Professional Documents

Culture Documents

Aluminium Cassette

Uploaded by

Harish NegiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aluminium Cassette

Uploaded by

Harish NegiCopyright:

Available Formats

Aluminium Cassette - Technical Data

The easy to install supporting structure made of light aluminium profiles allows for the cladding of building facades up to 100 m high. Additionally, the walls can be fitted with thermal insulation material before installation to save energy.

Profile Cassette

Profiled panel length [m] bis 6

Cover width [mm] 365 - 500

Metal thickness [mm] 1,5

Supporting structure: Steel, Wood, Aluminium Vertical section - Aluminium Cassette Cross section

Regardless of which season, you can install Aluform cassettes quickly, easily and inexpensively. Depending on the construction project, the cover widths can be chosen between 365 and 500 mm . Since the cassettes are manufactured with the use of roll forming machines, longer lengths are also possible. This allows for facade designs without the use of annoying diagonal joints

CONVINCING ADVANTAGES THAT EVERY ARCHITECT, INSTALLER AND CONTRACTOR LIKE TO MAKE USE OF INCLUDE:

lightweight good processing characteristics high thermal reflection in summer corrosion resistant under normal weather conditions non-combustibility maintenance-free

The design of a cassette aluminium ventilated facade consists of a protectively-decorative facing part which is mounted on some distance from a wall. The air interval allows to lift considerably protective properties of all system where the special warmly isolating covering of building object enters also.

Usually facing of cassette aluminium ventilated facades carry out from the aluminium composit panel or aluminium monosheet. Application of front aluminium allows to lower cost of aluminium designs of a facade several times. It reduces cost of a hinged facade. Besides aluminium application, in designs of a cassette aluminium hinged facade, allows to create the difficult architectural forms inaccessible at application of "stone". All these factors lead to that the part of cassette facades with facing of aluminium materials grows and will grow in the future . The design of cartridges of a composite consists of four basic parts: 1. A heater 2. Protection against the wind 3. A fixing subsystem 4. Cassettes

A heater It joins an external wall. It is made of ecologically pure mineral fibre (fibration of structure provides sound insulation). Heater plates consist of two parts: the first part is soft, adjoins directly to the wall surface, the second part is external, more dense and steady. Protective feature of a heater consists that it covers all surface of a wall, saving thus a premise from a frost and a condensate which increases building service. Protection against the wind The heater is protected by a membrane from influence of streams of air. The membrane carries out two basic functions: Humidity regulation. The moisture from building walls through a membrane leaves from a facade an ascending stream of air. Thus, the atmospheric moisture does not get in a heater. Protective function. The membrane protects mineral cotton wool of a heater from aeration. Fixing subsystem The design represents set of arms and directing, fixed on a wall. Aluminium arms are passed through a layer of a heater and are responsible for distance adjustment between a wall and directing. Directing represent aluminium profiles on which facing panels are fasten. At correct assemblage and successfully chosen fixing system the cassette hinged ventilated facade provides uniform loading on a wall, not causing mechanical deformations of a design, and also a different sort of thermal deformations. Systems of aluminium cassette hinged facades possess possibility of regulation of distances between a wall and external facing. Cassettes The external surface of an aluminium facade should represent a plane close to ideally equal. Therefore aluminium cassettes is an important part of a facade. Aluminium cassettes should be by all means homogeneous for structure, rigid, easy and steady against climatic changes. The most various types of panels are used for facing in systems of hinged ventilated facades. Manufacturing of

cartridges, as a rule, is carried out in the style which is in harmony with other elements of a facade: window apertures, doorways, a roof. The basic advantages of cassette hinged ventilated aluminium facades : Attractive aluminium cassette facades. One of the main advantages of cassette hinged facades of aluminium are boundless possibilities of a choice of modern front materials, formats and colours, the colour scale assumes various decisions for architectural registration of buildings.

