Professional Documents

Culture Documents

Catalo MBAkho

Uploaded by

Muopdang NguyenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Catalo MBAkho

Uploaded by

Muopdang NguyenCopyright:

Available Formats

- 1 -

IONG CONG IY IHIEI 8[ kY IHUAI IEN

CONG IY INHH NN MOI IHANH VIEN IHIEI 8[ IEN

ELECTRICAL TECHNICAL EQUIPMENT CORPORATION

ELECTRICAL EQUIPMENT LINITED COMPANY

MAY BIEN AP KHO

CAST RESIN TRANSFORMER

CONG TY TNHH NN 1 TV THIET B IEN - ELECTRICAL EQUIPMENT LIMITED COMPANY

NG SO 9-KHU CONG NGHIEP BIEN HOA-VIET NAM - NO.9 STREET BIEN HOA INDUSTRIAL ZONE-VIETNAM

TEL: (061)3 836139 -3836140 - 3836897 - 0903934918 - FAX: 84-61-3836070

Website: www.thibidi.com.vn - E-mail: tmthibidi@hcm.vnn.vn

- 2 -

1. May bien the kho THIBIDI THIBIDIs Cast Resin Transformer 3

2. ng dung Applications 4

3. Cau truc Construction 5

4. Phu kien Accessories 6

5. Cong nghe Technology 8

6. Th nghiem Quality Assurance 9

7. Lap at va Hoat ong Intallation & Operation 10

8. Van chuyen va Lu kho Handling and Storage 17

9. Vn hnh & Bo dng Commissioning and Maintenance 18

10. c tnh k thut Technical Specification 19

NI DUNG CONTENTS

- 3 -

1 1. . M M y y b bi i n n p p k kh h T TH HI IB BI ID DI I T TH HI IB BI ID DI I s s C Ca as st t R Re es si in n T Tr ra an ns sf fo or rm me er r

1.1. Chu la Fire resistant

Cuon day c uc bang nha Epoxy v i ac tnh khong bat l a, t dap tat la va

chong chay do tia la ien.

The cast coil with Epoxy resin with non-flammable characteristics has a self-fire-extinguishing

performance, to be free from a fire from electrical sparks.

1.2. Lc ngn mch cao hn Higher short circuit strength

Cuon day uc nha Epoxy co sc ben c va ien cao ket hp vi ket cau may vng

chac chu ng c lc do ngan mach gay ra, do va cham be ngoai va cac rung

ong khac thng.

The cast coil with Epoxy resin with the high electrical and mechanical strength is manufactured in a

robust structure against an electromechanical force occurring during short circuit, external

impacts, and abnormal vibrations.

1.3. Chng m Moisture proof

Cuon day uc nha Epoxy lam tang sc ben chat cach ien va khong lam giam tnh

cach ien chat do hi am gay ra va nhng phan ng lam lao hoa vat lieu cach ien,

ngay ca sau mot thi gian dai khong bao dng.

The cast coil with Epoxy resin has an enhanced dielectric strength and doesnt suffer from the

deterioration of dielectric property due to humidity and the aging effects of insulating materials,

even after a long term without maintenance.

1.4. Kch thc gn Compact size

Kieu dang nho gon va trong lng nhe c the hien qua mau thiet ke, qua hnh dang

cuon day c uc nha Epoxy di moi trng chan khong va vat lieu cach ien tot.

Compact size and lightweight type can be embodied by designing and manufacturing the coil by

casting in a high vacuum using Epoxy resin and insulating materials with good dielectric strength.

1.5. Kh nng qu ti cao High overload capability

Cuon day uc nha Epoxy co he so thi gian gia nhiet cao v the co the chu c s

qua tai cao hn.

The cast coil with Epoxy resin has a high thermal time constant factor, therefore it can endure much

higher overloads for a short time.

1.6. Tn tht thp, n thp Low loss, low noise

Ton that thap, o on thap c the hien bang viec s dung tole silic t ton that va vat lieu cach

ien tot.

Low-loss and low-noise are embodied through the optimal compact design using silicon steel of low-

loss and good insulating materials.

1.7. Bo dng d dng Maintenance free

Khong can kiem tra mc dau cung nh th nghiem mau dau.

No checking of oil level or no dielectric test oil.

Cuon day uc nha khong lam giam ac tnh cach ien do am t va o am, v the de dang

kiem tra va bao quan may bien ap ke ca cuon day.

The cast coil with Epoxy resin doesnt suffer from the deterioration of an insulating property due to

humidity and moisture, therefore it is easy to inspect and maintain a transformer including the coil.

1.8. Mi trng an ton Environmentally safe

Khong phat sinh dau hay kh oc vao kh quyen.

No emit of oil or toxic gases into the atmosphere.

oi vi may bien ap dau th de b o nhiem moi trng hn do dau chay r ra.

Comparing to an oil-immersed transformer, it is free from an environmental pollution due to oil

spill.

