

n

P

o

w

e

r

,

1

8

J

u

n

e

2

0

0

3

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

prEN 1011-8:2002 (E)

11

Numbers and types of internal imperfections with reference to Table A.2:

14) gas cavities

15) solid inclusions

16) lack of fusion (incomplete fusion)

17) internal cracks

18) crater pipe

The limits for the types of external and internal imperfections listed above are categorized by three quality levels (B, C,

D). These quality levels can differ for each imperfection type.

A.2.3 Inspection and testing

The conformity of the weld with the requirement classes given in Table A.1 and the limits for external and internal

imperfections given in Table A.2 shall be verified by visual examination and, if required, by destructive or

non-destructive testing. Any other requirements shall be verified by suitable tests carried out on test specimens

produced at the same time as the welding of the casting. The test type, the scope and range of testing and the time of

testing shall be defined and recorded.

Table A.1 Criteria and requirement classes for fusion welding of cast iron castings

Requirement class

No. Criterion

1 2 3

1

Weld workmanship a) external imperfections

b) internal imperfections

+

+

+

-

+

2 Hardening traverse (e.g. for wear) + -

3 Strength + -

4 Toughness -

5 Reduction of internal stress - -

6 Machining - -

7 Corrosion - -

8 Weld tightness - -

9 Microstructure -

10 Coating - -

11 Colour match - -

+ mandatory requirement

no requirement

- requirement to be agreed

Class 1 for castings for safety components only, e.g. required monitoring plant

Class 2 for castings with special requirements

Class 3 for castings without special requirements

L

i

c

e

n

s

e

d

C

o

p

y

:

T

o

m

M

a

g

e

e

,

H

o

w

d

e

n

P

o

w

e

r

,

1

8

J

u

n

e

2

0

0

3

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

prEN 1011-8:2002 (E)

12

Table A.2 Limits for external and internal imperfections

Limits for imperfections for quality level

No.

Type of

imperfection

Requirements/

remarks

B C D

External imperfections

a

1 Excess weld metal,

see Figure A.1

Smooth transition is

required; only for

non-homogeneous

welding without

subsequent ma-

chining

h s 1 mm + 0,1 b,

max. 5 mm

h s 1 mm + 0,15 b,

max. 7 mm

h s 1 mm + 0,25 b,

max. 10 mm

2 Excessive con-

vexity, see Figure

A.2

Smooth transition is

required; only for

non-homogeneous

welding without

subsequent ma-

chining

h s 1 mm + 0,15 b,

max. 4 mm

h s 1 mm + 0,25 b,

max. 5 mm

No special require-

ments

3 Incompletely filled

groove, see Figure

A.3

The filled groove

thickness shall not

be below the mini-

mum tolerance of

the wall thickness.

Smooth transition is

required; only for

non-homogeneous

welding without

subsequent ma-

chining

h s 0,05 t,

max. 3 mm

h s 0,1 t,

max. 3 mm

h s 0,2 t,

max. 4 mm

4 Fillet weld having a

throat thickness

smaller than the

nominal value, see

Figure A.4

Only for non-homo-

geneous welding

without subsequent

machining

Not permitted h s 0,5 mm + 0,1 a

max. 1 mm

h s 0,5 mm + 0,1 a

max. 2 mm

5 Excessively asym-

metric fillet weld,

see Figure A.5

Only for non-homo-

geneous welding

without subsequent

machining

h s 1,5 mm + 0,5 a h s 2 mm + 0,15 a

Occasional local

excess permitted

h s 2 mm + 0,2 a

Occasional local

excess permitted

6 Undercut and root

concavity, see Fig-

ure A.6

Smooth transition is

required; undercut

at the top pass at

butt joints and root

imperfections at the

transition between

weld seam and par-

ent metal. Smooth

edge rounding is

not an undercut

h s 0,5 mm h s 1 mm h s 1,5 mm

7 End-crater pipe Open crater reduc-

ing the cross-

section of the weld

Not permitted Short imperfections

up to 2 mm depth

without sharp tran-

sitions permitted

Short imperfections

up to 4 mm depth

without sharp tran-

sitions permitted

8 Surface pore In top pass and root

pass

Discrete pores up to

5 % of weld area

with maximum pore

diameter of 3 mm

Discrete pores up to

10 % of weld area

with maximum pore

diameter of 5 mm

Discrete pores up to

20 % of weld area

with maximum pore

diameter of 5 mm

L

i

c

e

n

s

e

d

C

o

p

y

:

