Professional Documents

Culture Documents

Tungsten Carbide

Uploaded by

Izwan HanafiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tungsten Carbide

Uploaded by

Izwan HanafiCopyright:

Available Formats

Tungsten carbide

From Wikipedia, the free encyclopedia

Tungsten carbide

Tungsten carbide milling bits Identifiers CAS number 12070-12-1 Properties Molecular formula WC Molar mass 195.86 gmol-1 Appearance grey-black lustrous solid Density 15.8 gcm-3, solid Melting point 2870 C, 5198 F (3143 K) Boiling point 6000C, 10832 F (6273 K) Solubility in water Insoluble. Structure Hexagonal, hP2, Crystal structure space group = P6m2, No. 187[1] Hazards EU classification not listed Related compounds Tungsten boride Other anions Tungsten nitride Molybdenum carbide Other cations Titanium carbide Silicon carbide (verify) (what is: / ?) Except where noted otherwise, data are given for materials in their standard state (at 25 C, 100 kPa) Infobox references

Tungsten carbide (WC) is an inorganic chemical compound containing equal parts of tungsten and carbon atoms. Colloquially, tungsten carbide is often simply called carbide. In its most basic form, it is a fine gray powder, but it can be pressed and formed into shapes for use in industrial machinery, tools, abrasives, as well as jewelry. Tungsten carbide is approximately three times stiffer than steel, with a Young's modulus of approximately 550 GPa,[2] and is much denser than steel or titanium. It is comparable with corundum (-Al2O3) or sapphire in hardness and can only be polished and finished with abrasives of superior hardness such as cubic boron nitride and diamond amongst others, in the form of powder, wheels, and compounds.

Contents

[hide]

1 Chemical properties 2 Physical properties 3 Structure 4 Applications o 4.1 Machine tools o 4.2 Military o 4.3 Sports o 4.4 Domestic 5 Toxicity 6 References 7 External links

[edit] Chemical properties

There are two well characterized compounds of tungsten and carbon, WC and tungsten semicarbide, W2C. Both compounds may be present in coatings and the proportions can depend on the coating method.[3] WC can be prepared by reaction of tungsten metal and carbon at 14002000 C.[4] Other methods include a patented fluid bed process that reacts either tungsten metal or blue WO3 with CO/CO2 mixture and H2 between 900 and 1200 C.[5] Chemical vapor deposition methods that have been investigated include:[4] WC can also be produced by heating WO3 with graphite in hydrogen at 670 C following by carburization in Ar at 1000 C or directly heating WO3 with graphite at 900C. [6]

tungsten hexachloride with hydrogen, as a reducing agent, and methane, as the source of carbon at 670 C (1,238 F) WCl6 + H2 + CH4 WC + 6 HCl

reacting tungsten hexafluoride with hydrogen, as reducing agent, and methanol, as source of carbon at 350 C (662 F) WF6 + 2 H2 + CH3OH WC + 6 HF + H2O

At high temperatures WC decomposes to tungsten and carbon and this can occur during high-temperature thermal spray, e.g. high velocity oxygen fuel (HVOF) and high energy plasma (HEP) methods.[7] Oxidation of WC starts at 500600 C.[4] It is resistant to acids and is only attacked by hydrofluoric acid/nitric acid (HF/HNO3) mixtures above room temperature.[4] It reacts with fluorine gas at room temperature and chlorine above 400 C (752 F) and is unreactive to dry H2 up to its melting point.[4]

WC has been investigated for its potential use as a catalyst and it has been found to resemble platinum in its catalysis of the production of water from hydrogen and oxygen at room temperature, the reduction of tungsten trioxide by hydrogen in the presence of water, and the

isomerisation of 2,2-dimethylpropane to 2-methylbutane.[8] It has been proposed as a replacement for the iridium catalyst in hydrazine powered satellite thrusters.[9]

[edit] Physical properties

Tungsten carbide is high melting, 2,870 C (5,200 F), extremely hard (8.59.0 Mohs scale, Vickers hardness number = 2242) with low electrical resistivity (~2107 Ohmm), comparable with that of some metals (e.g. vanadium 2107 Ohmm).[4][10] WC is readily wetted by both molten nickel and cobalt.[11] Investigation of the phase diagram of the W-C-Co system shows that WC and Co form a pseudo binary eutectic. The phase diagram also shows that there are so-called -carbides with composition (W,Co)6C that can be formed and the fact that these phases are brittle is the reason why control of the carbon content in WC-Co hard metals is important.[11]