- 4 -

2 2. . n ng g d d n ng g A Ap pp pl li ic ca at ti io on ns s

Trong ta nh Inside buildings

Trong ng hm In tunnels

Trong nh my ch bin thc phm In food processing plants

Trn tu b On ship

Trn khu cu trc On cranes

Trn sn ngoi khi On off-shore flatforms

- 5 -

3 3. . C C u u t tr r c c C Co on ns st tr ru uc ct ti io on n

1. u ct h p LV terminal 7. Mc cu my Lifting lug

2. Li tole Core 8. Nhit k Digital thermometer

3. u ct cao p HV terminal 9. Cn m Spacer

4. Cun dy cao p HV coil 10. u ni iu chnh Tap terminal link

5. Cun dy h p LV coil 11. Thanh ni pha Phase connection lead

6. Chn my Base channel 12. X kp li tole Frame

13. Tip a Grounding terminal

- 6 -

4 4. . P Ph h k ki i n n A Ac cc ce es ss so or ri ie es s

4.1. Ph kin c bn Standard Accessories

u ct bn h LV terminal

u ct bn cao HV terminal

u ni iu chnh c np bo v -

Tap terminal link & protection cover

Mc cu Lifting lug

Tip a Grounding terminal

Thanh ni pha Phase connection lead

ng h o nhit k thut s

Digital thermometer

m chng rung Anti vibration pad

- 7 -

4.2. Ph kin ty chn Optional Accessories

Bnh xe 2 chiu Bi-directional wheel

Qut lm mt Cooling fan

B iu khin nhit Temperature

controller

V bao bo v Enclose

- 8 -

5 5. . C C n ng g n ng gh h - - T Te ec ch hn no ol lo og gy y

5.1. Li t

Loi t c lam t nhng la tole silic a

c nh hng c bao ve bang oxit vo

c.

S chon la cap tole, mau cat tole va

phng phap lap lo i tole giup giam toi

thieu mc ton that va dong khong tai cung

nh tao nen o on rat nho.

Sau khi lap tole, e bao ve chong an mon

s dung nha alkyd cap F c say trong

lo.

5.1. Magnetic core

The magnetic core is made from laminations of

grain oriented silicone steel insulated with

mineral oxide.

The choice of the grade of steel, the cutting

pattern and the method of assembly minimizes

loss level and no-load current with the effect of a

very low noise level.

Once assembled, it is corrosion protected using a

class F, oven-dried alkyd resin.

5.2. Cun dy h p

Cuon day ha ap thng lam bang la nhom

(la ong tuy thuoc vao yeu cau). Ky thuat

nay lam giam lc ngan mach doc truc.

Cac lp cuon day c cach ien bi vat

lieu cap F. a c tam trc nha epoxy

hoat hoa nhiet.

au cuoi cua day c bao ve va cach

ien bang chat cach ien cap F, c phu

nha epoxy hoat hoa nhiet.

Toan bo cuon day c polyme hoa bang

cach at vao trong noi hap trong 2 gi

130

0

C e am bao:

- Chong lai s xam thc cua kh quyen

cong nghiep cao

- Sc chu ng chat ien moi cao

- Chu ng c lc ngan mach hng

knh tot.

5.2. Low voltage winding

The low voltage winding is usually made of

aluminium sheet (copper upon request). This

technique reduces axial stresses under short

circuit.

The layers of the winding are insulated by a class

F material. Pre-impregnated with heat-activated

epoxy resin

The end of the winding are protected and

insulated using a class F insulator, coated with

heat-activated epoxy resin

The whole winding is polymerized by being

placed in an autoclave for 2 hours at 130

0

C which

guarantees:

- Outstanding resistance to industrial

atmosphere aggression

- Excellent dielectric withstand

- Very good resistance to radial stresses under

bolted short circuit conditions

5.3. Cun dy cao p

Cuon day cao ap thng c quan bang

day nhom cach ien (day ong tuy thuoc

vao yeu cau)

Vi dong ien ln hn, co the quan day

theo cong nghe goi la dai

Phng phap nay th thng cho ng suat

thap hn so vi cach quan day theo lp.

Cuon day c uc va c o khuon

di moi trng chan khong.

5.3 High voltage winding

The high voltage winding is usually wound from

insulated aluminium wire (copper upon request)

For higher currents, the medium voltage winding

may be wound using so-called strip technology

These methods are used to obtain very low stress

between adjacent conductors

The high voltage winding is cast and molded

under vacuum.

- 9 -

6 6. . T Th h n ng gh hi i m m - - T Te es st ts s

Tiu chun c cng nhn Recognized Standard

(ISO 9001)

Th nghim thng thng

Routine tests

1. Kt cu 1. Construction

2. o in tr 2. Resistance measurements

3. o t s 3. Ratio test

4. Th t u dy 4. Polarity and phase relation test

5. Tn tht c ti v tr khng 5. Load loss and impedance

6. Tn tht khng ti v dng khng ti 6. No-load loss and exciting

7. Th in p cung cp (cao p) 7. Applied potential test

8. Th qu in p cm ng 8. Induced over discharge

Th nghim in hnh

Type test

1. Th xung 1. Impulse test

2. Th tng nhit 2. Temperature rise test

Th c bit

Special tests

1. Th dng ngn mch 1. Short circuit test

2. Th n 2. Noise level test

3. Th kh nng chu la 3. Fire resistant test

4. Th shock nhit 4. Heat shock test

- 10 -

5 5. . L L p p t t v v h ho o t t n ng g - - I In ns st ta al ll la at ti io on n & & O Op pe er ra at ti io on n

7.1. Tng qut

Do khong co chat ien moi long va cach x

l chay tuyet vi, khong can e phong chay

nhng can lam theo nhng quy nh sau:

Khong nen at may bien ap vung co

nguy c ngap lut.

o cao khong qua 1000 met tr khi co o

cao cao hn th c xac nh vao luc tha m

do.

