Professional Documents

Culture Documents

Design Beam

Uploaded by

monirithneangCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Beam

Uploaded by

monirithneangCopyright:

Available Formats

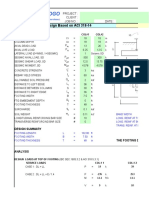

I/ Design Beam GB9A effective span= m

1 - Loading Slab Panel x m and mTHK (Slab on one side of the beam)

Dead Load

Slab kN/m x m / = kN/m

Beam kN/m x m / = kN/m

Other kN/m x m = kN/m

Wall 10cm kN/m x m = kN/m

Wall 20cm kN/m x m = kN/m

Floor Finished kN/m x m = kN/m

Total Dead Load kN/m (Trapezoidal Dead load per m lenght

Live Load or Imposed load on one side of the beam)

Floor LL kN/m x m / = kN/m

Total live Load kN/m (Trapezoidal Live load per m lenght

Design Load on one side of the beam)

Design Load ( x )+( x ) = kN/m (Trapezoidal load= kN/m)

Convert Trapezoidal load to uniformly distributed load

Uniformly distributed Load ( x ) = kN/m

Load on the other side of the bem ( - ( x / )= kN/m (Reduce 30% for the load on

the other side)

Total Load on both side of the bem + = kN/m

2 - Bending Moment

Max moment at support M

sup

= = kN/m

Max moment at mid spanM

mid

= = kN/m

BS8110 REF. OUTPUT CALCULATION

- ql/12 -255.89

7.7 3.4

1

0.12

24

7.7

6.48

ql/24 127.94

25 1.05

2.25

4

2.08 7.7

7.7 2.25

2.25

1.2

0

2.25

0

2.7

0

2.25 m 9

18.2

1.5 2.25 3.38

30 100

9

1.6 #### 1.4 9.00 41.7

30.5 #### 51.8

41.7

21.3

41.73 0.73 30.5

30.5 ####

2 xe xe xe l n M = | = xe | = xe M 2 x xm xm l n M = | kNm = xm M 2 x ye ye l n M = | = xm | = ye | = ye M kNm 2 x ym ym l n M = | = ym | = ym M kNm = = z f M A y xe req s 87 . 0 , = cu f 2 mm N = bar rolling y f , 2 mm N = y f 2 mm N m mm / 2 = pro s A , 2 mm = = z f M A y xm req s 87 . 0 , m mm / 2 m mm / 2 m mm / 2 = = z f M A y ye req s 87 . 0 , = = z f M A y ym req s 87 . 0 , 2 mm N 2 mm N = = x xe force l n V | m kN/ = = bd V V force stress / 2 mm N = |.| \| ||.| \| = 4 1 3 1 , 400 100 25 . 1 75 . 0 d bd A V pro s capacity 2 mm N m kN/ = = bd V V force stress / 2 mm N = |.| \| ||.| \| = 4 1 3 1 , 400 100 25 . 1 75 . 0 d bd A V pro s capacity 2 mm N = = x ye force l n V | = pro s A , 2 mm = pro s A , 2 mm = pro s A , 2 mm 2 xe xe xe l n M = | = xe | = xe MkNm2 x xm xm l n M = | kNm= xm M 2 x ye ye l n M = | = xm | = ye | = ye MkNm2 x ym ym l n M = | = ym | = ym MkNm= = z f M A y xe req s 87 . 0 , = cu f 2 mm N = bar rolling y f , 2 mm N = y f 2 mm N m mm / 2 = pro s A , 2 mm = = z f M A y xm req s 87 . 0 , m mm / 2 m mm / 2 m mm / 2 = = z f M A y ye req s 87 . 0 , = = z f M A y ym req s 87 . 0 , 2 mm N 2 mm N = = x xe force l n V | m kN/ = = bd V V force stress / 2 mm N = |.| \| ||.| \| = 4 1 3 1 , 400 100 25 . 1 75 . 0 d bd A V pro s capacity 2 mm N m kN/ = = bd V V force stress / 2 mm N = |.| \| ||.| \| = 4 1 3 1 , 400 100 25 . 1 75 . 0 d bd A V pro s capacity 2 mm N = = x ye force l n V | = pro s A , 2 mm= pro s A , 2 mm= pro s A , 2 mm2 mm2 mm2 mm2 mm kNm

