Professional Documents

Culture Documents

30 Reviews of Slope Failure in Lowwall Area 3 of Mae Moh Mine

Uploaded by

mook12345Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

30 Reviews of Slope Failure in Lowwall Area 3 of Mae Moh Mine

Uploaded by

mook12345Copyright:

Available Formats

Rock Mechanics, Fuenkajorn & Phien-wej (eds) 2011.

ISBN 978 974 533 636 0

Reviews of slope failure in lowwall area 3 of Mae Moh mine

P. Doncommul, P. Pimklang, N. Mungpayabal & A. Chaiwan Geotechnical Engineering Department of Mae Moh Mine , Electricity Generating Authority of Thailand, Mae Moh, Lampang, Thailand

Keywords: Slope failure, slope stability, shear strength, lowwall, coal mine ABSTRACT: Lowwall area 3 is located in the north east pit area of Mae Moh mine. This trial area was excavated in February 1996. The first failure occurred in June and progressed to the east in September 1996 as the second failure. After heavy rain, the third and fourth failures of the whole area occurred in August and September 1998 with more than 3 millions cubic meters of mass movement. Detailed geologic structures, shear strength of the materials and monitoring results of failures were collected and reviewed. Lessons learnt from this review are very useful for future works of the mine and for those who involved in this subject. 1 INTRODUCTION

The Mae Moh mine is located at latitude 181821 N and longitude 994402 E, about 630 km north of Bangkok, and 30 km east of Lampang central (Figure 1). Coal mining in the Mae Moh open pit lignite mine is operated by the Electricity Generating Authority of Thailand (EGAT). This mine is the largest open pit mine in Thailand, with 4 km wide, 7.5 km long and 270 m deep. Lignite from this mine is the most important source of coal which according to statistics in April 2008, is the lowest cost fuel for electricity generating in Thailand (Figure 2).

Figure 1. Location of the Mae Moh mine in Lampang province, Thailand. 219

Reviews of slope failure in lowwall area 3 of Mae Moh mine

14

Solar cell

Fuel cost (Bath/Unit)

12 10 8 6 4 2 0 Lignite Natural gas Diesel Fuel oil

Fuel type

Figure 2. Fuel costs in Thailand as of April 2008. The Mae Moh mine and its thermal power plants started operation in 1955 and its production capacity has been progressively increased. Recently this power plant includes the total number of 10 units which consumes up to 50,000 tons of coal per day, serving 21.65% of the total electricity demands in Thailand (Figure 3). Therefore the annual requirement of coal for power plant is approximately 15-16 million tons. This high requirement of lignite indicates a huge volume of overburden excavation with open pit mining, which is estimated as 60-80 million cubic meters per year. The geological and economical lignite reserves in Mae Moh mine are approximately 1,140 million tons and 814 million tons, respectively. The total volume of coal excavated so far is 300 million tons (as of 2007). The current deepest level of the lignite pit is 270 meters. In the future, EGAT plans to excavate to the depth of 280 meters in 2017, 326 meters in 2022, 350 meters in 2028, and eventually to the final depth of 490 meters. To dig up more lignite by deepening the excavations in the pit, serious engineering problems are encountered due to the influence of underground water pressure (Giao, 1992), the instability of rock slopes and huge stress relief. Moreover, the presence of weak and thin layers of clay seam filling forming a shear plane becomes a significant problem because of their extremely low strength (EGAT, 1985).

Renew 1.25% Diesel 0.40% Coal 21.65%

Hydropower 5% Fuel oil 1.70%

Natural Gas 70%

Figure 3. Electricity sources in Thailand as of June 2008. 220

Rock Mechanics, Fuenkajorn & Phien-wej (eds) 2011. ISBN 978 974 533 636 0

MAE MOH MINE GEOLOGY

Mae Moh mine is in Mae Moh tertiary basin with more than 1,000 m of maximum thickness. Sediment in this basin was classified in to three formations from lower Huai King, Na Khaem and Huai Luang formations. Huai King formation consists of sandstone, siltstone, mudstone claystone and conglomerate with green, yellow, blue and purple in color. Na Khaem formation composes of grey, greenish grey mudstone clay and some sand with five zones of coal J,K,Q,R and S. The main seams are K and Q. Huai Luang formation mostly are red brown stiff clay and some sand. All stratas lying above K seam are overburden and claystone layers under Q coal seam are defined as underburden with some green sheared clays inter-bedded. Most stratas dip 10-15 degrees to the center of the basin. Normal faults found through out the basin (Figure 4). 3 NORTHEAST PIT SLOPE DESIGN CRITERION