T

o

m

M

a

g

e

e

,

H

o

w

d

e

n

P

o

w

e

r

,

1

8

J

u

n

e

2

0

0

3

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

prEN 1011-8:2002 (E)

13

Table A.2 (continued)

Limits for imperfections for quality level

No.

Type of

imperfection

Requirements/

remarks

B C D

9 Visible slag inclu-

sions

In top pass and root

pass

Not permitted Visible imper-

fections up to 10 %

of weld area with a

maximum diameter

of 4 mm are

allowed, provided

these are

dispersed.

Visible imper-

fections up to 25 %

of weld area with a

maximum diameter

of 4 mm are

allowed

10 Spatter Fused metal spatter

on weld or casting

surfaces

Acceptance dependent upon the application

11 Stray arcing Localised spatter Not permitted Not permitted No requirements

12 Visible cracks All types of cracks

except micro cracks

(h l < 1 mm)

b

Not permitted Not permitted Not permitted

13 Crater crack All types

b

Not permitted Allowed Allowed

Internal imperfections

14 Gas cavities Gas cavities are

single voids or

pores, clusters of

pores, pore lines,

elongated cavities

Small randomly dis-

persed cavities with

a diameter of up to

1 mm are allowed,

but no continuous

or wormhole

porosity

Locally permitted

with a diameters up

to 3 mm, but no

connected porosi-

ties, no clusters of

pores and non con-

tinuous wormhole

porosity.

No special require-

ments

15 Solid inclusions Solid inclusions are

non-homogeneous

metal inclusions,

single slags, slag

lines and clusters of

slags

Up to 3 imperfec-

tions per 50 mm

50 mm of weld sur-

face with a diameter

of up to 2 mm

Up to 3 imperfec-

tions per 50 mm

50 mm of weld sur-

face with a diameter

of up to 5 mm

No special require-

ments

16 Lack of fusion Incomplete fusion of

the joint flanks,

between the weld-

ing bead and the

welding pass

b

Not permitted

Acceptance in low stress areas only

17 Internal cracks Internal cracks

within the filler

metal and within the

heat-affected

zone

b

Not permitted Less than 1 mm

long

No special require-

ments

18 Crater pipe A shrinkage cavity

at the end of a weld

run and not elimi-

nated before or

during subsequent

weld runs

Not permitted Not permitted No special require-

ments

a

Dimensional variations are allowed within the relevant casting tolerances

b

Proof of conformity is often difficult. Indications resulting from non-destructive examination tests with values up to

1 mm + 0,05 wall thickness in millimetres are not classified as lack of fusion and cracks

L

i

c

e

n

s

e

d

C

o

p

y

:

T

o

m

M

a

g

e

e

,

H

o

w

d

e

n

P

o

w

e

r

,

1

8

J

u

n

e

2

0

0

3

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

prEN 1011-8:2002 (E)

14

Figure A.1 Excess weld metal Figure A.2 Excessive convexity

Figure A.3 Incompletely filled groove Figure A.4 Fillet weld

Figure A.5 Excessively asymmetric fillet weld Figure A.6 Undercut and root concavity

Key to figures A.1 to A.6 is given below:

a nominal throat thickness of fillet welds

b weld width

h weld thickness deviation

t component wall thickness

L

i

c

e

n

s

e

d

C

o

p

y

:

T

o

m

M

a

g

e

e

,

H

o

w

d

e

n

P

o

w

e

r

,

1

8

J

u

n

e

2

0

0

3

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

prEN 1011-8:2002 (E)

15

Annex B

(informative)

Welding technology for cast iron castings

B.1 General

For welding cast iron castings, one of the three following procedures is generally used:

welding with either homogeneous or semi-homogeneous filler metal (see Table B.1);

welding with non-either homogeneous or semi-homogeneous filler metal (see Table B.2);

welding without filler metal.

