Professional Documents

Culture Documents

Western Mindanao State University 2

Uploaded by

Kelvin John Sajulan CabanieroOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Western Mindanao State University 2

Uploaded by

Kelvin John Sajulan CabanieroCopyright:

Available Formats

1

INTRODUCTION Bamboo or kawayan locally known is a woody perennial belonging to the family of grasses Poaceae. It is one of the fastest-growing plants on Earth with reported growth rates of 100 cm in 24 hours (ASST, 2011). It is primarily growing in regions of tropical or warmer climates like in some country in Asia. A 20-meter hardwood tree can take up to 100 years to replace. In comparison, a 20-meter bamboo Culm can be replaced in as little as 50 days (SBI). A bamboo grove also releases some 35 percent more oxygen into the air than a similar-sized stand of trees, and it matures (and can be replanted) within seven years (compared to 30-50 years for a stand of trees), helping to improve soil conditions and prevent erosion along the way. Bamboo also is one of the important materials for Furniture, establishment, agroforestry, engineering and many purposes in our community and society. This also one of the highly demand in world market. Bamboo plantation is a productive activity which can help the economy, environment and poor communities region. According to Bareja, There are more than 1,000 species of bamboo worldwide and it was documented that there were 62 native and introduced species of bamboo in the Philippines with various growth habits including clump and nonclump-forming, erect and climbing types. Twenty one (21) of these are endemic or native to the country. Thirteen (13) are climbers and 8 are erect (Bareja B., 2010).The Philippines has several

species of bamboo which is highly recommended for market such as Bambusa spp. ( kawayan tinik, bayog, and kawayan tatoo) , machiku and giant bamboo (Bareja B., 2010). The PCARRDs Bamboo Information Network describes Kawayan tinik as clump forming, has spiny branches, and produces clumps that grow to a maximum of 20 centimeters (cm) in diameter with internodes of up to 60 cm long. It reaches up to 20 meters high and has superior strength and durability.. It is also one of the seven major species recommended for shoot production in Yunan, China and is still considered as the best species for shoots in the Philippines. As a grass, it regenerates faster than wood, has a very short growth cycle, and can be harvested four years after planting (PCARRD, 2001). Kawayan tinik regenerates faster than wood, has a very short growth cycle, and can be harvested four to seven years after planting. As one of the economically important species of bamboo, it is considered as the best species for shoot production in the Philippines. Its other uses include furniture, handicraft, construction, food, biofuel, and environmental protection. Benefits of bamboo plantation A bamboo grove also releases some 35 percent more oxygen into the air than a similar-sized stand of trees, and it matures (and can be replanted) within seven years (compared to 30-50 years for a stand of trees), helping to improve soil conditions and prevent erosion along the way (Environmental magazine, 2008).

Bamboo also is the best solution for the problem of global warming in many ways: 1) Bamboo absorbs Carbon dioxide and releases oxygen into the atmosphere 3 to 4 times higher than many other trees. 2) One bamboo tree generates plenty of natural oxygen sufficient for more than one human beings daily requirement 3) Grows more than one foot a day and covers with good canopy faster than any other tree and cooling the surroundings. 4) Bamboo can replace the wood from forest for all applications such as paper, flooring, furniture, charcoal, etc. 5) Bamboo co-polymer plastic replaces 50% of plastic which is essential but not eco friendly. 6) Bamboo effectively cleans the water pollution of the septic tank discharge and factory effluent by its natural affinity for nitrogen, phosphorus and heavy metals. 7) Bamboo enriches the soil naturally and prevents soil erosion.

Project Description The project proposes to produce bamboo pole for the lumber yard, furniture and handicraft business in different market in Zamboanga City, each market will be survey and ask what will be their demand of bamboo pole to estimate the distribution of the pole on the different market. The harvesting of bamboo will be operating quarterly in a year. Each operation in 2 hectare will produce 1,636 poles. The kawayayng tinik (bambusa blumeana) will be the variety to be choosing for the plantation of the bamboo. The site of the plantation will be in WMSU-EFA, Upper Lapaz, Zamboanga City. Site was choose because it is one of the area in lapaz where residents depend only with their activities (kaingin making) which results of destruction of the forest, While with this bamboo plantation it has environmental and economical benefits to gain for the

community and also the WMSU-EFA management have less problem on the resident living there. Objectives The business aims is to improve/develop the WMSU-EFA in Upper Lapaz. Specifically it aims to attain the following objectives: 1. To determine the feasibility of the business. 2. To be able to identify the total cost, total revenue and profit of the production in 2 hectare for bamboo plantation.

