Professional Documents

Culture Documents

Significance of The Ratio of Tensile Strength To Yield Stress

Uploaded by

Beth HtebOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Significance of The Ratio of Tensile Strength To Yield Stress

Uploaded by

Beth HtebCopyright:

Available Formats

SIGNIFICANCE OF THE RATIO OF TENSILE STRENGTH TO YIELD STRESS (TS/YS) OF REINFORCING BARS

Emilio M. Morales, MSCE

Synopsis: The Tensile Stress (TS) and Yield Stress (YS) of rebars are the primary reference material properties and control used by the Structural Design Engineer in his design to assure that reinforced concrete members behave in a manner assumed and predicted by Reinforced Concrete Design Theory and Practice. Almost unclear to the Engineering community is the significance of the relationship between these two values which is expressed as the TS/YS ratio. Although the ACI Code and most international codes pertaining to Reinforced Concrete Design in Earthquake Zones, such as the UBC specify that the TS/YS ratio shall not be less than 1.25, its significance to the Design Engineer and the project manager is obscured by the focus given on the Tensile Strength and Yield Strength individually. It is the objective of this paper to explain the critical importance of considering the TS/YS ratio and for the engineering community to understand the importance of maintaining this ratio to 1.25 or greater. In the quest for globalization of commerce, there is a trend towards adoption of ISO Standards in the interest of rationalization and Fair Trade. The local committee TC-11 formed by the BPS is in the forefront of ensuring that these standards are geared to suit local conditions. Nowhere is this more important than in the issue of the TS/YS ratio for rebars which is undergoing revision. A better understanding of this issue would aid in assuring that our standards such as PNS 49 for rebars are responsive to and suited to our high Seismic Hazards and that the TS/YS ratio should be maintained. 1. INTRODUCTION The design of reinforced concrete structures in seismically active regions require special considerations unique to this kind of exposure. Particularly in the Philippines, which has a very high seismic risk, attention to detailing of reinforced concrete takes on a very important meaning and is of high priority to the Design Engineer. Due to the narrow focus on test results, more specifically on the individual Tensile Strength (TS) and Yield Strength (YS) of reinforcing bars, the critical relationship between the two properties expressed as the ratio TS/YS is oftentimes lost to the Design Engineer and the Construction Manager.

Worse, due to inattention or plain ignorance, higher strength reinforcing bars than originally intended in the design are passed on or accepted without realizing the dire consequences related to such actions. More often than not, when the Engineer reviews the test results on reinforcing bars submitted by the contractor or the Independent Laboratory, he/she merely looks at these values and checks whether they meet or exceed the specified code minimum. Being satisfied that this is so, the Engineer then accepts the materials for use in the Building. In some instances this may suffice, by chance but there are many occasions where such cursory checks are not enough. It is necessary to ensure that the TS/YS Ratio satisfy the requirement contained in Subsection 5.21.2.5.1 of the National Structural Code of the Philippines and the ACI Code as it pertains to Earthquake Resistant Design. This subsection reads: 5.21.2.5.1 Reinforcement resisting earthquake induced axial forces in frame members and in wall boundary members shall comply with ASTM A-706 PNS 49. Grades 275 and 415 reinforcement are allowed in these members if (a) the actual yield strength based on mill tests does not exceed the specified yield strength by more than 120 MPa (retests shall not exceed this value by more than an additional 20 MPa) and (b) the ratio of the actual Ultimate Tensile Stress to the actual yield stress is not less than 1.25. At first glance, the above requirements may seem baffling, for why should there be a ceiling cap placed on the yield stress? Why are the steel Grades limited to PNS Grades 275 and 415 for Seismic Design? Isnt stronger necessarily better? Also, why should there be a mandatory minimum value of 1.25 applied on the Tensile Stress to Yield Stress ratio. Clearly, there is a need for an explanation. This explanation is conveniently and clearly found in the commentary of ACI 318 R-95 most specifically commentary R 21.25. (See Appendix A) However, as stated earlier, the importance of these provisions and the reasons behind it are obscured or lost or relegated to the background. To confound this issue, there is a move to realign our standards with that of the world, mainly thru adoption of ISO Standards in keeping with liberalization of trade and elimination of barriers to trade. Present ISO standards, the so called EUROCODES require a TS/YS ratio of 1.05 and 1.08 which is very much below the ratio 1.25 given in our present NSCP Code and PNS 49. Tests conducted in Italy, Macchi (1996) which is also a seismically active region, indicate that these values are inadequate to ensure ductility under simulated earthquake loading.