After extensive program of geotechnical study on the Mae Moh mine in 1985, slope criteria were designed for each part of northeast pit. For the high-wall area 1:3 (vertical-to-horizontal) slope was set up. In the low-wall part with no normal fault, slope was designed parallel to bedding plane of the underburden. In the low-wall area with fault, some parts of underburden were planned to cut for appropriate slope angle according to the throw of the fault. 4 C-ROAD FAILURE

In 1988, a failure occurred in the south low-wall of northeast pit (Figure 5). The failure affecting C- road, one main haul road of this area. Failure plane is the combination of fault on upper part and sheared bedding plane of the underburden in lower part. After extensive program of drilling investigation, detailed pit mapping, laboratory testing and back analysis. It was found that weak green clay layer and water pressure along fault and bedding plane were the main causes of this failure. To overcome this type of failure, horizontal drain holes were drilled to drain water from the fault plane inside rock mass and to control water pressure in the slope. The results from extensive drilling along low-wall area showed sheared green clay layers inter-bedded in the underburden through out the low-wall area. The low-wall of the north east pit had been divided into 4 small areas due to their geometry. Low-wall areas 1 and 2 with geometry similar to C-road failure were redesigned to leave more underburden in place as a countered weight and drill drained holes along the slope. Areas 3 and 4 are quite different, their bedding planes dip into the pit with more steep angle, which require a different method to solve these problematic areas.

Figure 4. Stratigraphy and a typical cross section of Mae Moh main basin. 221

Reviews of slope failure in lowwall area 3 of Mae Moh mine

Figure 5. Photograph of C-road failure.

slope 340 slope

B2/6 F7 B0/8 F170/175 B 100/4 F 160/70 B 103/3

B 102/8

320

300

280

260

CR aod

0 50 100 150 200

250

Figure 6. Map and cross section of C-road failure. 5 LOWWALL AREA 3

Lowwall area 3 mine grid is N35-N41 and W5-W12, located in the northeast part of northeast pit. Bedding planes of the underburden in this area dip toward the pit with 10-18 degrees. There are some westward normal faults cut and offset the coal and the underburden into many blocks (Figures 7 through 11). According to mine plan, once coal in front of the faulted block is mined out, bedding plane of weak green clays behind will be day-lighted. Rock mass above these layers will move along bedding plane due to inclination of these planes are greater than their friction angle. It is quite clear that Lowwall area 3 is unstable. Mine geotechnical group proposed to make trial area by providing the receiving berm for sliding mass and hope it could stop within this provided area. Visual inspection, detailed pit mapping and monitoring were carried out to understand the true mechanisms of the slope movement and water pressure. Information and experience from this area will be useful for the deep mine slope design in the future.

222

Rock Mechanics, Fuenkajorn & Phien-wej (eds) 2011. ISBN 978 974 533 636 0

500m.

Figure 7. Map of lowwall of the northeast pit, plan and cross section of lowwall area 3.

100 m. Figure 8. Pit map, cross section and photograph of lowwall area 3 at the first failure. 223

Reviews of slope failure in lowwall area 3 of Mae Moh mine

100 m. Figure 9. Boundary and cross section of the second failure of lowwall area 3.

100m. Figure 10. Map of the third and fourth failure. of lowwall area 3.

Figure 11. Cross section of the lowwall area 3 and the length each failure. 6 EXCAVATION AND FAILURE OF LOWWALL AREA3

Lowwall area 3 was started to excavate in January, 1996 from the upper part at +280 msl. Lowering bench-by-bench, from +280 msl. to +239 msl. Detailed pit mapping was done continuously and cracks were observed along the fault even in dry season. After green clay 224

