Professional Documents

Culture Documents

PROJECT STANDARDS and Specifications Grounding and Over Voltage Protection Rev01

Uploaded by

Adi ZulhamdiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PROJECT STANDARDS and Specifications Grounding and Over Voltage Protection Rev01

Uploaded by

Adi ZulhamdiCopyright:

Available Formats

Page : 1 of 23

KLM Technology Group

Project Engineering Standard

Rev: 01 April 2011

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

GROUNDING AND OVERVOLTAGE PROTECTION (PROJECT STANDARDS AND SPECIFICATIONS)

TABLE OF CONTENT

SCOPE REFERENCES DEFINITIONS AND TERMINOLOGY BONDING AND GROUNDING MATERIALS AND METHODS Bonding and Grounding Conductors Bonding and Grounding Connections Grounds Substation and Generating Station Grounds SYSTEM NEUTRAL GROUNDS Ground Resistance Grounding Conductor Size Grounding Conductor Insulation ENCLOSURE GROUNDING Wiring Systems Wiring Systems Equipment Ground Returns Conduit Ground Returns Ground Return Through Flexible Conduit OVERVOLTAGE PROTECTION FOR POWER SYSTEMS STRUCTURE LIGHTNING PROTECTION BONDING AT LOADING STATIONS

2 2 2 3 3 4 5 6 6 6 6 7 7 7 8 8 9 9 10 11 13 14

KLM Technology Group

Project Engineering Standard

GROUNDING AND OVERVOLTAGE PROTECTION (PROJECT STANDARDS AND SPECIFICATIONS)

Page 2 of 23

Rev: 01

April 2011

SCOPE This Project Standard and Specification covers requirements governing the grounding, over voltage protection, and lighting protection facilities for electrical power system and equipment, structures and buildings. This Project Standard and Specification does not cover process instrumentation system. REFERENCES Lighting protection for structures without metallic frames or siding shall be in accordance with ANSI Standard C5.1, Lighting Protection Code, or equivalent national standard. DEFINITIONS AND TERMINOLOGY Acceptable and preferred practices - Where this Project Standard and Specification list more than one type of equipment or method as acceptable, the Contractor shall make the selection based on the installed cost. Where one particular type of equipment or method is listed as preferred, it shall be selected, provided it is lower or equivalent in installed cost than other acceptable type or methods. Bonding - Two or more objects are considered to be bonded if connected together through a conducting path. Objects which are not inherently in contact with each other through a conducting path may be bonded by connecting them together with a bonding conductor. Equipment - The term equipment as used in this Project Standard and Specification applies to all electrical distribution, control and utilization components and includes such as transformers, panel boards, lighting fixtures, receptacles, switching devices, and motors. Ground return path - A metallic connection between the metal enclosure of electrical equipment and the system neutral ground of the power supply to the equipment. If the system neutral is grounded through impedance, the ground return path must connect on the ground side of the impedance. Grounding - An object is considered to be grounded when connected by a conducting connection, either inherently or by a grounding conductor, to the earth.

KLM Technology Group

Project Engineering Standard

GROUNDING AND OVERVOLTAGE PROTECTION (PROJECT STANDARDS AND SPECIFICATIONS)

Page 3 of 23

Rev: 01

April 2011

Grounds - Grounding electrodes, buried grounding conductors, or underground metallic water piping. Liquids - Are classified as accumulators if their conductivity is 50 picomhos/meter or less. Distilled petroleum products including petroleum solvents, are generally accumulators. Crude oil, residual fuel oil, asphalt (both penetration or cutback), Bunker C, residual products with Conradson carbon above 1% and water soluble products such as alcohol have high conductivity and are classified as non-accumulators. Switch loading - Loading a high flash cargo into a shipping vessel previously containing a low flash cargo, without cleaning or gas freeing the vessel. The high flash cargo must be treated as low flash during loading in such cases. The zone of lighting protection - The space enclosed by a cone with its apex at the highest point of a properly grounded rod, wire, or metal structure and has a radius at its base of twice the height of the rod. BONDING AND GROUNDING MATERIALS AND METHODS Bonding shall be provided where necessary to insure the electrical continuity of grounding circuits and where necessary to provide a path for the dissipation of static charges. Bonds provided for the dissipation of static charges shall have a resistance of one meg ohm or less. Bonding and Grounding Conductors 1. Bonding, grounding, and buried ground return conductors shall be bare stranded medium-hard-drawn copper. Minimum sizes shall be 2 Awg. (32 mm2, 0.05 in2) for underground conductors and 6 Awg. (13 mm2 , 0.02 in2) for aboveground conductors. 2. Ground return conductors located within cable assemblies may be uninsulated and shall be of the same material and stranding as the cable line conductors. 3. Conductors sizes shall be increased above the minimum sizes if required to: - Insure adequate mechanical strength. - Withstand the thermal stresses of ground fault currents. 4. Grounding conductor burial depths shall be at least 18 inches. Burial depths in switch or transformer yards graded with stone shall be at least 12 inches below the stone.