1

3 - Beam Section

b= (0.4 to 0.5)h= (0.4 to 0.5) . b= mm b= mm

Cover: C= mm ;Assume Steel Bar D

R

= mm ; D

T

= mm

d= h - C - D

R

/2 - D

T

/2 = = mm d'= mm

ii - Define Steel Area

Assume fcu= N/mm ; fy v= N/mm fy = N/mm

a - Define Steel Area at Support Mmax= kNm

x

x x

z = = = mm

that z mm z = mm

A

s

= =

A

s

=

mm

2

T A

s

=

mm

2

P=100(As,req / bd)= > < 4

b - Define Steel Area at Mid span Mmax= kNm

x

x x

z = = = mm

that z mm z = mm

A

s

= =

A

s

=

mm

2

T A

s

=

mm

2

P=100(As,req / bd)= > < 4

[(k'. fcu.b.d^2)/(0.87.fy.z)]+As' [(0.13x30x200x362^2) x10^6)/ (0.87x390x297)]+1256

2285.92 Assume 9 20 2826

d.[0.5+(0.25-(k'/0.9))^(1/ 2)] .[0.5+(0.25-(0.132/ 0.9)^(1/ 2))] 297

297 not exceed 0.95d= 344

390

k=

M

=

160

(Doubly Reinforced

Section)

bd

2

fcu 200 131044

0.156

35

297

344 so 344

400 - 25 - 3 - 10

10

6

362

mm 400

(Doubly Reinforced

Section)

20

h= to

10

L

k=

bd

2

fcu

=

15

=

7700

10

255.89

h=

400

256

h= 550 mm

248

0.156

to

200

6

0.95d=

362.[0.5+(0.25-(0.132/ 0.9)^(1/ 2))] d.[0.5+(0.25-(k'/0.9))^(1/ 2)]

L

M

30 250

0.325 >

30 131044 200

not exceed

3087.46 Assume 11 20 3454

[(k'. fcu.b.d^2)/(0.87.fy.z)]+As' [(0.13x30x200x362^2)x10^6) / (0.87x390x343.9)]+2198

30

10

6

OK

so

160

0.203 >

OK

15

25

3.53 0.13

4.32 0.13

7700

2

c - Check Deflection

x

x

5 5

8 8

- fs

(0.9+(M / bd

2

))

= ( table3.9 in Code BS8110 Part 1 1985)

= x =

= lx / dx = / =

= > =

c - Link

Max Shear at Support

= kN

= / bd = / = N/mm

V

capacity

= (0.79/1.25) [(100As/bd)^(1/3)] [(400/d)^(1/4)] [(fcu/25)^(1/3)]

= x

=

= N/mm > N/mm (Case 3 in table3.7 in Code BS8110)

A

sv

(b

v

S

v

(v

s

-v

c

))/0.87f

y

Assume 6 mm Area of link mm

2

Link SpacingS

v

(A

sv

x 0.87f

y

)/(b

v

(v

s

-v

c

)) = mm mm

Hence R6@80

Shear at L/4 from the support

= kN

= N/mm

= N/mm Assume 6 mm Area of link mm

2

Link SpacingS

v

(A

sv

x 0.87f

y

)/(b

v

(v

s

-v

c

)) = mm mm 60.3

80

180

V

cap.