Rock Mechanics, Fuenkajorn & Phien-wej (eds) 2011. ISBN 978 974 533 636 0

layers were day-lighted about 200 m long and with some rain, more movement found both from monitoring equipments and visual inspection. Finally, the first failure occurred on the 16th of June 1996. Failure size was 80 m (w) 120 m (l) 30 m (h). It was clear that the failure plane was along the top of G1A layer. Failure mass movement was about 20 m at the toe and stopped on the providing floor. However, the second failure occurred within rain season on the 15th of September 1996. The second failure extended more to the east and moved more than 60 m to the west at toe. The north and south of the failure boundary extended only 20 m. Some parts of failure mass at toe were cleaned up. The excavation extended more both in north and south and also lowering to +200 msl according to mine planning in the two following years. The length of the undercut planes extended to the maximum of 500 m. Then, during the rainy season of the second year, the third failure occurred on 20th August 1998 with the full length of excavated slope face. Failure mass was approximately three million cubic meters. After very heavy rained on the 6th of September of that year, the fourth failure occurred as mud and debris flows. These materials flowed over the providing area and affected the active working face. 7 MONITORING DATA

Some monitoring equipments were installed both before and during excavation (Figure 12). Results of these instruments are summarized as follows. 7.1 Inclinometers

Six inclinometers were installed at the top of slope, outside the excavated area. LWI301, total depth 70 m installed in March 1996, very close to the limit of cut and collapsed with first failure of area 3. Four measurements were obtained before it failed. Maximum displacement showed about 1 cm at the depth of 20-22 m. LWI302 installed at 100 m north of LWI301, outside the first and second failure boundaries. The total depth was 80 m. Maximum displacement was 1.5 cm at depth of 16 m with 4 records, the last was on the 15th of October 1996. LWI303 installed with 80 m deep at 100 m north of LWI302. The maximum displacement was 4.5 cm at the depth of 21-23 m. Same as LWI304 and LWI305, the maximum displacement occurred at the same layer, G1A. Rate of the mass movement of LWI303 from chart shown in Figure 13 shows that the movement rate was affected by rain and the movement rate decreased after the first and second failures had occurred.

100m.

Figure 12. Locations of inclinometer and piezometer in lowwall area 3.

225

Reviews of slope failure in lowwall area 3 of Mae Moh mine

Figure 13. Records of inclinometer LWI303 and movement rate. 7.2 Piezometers

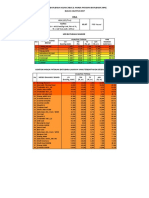

Seven piezometers installed in area 3, as shown in Figure 14, were selected to plot with rainfall data in two groups. The first group is in the southern part composed of the LWP178, LWP 192 and LWP181. The first one was installed in G1A layer, the second and the third were installed in G1 layer. The LWP178 located in the lower part of area 3. It gradually fell down and responded to the rain fall then dried out in 1995 before excavation started. The LWP192 and LWP181were located far to the east of the failure area. The LWP192 slowly fell down from year 1993 to 1998. It responded to the rain fall in the years 1995 and 1996. The LWP181 was high in piezometric level compared to the first two piezometers. It fell down rapidly in the middle and late 1996, and dropped to zero in late 1997. These 3 piezometers showed that they were different in piezometric level, responded to the rain and failure events. The second group including LWP1105, LWP1106, LWP1113 and LWP1114. LWP1106 was in the middle of area 3. The LWP1105, LWP1113 and LWP1114 were located in the northeast of area 3. The LWP1106 suddenly rose up in June 1997 and between September and October 1997 then failed with the third failure on the 20th of August 1998. LWP1105 rose up rapidly from 20 kPa. in September to October 1997, and jumped up to 150 kPa before the third failure occurred. LWP1113 climbed up continuously from 30 to 160 kPa, not responded to rain before the third failure of area 3. LWP1114 started with 120 kPa and jumped up to 150 kPa before failing. LW1113 and LWP1114 showed leakage of water with high pressure from the adjacent area into the east of area 3, and may be the main cause of the third fail in this area.

Figure 14. Piezometer data in lowwall area 3.

226

Rock Mechanics, Fuenkajorn & Phien-wej (eds) 2011. ISBN 978 974 533 636 0

BACK ANALYSIS

Cross section NE6.2 was selected for back analysis of the first failure (Figure 15). There are at least six normal faults in this cross section. Claystone and green clay layers in each fault block varied in dip angle. Three material types are definded; claystone, G1A green clay and fault. The material parameters for the claystone are as follows: unit weight = 19.5 kN/m3, cohesion is 100 kPa, and friction angle = 25 degrees. For G1A, cohesion is 0 kPa. friction angle = 12 degrees. The fault plane properties are as follows: cohesion = 0 kPa, friction angle = 17 degrees. The analysis result shows that, for dry case, the factor of safety is 0.981. The back analysis result was well correspond to the field evidence before sliding occurred.