[edit] Structure

-WC structure, carbon atoms are gray.[1] There are two forms of WC, a hexagonal form, -WC (hP2, space group P6m2, No. 187),[1][12] and a cubic high-temperature form, -WC, which has the rock salt structure.[13] The hexagonal form can be visualized as made up of hexagonally close packed layers of metal atoms with layers lying directly over one another, with carbon atoms filling half the interstices giving both tungsten and carbon a regular trigonal prismatic, 6 coordination.[12] From the unit cell dimensions[14] the following bond lengths can be determined; the distance between the tungsten atoms in a hexagonally packed layer is 291 pm, the shortest distance between tungsten atoms in adjoining layers is 284 pm, and the tungsten carbon bond length is 220 pm. The tungsten-carbon bond length is therefore comparable to the single bond in W(CH3)6 (218 pm) in which there is strongly distorted trigonal prismatic coordination of tungsten.[15] Molecular WC has been investigated and this gas phase species has a bond length of 171 pm for 184W12C.[16]

[edit] Applications

[edit] Machine tools

This section does not cite any references or sources. Please help improve this section by adding citations to reliable sources. Unsourced material may be challenged and removed. (November 2010) See also: Cemented carbide Carbide cutting surfaces are often used for machining through materials such as carbon steel or stainless steel, as well as in situations where other tools would wear away, such as highquantity production runs. Carbide generally produces a better finish on the part, and allows faster machining. Carbide tools can also withstand higher temperatures than standard high speed steel tools. The material is usually called cemented carbide, hardmetal or tungstencarbide cobalt: it is a metal matrix composite where tungsten carbide particles are the aggregate and metallic cobalt serves as the matrix.

[edit] Military

This section does not cite any references or sources. Please help improve this section by adding citations to reliable sources. Unsourced material may be challenged and removed. (November 2010) Tungsten carbide is often used in armor-piercing ammunition, especially where depleted uranium is not available or is politically unacceptable. The first use of W2C projectiles occurred in German Luftwaffe tank-hunter squadrons, which used 37 mm autocannon equipped Junkers Ju 87G dive bomber aircraft to destroy Soviet T-34 tanks in World War II. Owing to the limited German reserves of tungsten, W2C material was reserved for making machine tools and small numbers of projectiles for elite combat pilots, like Hans-Ulrich Rudel. It is an effective penetrator due to its combination of great hardness and very high density. Tungsten carbide ammunition can be of the sabot type (a large arrow surrounded by a discarding push cylinder) or a subcaliber ammunition, where copper or other relatively soft material is used to encase the hard penetrating core, the two parts being separated only on impact. The latter is more common in small-caliber arms, while sabots are usually reserved for artillery use. Tungsten carbide is also an effective neutron reflector and as such was used during early investigations into nuclear chain reactions, particularly for weapons. A criticality accident occurred at Los Alamos National Laboratory on 21 August 1945 when Harry K. Daghlian, Jr. accidentally dropped a tungsten carbide brick onto a plutonium sphere, causing the subcritical mass to go supercritical with the reflected neutrons.

[edit] Sports

This section does not cite any references or sources. Please help improve this section by adding citations to reliable sources. Unsourced material may be challenged and removed. (November 2010)