In the absence of a pre-set qualification scheme, a preliminary test should be carried to make sure that the chosen

procedure is suitable. Subsequently, if required, a welding procedure specification (WPS) can be prepared.

B.2 Preparation for welding

The casting area to be welded and the adjacent area should be properly cleaned prior to welding. The casting skin in

these areas should be removed. Weld preparation should be carried out in accordance with EN ISO 9692-2 and,

additionally, the shape and size of any joints should be taken into account.

Groove preparation should preferably be carried out mechanically, e.g. by grinding. If groove preparation is carried out

thermally, e.g. by plasma arc cutting or powder flame cutting, the molten rim zone should be ground after solidification

to remove any hardened zones and/or cracks. Flame-cutting, oxy-acetylene and arc-air-gouging are not suitable for

cast irons.

B.3 Backing bar

The need for a backing bar depends on the welding process, the preheating temperature, the cast iron grade and the

weld geometry.

When a high level of dilution is expected between the molten material and any backing bar, the effect of this dilution

should be considered. To avoid any alteration to the chemical composition of the molten material, either a backing bar

of the same chemical composition or a refractory material should be chosen.

B.4 Heat and temperature distribution

Equal temperature distribution through the section of the casting should be ensured during pre-heating and cooling.

The pre-heating temperature and the heating rate depend on the casting material type, the casting material grade, the

complexity of the casting and the welding process. When a casting of complex design is heated (locally or

completely), in order to avoid cracks and distortion, the heating rate should be s 50 K/h until the temperature of the

casting reaches 450 C.

NOTE Examples of common heating processes are furnace heating, heating by means of a gas torch, heating elements

and inductive heating.

L

i

c

e

n

s

e

d

C

o

p

y

:

T

o

m

M

a

g

e

e

,

H

o

w

d

e

n

P

o

w

e

r

,

1

8

J

u

n

e

2

0

0

3

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

prEN 1011-8:2002 (E)

16

Table B.1 Welding of cast iron castings with homogeneous or semi-homogeneous filler metals

Grey cast iron

Spheroidal graphite

cast iron

Malleable cast iron,

blackheart

Malleable cast iron,

whiteheart

Malleable cast iron,

weldable grade

Procedure Method

GJL GJS GJMB GJMW

EN-GJMW-360-12

(EN-JM1020)

Preparation Removing the casting skin in the casting welding area and its adjacent area and cleaning them.

thermal Plasma arc cutting; powder flame cutting

(arc-air cutting conditional, flame cutting not suitable).

all methods all methods

Weld preparation

mechanical Machining, grinding, back-chipping

Use of backing bar Graphitic material, loam, ceramics, spheroidal graphite cast iron, unalloyed steel

1) Preheating Normal temperature: T

p

= 550 C, max. 700 C (dependent on the procedure);

Semi-homogeneous filler metal: T

p

= 250 C to 550 C

Maximum heating rate (dependent on the casting or component)

2) Casting

temperature

during welding

Homogeneous filler metal: outside welding area 450 C

Semi-homogeneous filler metal: outside welding area 250 C

(Semi-homogeneous filler metal: not recommended for grey cast irons GJL)

Thermal treatment rec-

ommendations

(local casting welding

area or complete cast-

ing)

3) Cooling rate Dependent on the complexity of the casting or component.