0.961

Claystone Unit Weight Cohesion Phi G1A Unit Weight Cohesion Phi fault Unit Weight Cohesion Phi 20 kN/m3 0 kPa 17 degree 20 kN/m3 0 kPa 12 degree 19.5 kN/m3 100 kPa 25 degree

300 290 280 270

300 290 280 270 260 250 240 230 220 0 20 40 60 80 100 120 140 160 180 200

ElE.

260 250 240 230 220

Distance

Figure 15. Back analysis of section NE 6.2. 9 CONCLUSIONS

Some lowwall areas of the Mae Moh mine pose the risk of slope stability problem. To avoid this risk, removal of the potential movement materials should be the last solution due to the cost. For the best alternative solution under consideration, detail geometry of each area should be well investigated and understood. Mitigation and option of remedial works have to be evaluated and compared as early as possible to get the best option. Lesson learnt from the C-road failure was applied for the low-wall area 3 trial area. Its geometry and weak layers show that it will be certainly fail unless it is removed before undercutting. Geotechnical department of the mine proposed to allow the failure to occur, and provide the receiving area while monitoring its mechanisms. The first failure occurred as predicted, but the second to fourth failures were more severe than expected due to the heavy rain and the disintegrated sliding material. Scale of the first failure and the data collected from these movements are valuable for the mitigation for the future mine areas, such as area 4.1 and area 4. ACKNOWLEDGEMENT This paper is summarized from failure records of Slope Stability Analysis Section and monitoring data from Slope Stability Monitoring Section, Geotechnical Engineering Department, Mine Planning and Administration Division of Mae Moh Mine. Permission to publish this paper is gratefully acknowledged. REFERENCES Electricity Generating Authority of Thailand, 1985. Geotechnical Report Volume1, Thailand Australia lignite Mine Development Project, Mae Moh Mine. Thawonwisuttikul D. , Jariyabhumi, O.(1994). Lesson learnt from slope failure at Mae Moh mine, The Fifth Mining Conference, Songkla: Prince of Songkla University, 1994,pp. 3-41-56. 227

You might also like

- Stability of Embankments On Soft GroundDocument17 pagesStability of Embankments On Soft GroundYang Ching HianNo ratings yet

- 2004 Geological Risk in The Use of TBMs in Heterogeneous Rock MassesDocument16 pages2004 Geological Risk in The Use of TBMs in Heterogeneous Rock Massesrd3704714No ratings yet

- 2009 Emilia East 1250 M Well ProposalDocument35 pages2009 Emilia East 1250 M Well ProposalPedro TorquemadaNo ratings yet

- Group 12 SUMMARY (Paper 22) Shallow Gas On Talangjimar FieldDocument2 pagesGroup 12 SUMMARY (Paper 22) Shallow Gas On Talangjimar FieldIzhar JuniorNo ratings yet

- Appendix E3 - OP Pioneering and Pre-ProductionDocument18 pagesAppendix E3 - OP Pioneering and Pre-Productionfedericot14No ratings yet

- Coal Seam Modelling and Mine Plalnning Using Results of A 3D SeisDocument16 pagesCoal Seam Modelling and Mine Plalnning Using Results of A 3D SeisKorchak JohnNo ratings yet

- Surface Effects of Total Coal-Seam Extraction by Underground Mining MethodsDocument11 pagesSurface Effects of Total Coal-Seam Extraction by Underground Mining MethodsInpensyah HarianjaNo ratings yet

- Exploration KerinciDocument6 pagesExploration KerinciNovia Pirma Yeni PirdausNo ratings yet

- Overcoming squeezing in Venezuela's Yacambú-Quibor tunnelDocument30 pagesOvercoming squeezing in Venezuela's Yacambú-Quibor tunnelFelipe UribeNo ratings yet

- Two Years of Jet-Grouting in British ColumbiaDocument10 pagesTwo Years of Jet-Grouting in British ColumbiaabbidubbiNo ratings yet

- Latest Technology Ofunderground Rock Cavern Excavation in JapanDocument18 pagesLatest Technology Ofunderground Rock Cavern Excavation in JapanpbldzcmsNo ratings yet

- Ulusay VD., 2001Document18 pagesUlusay VD., 2001Melikhann KarakasNo ratings yet