Nhiet o moi trng gii han trong

khoang sau:

- Nho nhat: -25

0

C

- Ln nhat: +40

0

C

Nhiet o moi trng cho may bien ap kho

tieu chuan c thiet ke theo IEC726:

- Ln nhat: 40

0

C

- Trung bnh cua ngay: 30

0

C

- Trung bnh cua nam: 20

0

C

V tr thong gio phai giup tieu tan ton that

tong cua may bien ap.

Trong khong kh o nhiem nang (dau may

gia cong kim loa i, bui dan ien) khong kh

vao tiep xuc vi thiet b nen c lam sach

neu co the (qua bo loc, loc au vao cua

khong kh ben ngoai qua ng ong).

May bien ap ngay ca co vo bao ve IP21

cung c thiet ke e lap at trong nha.

Nen d phong cho cac au no i va cac lo

ket noi.

Khong co vo bao ve (IP00) (Hnh 1)

Trong ket cau nay, may bien ap phai c

bao ve chong lai nhng tiep xuc, va cham

trc tiep.

Ngoai ra:

Phai can than tranh nhng ni co nc

ri vao may (v du: hi nc ngng tu t

ng ong at ben tren)

Duy tr khoang h toi thieu en tng xay,

theo bang sau ay:

5.1. General information

Due to the absence of any liquid dielectric and

the excellent fire behaviour of transformers, no

anti-fire precautions are necessary providing

the following guidlines are followed:

The transformer should not be installed in a

flood hazard area.

The altitude should not be above 1000 meters

unless a higher altitude is specified at the time

of inquiry

The ambient temperature for the transformer

to be within the following limits:

- Minimum: 25

0

C

- Maximum: +40

0

C

Standard transformers are designed in

accordance with IEC726 for an ambient

temperature of:

- Maximum: 40

0

C

- Daily average: 30

0

C

Yearly average: 20

0

C

The local ventilation should allow the

dissipation of the transformer total losses.

In highly polluted atmospheres (metal

machining oil, conductive dust), the air coming

into contact with the device should if possible be

cleaned (filtering, inlet of outside air via a

ducting)

The transformer even with IP21 metal

enclosure is designed for an indoor installation.

Provision should be made for access to

connectors and tapping links.

Without enclosure (IP00) (figure 1)

In this configuration, the transformer must be

protected against direct contact.

In addition:

Care must also be taken to eliminate risks of

water drops on the transformer (example:

condensation from overhead pipings).

Maintain minimum clearance to the walls

according to the following table:

- 11 -

Kch thc Dimensions

(mm)

Cp cch in

Insulation

(kV)

Tng bao bc

Full wall

Li thng gi

Ventilation grill

12 120 300

17.5 220 300

24 220 300

Co vo bao ve (IP21) (Hnh 2)

Duy tr khoang cach toi thieu la 200mm

t mat ngoai vo bao ve en tng xay

dng e am bao u lam mat.

With IP21 metal enclosure (figure 2)

A minimum distance of 200mm between the

exterior of the enclosure and the walls of the

building should be maintained to ensure

adequate cooling.

Hnh 2 - Khong cch lp t khng c v bo v IP00

Figure 2 Installation distance without enclosure IP00

X

X

X

X

Hnh 2 - Khong cch lp t c v bo v

Figure 2 installation distance with enclosure

500mm

200mm

HV

LV

2

0

0

m

m

2

0

0

m

m

- 12 -

7.2. Thng gi

Xac nh chieu cao va dien tch lo thong

gio

Trng hp lam mat t nhien (AN), s

thong gio cua tram hay vo bao ve phai am

bao tnh oi lu t nhien, lam tieu tan nhiet

sinh ra do ton that tong cong cua may.

Trng hp tram khong u thong gio, s

thong gio thch hp bao gom lng khong kh

mat lay vao qua tiet dien S ay tram va

lng khong kh lay ra qua tiet dien S pha

oi dien ben tren, ng vi o cao H so v i lo i

khong kh vao (Hnh 1 va 2)

e am bao lam mat co hieu qua cho may

bien ap va s lu thong khong kh u, th

can phai gi mot khoang khong di ay

may toi thieu la 150mm, bang cach lap

nhng banh xe hay nhng con nang tng

ng.

Chu y rang s lu thong khong kh b han

che se lam giam co ng suat qua tai va cong

suat thc cua may.

Cong thc tnh thong gio (Hnh 1):

Va S=1.10xS

P = Tong ton that co tai va khong tai, tnh

bang kW 120

0

C

S = Dien tch cua lo thong gio lay vao, tnh

bang m

2

.

S = Dien tch cua lo thong gio i ra, tnh

bang m

2

.

H = o cao gia lo thong gio lay vao va i ra

Cong thc nay phu hp vi nhiet o mo i

trng trung bnh la 20

0

C va o cao di

1000m

V d:

- May bien ap co cong suat 1000kVA

- P

0

=1780W, P

cc

(120

0

C)=9140W, ngha la

P=10.9kW

Neu o cao gia 2 lo =2m, th dien tch be

mat lo thong gio lay va o can thiet la

S=1.4m2.

7.2. Ventilation

Determination of the height and area of

ventilation grills

In the general case of natural cooling (AN)

the ventilation of the substation or of the

enclosure must ensure by natural convection

the dissipation of the heat produced by the

transformers total losses.

In case of a no sufficiently ventilation

substation, appropriate ventilation will consist

of a fresh air intake opening of S section at the

bottom of the local and an air outgoing

opening S located above on the opposite wall

at height H meters above the intake opening

(figure 1 and 2).