Durability The cassette aluminium hinged facade does not demand repair and does not lose the qualities for a long time. Aluminium front panels do not lose operational properties under the influence of a sunlight, deposits, an atmospheric dust, acids and salt suspensions for many years. Protection of object against a moisture Moisture accumulation in a building wall leads to its accelerated destruction as a result of repeatedly repeating cycle of freezing and thawing, essentially reduces heat insulation properties of a wall. Installation of a hinged ventilated cassette facade allows to solve cardinally the given problem as thanks to the features it reduces moisture content in a concrete wall. As a result the comfortable microclimate is formed indoors, there is no occurrence of fungi and a mould. On the other hand, there is no also an excessive dryness of air in premises. Thermal protection improvement The cassette aluminium hinged facade allows to improve indicators of a thermal protection of protecting designs considerably. The external thermal protection allows to strengthen warmly heat-

sink ability of a file of a wall essentially. This advantage of an aluminium hinged cassette facade is widely used at reconstruction of the buildings which walls demand additional warming. Sound insulation improvement The cassette aluminium facade essentially raises sound-proof characteristics of a wall as front aluminium panels and a thermal protection possess sound-proof properties in a wide range of frequencies. Fire stability There is difficultly combustible and nonflammable materials. The panels of facing made of sheet aluminium correspond to modern fire-prevention requirements. The cassette aluminium facade is recommended to application at facing of buildings with increased requirements of fire safety. The minimum leaving while in service Cassette aluminium ventilated facade are easily cleared of the dust which has settled on it and aggressive water touches . Ease of repair The cassette hinged ventilated facade allows quickly, without dismantle of all design to carry out repairs and replacement of its separate parts. It considerably reduces the price and reduces volume of repair work. Especially it is actual in casual damage of a surface of a facade. Installation of a cassette aluminium hinged ventilated facade : 1. Installation of arms; 2. Heater installation 3. Installation of the directing; 4. Installation of facing cassettes. Installation of arms For indemnification of roughnesses of a wall of a building are used power (for fastening in concrete) and intermediate (for fastening in cellular concrete) arms of various standard sizes. Arms allow to regulate horizontal and vertical alignment of a design, including indemnification of roughnesses of a surface of the basic wall. Heater installation After installation of arms is finished, before installation directing on a wall are established warmly insullated panels. To avoid freezing, panels should be cut out under the form of corners, deepenings, arms. The surface warmly insulated panels is closed by a vlago-wind-shelter film. The thermal protection fixture on a facade is made according to recommendations of firms - suppliers and the design organisation. Installation of the directing The directing serve for fastening on them of front cartridges. The vertical row of the directing is mounted, starting the bottom section.

Connection directing on a vertical is made on a power arm. Thus the bottom directing fastens on an arm rigidly, on two bolts, and top - on a rivet in an oval aperture on an arm that allows directing to be extended and shortened at change of air temperature. Installation of cassettes After installation on a heater and skeleton facade from below installation of hinged aluminium cassettes upwards is made. Thus the sizes of cassettes and appearance of a facade are defined according to the task for an architectural part of the project of the facade. The bottom part of the cassette is put in the lock with the top part of the bottom cassette, and the top part fastens exhaust rivets or self-cut screws to the directing.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- All in One ALE ReviewerDocument53 pagesAll in One ALE Reviewergulay yuo100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- ChopDocument20 pagesChopfabian paezNo ratings yet

- Renaissance ArchitectureDocument12 pagesRenaissance ArchitecturePaulaTrishaValleNo ratings yet

- International Case Study Kumra Ankara Turkey: - Kaivalya PathadeDocument12 pagesInternational Case Study Kumra Ankara Turkey: - Kaivalya PathadekattyNo ratings yet

- Building Info ModularDocument1 pageBuilding Info ModularHarish NegiNo ratings yet

- Report On Agra ND JaipurDocument12 pagesReport On Agra ND JaipurHarish NegiNo ratings yet

- Report On Agra ND JaipurDocument12 pagesReport On Agra ND JaipurHarish NegiNo ratings yet

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- MBBM Building Climatology-EDocument6 pagesMBBM Building Climatology-EHarish NegiNo ratings yet

- Greek and Roman ArchitectureDocument72 pagesGreek and Roman ArchitectureChiara Mata IgnacioNo ratings yet