- 23G-04 1 06Document17 pages23G-04 1 06Anonymous D5s00DdUNo ratings yet

- Preliminary Findings From An Investigation of Improved Ground Performance During The 1999 Turkey EarthquakesDocument17 pagesPreliminary Findings From An Investigation of Improved Ground Performance During The 1999 Turkey EarthquakessertackcdgNo ratings yet

- Burren Energy: Title Page 1Document25 pagesBurren Energy: Title Page 1Iker Astigarraga EpeldeNo ratings yet

- Managing Geotechnical Challenges Hydropower Dam ConstructionDocument10 pagesManaging Geotechnical Challenges Hydropower Dam Constructionmining10No ratings yet

- Overcoming Squeezing in The Yacambu Quibor Tunnel PDFDocument33 pagesOvercoming Squeezing in The Yacambu Quibor Tunnel PDFajgarcesv7301No ratings yet

- Case Study Delayed Failure of A Deep Cutting in Lodgement TillDocument10 pagesCase Study Delayed Failure of A Deep Cutting in Lodgement TillthadikkaranNo ratings yet

- RF Modulus Settlement Plate-Nam Ngum 2 CFRD 0211Document14 pagesRF Modulus Settlement Plate-Nam Ngum 2 CFRD 0211szarnaniNo ratings yet

- An Open-Pit Coalmine Surcharged by Artesian Water PressureDocument22 pagesAn Open-Pit Coalmine Surcharged by Artesian Water PressurebrowncasNo ratings yet

- Back Analysis of High Tunnel Convergences in Clayey MarlsDocument10 pagesBack Analysis of High Tunnel Convergences in Clayey MarlsAnonymous Gon7kIsNo ratings yet

- 2008 Justb Granite QuarryDocument8 pages2008 Justb Granite QuarryBruno GoesNo ratings yet

- Evaluation of Effect of August 17 1999 Marmara EarthquakeDocument8 pagesEvaluation of Effect of August 17 1999 Marmara EarthquakeSUELERO88No ratings yet

- TORCOROMA RepDocument27 pagesTORCOROMA RepMario PrinceNo ratings yet

- NATM, EPBM and Cut and Cover Tunneling ApplicationsDocument15 pagesNATM, EPBM and Cut and Cover Tunneling ApplicationsChin Thau WuiNo ratings yet

- Slope Paper 247Document13 pagesSlope Paper 247rNo ratings yet

- Monitoring embankment project using rigid inclusions and vacuum consolidationDocument10 pagesMonitoring embankment project using rigid inclusions and vacuum consolidationStephen ButtlingNo ratings yet

- Remedial Measures To A Building Settlement ProblemDocument5 pagesRemedial Measures To A Building Settlement ProblemEswara PrasadNo ratings yet

- SMART Geot AspectsDocument15 pagesSMART Geot AspectsmrlobboNo ratings yet

- Dudi Za SCI enDocument8 pagesDudi Za SCI enIgnjatović DraganNo ratings yet

- TS2A3Document8 pagesTS2A3Harold TaylorNo ratings yet

- Omechanics Wellbore Stability Analysis in Successful Drilling of A Challenging HPHT Exploration Well in North SumatraDocument21 pagesOmechanics Wellbore Stability Analysis in Successful Drilling of A Challenging HPHT Exploration Well in North SumatraHerry SuhartomoNo ratings yet

- WTC2013-Construction Aspects For Lot 3 São Paulo Metro Line 5 ExpansionDocument8 pagesWTC2013-Construction Aspects For Lot 3 São Paulo Metro Line 5 ExpansionMapeixNo ratings yet

- Tunnelling Through Challenging Ground Conditions Under Major Infra-Structures in SingaporeDocument15 pagesTunnelling Through Challenging Ground Conditions Under Major Infra-Structures in SingaporeGoh Kay Yun100% (1)

- Keruntuhan Galian DalamDocument16 pagesKeruntuhan Galian Dalamlimara65No ratings yet

- Guri Plunge Pool Develop PDFDocument6 pagesGuri Plunge Pool Develop PDFArturo MarcanoNo ratings yet

- M. Farhad Howladar - Coal Mining Impacts On Water Environs Around The Barapukuria Coal Mining Area, DinajpurDocument12 pagesM. Farhad Howladar - Coal Mining Impacts On Water Environs Around The Barapukuria Coal Mining Area, DinajpurAbu NaserNo ratings yet

- Analysis of Failure of Retaining WallDocument39 pagesAnalysis of Failure of Retaining Wallamansingh9119No ratings yet