The Bureau of Product Standards TC 11 Committee or Steel Products (of which the author is a member) is at the forefront of this activity. Representation by ASEP in this committee will help to preserve the existing TS/YS ratio of 1.25. In addition, the engineering community should insist that the TS/YS ratio be published on all mill certificates and laboratory test results to ensure that this requirement is amply satisfied and the end user properly informed. It is the purpose of this paper to expound on these requirements in the hope that a greater understanding of these provisions would result in giving these due importance and attention that these deserve. 2. PRACTICAL AND THEORETICAL CONCEPTS In order to understand the foregoing issues at hand, we would need to review and/or understand some very critical aspects related to seismic design. 2.1 Stress Strain Behavior of Steel Reinforcing bars in Uniaxial Tension Steel behaves as a linearly elastic material within the elastic limit (stress is directly proportional to strain) until yielding occurs. Beyond t is point and prior to ultimate failure, stress is no longer h proportional to strain. However, considerable strength development after a yield plateau is developed, occurs (although non-linear) prior to failure. This region is known as the strain hardening region where further strength gain results due to proportionately larger strains imposed. Beyond the strain hardening region, further straining results in strain softening until failure occurs. The peak stress is considered the ultimate stress. The typical curve shown below is taken from (Paulay and Priestley, 1992):

Yield Plateau

The above typical stress strain curves indicate that ultimate strain and the length of the yield plateau decrease as the yield strength increases. This development is not at all desirable because the steel stress that may develop in a section may greatly exceed the yield stress leading to shear failures or unexpected flexural hinging. It would be therefore desirable to limit the steel grades used as indicated by NSCP 5.21.2.5.1. 2.2 Ductility Versus Brittleness The term ductility refers to the ability of a member to undergo large deformations without rupture as failure is occurring. Ductile members could therefore bend and deform excessively but they remain intact. This essential capability of properly designed and detailed RC members ensures against total structure collapse and provides protection to building occupants at the critical instant when failure is occurring. Brittle members on the other hand fail suddenly and completely with very little warning. This sudden failure may damage adjacent elements or overload other portions leading to progressive total collapse. Ductility includes the ability to survive large deformations and a capacity to absorb energy by hysteritic behavior. For this reason, it is the single most important property sought by the designer of buildings located in regions of high seismicity. It is therefore necessary to ensure ductility of members to allow visible development of large deformations before total collapse occurs, thus providing ample warning to occupants. While ductility is assumed by proper seismic detailing provision, it is equally important to ensure that the reinforcing bars behave as intended by maintaining a cap on the yield stress and by ensuring that the TS/YS ratio is > 1.25. In general, seismic forces that could be developed in a structure during a seismic event decrease with increasing ductility. However, the amount of ductility permissible may be a function of acceptable deformation magnitudes. 2.3 Structure Stiffness The structural response of structures to earthquakes is dependent on the relative stiffness of the system, the ability of the system to dissipate energy and the inherent ductility of the system. A rigid structure will attract load during an earthquake; more flexible structures will develop smaller seismic forces. However, the degree of flexibility that may be acceptable is limited by the effects of large lateral displacements resulting from flexibility (Kinitzsky et al 1993). 2.4 Reinforcement Percentage The amount of steel reinforcement commonly expressed as a percentage of area of steel to concrete is important in Reinforced Concrete Design and more so in seismic resistance of RC Structures.

In an over reinforced flexural member (large steel percentage) the failure mode is brittle. This is because crushing failure of concrete is reached before yielding of the reinforcement occurs. The same failure mode is realized in an under reinforced beam. When the tensile stress of the limited steel area is reached, the modulus of rupture of concrete is exceeded causing the concrete to crack and immediately release this load on the steel reinforcement. If the steel area is too small to carry this force, the rebar will snap and cause sudden failure. Ideally the only desirable mode of failure, a ductile one, can be induced by moderate percentage of steel. This failure is initiated by gradual yielding of the steel while concrete strains are still relatively low. Thus, large deflection are attained before final collapse occurs Leet (1991). From the foregoing concepts, the following conclusions could be made: Ductile behavior should be assured through careful material selection, design and detailing. Some flexibility in the structure is needed to reduce seismic forces through energy absorption and dissipation. Moderate levels of reinforcement should be used to assure ductile behavior.