To ensure efficient cooling of the

transformer and sufficient air circulation, it is

essential to maintain a minimum height of 150

mm under the live section, by installing castors

or an equivalent booster

It must be noted that restricted air

circulation reduces the transformers

continuous and short- term overload capacity.

Formula for ventilation (figure 1):

and S=1.10xS

P = sum of the transformers no-load and load

losses expressed in kW at 120C.

S = area of the lower air intake opening (allow

for mesh factor) expressed in m

2

.

S = area of the air outlet opening (allow for

mesh factor) expressed in m

2

.

H = height difference between the two

openings expressed in metre.

This formula is valid for an average ambient

temperature of 20

0

C and an altitude of 1000m

Example:

- one single transformer 1000kVA

- P

0

=1780W, P

cc

at 120

0

C =9140W,

i.e. P=10.9kW

If the distance between the grills=2m, then

S=1.4m

2

of net surface area necessary.

If we imagine a grill obstructing the air inlet by

0.18P

S

H

=

0.18P

S

H

=

- 13 -

Neu chung ta tng tng co tam li can tr

30% luong khong kh i vao, th dien tch be

mat cua lo thong gio lay va o la 1.4mx1.4m

va dien tch cua lo thong gio i ra la

1.4mx1.5m.

Thong gio cng bc (Hnh 2):

Can thiet neu nhiet o moi trng tren 20

0

C

hay phong nho va kem thong thoang c

ng dung cho viec qua tai thng xuyen.

Quat co the c ieu khien bi bo cam ng

nhiet va hoat ong nh la quat hut thong gio

at tren tran cua phong

Lu lng cua dong kh (m3/s) 20

0

C

=0.1xP; Trong o: P = Tong ton that co tai va

khong tai, tnh bang kW 120

0

C.

30%; the air inlet grill surface area should

then be 1.4m x 1.4m, and that of the air outlet

should be 1.4m x 1.5m.

Forced ventilation (figure 2):

Forced ventilation of the substation is

necessary for ambient temperatures above

20

0

C or small or badly ventilated rooms for

applications with frequent overloads.

The fan can be controlled by a thermostat

controlled and operate as an extractor in the

top part of the room.

Advised flow (m

3

/second) at 20

0

C =0.1xP

P = sum of the transformers no-load and load

losses expressed in kW at 120C.

Hnh 2 - Trm thng gi cng bc

Figure 2 Substation forced ventilation

H

S

S

Hnh 1 - Trm thng gi t nhin

Figure 2 Substation natural ventilation

H

S

S

- 14 -

7.3. Cc u ni

Cac au noi HV va LV i vao co the at

ben tren hay di ay.

au noi ben MV c lam bang cap dan

ien.

au noi ben LV thong thng c lam

bang cap dan ien, nhng cung co the

bang cach khac rat an toan dung Thanh

ong tien che (PBT).

Cac trng hp cho thay dung day cap

hay thanh ong phai c nang tranh

ng suat c tren cac au cot HV hay LV,

hay cac au cam HV.

au noi HV nen at ben tren thanh noi

tam giac. au noi LV nen at tai phan tren

cua may.

Chu y:

- Khoang cach gia day cap HV, thanh

ong noi va be mat cua boi day toi thieu

la 120mm ngoai tr tren be mat ben HV

o khoang h toi thieu se c an

nh bi au cap HV.

- Khoang h en thanh tam giac HV ben

ngoai cung phai toi thieu la 120mm.

- Lp phu nha pha ngoai, hay s dung

au cam plug-in khong bao ve chong lai

tiep xuc trc tiep va khong c cham

vao may bien ap khi no co ien.

May khong co vo bao ve (IP00)

Tieu chuan au noi HV va LV

- au day LV ra (hay vao) co the at pha

tren hay pha di (hnh 1 va 2)

- au day HV ra (hay vao) co the at pha

tren hay pha di (hnh 1 va 2)

Trong trng hp au day ra (hay va o) t

pha di th can phai at mot mieng em

Noi HV bang au cam plug-in (hnh 3)

Noi LV bang ong dan ien tien che

(hnh 4)

V tr lap at n gian hoa that nhieu neu

co the, e viec ieu chnh, lap rap va thao

d de dang.

- May bien ap khi ban trang b san thanh

ong tien che

- Kha nang ieu chnh lap at nay khoang

15mm cho 3 hng

- Viec noi va thao mat khoang mot gi

giup dch vu cung cap lien tuc.

7.3. Connections

The incoming HV and LV connections can be

made from the top or the bottom.

MV side connections are made by cables

LV side connections are made conventionally by

cables, but can also be made using the very

safe alternative using Prefabricated Busbar

Trunking (PBT).

In all cases shown the cables or busbars must be

supported to avoid mechanical stress on the HV

or LV terminals or HV plug in connectors.

The HV connections should be made to the top of

part of the delta connection bars. The LV

connections are made at the top of the

transformer.

Warning:

- The distance between HV cables or busbars

and the surface of the winding should be at

least 120 mm except on the flat face of the HV

side where the minimum clearance will be set

by the HV terminal.

- The clearance to the outer HV delta bar should

also be a minimum of 120 mm.

- The resin coating, or the use of plug in

connectors does not give protection against

direct contact and the transformer must not be

touched when it is energized.

Without metal enclosure (IP00)

Standard HV and LV connections

- The outgoing (or incoming) LV conductors can

be made from above or below (figures 1 and

2).