- Assessment of Dust Generation Due To Opencast Coal Miningan Indian Case StudyDocument9 pagesAssessment of Dust Generation Due To Opencast Coal Miningan Indian Case Studysaurabh shrivastavaNo ratings yet

- Geotechnical Aspects of The SMART Tunnel, 2006Document15 pagesGeotechnical Aspects of The SMART Tunnel, 2006freezefreeze100% (1)

- A Major Step For A Pipeline: Crossing The Serra Do Mar State Park in BrazilDocument11 pagesA Major Step For A Pipeline: Crossing The Serra Do Mar State Park in BrazilDheeraj Chowdary DhanekulaNo ratings yet

- 11 Tunnelling With Hidraulic Drills at Abajora Hidro Eletric Plant in NorwayDocument0 pages11 Tunnelling With Hidraulic Drills at Abajora Hidro Eletric Plant in Norwaycastille1956No ratings yet

- Delayed FailureDocument8 pagesDelayed FailureZeal LeaNo ratings yet

- Remedial Measures To A Building Settlement Problem PDFDocument4 pagesRemedial Measures To A Building Settlement Problem PDFAntony Prasanth M ANo ratings yet

- Energies: Impact of Shear Zone On Rockburst in The Deep Neelum-Jehlum Hydropower Tunnel: A Numerical Modeling ApproachDocument16 pagesEnergies: Impact of Shear Zone On Rockburst in The Deep Neelum-Jehlum Hydropower Tunnel: A Numerical Modeling Approachgioinfra IndiaNo ratings yet

- Coal Exploration ReportDocument58 pagesCoal Exploration Reportpuput utomoNo ratings yet

- Mining Geomechanics - AWestern. AustraliaDocument6 pagesMining Geomechanics - AWestern. AustraliaAlonso ValerianoNo ratings yet

- WTC2015 - Design and Construction Aspects of A Conventional Shallow Tunnel in Very Soft SoilDocument6 pagesWTC2015 - Design and Construction Aspects of A Conventional Shallow Tunnel in Very Soft SoilMapeixNo ratings yet

- Delineate Facies Distribution in Tiaka Carbonate ReservoirsDocument13 pagesDelineate Facies Distribution in Tiaka Carbonate ReservoirsMuhammad Raiees AmjadNo ratings yet

- Coal Bed Methane PotencyDocument8 pagesCoal Bed Methane PotencyTomy Efraim SitumorangNo ratings yet

- Primary and Secondary Tunnel Lining Design Methodology-2Document3 pagesPrimary and Secondary Tunnel Lining Design Methodology-2grktnc100% (1)

- Assignment No.1 CE642Document16 pagesAssignment No.1 CE642Yogesh NautiyalNo ratings yet

- Docslide - Us Bilgin N Et Al 2006 TBM Cutting Performance in IstanbulDocument3 pagesDocslide - Us Bilgin N Et Al 2006 TBM Cutting Performance in IstanbulAymanSobhyNo ratings yet

- Mitigation Measures For The Protection of WorkingDocument7 pagesMitigation Measures For The Protection of WorkingEvelin Carla Mamani ArroyoNo ratings yet

- Tunnelling and Underground Space Technology: SciencedirectDocument9 pagesTunnelling and Underground Space Technology: SciencedirectEduardo CepedaNo ratings yet

- Extreme Excavation in Fault Zones and Squeezing Ground at The Kargi HEPP in TurkeyDocument11 pagesExtreme Excavation in Fault Zones and Squeezing Ground at The Kargi HEPP in TurkeynishantNo ratings yet

- Displacement analysis of left abutment slope for Jinping I damDocument10 pagesDisplacement analysis of left abutment slope for Jinping I damgia26No ratings yet

- Plate Boundaries and Natural HazardsFrom EverandPlate Boundaries and Natural HazardsJoao C. DuarteNo ratings yet

- Fault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureFrom EverandFault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureMarion Y. ThomasNo ratings yet

- Annual Report Accounts 2017-18 10082018 PDFDocument338 pagesAnnual Report Accounts 2017-18 10082018 PDFbrishti bepariNo ratings yet

- Using The Coal Mine Roof Rating (CMRR) To Assess Roof Stability in U.S. Coal MinesDocument8 pagesUsing The Coal Mine Roof Rating (CMRR) To Assess Roof Stability in U.S. Coal MinesUdit kumarNo ratings yet