From 450 C to 150 C 50 K/h for castings sensitive to stress

Post weld heat treatment Separate heat

treatment or use of

the residual welding

heat

Any heat treatment method can be used, dependent on the parent metal, size and shape of

the casting and other requirements.

not necessary for

wall thicknesses

8 mm;

> 8 mm (see left)

Licensed Copy: Tom Magee, Howden Power, 18 June 2003, Uncontrolled Copy, (c) BSI

prEN 1011-8:2002 (E)

17

Table B.1 (continued)

Grey cast iron

Spheroidal graphite

cast iron

Malleable cast iron,

blackheart

Malleable cast iron,

whiteheart

Malleable cast iron,

weldable grade

Procedure Method

GJL GJS GJMB GJMW

EN-GJMW-360-12

(EN-JM1020)

Oxy-acetylene

welding (311)

GJL rod

GJS rod

GJS rod

Welding rods GII

prEN 12536

GJL or GJS

electrode covered or

not covered

GJS electrode, covered or not covered

Alloy coated steel

electrode

Coated steel electrode. Coating with or without alloy

Manual metal arc

welding (111)

Coated welding rod

Coated welding elec-

trode, e.g. B-type

EN 499

Gas shielded metal

arc welding (13)

Wire electrodes with or without alloy for interpass temperature 300 C only Wire electrode, un-

alloyed EN 440

TIG welding (141) Filler rods, cored wires for interpass temperatures 300 C only Unalloyed rods

EN 1668

Self-shielded tubu-

lar-cored arc welding

(114)

Cored wire; deposited metal (GJS) Wire electrode, un-

alloyed EN 758

Cast welding GJL or GJS melt

material

GJS melt material

Liquid metal welding Same as cast welding, but with additional

use of electrodes

Not normally used

Use of filler metals

Plasma arc

welding (15)

With or without small amounts of filler metal

Use of flux With or without alloy, can be used to improve the welding conditions.

NOTE The numbers in brackets show the fusion welding process reference number, see clause 7.

T

p

= preheating temperature

Licensed Copy: Tom Magee, Howden Power, 18 June 2003, Uncontrolled Copy, (c) BSI

prEN 1011-8:2002 (E)

18

Table B.2 Welding of cast iron castings with non-homogeneous filler metal

Grey cast iron

Spheroidal graphite

cast iron

Malleable cast iron,

blackheart

Malleable cast iron,

whiteheart

Procedure Method

GJL GJS GJMB GJMW

a

Preparation Removing the casting skin in the casting welding area and its adjacent area and cleaning them.

thermal Plasma arc cutting; powder flame cutting

(arc air cutting conditional, flame cutting not usable)

all methods

Weld preparation

mechanical machining, grinding, back-chipping

1) Preheating T

p

max. 300 C Dependent on the decar-

burisation, not ne-

cessesary for wall thick-

nesses up to 4 mm.

2) Interpass tempe-

rature T

i

Interpass temperature T

i

= T

p

+ 50 K

Thermal setting recom-

mendations

(local welding area or

complete casting)

3) Cooling In still air

Post-weld heat treatment Separate heat treatment

or use of the residual

welding heat

Any heat treatment method can be used, dependent on the parent material, complexity of the casting and other

requirements.

Manual metal arc

welding (111)

Covered welding rod, according to prEN ISO 1071

Gas shielded metal arc

welding (13)

Solid wire electrodes, covered wire electrodes, according to prEN ISO 1071

TIG welding (141) Solid rods, filler rods, solid wire, filler wire, according to prEN ISO 1071

Self shielded tubular-

cored arc welding (114)

Cored wire electrode, according to prEN ISO 1071

Filler metals and powder

Plasma arc cutting, pow-

der flame cutting

Solid or cored wire electrodes, metallic powder

NOTE The numbers in brackets show the fusion welding process reference number, see clause 7.

a

Weldable malleable cast iron EN-GJMW-360-12 (EN-JM 1020) (wall thickness 8 mm) can be welded with commercial unalloyed filler metals.