A Nokian tire with tungsten carbide spikes. The spikes are surrounded in aluminum. Hard carbides, especially tungsten carbide, are used by athletes, generally on poles which strike hard surfaces. Trekking poles, used by many hikers for balance and to reduce pressure on leg joints, generally use carbide tips in order to gain traction when placed on hard surfaces (like rock); carbide tips last much longer than other types of tip. While ski pole tips are generally not made of carbide, since they do not need to be especially hard even to break through layers of ice, rollerski tips usually are. Roller skiing emulates cross country skiing and is used by many skiers to train during warm weather months. Sharpened carbide tipped spikes (known as studs) can be inserted into the drive tracks of snowmobiles. These studs enhance traction on icy surfaces. Longer v-shaped segments fit into grooved rods called wear rods under each snowmobile ski. The relatively sharp carbide edges enhance steering on harder icy surfaces. The carbide tips and segments reduce wear encountered when the snowmobile must cross roads and other abrasive surfaces. Some tire manufacturers, such as Nokian and Schwalbe, offer bicycle tires with tungsten carbide studs for better traction on ice. These are generally preferred to steel studs because of their superior resistance to wear. Tungsten carbide may be used in farriery, the shoeing of horses, to improve traction on slippery surfaces such as roads or ice. Carbide-tipped hoof nails may be used to attach the shoes,[17] or alternatively borium, tungsten carbide in a matrix of softer metal, may be welded to small areas of the underside of the shoe before fitting.[18]

[edit] Domestic

Tungsten carbide is sometimes used to make the rotating ball in the tips of ballpoint pens that disperse ink during writing.[19]

A tungsten carbide ring Tungsten carbide can now be found in the inventory of some jewelers, most notably as a primary material in men's wedding rings. When used in this application the bands appear with a lustrous dark hue often buffed to a mirror finish. The color is more similar to that of hematite than to that of platinum. The finish is highly resistant to scratches and scuffs, holding its mirror-like shine for years. Although it is possible to inlay precious metals, woods, and other materials, these are less scratch-resistant than tungsten carbide. A common misconception concerning tungsten carbide rings is that they cannot be removed in the case of emergency medical treatment, requiring the finger to be removed instead. This is not true. Emergency care providers have specialized tools that allow them to easily break tungsten rings into large pieces. As a result, it is easier and less dangerous to remove tungsten carbide rings than gold, silver, or titanium without injuring the hand or finger.[20] An easier way to remove tungsten carbide rings is to use a tool such as a vise, which can be used to shatter the ring.[21] Many manufacturers of this emerging jewelry material state that the use of a cobalt binder may cause unwanted reactions between the cobalt and the natural oils on human skin. Skin oils cause the cobalt to leach from the material. This is said to cause possible irritation of the skin and permanent staining of the jewelry itself. Many manufacturers now advertise that their jewelry is "cobalt free". This is achieved by replacing the cobalt with nickel as a binder.[22]

[edit] Toxicity

The primary health risks associated with carbide relate to inhalation of dust, leading to fibrosis.[23] CobaltTungsten Carbide is also reasonably anticipated to be a human carcinogen by the National Toxicology Program.[24]

[edit] References

1. ^ a b c Krawitz, Aaron D.; Reichel, Daniel G.; Hitterman, Richard (1989). "Thermal Expansion of Tungsten Carbide at Low Temperature". Journal of the American Ceramic Society 72 (3): 515. doi:10.1111/j.1151-2916.1989.tb06169.x. 2. ^ Elastic Properties and Young Modulus for some Materials 3. ^ Jacobs, L.; M. M. Hyland; M. De Bonte (1998). "Comparative study of WC-cermet coatings sprayed via the HVOF and the HVAF Process". Journal of Thermal Spray Technology 7 (2): 213218. doi:10.1361/105996398770350954. 4. ^ a b c d e f Pierson, Hugh O. (1992). Handbook of Chemical Vapor Deposition (CVD): Principles, Technology, and Applications. William Andrew Inc.. ISBN 0815513003. 5. ^ Lackner, A.,Filzwieser A. "Gas carburizing of tungsten carbide (WC) powder" U.S. Patent 6,447,742 (2002) 6. ^ Zhong, Y.; et al. (2011). Journal of Materials Science 46: 6323. doi:10.1007/s10853-010-4937-y. 7. ^ Nerz, J.; B. Kushner; A. Rotolico (1992). "Microstructural evaluation of tungsten carbide-cobalt coatings". Journal of Thermal Spray Technology 1 (2): 147152. doi:10.1007/BF02659015.