3. THE TS/YS RATIO AND ITS IMPORTANCE 3.1 The Problem There have been many occasions in the past where overstrength reinforcing bars (Higher and/or Higher Tensile Strength) are innocently accepted by the Design Engineer or passed the supplier as the specified grade in the mistaken belief that stronger is necessarily Sometimes higher g rade steels failing to meet the specs are downgraded and used as lower reinforcing bars. Yield on by better. grade

In another previous paper by this author Morales (1997) this matter had been brought to the attention of the Engineering community. However, it was felt, due to the ongoing deliberations on trade liberalization and rationalization that this issue be delved with in more detail so that its implications could be fully understood. In some occasions too, the Engineer does not even see the test results and relies on his Junior Engineer to monitor them. The Junior Engineer, lacking in experience and knowledge upon seeing that the test results are greater than the specified, reports that everything is well and so the problem does not get attended to until it is too late. These real life examples bring to fore the need to understand the important of the TS/YS ratio and why greater attention should be given to test results. Let us now discuss the technical issues involved and its effect on our structures.

3.1.1

Yield Strength (YS)

The NSCP, which also echoes the requirements set forth in ACI 318 and the Uniform Building Code of the USA, sets a cap or limit to the Yield Strength of Reinforcing bars. More specifically it requires that: a) The actual yield strength based on mill tests does not exceed the specified yield strength by more than 120 MPa (retests shall not exceed this value by more than 20 MPa).

Definitely, there must be a reason behind this requirement. A very much higher yield strength than that nominally assumed in the design is fraught with problems. A higher yield stress will: Paulay (1992) 1) Induce higher concentrations of shear and bond stresses at time of development of the yield moments during seismic loading. Shear and bond type failures are explosive and brittle modes of failure and should therefore be avoided. Attract larger lateral forces as a rule because energy absorption initiated at yielding or partial yielding is postponed and thus higher seismic inertia forces are generated further complicating the problem. Prevent the formation of an extended yield plateau which is undesirable. An extended or longer yield plateau is desirable and stems from requirements of capacity design. It is necessary that the shear strength of all elements and flexural strength of sections not intended as plastic hinges should exceed the forces corresponding to development of flexural overstrength at the designated plastic hinge locations. If the rebar exhibits early and rapid strain hardening, the steel stress a a section with higher ductility may exceed the t yield stress by an excessive margin. If there is considerable variation in the yield strength, the actual flexural strength of a plastic hinge may greatly exceed the intended value postponing its formation until more critical loading is sustained. This can cause unexpected plastic hinging at unintended and more dangerous locations. 3.1.2 Tensile Strength (TS)

2)

3)

4)

Higher Tensile Strengths invariably means increased Brittleness. This is indicated by a reduced yield plateau and a very limited strain hardening region. This means that the yield region and its capacity to absorb energy through inelastic deformation is severely limited. In addition, the use of higher Tensile Strengths if unanticipated in the design could also correspondingly elevate the yield stress leading to problems stated earlier in the discussions on the implication of a higher Yield Stress (YS).

For this reason, the NSCP and the source codes (ACI 318 and UBC) limit the allowable steel grades for use in seismic regions. 3.1.3 The Ratio TS/YS