Licensed Copy: Tom Magee, Howden Power, 18 June 2003, Uncontrolled Copy, (c) BSI

prEN 1011-8:2002 (E)

19

Bibliography

In the preparation of this European Standard, use was made of a number of documents for reference purposes.

These informative references are cited at the appropriate places in the text and the publications are listed hereafter.

EN 440, Welding consumables Wire electrodes and deposits for gas-shielded metal arc welding of non alloy and

fine grain steels Classification.

EN 499, Welding consumables Covered electrodes for manual metal arc welding of non alloy and fine grain

steels Classification.

EN 758, Welding consumables Tubular cored electrodes for metal arc welding with and without a gas shield of

non alloy and fine grain steels Classification.

EN 1561, Founding Grey cast irons.

EN 1562, Founding Malleable cast irons.

EN 1563, Founding Spheroidal graphite cast irons.

EN 1668, Welding consumables Rods, wires and deposits for tungsten inert gas welding of non-alloy and fine

grain steels Classification.

EN ISO 9692-2, Welding and allied processes Joint preparation Part 2: Submerged arc welding of steels

(ISO 9692-2:1998).

prEN ISO 1071, Welding consumables Welding consumables for fusion welding of cast iron Classification

(ISO/DIS 1071:2000).

L

i

c

e

n

s

e

d

C

o

p

y

:

T

o

m

M

a

g

e

e

,

H

o

w

d

e

n

P

o

w

e

r

,

1

8

J

u

n

e

2

0

0

3

,

U

n

c

o

n

t

r

o

l

l

e

d

C

o

p

y

,

(

c

)

B

S

I

You might also like

- Bs en 1011 Part 5Document14 pagesBs en 1011 Part 5shaggeruk100% (1)

- BS EN ISO 15607-2003 金属材料焊接程序规范和合格鉴定.总则 PDFDocument22 pagesBS EN ISO 15607-2003 金属材料焊接程序规范和合格鉴定.总则 PDFunknown1711100% (1)

- Final Draft Pren Iso 15607: European Standard Norme Européenne Europäische NormDocument19 pagesFinal Draft Pren Iso 15607: European Standard Norme Européenne Europäische Normunnamed90100% (1)

- ISO - TR - 15608 - Welding Guide Line PDFDocument10 pagesISO - TR - 15608 - Welding Guide Line PDFDacher DanielNo ratings yet

- DIN en ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and RotationDocument12 pagesDIN en ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and RotationHector Flores GarciaNo ratings yet

- Minimum Requirements IweDocument52 pagesMinimum Requirements IweIonutz TelteuNo ratings yet

- Udlp-Tacom Welding Code, Almn (Ansi-Aws d1.2)Document120 pagesUdlp-Tacom Welding Code, Almn (Ansi-Aws d1.2)mtcengineering100% (2)

- Reduce Hydrogen Cracking with Proper PreheatDocument3 pagesReduce Hydrogen Cracking with Proper PreheatVJG369No ratings yet

- Iso Fdis15614 13 2021Document24 pagesIso Fdis15614 13 2021arabsniperNo ratings yet

- BS 5996 (1993) Specification ForAcceptanc Levels For Internal Imperfections in Steel Late, Strip and Wide Flats, Based On Ultrasonic TestingDocument14 pagesBS 5996 (1993) Specification ForAcceptanc Levels For Internal Imperfections in Steel Late, Strip and Wide Flats, Based On Ultrasonic TestingZoltán PálfyNo ratings yet

- BS 709 Destructive TestingDocument17 pagesBS 709 Destructive TestingGabrieleNo ratings yet

- Tungsten ElectrodesDocument2 pagesTungsten ElectrodesSyed Furqan Rehmani0% (2)

- Welding Procedure Specification StandardDocument18 pagesWelding Procedure Specification StandardIonut Florica100% (1)

- Drop Weight Tear Testing of High Toughness Pipeline MaterialDocument8 pagesDrop Weight Tear Testing of High Toughness Pipeline MaterialKK SinghNo ratings yet