- The outgoing (or incoming) HV conductors can

be made from above or below (figures 1 and 2)

In case of an outgoing (or incoming) conductors

from below it is necessary to put a spacer

HV connections with plug in connectors (figure

3)

LV connections using prefapricated electrical

ducting (figure 4)

On site installation is simplified as far as

possible, with very easy fitting, assembly and

dismantling:

- The transformer is delivered pre-equipped with

the PBT connection interface

- The possibility of adjusting on site by 15mm in

all directions

- Connection and disconnection is achieved

within an hour at most proving optimum

continuity of service.

- 15 -

May co vo bao ve IP21

Tieu chuan au noi HV va LV (Hnh 1&2).

- au day LV ra (hay vao) phai i hng

len t au cot va nam di nap vo bao ve.

au day LV khong bao gi i qua cuon

day cao ap va vo bao ve.

- au day HV ra (hay vao) co the i qua

ben tren (hnh 1) hay pha di (hnh 2).

Noi au day HV t pha di

- au day HV ra (hay vao) co the i pha

di en trc tiep au cot noi (hnh 2).

Trong trng hp nay au day i vao

c a qua canh ca pha di ben

With IP21 metal enclosure

Standard HV and LV connections (figures 1

and 2)

- The outgoing (or incoming) LV conductors

must go upwards from the terminals under

the enclosure cover. The LV conductors

should never pass between the HV coils and

the enclosure.

- The outgoing (or incoming) HV conductors

can pass above (figure 1) or below (figure 2).

HV connection from below

- The outgoing (or incoming) HV conductors

can come from below directly to the

connection terminal (figure 2). In this case

incoming conductors are passed through the

n LV

HV

Cp

Cables support

Hnh 1Tiu chun u ni HV & LV pha trn

Figure 1 Standard HV and LV connections from above

n

LV

HV

Cp

Cables support

Hnh 3Ni HV bng u ni cm plug-in

Figure 3HV connections with plug in connectors

120

min

120

min

Hnh 2Tiu chun u ni HV & LV pha di

Figure 2 Standard HV and LV connections from below

120

min

120

min

Thanh m

Spacer

HV

- 16 -

phai nam pha HV.

- Day cap HV phai c gi chat ben trong

vo bao ve bang cai kep (hnh 2).

Nen xac nh tnh kha thi loa i au noi e co

s tng quan gia tiet dien va ban knh

uon cong cap vi cho trong trong vo che

bao ve.

Noi HV bang au cam plug-in (hnh 3)

Noi au LV bang ong dan ien tien che

(hnh 4)

Ch :

Can xac nh tnh phu hp cua hang muc

bao ve IP21 sau khi a khoan tam em

cach ien cho HV, LV va nhng phan khac.

removable flap door located at the bottom on

the right HV side.

- The HV cables must be fastened inside the

enclosure on clamp (figure 2).

It is advisable to verify the feasibility of this type

of connection in relation to the section and the

bending radius of cables and the space available

in the enclosure.

HV connection by plug in connector (figure

3)

LV connections using prefapricated electrical

ducting (figure 4)

Warning:

It is necessary to verify conformity with the IP21

protection index after having drilled the

insulation gland plate for HV, LV and others.

LV

HV

C

C

a

b

l

e

s

s

u

p

p

o

r

t

C

C

a

b

l

e

s

s

u

p

p

o

r

t

Hnh 3Ni HV bng u ni cm plug-in

Figure 3HV connections with plug in connectors

n

Hnh 1Tiu chun u ni HV & LV pha trn

Figure 1 Standard HV and LV connections from above

C

C

a

b

l

e

s

s

u

p

p

o

r

t

C

C

a

b

l

e

s

s

u

p

p

o

r

t

LV

HV

Hnh 2Tiu chun u ni HV & LV pha di

Figure 2 Standard HV and LV connections from below

HV

Hnh 4-Ni LV bng PBT v v bo v

Figure 4-LV connections with PBT and enclosure

- 17 -

7 7. . V V n n c ch hu uy y n n v v L L u u k kh ho o - - H Ha an nd dl li in ng g a an nd d S St to or ra ag ge e

Vn chuyn Handling

May bien ap c trang b cac phan d phong

e van chuyen an toan.

Nang chuyen bang day (hnh 1)

Dung 4 lo moc cau e nang may bien ap

khong co vo bao ve va 2 patte cau cho may

bien ap co vo bao ve. Day nang khong c

tao thanh goc trong ln hn 60

0

.

Nang chuyen bang xe nang (hnh 1&2)

Trc tien kiem tra cong suat nang cua xe

nang. Neu phu hp, a cang nang vao di

ranh chan may sau khi thao ri con lan ra.

Keo day

Khi keo may bien ap co hay khong co vo bao

ve nen keo t chan may ben di. V muc

ch nay nen moi ben cua chan may co lo

ng knh 27mm. Co the keo theo 2 hng:

doc theo truc chan may hay vuong goc vi

truc chan may

Lap rap con lan

Ca 2 viec nang chuyen bang day (hnh 1)

Hay nang chuyen bang xe nang (hnh 1

& 2)

V tr cang nang luon nam di chan may

- at go ke cao hn chieu cao con lan va

may bien ap ta len go ke.

- nh v nhng cai kch oi va lay go ke ra.

- Lap con lan vao ung v tr (con lan hai

chieu).

- Ha thap va e cho may bien ap ta len

nhng con lan cua chung.

The transformers are equipped with

provisions for safe handling.

Lifting with slings (figure 1)

Lifting is carried out using the 4 lifting holes

for a transformer without an enclosure and by

2 lifting lugs in the case of a transformer with

an enclosure. The slings should not form an

inside angle greater than 60

0

.