8. ^ Levy, R. B.; M. Boudart (1973). "Platinum-Like Behavior of Tungsten Carbide in Surface Catalysis". Science 181 (4099): 547549. doi:10.1126/science.181.4099.547. PMID 17777803. 9. ^ Rodrigues, J.A.J.; G.M. Cruz; G. Bugli; M. Boudart; G. Djga-Mariadassou; (1997). "Nitride and carbide of molybdenum and tungsten as substitutes of iridium for the catalysts used for space communication". Catalysis Letters 45: 12. doi:10.1023/A:1019059410876. 10. ^ Kittel, Charles (1995). Introduction to Solid State Physics (7 ed.). Wiley-India. ISBN 108126510455. 11. ^ a b Ettmayer, Peter; Walter Lengauer (1994). Carbides: transition metal solid state chemistry encyclopedia of inorganic chemistry. John Wiley & Sons. ISBN 0471936200. 12. ^ a b Wells, A. F. (1984). Structural Inorganic Chemistry (5 ed.). Oxford Science Publications. ISBN 0198553706. 13. ^ Sara, R. V. (1965). "Phase Equilibria in the System TungstenCarbon". Journal of the American Ceramic Society 48 (5): 251257. doi:10.1111/j.11512916.1965.tb14731.x. 14. ^ Rudy, E.; F. Benesovsky (1962). "Untersuchungen im System Tantal-WolframKohlenstoff". Monatshefte fr chemie 93 (3): 11761195. doi:10.1007/BF01189609. 15. ^ Kleinhenz, Sven; Valrie Pfennig; Konrad Seppelt (1998). "Preparation and Structures of [W(CH3)6], [Re(CH3)6], [Nb(CH3)6]-, and [Ta(CH3)6]-". ChemistryA European Journal 4 (9): 168791. doi:10.1002/(SICI)15213765(19980904)4:9<1687::AID-CHEM1687>3.0.CO;2-R. 16. ^ Sickafoose, S.M.; A.W. Smith; M. D. Morse (2002). "Optical spectroscopy of tungsten carbide (WC)". J. Chem. Phys. 116 (993): 993. doi:10.1063/1.1427068. 17. ^ "Road nail". Mustad Hoof Nails. Retrieved July 2011. 18. ^ Breningstall, F. Thomas. "Winter shoes". Windt im Wald Farm. Retrieved July 2011. 19. ^ "How does a ballpoint pen work?". Engineering. HowStuffWorks. 1998-2007. Retrieved 2007-11-16. 20. ^ "Are tungsten rings almost impossible to remove in an emergency?". Tungsten Direct. Retrieved 2011-05-26. 21. ^ "How To Remove A Tungsten Rings". Fable Designs. Retrieved 2009-05-12. 22. ^ "Tungsten Carbide Manufacturing". Forever Metals. Retrieved 2008-08-30. 23. ^ Sprince, NL.; Chamberlin, RI.; Hales, CA.; Weber, AL.; Kazemi, H. (Oct 1984). "Respiratory disease in tungsten carbide production workers". Chest 86 (4): 54957. doi:10.1378/chest.86.4.549. PMID 6434250. 24. ^ "12th Report on Carcinogens". National Toxicology Program. Retrieved 2011-0624.

[edit] External links

International Chemical Safety Card 1320 NIOSH Pocket Guide to Chemical Hazards

Categories:

Tungsten compounds Carbides Superhard materials

Log in / create account Article Discussion Read Edit View history

Main page Contents Featured content Current events Random article Donate to Wikipedia

Interaction Toolbox Print/export Languages

Help About Wikipedia Community portal Recent changes Contact Wikipedia

Bn-lm-g Catal esky Deutsch Espaol Franais Italiano Nederlands Polski Portugus Svenska This page was last modified on 29 September 2011 at 18:03.

Text is available under the Creative Commons Attribution-ShareAlike License; additional terms may apply. See Terms of use for details. Wikipedia is a registered trademark of the Wikimedia Foundation, Inc., a non-profit organization. Contact us Privacy policy About Wikipedia Disclaimers Mobile view

You might also like

- Metallurgy Assignment - Rev - 3Document21 pagesMetallurgy Assignment - Rev - 3Maria CutajarNo ratings yet

- TUNGSTENDocument14 pagesTUNGSTENetsimoNo ratings yet

- Mineral Resources: Definition, Characteristics, Mining Pro Cess, Use & ExploitationDocument42 pagesMineral Resources: Definition, Characteristics, Mining Pro Cess, Use & ExploitationCrisha Mae Tibor0% (1)