- List of Welding CodesDocument10 pagesList of Welding CodesVijayakumar Samy0% (2)

- Iso 3834-2Document16 pagesIso 3834-2NONNE NaineNo ratings yet

- Iso 3834-4 - 2005Document8 pagesIso 3834-4 - 2005Necdet AydemirNo ratings yet

- Rules For Carrying Out Non-Destructive Examinations of Welding PDFDocument43 pagesRules For Carrying Out Non-Destructive Examinations of Welding PDFHasib Ul Haque AmitNo ratings yet

- Iso 23277-2006 PDFDocument8 pagesIso 23277-2006 PDFAtim SahidNo ratings yet

- 1011-2e DIN en Ion For Arc Welding of Ferritic SteelDocument58 pages1011-2e DIN en Ion For Arc Welding of Ferritic SteelЛюбомир ЛюбеновNo ratings yet

- ISO 1579-1 (Part Only)Document5 pagesISO 1579-1 (Part Only)sn200709100% (1)

- En10168 2004Document12 pagesEn10168 2004rimshadtpNo ratings yet

- NDE of BoilersDocument6 pagesNDE of Boilersshabbir626100% (1)

- CEN ISO TR 20174 EN Grouping System-Japan PDFDocument29 pagesCEN ISO TR 20174 EN Grouping System-Japan PDFumur kaçamaklıNo ratings yet

- WRC 1992Document8 pagesWRC 1992Ramu Nallathambi100% (1)

- EN 288-3xDocument38 pagesEN 288-3xSyah Reza Maulana0% (1)

- BS 5276-3-1979Document10 pagesBS 5276-3-1979anoopkumarNo ratings yet

- En 1090 Workshop 14 June 2019 FinalDocument2 pagesEn 1090 Workshop 14 June 2019 FinalHanuman RaaoNo ratings yet

- International StandardDocument12 pagesInternational StandardRajesh ThakurNo ratings yet

- Cen TR 14633 (E)Document9 pagesCen TR 14633 (E)consssNo ratings yet

- Iso 15609-1-2019Document19 pagesIso 15609-1-2019HarikeshRana100% (2)

- BS709 1983Document17 pagesBS709 1983Sang SekNo ratings yet

- 9 ISO 15608 Grouping of MaterialsDocument14 pages9 ISO 15608 Grouping of MaterialsTuTuy An100% (1)

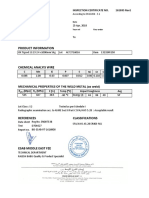

- Inspection certificate for Tigrod 13.23 wireDocument1 pageInspection certificate for Tigrod 13.23 wirenwoforNo ratings yet

- PDFDocument15 pagesPDFkumarkk1969No ratings yet

- BS en 12062Document16 pagesBS en 12062cheikh ahmedNo ratings yet

- BS en 1562-1997Document10 pagesBS en 1562-1997Srinivasan KrishnamoorthyNo ratings yet

- Iso 3834-2Document2 pagesIso 3834-2NEWES2014No ratings yet

- For Calibrating Magnetic Instruments Measure Ferrite Content Austenitic Duplex Ferritic-Austenitic Stainless Steel Weld MetalDocument31 pagesFor Calibrating Magnetic Instruments Measure Ferrite Content Austenitic Duplex Ferritic-Austenitic Stainless Steel Weld Metalvricardol100% (1)

- BS en 12668-1-2010Document48 pagesBS en 12668-1-2010lamhuu quangNo ratings yet

- 1.4301 Austenite Stainless SteelDocument3 pages1.4301 Austenite Stainless SteelSM Waqas ImamNo ratings yet

- Aws A5.17 PDFDocument37 pagesAws A5.17 PDFMarciel AmorimNo ratings yet

- Application for Certification according to DIN 18800-7Document9 pagesApplication for Certification according to DIN 18800-7gorgika papandNo ratings yet