1.08

55

Asv= 55

V

l/4

150

V

stress

2.07

Asv=

V

stress

2.32 V

capacity

48.2

+0.4= 1.48

=

bd

2

6.10

M

max

=

160 10

6

200 131044

fs = fy

A

s,req

A

s,pro

= x 390 x

2286

= 197 (Service Stress)

2826

modification factor = 0.55 +

477

= 0.97

120

Bassic span/depth 26

Allowable span/depth 26 0.97 25.3

7700

OK

362 21.3

Allowable span/depth 25.3 Actual span/depth 21.3

1.08

Actual span/depth

V

max

168

V

stress

V

max

200x362 2.32 168x(10^3)

0.63 [((100x2826)/(200x362))^(1/3)]x (400/362)^(1/4)x (30/25)^(1/3)

kNm 3 / 1 4 / 1 3 / 1 25 400 100 25 . 1 79 . 0 |.| \| |.| \| |.| \| cu f d bdAs

3

Hence R6@180

4

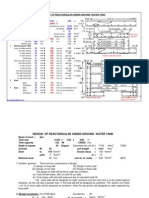

RE-Design Section of Ground Beam GB9A

I/ Design Beam GB9A effective span= m

1 - Loading Slab Panel x m and x m and mTHK

Dead Load

Slab kN/m x x = kN/m kN/m x x = kN/m

Beam kN/m x x = kN/m

Other kN/m x = kN/m kN/m x = kN/m

Wall 10cm kN/m x = kN/m kN/m x = kN/m

Wall 20cm kN/m x = kN/m kN/m x = kN/m

Floor Finished kN/m x = kN/m kN/m x = kN/m

Total Dead Load kN/m kN/m

Live Load or Imposed load

Floor LL kN/m x m = kN/m kN/m x m = kN/m

Total live Load kN/m kN/m

Triangle or Trapezoidal Design Load

= kN/m (1.4 x 16.11) + (1.6 x 3.75) = kN/m

Convert Trapezoidal load to uniformly distributed load for bending moment

Uniformly distributed Load x = kN/m x = kN/m

Total uniformly distributed load

+ = kN/m

(1.4 x 17.79) + (1.6 x 3.75) 30.9 28.6

17.8 16.1

3.75 3.75

1.5 2.5 3.75 1.5 2.5

OUTPUT

5

3.75

1.5 3.3 4.95 1.5 3.3

0 2.5

4.95

0 0 0 0 0 0

1.2 3.3 3.96 1.2 3.3 3.96

0 0 2.5 0

24 0.35 0.2 1.68

30.9 0.67 20.6

Left Side of the beam Right Side of the beam

24 0.12 2.5 7.2 24 0.12 2.5 7.2

BS8110 REF.

5 2.5 5 2.5 0.12

CALCULATION

28.6

20.6 18.8 39.43

0.66 18.8

5

2 - Bending Moment

Max moment at support M

sup

= = kN/m

Max moment at mid spanM

mid

= = kN/m

3 - Beam Section

b= (0.4 to 0.5)h= (0.4 to 0.5) . b= mm b= mm

Cover: C= mm ;Assume Steel Bar D

R

= mm ; D

T

= mm

d= h - C - D

R

/2 - D

T

/2 = = mm d'= mm

4 - Define Steel Area

Assume fcu= N/mm ; fy v= N/mm fy = N/mm

a - Define Steel Area at Support Mmax= kNm

x

x x

z = = = mm

that z mm z = mm

x = ( - )/ =

Compression Steel Area

Tension Steel Area

A

s

= =

A

s

=

mm

2

T A

s

=

mm

2

P=100(As,req / bd)= > < 4

ql/24

350

30

-82.14

mm h=

41.07

5000

- ql/12

to h=

L

to

L

=

5000

350 mm

10 15 10 15

h= 357

161 200

25 6 16

350 - 25 - 3 - 8 314 33

250 390

82.14

k=

M

=

82.1 10

6

0.139

bd

2

fcu 200 98596 30

298

< 0.156

(Singly Rienforced

Section)

d.[0.5+(0.25-(k/0.9))^(1/ 2)] 314.[0.5+(0.25-(0.139/ 0.9)^(1/ 2))] 254

not exceed 0.95d= 298 so

M /0.87 fy.z

811.592 Assume 5 16 1005

1.44 0.13 OK

[(82x10^6) / (0.87x390x298.3)]