The unique material strength properties TS & YS are individually important to consider and control as they influence the behavior of structures during seismic excitation as discussed earlier. Taken together as the Ratio TS/YS (known as the Strain Hardening Value in European practice), it indicates the ductility capacity of the structural member or component where it was used. The larger this ratio, the better for the structure. A large TS/YS ratio means a greater energy absorption capability before failure. In addition, larger deformations are experienced which could serve as visible warning to building occupants prior to total failure or collapse. Less Brittle behavior therefore is experienced. Professor Giorgio Macchi of the University of Pavia, Italy conducted experimental tests to determine the effect of the strain Hardening Value TS/YS on the performance of full scale RC columns subjected to Lateral Loads with or without axial loads. His findings contained in his published report Ductility Requirements for Reinforcement under EuroCodes Macchi (1996) revealed very interesting findings which underscored the necessity of maintaining a high TS/YS value or the Strain Hardening Value . We summarize his findings contained in this report: Details incorporating relatively low TS/YS ratios (<<1.25) showed that concentrations of Plastic strains are in a very limited vertical region of the test specimens. As a consequence, the very high local curvature was necessary for the required displacement causing considerable local deterioration and premature damage. This led to destruction of the concrete cover. The lack of confinement of the concrete cover allowed the bars in compression to buckle. The bars then failed in tension under reverse action. Reinforcing bars with TS/YS ratio of 1.4, as used in the tests, showed that plastic deformation spread over a considerable length along the specimen because of the high strain hardening value . Local curvature was smaller, the concrete cover remained intact and the bars did not fail. The RC member, therefore sustained higher top displacement. Insufficient strain hardening leads to high concentrations of strain. Insufficient steel elongation initiates earlier steel fracture at ultimate loads. There should be a cap or limitation on overstrength of reinforcing bars.

4. EFFECT OF BOND STRENGTH ON FLEXURAL DUCTILITY There have been concerns expressed earlier Cairns (1994) that improvements in the stiffness of bond force-slip relationship of reinforcing bars resulting from increases in the relative rib area of deformations may have a negative impact on the flexural rotation capacity (flexural ductility) of RC Beams. Similarly, there have been discussions in Europe aimed at reducing the relative rib area of reinforcing bars to improve Ductility. Tests conducted by (Tholen and Darwin, 1995) have shown that a relatively large change in relative area has no measurable effect on the distribution of flexural cracks or on the displacement and rotational capacity of beams in which plastic hinges develop. Concerns on either point have been proven to be not justified. The foregoing has been included if only to underscore the critical importance of the TS/YS ratio in assuring ductility, as any influence, no matter how it may seem insignificant to the uninformed, is being looked into by the engineering community to assure that ductility is enhanced and not diminished. 5. CONCLUSIONS This paper has focused on the need to look into the importance of assuring ductility of RC structures not only through proper and adequate seismic detailing but also by proper understanding and selection of Material properties. Of these, it is necessary to ensure that Reinforcing bars used in the structure meet the requirements of NSCP Subsection 5.21.2.5.1 particularly as it applies to a cap on the Yield strength and the prescribed minimum TS/YS ratio of 1.25 . This paper also reiterates the need to erase the misconception that higher strengths invariably mean stronger structures. The specified minimum TS/YS ratio of 1.25 helps to impart ductility to structures by: Assuring that deformation. significant energy absorption and dissipation occur during inelastic

Preventing the premature failure of reinforcing bars due to brittle behavior. Guaranteeing that plastic hinging develops at intended locations. Avoiding premature failure due to strain concentrations.

REFERENCES ASEP (1992) National Structural Code of the Philippines Volume 1. Structural Engineers of the Philippines (ASEP), Manila. Association of

ACI (1996) ACI Manual of Concrete Practice Part 3. American Concrete Institute (ACI), Farmington Hills, Michigan. Paulay, T . and Priestley, M.J.N. (1992) Seismic Design of Reinforced Concrete and Masonry Buildings, pp. 114. John Wiley & Sons, Inc., U.S.A. Krinitzsky, E.L., Gould, J.P. and Edinger, P.H. (1993) Fundamentals of Earthquake Resistant Construction, pp. 203. John Wiley & Sons, Inc., U.S.A. Leet, K. (1991) Reinforced Concrete Design, Second Edition, pp. 84-95. McGraw- Hill, Inc. , Singapore. Tholen and Darwin Effect of Reinforcing Bar Deformation Pattern on Flexural Ductility. ACI Structural Journal, V95 No. 1 January 1998 pp. 37-41. Macchi, G. (1996) Ductility Requirements for Reinforcement Under Euro Codes. Structural Engineering International, April 1996. Morales, E.M. (1997) Seventh International Convention on Structural Engineering: Facing the Challenge of Economic Growth Stronger is Not Necessarily Better The Significance of Tests and Properties of Civil Engineering Materials. Manila Midtown Hotel, Pedro Gil cor. M. Adriatico Street, Ermita, Manila ABOUT THE AUTHOR Emilio M. Morales, MSCE took up his masters degree at the Carnegie Institute of Technology, Carnegie-Mellon University, Pittsburgh, PA. USA in 1980. Formerly Senior Lecturer of Graduate Division, College of Engineering, University of the Philippines, Diliman, Quezon City. Presently, he is the Technical Manager of Philippine Geoanalytics, Inc., Civil Engineering Laboratory and Principal of EM2A & Partners & Company. Committee Member, TC-11, Bureau of Product Standards Technical Committee on Steel Products. He can be contacted at: EM2A Partners & Co., No. 17 Scout de Guia corner Scout Reyes Streets, Diliman, Quezon City. Telephone Nos. 371-18-04 & 06/ 410-29-23. Fax No. 3744338; E-mail: em2apart@pgatech.com.ph.