Lifting with a fork lift truck (figure 1&2)

The lifting capacity of the fork lift truck should

first be checked. If suitable, the forks should be

inserted inside the base channels after

removing the rollers.

Towing

Towing the transformer with or without

enclosure should be done from the underbase.

For this purpose hole of 27 mm. Diameter are

provided on every side of the

underbase.Towing can be done in two

directions: in the axis of the underbase and

perpendicular to that axis.

Fitting the rollers

Either by lifting with slings (figure 1)

or by lifting with a fork lift truck (figures

1 and 2)

In this case position the lifting forks in the

underbase channels.

- Place timbers of greater height than the

rollers under the channels and lower the

transformer on to them.

- Position jacks and remove the timbers.

- Attach the rollers in the desired position

(bidirectional rollers).

- Lower and remove allowing the transfomer

to rest on its rollers.

Lu kho Storage

May bien ap phai c bao ve trong kho

tranh nc ri vao va cong viec phat sinh bui

(xay dng nha, lam ng v.v...). Neu may

bien ap khi giao hang co nap nha th phai

gi nguyen nap nha nay trong thi gian lu

kho.

May bien ap co the lu tr nhiet o xuong

en 25

0

C.

The transformer should be protected in

storage from water drops and dust

generating work (masonry, sanding etc). If

the transformer is delivered with a plastic

cover which should be kept over the

equipment whilst it is in storage.

The transformer can be stored at a

temperature down to 25

0

C.

- 18 -

8 8. . V V n n h h n nh h v v b b o o d d n ng g - - C Co om mm mi is ss si io on ni in ng g a an nd d m ma ai in nt te en na an nc ce e

a vo vn hnh Commissioning

Kiem tra ni lap at may bien ap kho

ieu kien lap at: ni lap at phai sach

va tranh b ngap nc, ac biet la khong

at vao vung nc ri t tran nha. Phai

co bien phap thong gio e gia i thoat nhiet

phat ra t may bien ap.

Kiem tra may can cham soc trong thi

gian dai: khi nao bui bam tren may bien

the tuy theo thi k cham soc, loai tr bui

nay bang may hut bui hay thoi het bui

bang may nen va la m sach bang may hut

bui.

Bao boc nha e ngan can bui, inh oc,

boulon, vong em lo t vao v.v... phai gi

(duy tr) en khi ong ien (cap nguon).

(khi no i au cot th nhat va th hai, xe

rach tng phan).

Check points when installing a cast

resin transformer

Installing conditions : installing place must be

clean and free from care of submersion under

water, especially not exposed water drops from

a ceiling of it. There must be a ventilation

means for getting rid of the heat generated

from a transformer.

Check of a transformer being taken custody for

long term : When dusts are deposited on a

transformer according to long term custody,

eliminate dusts by a vacuum cleaner or blow

away dusts by compressor, and wipe it by a dry

duster.

A vinyl package for preventing from inserting

of dusts, screws, nuts, washers and etc, must be

maintained until power is on after installation.

(when connection of 1st and 2nd terminals,

tear off partly)

Momen xoan au cot noi HV Torque for HV Terminal connection

n v - unit (kg-cm)

Bulng Bolt M8 M10 M12 M16

Mmen Torque 100 205 360 885

im nng ca xe nng

Fork lift truck lifting

60

0

maximum

Hnh 1-Nng bng dy v xe nng

Figure 1-Lifting with slings or fork lift truck

Con ln

roll

Hnh 2-Lp rp con ln

Figure 2-Fitting the rollers

Kch i

jack

G k

Tim

- 19 -

Momen xoan au cot noi LV - Torque for LV Terminal connection

n v - unit (kg-cm)

Bulng Bolt M8 M10 M12 M16

Mmen Torque 125 250 405 1500

Kiem tra trc khi a ien vao

Lay bao boc nha, va kiem tra tnh trang

au noi, khoang cach canh ien, co

nhng chat la hay khong, trang thiet b co

b h hai hay khong, va momen cua

boulon.

Kiem tra au noi ieu chnh phu hp vi

nhan may hay khong.

Check points before receiving power

Get rid of a vinyl package, and check

connection status, insulating separation,

distance, whether alien substances remain,

whether a component is damaged, and bolt

torque.

Check whether tap connections accord with

that of a label.

o ien tr cach ien s dung ong ho o ohm (DC 1000V Megger) nh sau:

Measure insulations using an insulation ohmmeter(DC 1000V Megger) like below:

V tr o

Measuring point

Gia tr gii han

Limit value

Cuon cao at

High voltage coil grounding

250 Mohm

Cuon ha at

Low voltage coil grounding

50 Mohm

Cuon cao - cuon ha

High voltage coil Low voltage coil

250 Mohm

Khi gia tr o c thap hn cac gia tr

tren, kiem tra o am, neu ung, say kho

lai, va o ien tr ca ch ien la i lan na.

Tuy nhien neu viec o ien tr cach ien

van thap hn gia tr gii han xin lien he

vi dch vu sau ban hang.

When measuring values are below than above

values, check humidity, and if it is, get rid of

humidity by dryer, and measure an insulation

resistance again. Nevertheless if a measured

insulation resistance is below than the limit

value, contact with the A/S (after-sale service)

department.

Bo dng Maintenance

Trong tnh huong may ang van hanh,

thoi sach bui bang may nen kh kho moi

nam. Thi k lam sach tuy thuoc vao

hoan canh. Kiem tra cac boulon bat may

bang c-le can lc trong luc thc hien

cong viec bao dng.