- Metals: Sci 401 Lecture 8Document54 pagesMetals: Sci 401 Lecture 8Niña Viaña BinayNo ratings yet

- Improving Quality Welding Stainless Steel PipeDocument2 pagesImproving Quality Welding Stainless Steel PipeGordan SanticNo ratings yet

- Excercise Sheet Lecture 3Document30 pagesExcercise Sheet Lecture 3Mohamed ZaitoonNo ratings yet

- Iron and Steel MakingDocument90 pagesIron and Steel MakingTanzil ZaidiNo ratings yet

- Cambridge IGCSE Chemistry detailsDocument2 pagesCambridge IGCSE Chemistry detailsExeteurNo ratings yet

- ICME Workshop 140723Document93 pagesICME Workshop 140723RAMKUMAR100% (1)

- 23MNCRMO5Document1 page23MNCRMO5Mohan RaoNo ratings yet

- Ironmaking and Steelmaking Theory and PracticeDocument9 pagesIronmaking and Steelmaking Theory and PracticeRasul BzNo ratings yet

- Steel Vs AluminumDocument4 pagesSteel Vs AluminumincredibleMeNo ratings yet

- Heat Treatment 2Document12 pagesHeat Treatment 2Nataraj MohanNo ratings yet

- Cricket Rules: Object of The GameDocument6 pagesCricket Rules: Object of The GameRyanNo ratings yet

- Kaiser Aluminum Hard Alloy Drawn Seamless Tube Capabilities PDFDocument7 pagesKaiser Aluminum Hard Alloy Drawn Seamless Tube Capabilities PDFanhthoNo ratings yet

- AnswersDocument60 pagesAnswersInez YahyaNo ratings yet

- Rolling Report (Production)Document27 pagesRolling Report (Production)AhmedHassen7100% (8)

- Alloys and Types of SteelDocument16 pagesAlloys and Types of SteelRajatNo ratings yet

- Mathematics Gr12Document192 pagesMathematics Gr12Tsidy MofokengNo ratings yet

- Outokumpu Forta Range Stainless Steel DatasheetDocument16 pagesOutokumpu Forta Range Stainless Steel DatasheetNicola D'ettoleNo ratings yet

- Review - British Frame BuildersDocument5 pagesReview - British Frame Buildersvelorution100% (2)

- Chapter 58 - Tungsten - 2015 - Handbook On The Toxicology of MetalsDocument10 pagesChapter 58 - Tungsten - 2015 - Handbook On The Toxicology of MetalsChanWingSanNo ratings yet

- Remember That You Can Search Using "Edit"!: GCSE Questions and AnswersDocument112 pagesRemember That You Can Search Using "Edit"!: GCSE Questions and AnswerskhujistaNo ratings yet

- Ch-27.12 Common Applications of Various MaterialsDocument44 pagesCh-27.12 Common Applications of Various MaterialsSmruti Ranjan PattanayakNo ratings yet

- Chemistry in IndustryDocument45 pagesChemistry in IndustryAashay PatilNo ratings yet

- Low Press Carbg and High Press QNCHGDocument56 pagesLow Press Carbg and High Press QNCHGskluxNo ratings yet

- I.1 Intro To Organic CompoundsDocument74 pagesI.1 Intro To Organic CompoundsEng AlvarezNo ratings yet

- Metallurgical Industry 12.5-1 10/86: (Reformatted 1/95)Document3 pagesMetallurgical Industry 12.5-1 10/86: (Reformatted 1/95)rmuhumuzaNo ratings yet

- Atmospheric CorrosionDocument40 pagesAtmospheric Corrosionsynayak100% (1)

- The Use of Titanium in Family Automobiles: Current Trends: K. Faller and F.H. (Sam) FroesDocument2 pagesThe Use of Titanium in Family Automobiles: Current Trends: K. Faller and F.H. (Sam) FroesAmol HawaldarNo ratings yet

- Metalurgy 2Document15 pagesMetalurgy 2HArsh ModiNo ratings yet

- Welding Metallurgy: An Introduction To The CourseDocument10 pagesWelding Metallurgy: An Introduction To The CoursebassemNo ratings yet