MARKET FEASIBILITY Demand of the products Being the fastest growing grass which can shoot up a yard or more a day, bamboo reaches maturity quickly and is ready for harvesting in about 4 to 7 years. Bamboo does not require replanting after harvesting because its vast root network continually sprouts new shoots which almost zoom up while you watch them, pulling in sunlight and greenhouse gases and converting them to new green growth. Due to the diminishing wood supply, bamboos are now in high demand as raw material sources for furniture, handicraft and many products. The stable worldwide demand for wood and the increasing interest in sustainably produced timber further boost the potential market for industrial bamboo products. Among many western consumers, bamboo is an inherently sustainable resource. Thus industrial bamboo is seen to compete for hardwood in the twenty-first century. Supply of the products Knowing the Number of market (Lumberyard, furniture and handicraft business) in Zamboanga City is important to know the supply of demand on the production. One example on this will be the Angelinos lumber dealer; The Manager on the plantation will contract with this market, to supply their demand on bamboo pole. The cost of the bamboo will be php 100/pole (base on interview). Also the supply of demand shall be based on the existing competitors in supplying bamboo pole. The bamboo pole shall be delivering to the market of which that will be contract on supplying of bamboo pole.

PRODUCTION/TECHNICAL ASPECT

A. Production Process This study deals with the production of bamboo kawayan tinik (Bambusa blumeana) at WMSU experimental forest area in Upper Lapaz, Zamboanga City. The location will be survey to determine the right site for the plantation. It must be in flat area or is not more than about 7 or 8; it should not be greater than 15 slope (Growing bamboo, 2006). The area will be in 2 hectare and recommend to site the plantation where destructed area were kaingin making done by the people (uplanders). The area must be clear/brush for the plantation. Bamboo will be planted with a spacing of 7x7m in 2 hectare area, with a total number of 409 seedlings. Applying the fertilizer will be conducting after planting at list 4 months on the 1st year (ones a month of applying). The following year activities are more in intermediate treatment such as weeding. On the third year activity it will be on thinning, cutting or remove damaged, defective and dead culms to have good quality of shoots growing, also weeding, removal of competitors of nutrients of the clums. On the 4rth year will be on pruning, cutting of unnecessary branches to have nice clums and weeding same activities until on year 6. The harvesting year will be on the seven year. Dry season is the best time to harvest bamboo when the culms are lowest in terms of starch content level making it less susceptible to powder post beetle attack. No shoot emergence also occurs during this time; hence shoot damage is evaded (Rivera m, n.d).After harvesting in will be

distributed at different market (Lumberyard, furniture and handicraft business) in Zamboanga City.

Sample write-up figure 1 Flow process in the production of bamboo pole

site preparation

planting

intermidite treatment

harvesting

market

Fig. 2 shows the product produce (Bamboo pole)

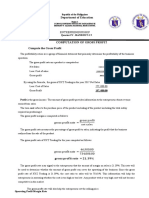

FINANCIAL FEASIBILITY To determine the profitability of this study the total cost will be computed over all activities done from year 0 to year 10, the 1st harvest will be on the year 7 until year 10. After determining the total cost and total revenue, it will be computed to know the profit based on the formula, same as with the NPV, BCR and ROI. Capital will be php.400, 000 which will be loan to the bank and invest to this plantation. Total seedlings cost The area will be in 2 hectare, the cost of the production will depend on the size of the plantation. 7x7 spacing will be use to plant the bamboo clumps. No. of seedlings =

= 409 seedlings With this total no. of seedlings, 20% mortality rate will be use have the total no. of seedlings 491 to be buy. Mortality rate of 20% =491 seedlings

The cost of per seedling (clumps) will be php 20.00 Cost= php 20.00 x 491 = php. 9,820

FIX COST The rental of the land will cost 10,000 per year to WMSU-EFA which is under the College of Forestry and Environmental Science. The annuity formula no. 4 was use to determine the future value of the amount after that the discounting formula no.2 was use to determine the present value.