- BS en 439 94 PDFDocument12 pagesBS en 439 94 PDFDario RamljakNo ratings yet

- CE Marking Requirements for Structural Steel PlatesDocument4 pagesCE Marking Requirements for Structural Steel PlatesSebastián Araya MoraNo ratings yet

- BS en 288-4-1992Document30 pagesBS en 288-4-1992CocaCodaNo ratings yet

- AWS-SCWI Certification Seminar & Exam Dates for 2019Document6 pagesAWS-SCWI Certification Seminar & Exam Dates for 2019yskushwah16No ratings yet

- 16mo3 MıgMagDocument4 pages16mo3 MıgMagKerem İnanNo ratings yet

- Comparison of Welding Inspector Qualification or Certification SchemesDocument7 pagesComparison of Welding Inspector Qualification or Certification Schemeswahyu santosoNo ratings yet

- BS en 1708-3-12Document22 pagesBS en 1708-3-12gaso99No ratings yet

- Sprayed ConcreteDocument41 pagesSprayed ConcreteLemmy MulandiNo ratings yet

- PREN 14620-5 Flat Bottom LNG Storage Tank-Testing PDFDocument13 pagesPREN 14620-5 Flat Bottom LNG Storage Tank-Testing PDFErol DAĞ100% (1)

- PrEN 124-5-2012 Rev Gully Tops and Manhole Tops For Vehicular and Pedestrian Areas - Part 5 - Gully Tops and Manhole Tops Made of CompositeDocument40 pagesPrEN 124-5-2012 Rev Gully Tops and Manhole Tops For Vehicular and Pedestrian Areas - Part 5 - Gully Tops and Manhole Tops Made of Compositesimpsonsungmsnlung67% (3)

- Draft For Public Comment: Latest Date For Receipt of Comments: 30 April 2013Document237 pagesDraft For Public Comment: Latest Date For Receipt of Comments: 30 April 2013mordidomi0% (1)

- BS en 1333-2006Document6 pagesBS en 1333-2006Lauren Garcia100% (1)

- (BS EN 50618) - Electric Cables For Photovoltaic SystemsDocument29 pages(BS EN 50618) - Electric Cables For Photovoltaic SystemsPiyush Goyal100% (5)

- BS EN 1333-2006 法兰及其接缝.管道部件.PN的定义和选择Document6 pagesBS EN 1333-2006 法兰及其接缝.管道部件.PN的定义和选择gdj1973No ratings yet

- ISO 9606-1-2012 COR 2-2016 DraftDocument7 pagesISO 9606-1-2012 COR 2-2016 DraftAhmadouxNo ratings yet

- Raft - MSDocument10 pagesRaft - MSabson pongNo ratings yet

- Research Final DraftDocument41 pagesResearch Final Draftluz catacutan100% (3)

- Self Clinch Metric 2011 Small PDFDocument34 pagesSelf Clinch Metric 2011 Small PDFpaula09No ratings yet

- Effects of Natural Coagulants in Textile Wastewater: IJSART - Volume 6 Issue 5 - MAY 2020Document4 pagesEffects of Natural Coagulants in Textile Wastewater: IJSART - Volume 6 Issue 5 - MAY 2020anand kumar sNo ratings yet

- New Tender Notice P-12-2018 DATED 13.8.2018 PPRADocument1 pageNew Tender Notice P-12-2018 DATED 13.8.2018 PPRAjust4qasimNo ratings yet

- Bahasa Inggris Kelas 1Document2 pagesBahasa Inggris Kelas 1Diyah LailaNo ratings yet

- Chap07 PDFDocument15 pagesChap07 PDFABNo ratings yet

- Bio-Epoxy For Aerospace Applications - Summary 22 June 2021Document6 pagesBio-Epoxy For Aerospace Applications - Summary 22 June 2021Namelezz ShadowwNo ratings yet