OUTPUT BS8110 REF. CALCULATION

314 298 0.45 34.9

No Steel Require

6

b - Define Steel Area at Mid span Mmax= kNm

x

x x

z = = = mm

that z mm z = mm

x = ( - )/ =

Compression Steel Area

Tension Steel Area

A

s

= =

A

s

=

mm

2

T A

s

=

mm

2

P=100(As,req / bd)= > < 4

c - Check Deflection

x

x

5 5

8 8

- fs

(0.9+(M / bd

2

))

= ( table3.9 in Code BS8110 Part 1 1985)

= x =

= lx / dx = / =

= > =

0.96 0.13 OK

M /0.87 fy.z [(41x10^6) / (0.87x390x298.3)]

405.796 Assume 3 16 603

0 298 0.45 -663

No Steel Require

k=

M

=

41.1 10

6

so

41.07

bd

2

fcu 200 98596 30

0.069

298

< 0.156

(Singly Rienforced

Section)

not exceed 0.95d= 298

d.[0.5+(0.25-(k/0.9))^(1/ 2)] .[0.5+(0.25-(0.069/ 0.9)^(1/ 2))] 288

M

max

=

41.1 10

6

= 2.08

=

bd

2

200 98596

fs = fy

A

s,req

=

164 (Service Stress)

A

s,pro

603

= x 390 x

406

314

Allowable span/depth 26 1.94 50.5

1.94

120

Bassic span/depth 26

modification factor

OK

0.55 +

477

=

Actual span/depth 15.9 5000

Allowable span/depth 50.5 Actual span/depth 15.9

BS8110 REF. CALCULATION OUTPUT

7

d - Link

Convert Trapezoidal load to uniformly distributed load for bending moment

Uniformly distributed Load x = kN/m x = kN/m

Total uniformly distributed load

+ = kN/m Total load per m lenght for

bending moment kN/m

Max Shear at Support

= = kN

= / bd = N/mm

V

capacity

= (0.79/1.25) [(100As/bd)^(1/3)] [(400/d)^(1/4)] [(fcu/25)^(1/3)]

= N/mm

= N/mm > N/mm

Assume 6 mm Area of link mm

2

Link SpacingS

v

(A

sv

x 0.87f

y

)/(b

v

(v

s

-v

c

)) = mm mm

Hence R6@120

Shear at L/4 from the support

= = kN

= N/mm

= N/mm Assume 6 mm Area of link mm

2

Link SpacingS

v

(A

sv

x 0.87f

y

)/(b

v

(v

s

-v

c

)) = mm mm

Hence R6@150

(Case 3 in table3.7 in Code BS8110)

OUTPUT

V

max

ql/2

15.5

+0.4= 1.23 1.18 V

capacity

V

stress

V

max

74.3

1.184

Asv= 55

1073 150

55

170 120

55.74 q(l-0.25l)/2

29.7

15.5

Asv=

0.83

V

stress

14.3

V

cap.

0.83

V

l/4

V

stress

0.89

BS8110 REF. CALCULATION

29.73

Left Side of the beam Right Side of the beam

30.9 0.5 28.6 0.5 14.3

8

Check Existing Section of Ground Beam GB7 (Along Grid 4 from Grid E-G)