KLM Technology Group

Project Engineering Standard

GROUNDING AND OVERVOLTAGE PROTECTION (PROJECT STANDARDS AND SPECIFICATIONS)

Page 4 of 23

Rev: 01

April 2011

5. If the wiring method is buried cable, grounding conductors shall be laid in the cable trenches as far as routing permits. 6. If the wiring method is underground conduit, grounding conductors shall be laid along a formed side of the duct banks as far as routing permits. 7. Where grounding cables cross under railroads, main roads, paved roads, or concrete paved areas, they shall be run in rigid metal conduit, pipe sleeves, or duct banks as required for wiring and cable systems. 8. Where grounding cables cross secondary roads which are not paved, burial depth or design of cable protective covering or both shall prevent damage either to the cables or to the covering from anticipated heavy loads such as mobile cranes or equipment transport vehicles. A safety factor of 1.5 shall be applied to the total loads. 9. Grounding conductors leaving the ground at grade shall be protected as follows: a. Conductors except those used for lightning protection shall be protected by rigid metal conduit or pipe sleeves where they are extended above grace. Lightning protection conductors shall be protection conductors shall be protected by non-metallic conduit sleeves. b. Sleeves shall extend a minimum of 6 in. below grade and 10 in. above grade. c. Metal sleeves shall be encased in concrete 3 in. thick all around. d. Concrete encasement shall extend 6 in. above grade. e. Non-metallic sleeves shall be rigidly heavy wall polyvinyl chloride or high density polyethylene conduit. f. Sleeves not required within switch or transformer yards or under elevated substations. Bonding and Grounding Connections All conductors connection to structures and equipment shall be made above ground as follows: a. Conductors shall be installed in one length between aboveground connection points. b. Single cable lengths shall also be installed between aboveground connection points and grounding electrodes or taps on common ground return cables. c. If splices or taps are required on underground runs, they shall be made with tool-installed compression connectors or by brazing or welding. d. Screw-type solderless connectors shall not be used underground. e. Splices or taps in underground runs shall be buried.

KLM Technology Group

Project Engineering Standard

GROUNDING AND OVERVOLTAGE PROTECTION (PROJECT STANDARDS AND SPECIFICATIONS)

Page 5 of 23

Rev: 01

April 2011

On equipment, conductor connections which are regularly disconnected for maintenance of the equipment shall be made with screw type solderless connectors. Other connections shall be made solderless connectors or by brazing or welding. All welded connections shall be made by a welding process equivalent to Cadweld or Thermoweld. Grounds 1. Grounds shall meet the resistances to earth specified herein throughout the year considering seasonal variation in soil conditions. 2. Buried grounding conductors serving as grounds shall have a length of not less than 25 ft. 3. Grounding Electrodes. If permanently installed and located within a reasonable distance of the equipment or structure to be grounded, the following may be used as grounding electrodes: - Underground metallic water piping if buried portion is greater than 10 ft. length. - Large underground metallic objects in intimate contact with earth such as pile casings or building frames. 4. Artificial grounding electrodes shall consist of driven rods and shall be as follows: a. Rods shall be copper clad steel 1 equivalent to Copperweld and shall have a minimum diameter of 5.8 in. b. Top of rods shall be at least 18 inches below grade. c. A grounding conductor shall connect the top of each rod to an accessible aboveground connection point. The connection point may be located on the structure or equipment to be grounded or on a nearby permanent structure to serve as a tie-in point for other grounding conductors. At tie-in points, conductors from rods shall be identified with corrosion resistant metal bands to facilitate their removal for test purposes. d. The grounding conductor shall be connected to the rod by brazing or welding and to the connection points by a screw type solderless connector. e. Rod top and its grounding conductor shall be buried. f. If more than one artificial electrode is connected to a ground system, the electrodes shall be spaced at least 10 ft. apart.

KLM Technology Group

Project Engineering Standard

GROUNDING AND OVERVOLTAGE PROTECTION (PROJECT STANDARDS AND SPECIFICATIONS)

Page 6 of 23

Rev: 01

April 2011

Substation and Generating Station Grounds All grounding electrodes at substations and generating stations shall be interconnected by grounding conductors. If grounding conductors are used in lieu of electrodes, all conductors shall be interconnected. SYSTEM NEUTRAL GROUNDS Ground Resistance Grounds for system neutrals shall have a resistance to earth as follows:

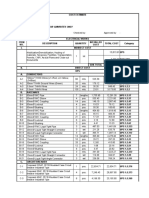

For impedance-grounded system (such as low resistance, high resistance, and reactance), the values above apply to the resistance to earth from the grounded side of the impedance, and do not include the impedance which is specified separately. Grounding Conductor Size 1. Grounding conductors used to ground power transmitter or generator neutrals shall have a cross sectional size not less than 32 mm2 (0.05 in2, 2-Awg.). In addition, the size shall limit temperature reached by the conductor, when carrying maximum ground fault current for the time allowed by the slowest responsive relay, to the following: a. For insulated conductors, to within the transient temperature for no damage to the insulation. b. For bare conductors: to 250C if connections to cable are made with pressure connectors; to 450C rise if connections to cable are brazed or welded. For copper conductor and 26C ambient, required size is

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Chilled Water Pipe Insulation Method StatementDocument2 pagesChilled Water Pipe Insulation Method StatementGündoğdu Akın75% (4)

- BS 648Document50 pagesBS 648Michael Newton0% (1)

- Project Synopsis Final 2Document6 pagesProject Synopsis Final 24254 prajwal taoriNo ratings yet

- BoqDocument2 pagesBoqJohn Carlo TolentinoNo ratings yet

- Bistra AnnouncementDocument55 pagesBistra AnnouncementMohammed Al-samarraeNo ratings yet

- Englishbest Toeic Reading-Comprehension-9Document3 pagesEnglishbest Toeic Reading-Comprehension-9Hoà HànNo ratings yet

- NEW - Structural Design & Analysis (Pt. 1)Document23 pagesNEW - Structural Design & Analysis (Pt. 1)Rein Aira OrdanezNo ratings yet

- Metal Grating & Fiberglass GratingDocument64 pagesMetal Grating & Fiberglass Gratingjohn leeNo ratings yet

- Mcode and Mname Commercial and Alternate Designations: Material - Cross - IndexDocument33 pagesMcode and Mname Commercial and Alternate Designations: Material - Cross - IndexMohamedNo ratings yet

- Ciht Industrial Training FileDocument48 pagesCiht Industrial Training FileRishabNo ratings yet

- Direct Expansion Air ConditioningDocument1 pageDirect Expansion Air ConditioningPrabhat Kumar100% (1)

- Driscoplex 6500 Pe2708 / (Pe2406) Pipe: Pipe & Fittings Data SheetDocument2 pagesDriscoplex 6500 Pe2708 / (Pe2406) Pipe: Pipe & Fittings Data SheetmariannyNo ratings yet

- Inventaa Hollow WallsDocument6 pagesInventaa Hollow WallsSumedh GuptaNo ratings yet

- Kidney Palasa-WO-2022.12.06Document8 pagesKidney Palasa-WO-2022.12.06Kanul RiyazNo ratings yet

- HZS 180 Concrete Batching PlantDocument2 pagesHZS 180 Concrete Batching PlantHenan NF Mechanical Installation Co., Ltd.No ratings yet

- Block 1 Types - Uses of ACDocument36 pagesBlock 1 Types - Uses of ACcem anılNo ratings yet

- Royal CordDocument1 pageRoyal CordWilfredoJrReyNo ratings yet

- Odwadniacz Termostatyczny th13Document1 pageOdwadniacz Termostatyczny th13Fernando Moreno pereiraNo ratings yet

- Product Information Flyer: CIMSTAR® 10-85VGDocument2 pagesProduct Information Flyer: CIMSTAR® 10-85VGsobheysaidNo ratings yet

- New SID ChecklistDocument19 pagesNew SID ChecklistDhanny MiharjaNo ratings yet

- The Use of Portable Hardness Testing in FieldDocument120 pagesThe Use of Portable Hardness Testing in Fieldantant3052No ratings yet

- Part HF Requirements For Boilers Constructed of Wrought MaterialsDocument21 pagesPart HF Requirements For Boilers Constructed of Wrought MaterialsKarthikeyan ParthasarathyNo ratings yet

- Rub Your Hands Together For 15 Seconds.: Thermal EnergyDocument33 pagesRub Your Hands Together For 15 Seconds.: Thermal EnergyFarhan Mukhtiar YousafzaiNo ratings yet

- Calculate Dimension of Electrical Panel From SLDDocument8 pagesCalculate Dimension of Electrical Panel From SLDShahjehanSajid100% (1)

- Brosur Kabel AC JemboDocument13 pagesBrosur Kabel AC JemboAdi Nu GrohoNo ratings yet

- Hydro-Mechanical Works 2.12 AnnexureDocument3 pagesHydro-Mechanical Works 2.12 AnnexuredishkuNo ratings yet

- Air Condition Size Calculator (1.1.17)Document3 pagesAir Condition Size Calculator (1.1.17)Ella CelineNo ratings yet

- Thermal Products Day-1 PDFDocument7 pagesThermal Products Day-1 PDFSachin KothariNo ratings yet

- KilnCooler TechnologyDocument6 pagesKilnCooler TechnologyJosé MoránNo ratings yet

- A New Method To Design End Plate Moment ConnectionsDocument31 pagesA New Method To Design End Plate Moment Connectionsjihu1170No ratings yet