- For Product Analysis of Steel Castings (: IS:6601 - 1987 I Permissible Deviations in Chemical CompositionDocument3 pagesFor Product Analysis of Steel Castings (: IS:6601 - 1987 I Permissible Deviations in Chemical Compositionrohan sharmaNo ratings yet

- Conversion of Waste Cooking Oil Into BiodieselDocument48 pagesConversion of Waste Cooking Oil Into BiodieselMUHAMMAD ADNANNo ratings yet

- Duct (HVAC) - Wikipedia, The Free EncyclopediaDocument4 pagesDuct (HVAC) - Wikipedia, The Free Encyclopediasaurabhjerps231221No ratings yet

- PDS Gyproc DuraLine MRDocument3 pagesPDS Gyproc DuraLine MRvietNo ratings yet

- OMN Coating Resins SolventBased PS Americas PDFDocument1 pageOMN Coating Resins SolventBased PS Americas PDFNatalia RodriguezNo ratings yet

- Green Chemical Engineering: 2 Xing Jiang, Jian Ren, Yong Kong, Zhiyang Zhao, Xiaodong Shen, Maohong FanDocument7 pagesGreen Chemical Engineering: 2 Xing Jiang, Jian Ren, Yong Kong, Zhiyang Zhao, Xiaodong Shen, Maohong FanEcNo ratings yet

- Brand FulunteDocument22 pagesBrand FulunteSameerNo ratings yet

- 0913070Z 171 SKY Series FiltersDocument8 pages0913070Z 171 SKY Series FiltersCarlos LopezNo ratings yet

- Technology of Paints & Coatings With FormulationsDocument15 pagesTechnology of Paints & Coatings With Formulationseiribooks46% (37)

- 'Test' On Oil, Alkanes, Alkenes and AlcoholsDocument3 pages'Test' On Oil, Alkanes, Alkenes and AlcoholsDaniella FreemanNo ratings yet

- Equipment Available for Extensive Testing at Civil Engineering Test Floor LabDocument2 pagesEquipment Available for Extensive Testing at Civil Engineering Test Floor LabMuhammad Sohail HussainNo ratings yet

- Clotan Steel Cold Formed Sections and Purlins Brochure DigitalDocument8 pagesClotan Steel Cold Formed Sections and Purlins Brochure DigitalPieter SteenkampNo ratings yet

- Paint System: Cargotec Finland Oy TampereDocument1 pagePaint System: Cargotec Finland Oy TampereEdward Erney Salas ValenzuelaNo ratings yet

- IGCSE Edexcel Chemistry - Chapter 10, 11, 12, 14, 15Document4 pagesIGCSE Edexcel Chemistry - Chapter 10, 11, 12, 14, 15JoannaNo ratings yet

- ChemtoolDocument9 pagesChemtoolgusfabi1No ratings yet

- Stunning range of bathroom fixtures in rose gold, gold and chrome blackDocument30 pagesStunning range of bathroom fixtures in rose gold, gold and chrome blackSj VNo ratings yet

- 2021 Inspection ReportDocument58 pages2021 Inspection ReportDaniel MillerNo ratings yet

- Astm A 751Document5 pagesAstm A 751Patricia MenaNo ratings yet

- Extraction and Characterization of Castor Seed Oil From Wild Ricinus Communis LinnDocument13 pagesExtraction and Characterization of Castor Seed Oil From Wild Ricinus Communis LinnWojciech RedutkoNo ratings yet

- Stora Enso's fact sheet on pulp bleaching methodsDocument2 pagesStora Enso's fact sheet on pulp bleaching methodsNataliaNo ratings yet

- 3-AAP Analysis ReportDocument11 pages3-AAP Analysis ReportPinjala AnoopNo ratings yet

- Step-By-Step For CEREC: Preparation CAD/CAM Process Try-InDocument2 pagesStep-By-Step For CEREC: Preparation CAD/CAM Process Try-InMichael XuNo ratings yet