You might also like

- Significance of The Ratio of Tensile StrengthDocument6 pagesSignificance of The Ratio of Tensile StrengthPaul Pinos-anNo ratings yet

- Design ConceptDocument34 pagesDesign ConceptKaushiki BhadauriaNo ratings yet

- Chapter 1Document8 pagesChapter 1Saker MohamedNo ratings yet

- What Makes A Special Moment Frame SpecialDocument3 pagesWhat Makes A Special Moment Frame SpecialMehdi FarrokhiNo ratings yet

- Ocbf and SCBF Earthquake Loads As Per Is 800 925Document2 pagesOcbf and SCBF Earthquake Loads As Per Is 800 925sandeep8057No ratings yet

- Post Tension Flat SlabsDocument14 pagesPost Tension Flat Slabsrahulgehlot2008No ratings yet

- 215R 74Document48 pages215R 74Michael RyanNo ratings yet

- Limit States Design PrinciplesDocument4 pagesLimit States Design PrinciplesvolminkNo ratings yet

- ASME-Notch-Toughness & Supplementary Essential VariablesDocument16 pagesASME-Notch-Toughness & Supplementary Essential VariablesSuleyman Halicioglu100% (2)

- Fracture Control Steel StructuresDocument14 pagesFracture Control Steel StructuresMarcoNo ratings yet

- 07 May 282 298Document17 pages07 May 282 298Deny SitorusNo ratings yet

- Earthquake Resistant Design of Steel StructuresDocument12 pagesEarthquake Resistant Design of Steel StructuresFranklin GarciaNo ratings yet

- Cyclic Loading AdalahDocument13 pagesCyclic Loading AdalahsyaniliffaNo ratings yet

- Seismic Design IntroductionDocument23 pagesSeismic Design IntroductionMahmood MuftiNo ratings yet

- Seismic Design To S16-09 PDFDocument13 pagesSeismic Design To S16-09 PDFDarryn McCormickNo ratings yet

- Guide to Earthquake-Resistant Concrete Design and DetailingDocument13 pagesGuide to Earthquake-Resistant Concrete Design and DetailingksshashidharNo ratings yet

- Chapter17 SeismicResistantDesignDocument54 pagesChapter17 SeismicResistantDesignaasimNo ratings yet

- Connection Characteristics in Seismic Proof Steel ConstructionDocument12 pagesConnection Characteristics in Seismic Proof Steel Constructionroma_luNo ratings yet

- Seismic Design of Reinforced Concrete Structures PDFDocument100 pagesSeismic Design of Reinforced Concrete Structures PDFJulian Andres Pulecio DiazNo ratings yet

- RC design topic 1 and 2Document16 pagesRC design topic 1 and 2thuo19601No ratings yet

- Over Strength and Force Reduction Factors of Multi Storey Reinforced-Concrete BuildingsDocument23 pagesOver Strength and Force Reduction Factors of Multi Storey Reinforced-Concrete Buildingslbychd100% (4)

- Shrinkage, Cracking and Deflection of Concrete StructuresDocument26 pagesShrinkage, Cracking and Deflection of Concrete StructuresNolan Pillay100% (1)

- 0 - Geotechnical Site Classification and Croatian National Annex For Eurocode 8 - P.kvasnicka, Leo Matesic and K.ivandic - 2011 - 8182Document10 pages0 - Geotechnical Site Classification and Croatian National Annex For Eurocode 8 - P.kvasnicka, Leo Matesic and K.ivandic - 2011 - 8182nebojsadj6411No ratings yet