Vn = a Vn = a Vn = 259,587

Vo = Vo = Vo = 41,925 Fix cost is Php 41,925

MANAGERIAL COST Manger cost will be php. 20, 00/year using annuity and discounted formula the cost computed from year 0 to year 10. Total management cost = 83,849

10

Production schedule from year 0 to year 10 In year 0, sites will be clear and plant the seedlings, also on the first month to 4rth month of planting it will be apply fertilizer (complete fertilizer) once a month.

Year 0 (table 1 shows the activity in year 0) Activities I. Site preparation *brushing/cleaning II. Planting *Digging hole and planting *Buying of Clumps seedling III. Transportation of seedlings *rental of tractor *Hauling of seedlings from source to area site IV. Other *Establishment of bank house Materials for establishments >labor *tools for planting II. Fertilizer *transportation *deliver to site *applying fertilizer >1st month >2nd month >3rd month >4rth month total Labor (2 hectare) 20 Unit MD Price (php) 400/labor Days of operation 1 day Amount (php) 8,000

20 __

409 Holes 491 seedlings

20/holes 20/seedlings

1 day

8,180 8,820

-20

day 491 seedlings

5,000/day 10/seedlings

1 day

5,000 4,910

--2 --------20 20 20 20

-Days materials 4 sacks 1 way deliver --2 hectare 2 hectare 2 hectare 2 hectare

2,000 100/day 200/tool 1,250/sack 200/deliver 50/sack 200/ labor 200/ labor 200/ labor 200/ labor

--2 days -----1 day 1 day 1 day 1 day 1 day 1 day

2,000 400 2,000 5,000 200 200 4,000 4,000 4000 4,000 60,710

11

In the 1st year the first activity will be on weeding, removing of competitors vegetation around the culms.

Year 1 (table 2 shows activity in year 2) Activities I. Weeding Q1 Q2 Q3 Q4 II. Fertilizer *transportation *deliver to site *applying fertilizer total 27,900 Labor (2 hectare) 20 20 20 20 ------20 Unit Price (php) Days of operation 1 day/Q 1 day/Q 1 day/Q 1 day/Q ---1 day 1 day 1 day Amount (php) 4,000 4,000 4,000 4,000 7,500 200 200 4000

2 hectare 2 hectare 2 hectare 2 hectare 6 sacks 1 way deliver --2 hectare

200/labor 200/labor 200/labor 200/labor 1,250/sack 200/deliver 50/sack 200/ labor

Year 2 (table 3 shows activity on year 3) Activities I. weeding Q1 Q2 Q3 Q4 II. thinning Thinning tool Total 22,000 Labor (2 hectare) 20 20 20 20 20 Unit Price (php) Days of operation 1 day/Q 1 day/Q 1 day/Q 1 day/Q 1 day ---Amount (php) 4,000 4,000 4,000 4,000 4,000 2,000

2 hectare 2 hectare 2 hectare 2 hectare 2 hectare 10 tools

200/labor 200/labor 200/labor 200/labor 200/labor 200/tools

12

Year 3 (table 4 shows activity in year 4) Activities I. weeding Q1 Q2 Q3 Q4 II. Pruning 1st operation 2nd operation *Pruning tool Labor (2 hectare) 20 20 20 20 30 -Unit Price (php) Days of operation 1 day/Q1 1 day/Q2 1 day/Q3 1 day/Q4 1 day/1st op. 1 day/2nd op ---Amount (php) 4,000 4,000 4,000 4,000 6,000 6,000 1,500

2 hectare 2 hectare 2 hectare 2 hectare 2 hectare 2 hectare 10 pruning tools

200/labor 200/labor 200/labor 200/labor 200/labor 200/labor 150/pruning tools

total

29,500

Year 4 (table 5 shows the activity on year 5) Activities I. weeding Q1 Q2 Q3 Q4 II. Pruning 1st operation 2nd operation Labor (2 hectare) 20 20 20 20 30 Unit Price (php) Days of operation 1 day/Q 1 day/Q 1 day/Q 1 day/Q 1 day/1st op. 1 day/2nd op Amount (php) 4,000 4,000 4,000 4,000 6,000 6,000