In case of general operating circumstance, get

rid of dusts and blow away over deposited

dusts by dry compressor every year. Cleaning

term depends on circumstances. Check

engagements of bolts by a torque wrench

during performing a maintenance work

- 20 -

9 9. . c c t t n nh h k k t th hu u t t T Te ec ch hn ni ic ca al l S Sp pe ec ci if fi ic ca at ti io on ns s

Tiu chun ch to : IEC-726 Manufacture Standard : IEC-726

Cng sut : 100kVA n 2500kVA Capacity : 100kVA to 2500kVA

Tn s : 50Hz Frequency : 50Hz

in p s cp : 22kV Primary voltage : 22kV

in p th cp : 0,4kV Secondary voltage : 0.4kV

iu chnh : 2x2,5% Tappings : 2x2.5%

Cp cch in : Cp F Insulation class : F class

tng nhit : 100

0

K Temperature rise : 100

0

K

L

H

C B A

A W

- 21 -

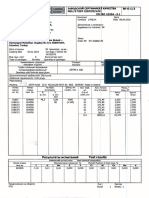

Dng in

A

(Rated Current)

Kch thc bao

(mm)

(Main dimensions)

Cng sut

KVA

(Rated

Capacity) I

1

(22kV)

I

2

(0,4kV)

Loi

(Type)

Tn hao

khng ti

P

0

(W)

(No-load

losses)

Tn hao

ngn mch

75

0

C

P

k

75

(load

losses)

in p

ngn mch

U

k

(%)

(Impedance

voltage)

Trng

lng

G(kg)

(Weight)

W L H A

100 2.6 144.3 100L1 440 1290

4

850 750 1260 1350 870

100 2.6 144.3 100L2 550 1290

4

850 750 1260 1350 870

160 4.2 230.9 160L1 600 2210

4

1100 750 1330 1380 900

160 4.2 230.9 160L2 750 2210

4

1100 750 1330 1380 900

200 5.2 288.7 200L1 760 2670

4

1230 750 1330 1460 900

200 5.2 288.7 200L2 970 2670

4

1230 750 1330 1460 900

250 6.6 360.8 250L1 860 3090

4

1440 750 1350 1520 920

250 6.6 360.8 250L2 1090 3090

4

1440 750 1350 1520 920

320 8.4 461.9 320L1 970 3760

4

1640 850 1380 1550 950

320 8.4 461.9 320L2 1230 3760

4

1640 850 1380 1550 950

400 10.5 577.4 400L1 1250 4270

4

1950 850 1460 1680 1010

400 10.5 577.4 400L2 1590 4270

4

1950 850 1460 1680 1010

560 14.7 808.3 560L1 1570 6000

4

2260 850 1530 1600 1040

560 14.7 808.3 560L2 2010 6000

4

2260 850 1530 1600 1040

630 16.5 909.3 630L1 1780 6030

4

2820 960 1650 1680 1130

630 16.5 909.3 630L2 2270 6030

4

2820 960 1650 1680 1130

750 19.7 1082.5 750L1 1900 7100

4.5

3080 960 1680 1730 1140

750 19.7 1082.5 750L2 2420 7100

4.5

3080 960 1680 1730 1140

1000 26.2 1443.4 1000L1 2290 9240

5

3420 960 1750 1800 1180

1000 26.2 1443.4 1000L2 2940 9240

5

3420 960 1750 1800 1180

1250 32.8 1804.2 1250L1 3300 11010

5.5

4200 1020 1880 1900 1280

1250 32.8 1804.2 1250L2 4280 11010

5.5

4200 1020 1880 1900 1280

1600 42 2309.4 1600L1 3360 11760

6

5000 1050 2090 1990 1370

1600 42 2309.4 1600L2 4300 11760

6

5000 1050 2090 1990 1370

2000 52.5 2886.8 2000L1 4160 13750

6

6000 1050 2200 2200 1520

2000 52.5 2886.8 2000L2 5700 13750

6

6000 1050 2200 2200 1520

2500 65.6 3608.4 2500L1 5120 17010

6

7700 1050 2300 2240 1590

2500 65.6 3608.4 2500L2 7000 17010

6

7700 1050 2300 2240 1590

- 22 -

Cac dung sai theo tieu chuan IEC - Tolerances in accordance with IEC standard

1. a. Tong ton hao +10% tong ton hao

1. a. Total losses +10% Tolal losses

b. Ton hao khong

tai hoac co tai:

+15% ton hao khong

tai hoac co tai vi ieu

kien la dung sai tong

ton that khong vt

qua.

b. load or no-load loss: +15% of each load or no-

load losses, provied that

the tolerance for total

losses is not exceeded

2. T le ien ap

2. Voltage ratio

T le ien ap danh

nh ( nac nh

mc)

Di cac gia tr sau:

a. +0.5% gia tr nh

mc qui nh

b. ty le phan tram cua

t le ien ap qui nh

tng ng 1/10 cua

phan tram ien ap

ngan mach nh mc

o c

Rated voltage ratio (on

principal tapping)

The lower of the folowing

values:

a. +0.5% for principal

value

b. 1/10 of actual

percentage impedance on

the principal tapping

T le ien ap nac

ieu chnh khac:

+1% tr cac trng

hp ngoai le ac biet

Voltage ratio on other

tapping

+1% except special cases

3. ien ap ngan mach

tai dong ien nh mc

10%

3. Short-circuit voltage at

rated current

10%

4. ien ap ngan mach

tai nhng nac ieu

chnh khac

15% gia tr cho phep

oi vi nac ieu chnh

nay

4. Short-circuit voltage at

other tappings

15% rated value for this

tapping

5. Dong khong tai +30% dong khong tai

qui nh

5. No-load current +30% rated no-load

current

6. Mc o on Khong co dung sai

6. Noise level No tolerance

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- D10R PDFDocument35 pagesD10R PDFluishvanegas100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Install Medium Voltage Lines SafelyDocument106 pagesInstall Medium Voltage Lines Safelyajayi micheal sunday100% (1)

- Saes H 101VDocument83 pagesSaes H 101Vacolombel100% (2)

- Heat ExchangerDocument17 pagesHeat ExchangerMedariTrinadh100% (2)

- Acsr Din en 50182 PDFDocument1 pageAcsr Din en 50182 PDFAdim CoMed ProNo ratings yet

- WinCC Graphics Designer PDFDocument414 pagesWinCC Graphics Designer PDFJoão FranciscoNo ratings yet

- GiaotrinhWinCC md48Document134 pagesGiaotrinhWinCC md48Muopdang NguyenNo ratings yet

- Bo Dieu Khien Truyen Dong Servo-MuopdangDocument210 pagesBo Dieu Khien Truyen Dong Servo-MuopdangMuopdang NguyenNo ratings yet

- Bien Tan Omron En-MuopdangDocument344 pagesBien Tan Omron En-MuopdangMuopdang NguyenNo ratings yet

- Bien Tan Omron En-MuopdangDocument344 pagesBien Tan Omron En-MuopdangMuopdang NguyenNo ratings yet

- Volvo s80 Premier 2005 Wiring DiagramDocument3 pagesVolvo s80 Premier 2005 Wiring Diagramjim100% (53)

- Mastertop 295 floor re-surfacingDocument3 pagesMastertop 295 floor re-surfacingFrancois-No ratings yet

- Chapter 41Document9 pagesChapter 41Shridhar KulkarniNo ratings yet

- Astm A513 PDFDocument3 pagesAstm A513 PDFgaminNo ratings yet

- Pipe Alcorcon1Document85 pagesPipe Alcorcon1Christopher Ysit100% (1)

- Why Proper Animal Waste Disposal Is Important:: Paper Presentation By: Saurabh Singh (22M1437)Document6 pagesWhy Proper Animal Waste Disposal Is Important:: Paper Presentation By: Saurabh Singh (22M1437)9027282493No ratings yet

- Grade 9 Assessment Tasks: Term 2 Matter and MaterialsDocument74 pagesGrade 9 Assessment Tasks: Term 2 Matter and MaterialsSaesha MahabeerNo ratings yet

- Fin FANDocument2 pagesFin FANNorman Morales100% (1)

- Changes in Matter Education Presentation in Orange Light Yellow Hand Drawn StyleDocument20 pagesChanges in Matter Education Presentation in Orange Light Yellow Hand Drawn StyleYam YrrehcNo ratings yet

- Dissolvine Product Guide 2017Document13 pagesDissolvine Product Guide 2017japerezle23No ratings yet

- Duramax Duragold Grease-Free Bushings.: Call Duramax Marine 440-834-5400 Fax 800.497.9283 Usa & CanadaDocument2 pagesDuramax Duragold Grease-Free Bushings.: Call Duramax Marine 440-834-5400 Fax 800.497.9283 Usa & CanadaRichard Piscoya Villegas100% (1)

- Fibregrid Brochure WebDocument39 pagesFibregrid Brochure Webjames.byrneNo ratings yet

- Insulating Systems For High-Voltage Rotating MachinesDocument16 pagesInsulating Systems For High-Voltage Rotating MachinesNikulin JoelNo ratings yet

- Estane Skythane S185A TPU: TypeDocument1 pageEstane Skythane S185A TPU: Typejuliushasan2No ratings yet

- 4806 en MiraDRAIN 9800 TDSDocument2 pages4806 en MiraDRAIN 9800 TDSabdalla el-saadaneyNo ratings yet

- 2kw Installation ManualDocument22 pages2kw Installation ManualGratian RealNo ratings yet

- MiniPAC Manual REV 4.3 July 25 2012Document78 pagesMiniPAC Manual REV 4.3 July 25 2012zfo302No ratings yet

- 48,3x5,08 824000Document2 pages48,3x5,08 824000Mehmet ŞaHanNo ratings yet

- mc4 DatasheetDocument8 pagesmc4 Datasheetdth dthNo ratings yet

- Click Bond Nutplate, Install and RemovalDocument35 pagesClick Bond Nutplate, Install and RemovalBlack SkyNo ratings yet

- E-K2-Demo-Teaching-Division-English 6 - AllamDocument8 pagesE-K2-Demo-Teaching-Division-English 6 - AllamJomar AllamNo ratings yet

- Renewal Parts - YK Mod F and Later HA-HB-HE-HG - G, H & J Series CompressorsDocument112 pagesRenewal Parts - YK Mod F and Later HA-HB-HE-HG - G, H & J Series CompressorsKannan KrishnamoorthyNo ratings yet

- Davi-BARCODE-MCB-FOUR ROLLDocument12 pagesDavi-BARCODE-MCB-FOUR ROLLبازرگانی راهیان کار و دانشNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument3 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- Circular Pelletizing Technology General Presentation: We Just Made It BetterDocument46 pagesCircular Pelletizing Technology General Presentation: We Just Made It BetterkalaiNo ratings yet