- Estimation of Curvature and Displacement DuctilityDocument13 pagesEstimation of Curvature and Displacement DuctilitySorin ScutarasuNo ratings yet

- CVS 416 Notes - 2016-17Document70 pagesCVS 416 Notes - 2016-17Victor KemeiNo ratings yet

- TRM27 StabilityDocument6 pagesTRM27 StabilityRoldan LetabanNo ratings yet

- 09A Steel Structure-174142-16188512242230Document90 pages09A Steel Structure-174142-16188512242230NamNo ratings yet

- DSS Lecture Note 4 - Lateral Loads - Seismic LoadDocument25 pagesDSS Lecture Note 4 - Lateral Loads - Seismic LoadMrSamspartNo ratings yet

- Evaluate Lateral Systems (Moment Frames, Shear Walls, Braced FramesDocument34 pagesEvaluate Lateral Systems (Moment Frames, Shear Walls, Braced FramesyathiNo ratings yet

- Design Office DampingDocument10 pagesDesign Office DampingEinNo ratings yet

- (Unit) Title of The Chapter Name of FacilitatorDocument35 pages(Unit) Title of The Chapter Name of FacilitatorDipesh BasnetNo ratings yet

- Seismic design requirements for building structuresDocument3 pagesSeismic design requirements for building structuresAkagami ShanksNo ratings yet

- Weld FatigueDocument10 pagesWeld FatigueBrandon AllenNo ratings yet

- Arijit Nandi - Design of RC StructuresDocument3 pagesArijit Nandi - Design of RC Structuresarijit nandiNo ratings yet

- Refuerzo Por DuctilidadDocument5 pagesRefuerzo Por Ductilidad4630220No ratings yet

- Unit1-RC Design (Introductory Lecture)Document49 pagesUnit1-RC Design (Introductory Lecture)Adrian MonteclaroNo ratings yet

- Limit State DesignDocument12 pagesLimit State DesignEzhil KumarNo ratings yet

- Microsoft Word - Hamburger-HigginsDocument10 pagesMicrosoft Word - Hamburger-HigginsRonald HamburgerNo ratings yet

- Understanding Strength Error Consequences in Seismic DesignDocument3 pagesUnderstanding Strength Error Consequences in Seismic Designsourabh mahanaNo ratings yet

- IntroductionDocument24 pagesIntroductionDexter JasmaNo ratings yet

- AISC Plastic Design in SteelDocument2 pagesAISC Plastic Design in Steelc1366No ratings yet

- Design of Masonry Infilled Reinforced Concrete Frames in Different Seismic CodesDocument12 pagesDesign of Masonry Infilled Reinforced Concrete Frames in Different Seismic CodesKrishna MurariNo ratings yet

- As-1170.4-2007 - Worked ExamplesDocument10 pagesAs-1170.4-2007 - Worked ExamplesMihnea CostacheNo ratings yet

- Structural Steel Buildings Commentary GlossaryDocument262 pagesStructural Steel Buildings Commentary GlossaryNico Dela RamaNo ratings yet

- Seismic Response of Nonstructural Components: Part A: Overview of Component Types and BehaviorDocument4 pagesSeismic Response of Nonstructural Components: Part A: Overview of Component Types and Behaviorrmm99rmm99No ratings yet

- 2018-Model For Assessment of Cracked Reinforced Concrete Membrane Elements Subjected To Shear and Axial Loads-Calvi, Bentz and CollinsDocument10 pages2018-Model For Assessment of Cracked Reinforced Concrete Membrane Elements Subjected To Shear and Axial Loads-Calvi, Bentz and CollinsLucas MarquesNo ratings yet

- LEC06Document59 pagesLEC06Hamza KhawarNo ratings yet

- Sliding Hinge Joint PDFDocument11 pagesSliding Hinge Joint PDFjcvalenciaNo ratings yet

- Ductile Detailing Steel Moment Frames Engelhardt SotoDocument22 pagesDuctile Detailing Steel Moment Frames Engelhardt SotocezapeNo ratings yet

- Two Mark QuestionsDocument9 pagesTwo Mark QuestionsNitin SureshNo ratings yet

- ECV 5223 Steel Structures NotesDocument43 pagesECV 5223 Steel Structures NotesMAGED MOHMMED AHMED QASEMNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Corrosion and its Consequences for Reinforced Concrete StructuresFrom EverandCorrosion and its Consequences for Reinforced Concrete StructuresNo ratings yet