I/ Check Existing GB7 effective span= m

A -Loading Slab Panel x m and x m and mTHK

Dead Load

Slab kN/m x x = kN/m kN/m x x = kN/m

Beam kN/m x x = kN/m

Roof Load kN/m x = kN/m kN/m x = kN/m

Wall 10cm kN/m x = kN/m kN/m x = kN/m

Wall 20cm kN/m x = kN/m kN/m x = kN/m

Floor Finished kN/m x = kN/m kN/m x = kN/m

Total Dead Load kN/m kN/m

Live Load or Imposed load

Floor LL kN/m x m = kN/m kN/m x m = kN/m

Roof LL kN/m x m = kN/m kN/m x m = kN/m

Total live Load kN/m kN/m

Triangle or Trapezoidal Design Load

= kN/m = kN/m

Convert Trapezoidal load to uniformly distributed load

Uniformly distributed Load x = kN/m x = kN/m

Total uniformly distributed load

+ = kN/m

1 18.6

47.4 18.59 65.96

47.4 1 47.4 18.6

4 3.3

13.2 4.4

(1.4 x 18.75) + (1.6 x 13.2) 47.4 (1.4 x 8.25) + (1.6 x 4.4) 18.6

0 1.7 0 0 0.83 0

13.2 4

1.1 1.65

18.8 8.3

1.1 4.4

1.5 3.3 4.95 1.5

3.3 3.96

0 0 0 0 0 0

1.2 3.3 3.96 1.2

0.83 0

24 0.2

0 1.7 0 0

BS8110 REF. CALCULATION

0.4 1.92

Left Side of the beam Right Side of the beam

24 0.1 24 0.1 1.1 2.64 3.3 7.92

OUTPUT

6.6

6.6 3.3 6.6 1.1 0.1

9

B -Bending Moment

Max moment at support M

sup

= = kN/m

Max moment at mid spanM

mid

= = kN/m

C -Beam Section

b= (0.4 to 0.5)h= (0.4 to 0.5) . b= mm b= mm

Cover: C= mm ;Assume Steel Bar D

R

= mm ; D

T

= mm

d= h - C - D

R

/2 - D

T

/2 = = mm d'= mm

D- Define Steel Area

Assume fcu= N/mm ; fy v= N/mm fy = N/mm

a - Define Steel Area at Support Mmax= kNm

Compression Steel Area

Existing Steel Area T A

s

'=

mm

2

Tension Steel Area

Existing Steel Area T A

s

=

mm

2

T A

s

'=

mm

2

Total Steel Area mm

P=100(As,req / bd)= > < 4

b - Define Steel Area at Mid span Mmax= kNm

Compression Steel Area

Existing Steel Area T A

s

'=

mm

2

Tension Steel Area

Existing Steel Area T A

s

=

mm

2

Total Steel Area mm

P=100(As,req / bd)= > < 4 2.355 0.13 OK

4 20 1256

1884

119.72

2 20 628

25 0

1884

2.355 0.13 OK

4 20 1256 0

239.43

2 20 628

400 - 25 - 4 - 10 361 35

30 250 390

400 212.143 200

25 8 20

10 15 10 15

to h= 400 mm

- ql/12 -239.43

ql/24 119.72

h= 471.429 mm

BS8110 REF. CALCULATION OUTPUT

h=

L

to

L

=

6600 6600

10

c - Link or Stirrup

Convert Trapezoidal load to uniformly distributed load for bending moment

Uniformly distributed Load x = kN/m x = kN/m

Total uniformly distributed load

+ = kN/m

Max Shear at Support

= = kN

= / bd = N/mm

Max Shear Stress 0.8(f

cu

^(1/2)) = N/mm

V

capacity

= (0.79/1.25) [(100As/bd)^(1/3)] [(400/d)^(1/4)] [(fcu/25)^(1/3)]

= N/mm

N/mm

Vc+0.4 Vs < 0.8(fcu^(1/2))

A

sv

(b

v

S

v

(v

s

-v

c

))/0.87f

y

Assume 6 mm Area of link mm

2

Link SpacingS

v

(A

sv

x 0.87f

y

)/(b

v

(v

s

-v

c

)) = mm mm

Hence R6@30

Existing Link 6 mm @ 150 mm not enough

Asv= 56.5

29.7 30

0.95

V

capacity

+0.4= 1.35

V

stress

V

max

3.015

4.38

47.4 18.59 65.96

V

max

ql/2 217.7

OUTPUT

Left Side of the beam Right Side of the beam

47.4 1 47.4 18.6 1 18.6

BS8110 REF. CALCULATION

11

Shear at L/4

= = kN

= / bd = N/mm

Max Shear Stress 0.8(f

cu

^(1/2)) = N/mm

V

capacity

= (0.79/1.25) [(100As/bd)^(1/3)] [(400/d)^(1/4)] [(fcu/25)^(1/3)]