- WetRacer Magazine Issue 04Document32 pagesWetRacer Magazine Issue 04DonaldPotterNo ratings yet

- Road Load Power EquationsDocument38 pagesRoad Load Power EquationsAndré RavazziNo ratings yet

- Making of SteelDocument9 pagesMaking of SteelnaveenNo ratings yet

- Famous PhysicistsDocument13 pagesFamous PhysicistsKari CorderoNo ratings yet

- Steel Grade: Material Data SheetDocument7 pagesSteel Grade: Material Data SheetRohit VanapalliNo ratings yet

- Serpolettes Tricycle 04Document24 pagesSerpolettes Tricycle 04Florin PalNo ratings yet

- Aluminium Alloy 6061 Composition Properties Temper and Applications of 6061 AluminiumDocument5 pagesAluminium Alloy 6061 Composition Properties Temper and Applications of 6061 AluminiumCésar TapiaNo ratings yet

- 7075 Aluminum Plate SuppliersDocument10 pages7075 Aluminum Plate Supplierssanghvi overseas incNo ratings yet

- Steel MakingDocument35 pagesSteel MakingBharichalo007No ratings yet

- Metal CastingDocument28 pagesMetal CastingAngel ChanteyNo ratings yet

- Super CatalogueDocument8 pagesSuper CatalogueITL200_UNo ratings yet

- Arcelor High Yield IfDocument4 pagesArcelor High Yield IfJayDadrassNo ratings yet

- New Metallic Materials-Al-Li AlloysDocument23 pagesNew Metallic Materials-Al-Li AlloyszorazhrNo ratings yet

- BS en 499Document12 pagesBS en 499Ali Clubist100% (1)

- Chemsheets AS 1027 (Amount of Substance)Document38 pagesChemsheets AS 1027 (Amount of Substance)R100% (1)

- Aluminium Specifications Properties Classifications and Classes PDFDocument13 pagesAluminium Specifications Properties Classifications and Classes PDFVinit MehtaNo ratings yet

- Composites in Bicycle ManufacturingDocument14 pagesComposites in Bicycle ManufacturingdreadshawnNo ratings yet

- Aluminum: Aluminum - Industry of The FutureDocument8 pagesAluminum: Aluminum - Industry of The Futurersraja435No ratings yet

- Aluminium Alloy Applications PDFDocument3 pagesAluminium Alloy Applications PDFKhanHasibKaisarNo ratings yet

- Faces of BicyclesDocument8 pagesFaces of Bicyclessherlyn5keh5dionio-1No ratings yet

- DynamometerDocument21 pagesDynamometerHussam El'SheikhNo ratings yet

- 3.3 Begum Sultana-Applied Chemistry Module 3.3-Extraction of Iron and Aluminium-IDocument4 pages3.3 Begum Sultana-Applied Chemistry Module 3.3-Extraction of Iron and Aluminium-ISk Jahidul Islam100% (1)

- Tungsten Carbide - Wikipedia, The Free EncyclopediaDocument6 pagesTungsten Carbide - Wikipedia, The Free EncyclopediaAmol VedpathakNo ratings yet

- Tungsten CarbideDocument47 pagesTungsten CarbideAmit DhekaleNo ratings yet

- NanotecnologiaDocument27 pagesNanotecnologiaviniciushiperNo ratings yet

- Understanding stainless steelmaking through computational thermodynamicsDocument10 pagesUnderstanding stainless steelmaking through computational thermodynamicsramizNo ratings yet

- Testing of Austenitic Stainless SteelsDocument64 pagesTesting of Austenitic Stainless SteelsmirelamanteamirelaNo ratings yet

- Duplex Stainless Steel 2d Edition PracticalDocument64 pagesDuplex Stainless Steel 2d Edition Practicalmahmoud_allam3No ratings yet

- Recovering Palm Oil From Empty Fruit Bunch LiquorDocument4 pagesRecovering Palm Oil From Empty Fruit Bunch LiquorMohd Noor Azam AkbarruddinNo ratings yet

- Asbcalcv 33Document1 pageAsbcalcv 33Izwan HanafiNo ratings yet

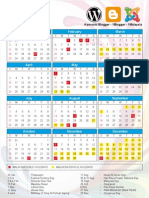

- Kalendar 2011Document1 pageKalendar 2011Izwan HanafiNo ratings yet

- Air Core Formation in The Hydro CycloneDocument6 pagesAir Core Formation in The Hydro CycloneIzwan HanafiNo ratings yet