- Introduction to Design of Building StructuresFrom EverandIntroduction to Design of Building StructuresRating: 4 out of 5 stars4/5 (22)

- Earthquake isolation method with variable natural frequencyFrom EverandEarthquake isolation method with variable natural frequencyNo ratings yet

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

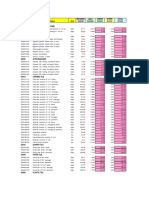

- Masonry Cost EstimatesDocument1 pageMasonry Cost EstimatesmrepzzzNo ratings yet

- ELECTRICAL COSTCODE PRICELISTDocument2 pagesELECTRICAL COSTCODE PRICELISTmrepzzzNo ratings yet

- Construction Cost Breakdown SheetDocument3 pagesConstruction Cost Breakdown SheetmrepzzzNo ratings yet

- Door and Window Cost EstimatesDocument2 pagesDoor and Window Cost EstimatesJeffreyNo ratings yet

- FurnishingsDocument1 pageFurnishingsJeffreyNo ratings yet

- FinishesDocument6 pagesFinishesmrepzzzNo ratings yet

- ConcreteDocument4 pagesConcretemrepzzzNo ratings yet

- Costcode Description Unit Material Qr/Unit Labor Hrs/Unit Labor Qr/Unit Other Qr/Unit Total Qr/Unit 14 Conveying Systems 14200 ElevatorsDocument1 pageCostcode Description Unit Material Qr/Unit Labor Hrs/Unit Labor Qr/Unit Other Qr/Unit Total Qr/Unit 14 Conveying Systems 14200 ElevatorsmrepzzzNo ratings yet

- BXPHARMADocument4 pagesBXPHARMASayeedNo ratings yet

- 2012 Green Plumbing Mechanical CodeDocument173 pages2012 Green Plumbing Mechanical CodeAS VatsalNo ratings yet

- EquipmentDocument1 pageEquipmentmrepzzzNo ratings yet

- NBCPDocument17 pagesNBCPArch. Jan EchiverriNo ratings yet

- Oral Practical & Experience Part 1Y2018 PDFDocument139 pagesOral Practical & Experience Part 1Y2018 PDFmrepzzzNo ratings yet

- Field FormulasDocument39 pagesField FormulasRoma EstradaNo ratings yet

- Preboard Schedule 2018 PDFDocument2 pagesPreboard Schedule 2018 PDFmrepzzzNo ratings yet

- Estimating Acoustical Ceilings ChecklistDocument1 pageEstimating Acoustical Ceilings ChecklistRyanNo ratings yet

- BXPHARMADocument4 pagesBXPHARMASayeedNo ratings yet

- School CodeDocument68 pagesSchool CodemrepzzzNo ratings yet

- Engineering Mathematics FormulaDocument4 pagesEngineering Mathematics FormulaMaw IubuybNo ratings yet

- TV SpliterDocument12 pagesTV SpliterSherif M. ElgebalyNo ratings yet

- Interlocking & Curb Stone Rev.1Document3 pagesInterlocking & Curb Stone Rev.1Shaddy Joseph Endrawes100% (1)

- BXPHARMADocument4 pagesBXPHARMASayeedNo ratings yet

- Qcs 2007 0110Document6 pagesQcs 2007 0110RotsapNayrbNo ratings yet

- Quality of Bid ChecklistDocument5 pagesQuality of Bid ChecklistmrepzzzNo ratings yet

- StaadPro Knowledge BaseDocument251 pagesStaadPro Knowledge Baseingsabrina100% (1)

- R3 DReferDocument335 pagesR3 DReferbenness11No ratings yet

- Qcs 2007 Section 1 Part-1 IntroductionDocument6 pagesQcs 2007 Section 1 Part-1 IntroductionRotsapNayrbNo ratings yet

- July 2015 Master Plumber Terms IncludedDocument5 pagesJuly 2015 Master Plumber Terms Includedzenzen1100% (1)

- QCS General Index PDFDocument1 pageQCS General Index PDFmrepzzzNo ratings yet

- Board of Master Plumber-SBDocument7 pagesBoard of Master Plumber-SBdereckaNo ratings yet