- Wikileaks Cablegate & Stratfor Ecowar: Conflict) Is Abbreviated ENRCDocument16 pagesWikileaks Cablegate & Stratfor Ecowar: Conflict) Is Abbreviated ENRCBenno HansenNo ratings yet

- Analyses of Non Fatal Accidents in An Opencast Mine by Logistic Regression Model A Case Study PDFDocument11 pagesAnalyses of Non Fatal Accidents in An Opencast Mine by Logistic Regression Model A Case Study PDFDr-Rabia AlmamalookNo ratings yet

- German Industrial Standard Din 22112 12010Document5 pagesGerman Industrial Standard Din 22112 12010Zlatko PentekNo ratings yet

- Coal's role in Malaysia's energy futureDocument12 pagesCoal's role in Malaysia's energy futurenisacoreNo ratings yet

- Sapphire and Garnet From Kalalani, Tanga Province, Tanzania 2Document13 pagesSapphire and Garnet From Kalalani, Tanga Province, Tanzania 2joniman9100% (1)

- Iron OreDocument27 pagesIron OreVijay Chander Reddy Keesara0% (1)

- Technocracy (Howard Scott - Science vs. Chaos) (1933) RDocument24 pagesTechnocracy (Howard Scott - Science vs. Chaos) (1933) RAnonymous yu09qxYCMNo ratings yet

- Prep Plant/tipple PermitsDocument3 pagesPrep Plant/tipple PermitsRishiraj SahooNo ratings yet

- Harga Patokan Batu Bara PDFDocument4 pagesHarga Patokan Batu Bara PDFErik HermawanNo ratings yet

- ABH-PARA Brief Review and Proposal - Rev4Document48 pagesABH-PARA Brief Review and Proposal - Rev4Dodo PrasetyoNo ratings yet

- Daftar Pustaka Koreksi YadiDocument6 pagesDaftar Pustaka Koreksi YadikusmayNo ratings yet

- Kuyasa BrochureDocument20 pagesKuyasa BrochuresafinditNo ratings yet

- CV Mining EngineerDocument7 pagesCV Mining EngineerFahroel MouNo ratings yet

- DMir 1912 04 10 001-UlsterDocument16 pagesDMir 1912 04 10 001-UlsterTitanicwareNo ratings yet

- Environmental Impact Assessment: Final Report After Public HearingDocument554 pagesEnvironmental Impact Assessment: Final Report After Public HearingRishabh100% (3)

- Underground MiningDocument191 pagesUnderground MiningrockyminNo ratings yet

- BANKOLA AREA Executive Contact ListDocument8 pagesBANKOLA AREA Executive Contact Listsantanughosh_emamiNo ratings yet

- Competent Person Report Maxwell Coal Resource EL5460 McElroy Bryan Geological Services 30.9.2018 Summary Geologically ReportDocument29 pagesCompetent Person Report Maxwell Coal Resource EL5460 McElroy Bryan Geological Services 30.9.2018 Summary Geologically ReportMudabbirNo ratings yet

- 10 Optimised BlastingDocument42 pages10 Optimised BlastingiwanAni50% (2)

- Ch4 Medieval TownsDocument65 pagesCh4 Medieval TownsJeremyNo ratings yet

- Disclosure To Promote The Right To InformationDocument21 pagesDisclosure To Promote The Right To InformationProfNDAcharyaNo ratings yet

- Geography Notes Part 3Document16 pagesGeography Notes Part 3Airfa MNo ratings yet

- CoalDocument18 pagesCoalKishore Kumar KamisettiNo ratings yet

- Calculations On Loading & HaulageDocument24 pagesCalculations On Loading & HaulageSarah Mae Ajon95% (22)

- 4underground Coal Mining MethodsDocument14 pages4underground Coal Mining MethodsAkhil Sai KrishnaNo ratings yet

- Thick Seam Mining Methods and Problems Associated With It: Submitted By: SAURABH SINGHDocument13 pagesThick Seam Mining Methods and Problems Associated With It: Submitted By: SAURABH SINGHPrabhu PrasadNo ratings yet

- Basic Mine VentilationDocument56 pagesBasic Mine Ventilationgirmay kasaye100% (1)

- Coal Vision 2030 stakeholder consultation commentsDocument39 pagesCoal Vision 2030 stakeholder consultation commentsShashank BhardwajNo ratings yet