- BOQ Raniya Institute 3-1-2021 - DR ArezDocument3 pagesBOQ Raniya Institute 3-1-2021 - DR ArezSaeed FatahNo ratings yet

- Owen Jones' influence on 19th century interior design theories and the transition to professional interior designDocument3 pagesOwen Jones' influence on 19th century interior design theories and the transition to professional interior designMaan MirallesNo ratings yet

- Elzinc ASS V 4.1.03 Eng PDFDocument2 pagesElzinc ASS V 4.1.03 Eng PDFDragoș Alexandru FodoreanuNo ratings yet

- Certprepod SfpartnerDocument10 pagesCertprepod SfpartnerDpanraj DSNo ratings yet

- Standard Specification - State of New York Department of TransportationDocument1,305 pagesStandard Specification - State of New York Department of TransportationVan Cuong PhamNo ratings yet

- Shopdrawing Baja PDFDocument13 pagesShopdrawing Baja PDFFatahullaNo ratings yet

- Concrete Tracking Sheet 23-Dec-21 To 29-Dec-21Document7 pagesConcrete Tracking Sheet 23-Dec-21 To 29-Dec-21Ahmed MoawadNo ratings yet

- Colonial ArchitectureDocument20 pagesColonial ArchitectureNandini SNo ratings yet

- Building Inspection Report: Address: 186 Evans Street Rozelle 2039Document13 pagesBuilding Inspection Report: Address: 186 Evans Street Rozelle 2039Antonio BesterNo ratings yet

- Post ModernDocument54 pagesPost ModernEngkos DzhanoNo ratings yet

- Structural Behavior of Steel-Concrete Composite BeamDocument12 pagesStructural Behavior of Steel-Concrete Composite BeamJaime Morales BazalduaNo ratings yet

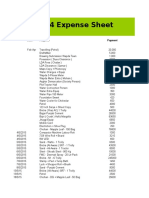

- Expense 106-B4Document46 pagesExpense 106-B4Anonymous 4eO2MfcUNo ratings yet

- Sanitary Fittings.Document21 pagesSanitary Fittings.anisha binthNo ratings yet

- Green Maintenance For Historic Masonry Buildings - A LCA ApproachDocument323 pagesGreen Maintenance For Historic Masonry Buildings - A LCA ApproachTheGimhan123No ratings yet

- CV - Tatiana Bilbao Estudio - EN - LowDocument12 pagesCV - Tatiana Bilbao Estudio - EN - LowArq. Joel HernadezNo ratings yet

- ESTOP-TDS-Estowrap 300 & 600Document5 pagesESTOP-TDS-Estowrap 300 & 600Dona Dwi SaputroNo ratings yet

- What Is Pre Construction Anti Termite TreatmentDocument4 pagesWhat Is Pre Construction Anti Termite TreatmentvinodNo ratings yet

- LEED v4 For Homes Design and Construction Checklist - 1 PAGEDocument7 pagesLEED v4 For Homes Design and Construction Checklist - 1 PAGEMihaela CiolacheNo ratings yet

- Literature Study and Case Studies of Student Housing For Architectural CollegesDocument16 pagesLiterature Study and Case Studies of Student Housing For Architectural CollegessowmyaNo ratings yet

- A Rare Opportunity at Siddha Weston, DalhousieDocument14 pagesA Rare Opportunity at Siddha Weston, DalhousieSourav ChakrabotyNo ratings yet

- ConcreteDocument112 pagesConcreteKalai ManiNo ratings yet

- Carras-An Barangay Hall Construction Project MaterialsDocument25 pagesCarras-An Barangay Hall Construction Project MaterialsJudy Anne BautistaNo ratings yet

- Structural Terms and Notes For Quick ReferenceDocument63 pagesStructural Terms and Notes For Quick ReferencegullipalliNo ratings yet

- Serenity Dormitory Project Construction Plans Week 1Document15 pagesSerenity Dormitory Project Construction Plans Week 1Gojo SatoruNo ratings yet

- Report MaharudraDocument59 pagesReport MaharudraSandip BudhathokiNo ratings yet