2 hectare 2 hectare 2 hectare 2 hectare 2 hectare

200/labor 200/labor 200/labor 200/labor 200/labor

total 28,000

13

Year 5 (table 6 shows the activity on year 5) Activities I. weeding Q1 Q2 Q3 Q4 II. Pruning 1st operation 2nd operation Labor (2 hectare) 20 20 20 20 30 Unit Price (php) Days of operation 1 day/Q 1 day/Q 1 day/Q 1 day/Q 1 day/1st op. 1 day/2nd op Amount (php) 4,000 4,000 4,000 4,000 6,000 6,000

2 hectare 2 hectare 2 hectare 2 hectare 2 hectare

200/labor 200/labor 200/labor 200/labor 200/labor

total

28,000

Year 6 (table 7 shows the activity on year 6) Activities I. weeding Q1 Q2 Q3 Q4 II. Pruning 1st operation 2nd operation Labor (2 hectare) 20 20 20 20 30 Unit Price (php) Days of operation 1 day/Q 1 day/Q 1 day/Q 1 day/Q 1 day/1st op. 1 day/2nd op Amount (php) 4,000 4,000 4,000 4,000 6,000 6,000

2 hectare 2 hectare 2 hectare 2 hectare 2 hectare

200/labor 200/labor 200/labor 200/labor 200/labor

total

28,000

14

The first harvest will be on the 7th year, the harvest pole will be deliver to the market which will be contract.

Year 7 (table 8 shows the activity in year 7) Activities I. weeding Q1 Q2 Q3 Q4 II. Harvesting *cost for labor Q1 Q2 Q3 Q4 *tool for harvest (power saw) III. Transportation of harvest (tractor) Total Labor (2 hectare) 20 20 20 20 30 30 30 30 --Unit Price (php) Days of operation 1 day/Q 1 day/Q 1 day/Q 1 day/Q 1 day operation Amount (php) 4,000 4,000 4,000 4,000 6000 6000 6000 6000 20,000

2 hectare 2 hectare 2 hectare 2 hectare 2 hectare 2 hectare 2 hectare 2 hectare 4 power saw day

200/labor 200/labor 200/labor 200/labor 200/labor 200/labor 200/labor 200/labor 5,000/power saw 5000

---

2 days

10,000

70,000

15

Year 8 (table 9 shows the activity in year 8) Activities I. weeding Q1 Q2 Q3 Q4 II. Harvesting *cost for labor Q1 Q2 Q3 Q4 III. Transportation of harvest (tractor) Total Year 9 (table 10 shows the activity in year 9) Activities I. weeding Q1 Q2 Q3 Q4 II. Harvesting *cost for labor Q1 Q2 Q3 Q4 III. Transportation of harvest (tractor) Total Labor (2 hectare) 20 20 20 20 Unit Price (php) Days of operation 1 day/Q 1 day/Q 1 day/Q 1 day/Q Amount (php) 4,000 4,000 4,000 4,000 Labor (2 hectare) 20 20 20 20 Unit Price (php) Days of operation 1 day/Q 1 day/Q 1 day/Q 1 day/Q Amount (php) 4,000 4,000 4,000 4,000

2 hectare 2 hectare 2 hectare 2 hectare

200/labor 200/labor 200/labor 200/labor

30 30 30 30

2 hectare 2 hectare 2 hectare 2 hectare day

200/labor 200/labor 200/labor 200/labor 5000

1 day operation

6000 6000 6000 6000 10,000

2 days

50,000

2 hectare 2 hectare 2 hectare 2 hectare

200/labor 200/labor 200/labor 200/labor

30 30 30 30

2 hectare 2 hectare 2 hectare 2 hectare day

200/labor 200/labor 200/labor 200/labor 5000

1 day operation

2 days

6000 6000 6000 6000 10,000

50,000

16

Year 10 (table 11 shows the activity in year 10) Activities I. weeding Q1 Q2 Q3 Q4 II. Harvesting *cost for labor Q1 Q2 Q3 Q4 III. Transportation of harvest (tractor) Total Labor (2 hectare) 20 20 20 20 Unit Price (php) Days of operation 1 day/Q 1 day/Q 1 day/Q 1 day/Q Amount (php) 4,000 4,000 4,000 4,000