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- RX Rotary Union (2 - 3 - ) Dual Flow BrochureDocument2 pagesRX Rotary Union (2 - 3 - ) Dual Flow BrochureFelySaezNo ratings yet

- Nordson XALOY - Extrusion - Catalogue - PC - Rev0Document20 pagesNordson XALOY - Extrusion - Catalogue - PC - Rev0berryeletricaNo ratings yet

- Scenic CarLife 99Document4 pagesScenic CarLife 99Lendl dela CruzNo ratings yet

- Composite MaterialsDocument399 pagesComposite MaterialsCharlton S.Inao100% (1)

- Boron Carbide, Boron Nitride, and Metal Borides: Ullmann's Encyclopedia of Industrial ChemistryDocument13 pagesBoron Carbide, Boron Nitride, and Metal Borides: Ullmann's Encyclopedia of Industrial ChemistryjaimeNo ratings yet

- Rock Drilling EquipmentDocument52 pagesRock Drilling EquipmentspencersimoyiNo ratings yet

- High Pressure Movitec PumpsDocument60 pagesHigh Pressure Movitec PumpsBerhanu Zemecha HabteNo ratings yet

- Solid Carbide End MillDocument33 pagesSolid Carbide End MillLuis PerezNo ratings yet

- Assab Royalloy: Prehardened Free Machining Stainless Holder SteelDocument7 pagesAssab Royalloy: Prehardened Free Machining Stainless Holder SteelNugroho Faris SudrajatNo ratings yet

- Piston Ring TribologyDocument108 pagesPiston Ring TribologyShrigopal Prajapat100% (2)

- WELDING CONSUMABLES-Hardfacing PDFDocument18 pagesWELDING CONSUMABLES-Hardfacing PDFmanuel_plfNo ratings yet

- Buehler SummetDocument136 pagesBuehler SummetinorwoodNo ratings yet

- Kennametal - Tungsten Carbide Composite Brazing Rods DatasheetDocument1 pageKennametal - Tungsten Carbide Composite Brazing Rods DatasheetsakthiNo ratings yet

- Imp ExamDocument15 pagesImp ExamMalvin Roix OrenseNo ratings yet

- Motor Grader Cutting Edges Motor Graders Motor Graders Motor Grader Cutting EdgesDocument4 pagesMotor Grader Cutting Edges Motor Graders Motor Graders Motor Grader Cutting EdgesPOPI1809No ratings yet

- Mechanical SealDocument22 pagesMechanical Sealkamal arabNo ratings yet

- Cutter HF 2020 LowresDocument1 pageCutter HF 2020 LowresSivaramanNo ratings yet

- FARO Gage: Product Catalog SpecificationsDocument12 pagesFARO Gage: Product Catalog SpecificationsedinsaquilNo ratings yet

- Hardsurfacing HandbookDocument24 pagesHardsurfacing HandbookscribdphinNo ratings yet

- B Gravograph 1Document12 pagesB Gravograph 1harisNo ratings yet

- Neuenkamp Slitting TechnologyDocument20 pagesNeuenkamp Slitting TechnologyAndré Augustos MissiasNo ratings yet

- Ceramic and GlassDocument27 pagesCeramic and Glasskautsar muafaNo ratings yet

- Fishing Tools PDFDocument45 pagesFishing Tools PDFRichard EVNo ratings yet

- AlloysDocument4 pagesAlloysmanu1589No ratings yet

- Converting Catalog PDFDocument16 pagesConverting Catalog PDFkbwoniu123No ratings yet

- Drill Bit - WikipediaDocument55 pagesDrill Bit - Wikipediaaddisugebre2125No ratings yet

- Drill Stem Components GuideDocument28 pagesDrill Stem Components Guidechonubobby100% (1)

- Brazingofcementedcarbides 1Document10 pagesBrazingofcementedcarbides 1Syed Noman AhmedNo ratings yet

- TM Mill Dull Grade v11Document97 pagesTM Mill Dull Grade v11Razvan RaduNo ratings yet