2 hectare 2 hectare 2 hectare 2 hectare

200/labor 200/labor 200/labor 200/labor

30 30 30 30

2 hectare 2 hectare 2 hectare 2 hectare day

200/labor 200/labor 200/labor 200/labor 5000

1 day operation

2 days

6000 6000 6000 6000 10,000

50,000

17

Harvesting (revenue) Operatio n in harvestin g 1st harvest Q1 Q2 Q3 Q4 total 2nd operatio n Q1 Q2 Q3 Q4 total No. of clum s in 2 ha. 4 poles / culm s Pric e /pol e (php ) Amou nt (php) Operatio n in harvestin g 3rd harvest Q1 Q2 Q3 Q4 total No. of clum s in 2 ha. 4 poles / culm s Pric e /pol e (php ) Amou nt (php)

409 409 409 409

1,63 6 1,63 6 1,63 6 1,63 6

100 100 100 100

163,60 0 163,60 0 163,60 0 163,60 0 654,40 0

409 409 409 409

1,63 6 1,63 6 1,63 6 1,63 6

100 100 100 100

163,60 0 163,60 0 163,60 0 163,60 0 654,40 0

409 409 409 409

1,63 6 1,63 6 1,63 6 1,63 6

100 100 100 100

163,60 0 163,60 0 163,60 0 163,60 0 654,40 0

4rth harvest Q1 Q2 Q3 Q4 total

409 409 409 409

1,63 6 1,63 6 1,63 6 1,63 6

100 100 100 100

163,60 0 163,60 0 163,60 0 163,60 0 654,40 0

Year

Total yield of bamboo(pole)/ year Php.

7 8 9 10

654,400 654,400 654,400 654,400

18

Total cost and total revenue Year 0 1 2 3 4 5 6 7 8 9 10 Fix cost Managerial cost total Cost (php) 60,710 27,900 22,000 29,500 28,000 28,000 28,000 70,000 50,000 50,000 50,000 Discounted cost (20%) 60,710 23,250 15,278 17,071 13,503 11,253 9,377 19,536 11,628 9,690 8,075 41,925 83,849 325,145 Revenue (php) Discounted cost (20%)

654,400 654,400 654,400 654,400

182,631 152,193 126,827 105,689

567,340

BCR = Profit = revenue cost =567,340 325,145 =1.74488 =242,195 NPV= revenue cost =567,340 325,145 =242,195 Return of investment = = =.74488x100 =74% x100 =

19

ORGANIZATIONAL FEASIBILITY The project will be partnership with the WMSU, and with the help of WMSU; the area will be allocate in proper location for the plantation and local resident of the area will be encourage to participate with this activities. The Manager of this project will be assign to get the permit for the project operation such as Mayor Permit, Business Permit and all requirements to be need for the plantation and operation. Operation of the project will be manage by the manager and with the help of the clerk/collector the bamboo plantation operation will be manage correctly by following the business plan to obtain the objectives of the feasibility.

20

SOCIO-ECONOMIC IMPACTS Bamboo plantation is a profitable in business. With this, the local resident will encourage to be dealing with his activities that has an economical and environment benefit to gain unlike with their usually livelihood activities (kaingin making) which has a big impacts in the forest destruction. Bamboo plantation rising should be encouraged & promoted due to their high value, productivity, uniformity of crop, choice of species linked to peoples need and industrial need. Productions of bamboo pole also give to the local communities to provide raw materials to start a business like dealing with handicraft, furniture and other business related to bamboo finish product.

21

CONCLUSION AND RECOMMENDATION The bamboo plantation is a short term production, within 4 to 7 years it is already be harvest, but I rather go to 7 years to have a good matured quality of bamboo pole. The cost of establishment from year 0 to year 10 was computed, the total cost will be php. 325,145.00 While the total revenue will be php. 567,340.00 The feasibility study result a profitable business in the future, base on the computation of NPV and BCR, the NPV will be php. 242,195.00 And the BCR will be 1.74 which means that this business will profitable and the Return of Investment (ROI) will be 74% which mean in 1-2 years cycle of harvesting the investment or the cost of the project will return. Bamboo plantation will be recommended on business based on the result of the feasibility study.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SAP Return On InvestmentDocument9 pagesSAP Return On InvestmentsrinivaspanchakarlaNo ratings yet

- RAILROAD Joint Petition For Rulemaking To Modernize Annual Revenue Adequacy DeterminationsDocument182 pagesRAILROAD Joint Petition For Rulemaking To Modernize Annual Revenue Adequacy DeterminationsStar News Digital MediaNo ratings yet

- Launchpad To Triumph - Mastering The Startup OdysseyDocument40 pagesLaunchpad To Triumph - Mastering The Startup OdysseyRafik SamyNo ratings yet

- Ubd in TleDocument4 pagesUbd in TleArnold VidarNo ratings yet

- 20180731103923D5760 GNBCY PP Chap13 Performance Measurement in Decentralized Organizations With Cover PageDocument112 pages20180731103923D5760 GNBCY PP Chap13 Performance Measurement in Decentralized Organizations With Cover PageBENNo ratings yet

- Top Glove Group AssignmentDocument24 pagesTop Glove Group AssignmentvithyaNo ratings yet

- Ford Financial AnalysisDocument10 pagesFord Financial AnalysisPhú TrươngNo ratings yet

- Business Plan Outline - 1Document11 pagesBusiness Plan Outline - 1Ruel PeneyraNo ratings yet

- Soal Latihan Pertemuan KelimaDocument7 pagesSoal Latihan Pertemuan KelimaErvian RidhoNo ratings yet

- Investment Agreement - Thalaivi - 15.03.2021 - TrackDocument17 pagesInvestment Agreement - Thalaivi - 15.03.2021 - Tracknitish6413No ratings yet

- Tancet MBA: Quest I On Paper 2014Document29 pagesTancet MBA: Quest I On Paper 2014joyal JoyalNo ratings yet

- Entrepreneurship: Quarter 1 - Module 7: 1. Branding 2. The Business PlanDocument27 pagesEntrepreneurship: Quarter 1 - Module 7: 1. Branding 2. The Business PlanSheyn RanayNo ratings yet

- Emarketer Report Email Marketing Benchmarks Relevancy Frequency Deliverability Mobility 5Document18 pagesEmarketer Report Email Marketing Benchmarks Relevancy Frequency Deliverability Mobility 5CHRISTIAN DAVID PALACIOS YANEZNo ratings yet

- Quarter 4 Entrep Handout 2 With WW PTDocument5 pagesQuarter 4 Entrep Handout 2 With WW PTRodalyn Pang-ot100% (1)

- Q9Document9 pagesQ9asastuffNo ratings yet

- Forrester BrandCX PDFDocument17 pagesForrester BrandCX PDFkhamdb100% (1)

- Features and Benefits: Harmony/INFI90 SystemDocument34 pagesFeatures and Benefits: Harmony/INFI90 SystemAriel SierraNo ratings yet

- ERP Selection Checklist - ERP FocusDocument3 pagesERP Selection Checklist - ERP FocusDennis NebekerNo ratings yet

- Fesibility StudyDocument4 pagesFesibility StudyNetaji RaoNo ratings yet

- Chapter (8) : Financial Ratios Analysis: February 2019Document31 pagesChapter (8) : Financial Ratios Analysis: February 2019ALAQMARRAJNo ratings yet

- An Investment Opportunity: Triumph's CryptocurrencyDocument25 pagesAn Investment Opportunity: Triumph's Cryptocurrency- hermanNo ratings yet

- Dossier December en CompressedDocument53 pagesDossier December en CompressedJuan David PalacinoNo ratings yet

- 2022 Revised Chapter 9 Post-Covid19 BSTD Grade 12 Notes On Investment SecuritiesDocument15 pages2022 Revised Chapter 9 Post-Covid19 BSTD Grade 12 Notes On Investment SecuritiesAmogelang MboqeNo ratings yet

- Hello Accounts Class 12Document27 pagesHello Accounts Class 12kakuNo ratings yet

- Hec 1Document2 pagesHec 1Allan Mark Ong100% (1)

- SHRM HR MetricsDocument17 pagesSHRM HR MetricsAlaa HassaninNo ratings yet

- Course Final Paper Ayala LandDocument15 pagesCourse Final Paper Ayala LandNevan NovaNo ratings yet

- Application of HR MetricsDocument8 pagesApplication of HR MetricsDeepak GoswamiNo ratings yet

- Return On Investment (ROI)Document1 pageReturn On Investment (ROI)NURUL FAEIZAH BINTI AHMAD ANWAR / UPMNo ratings yet

- European-Family-Business-Barometer 2018 - 7th EditionDocument40 pagesEuropean-Family-Business-Barometer 2018 - 7th EditionGabriela StanciulescuNo ratings yet