= N/mm

N/mm

Vc+0.4 Vs < 0.8(fcu^(1/2))

A

sv

(b

v

S

v

(v

s

-v

c

))/0.87f

y

Assume 6 mm Area of link mm

2

Link SpacingS

v

(A

sv

x 0.87f

y

)/(b

v

(v

s

-v

c

)) = mm mm

Hence R6@50

Existing Link 6 mm @

d - Check Deflection

x

x

5 2

8 3

- fs

(0.9+(M / bd

2

))

= ( table3.9 in Code BS8110 Part 1 1985)

= x =

= l / 250 = / = mm

OUTPUT BS8110 REF. CALCULATION

250 26.4

Allowable span/depth 26 0.987 25.6736

Bassic span/depth 26

modification factor =

Actual span/depth 6600

x

1884

= 260

0.55 +

477

= 0.99

120

(Service Stress)

1884

fs = fy

A

s,req

= x

A

s,pro

390

= 4.59

bd

2

200 130321

M

max

=

120 10

6

not enough

Asv= 56.5

46.7 50

1.6

0.95

V

capacity

+0.4= 1.35

150 mm

V

max

ql

l/4

/ 2 163.3

V

stress

V

max

2.261

12

= < =

e - Check Cracking

1/ CLear distance between horizontal tension bars

Allowable clear distance between bars

= (table 3.28)

S

1

= (b-2(cover)-2(

links

)-2(

bar

))/2

= mm <

Clear Distance between the face of the beam and nearest longitudinal bar in tension

S

2

= ((y

2

+y

2

)^(1/2))-(

bar

/2)

y = cover+

link

+(

bar

/2)

= mm

Allowable distance

= 155x0.5 = mm

S

2

= mm < bar should be provided in side faces of beam to control cracking

Distance between bars

BS8110 REF. CALCULATION OUTPUT

43

77.5

NO

Refer 3.12.11.2.3 BS8110

155

47 155 OK

Actual span/depth 26.4

50.8 77.5

Allowable span/depth 25.674

13

Sb mm

Minimum size bar

> ((S

b

b/f

y

)^(1/2))

> mm Provide @ DB12 250

250

11.3

14

OUTPUT

15

OUTPUT

16

OUTPUT

17

OUTPUT

18

OUTPUT

19

20

Check Existing Section of Ground Beam GB9 (Along Grid E from Grid 7'-9')

I/ Check Existing GB9 effective span= m

A -Loading Slab Panel x m and x m and mTHK

Dead Load

Slab kN/m x x = kN/m kN/m x x = kN/m

Beam kN/m x x = kN/m

Roof Load kN/m x = kN/m kN/m x = kN/m

Wall 10cm kN/m x = kN/m kN/m x = kN/m

Wall 20cm kN/m x = kN/m kN/m x = kN/m

Floor Finished kN/m x = kN/m kN/m x = kN/m

Total Dead Load kN/m kN/m

Live Load or Imposed load

Floor LL kN/m x m = kN/m kN/m x m = kN/m

Roof LL kN/m x m = kN/m kN/m x m = kN/m

Total live Load kN/m kN/m

Triangle or Trapezoidal Design Load

= kN/m = kN/m

Convert Trapezoidal load to uniformly distributed load

Uniformly distributed Load x = kN/m x = kN/m

Total uniformly distributed load

+ = kN/m

0.83 0 0 1.7 0 0

(1.4 x 14.46) + (1.6 x 8.8)

OUTPUT

7.7

7.7 2.2 7.7 1.65 0.1

BS8110 REF. CALCULATION

Left Side of the beam Right Side of the beam

24

24 0.2 0.4 1.92

1.65 3.96

0 0 0

3.3 3.96

0.1 2.2 5.28 24 0.1

0.83

1.2 3.3 3.96 1.2

0 1.7

1.65 2.48

0 0 0 0 0 0

1.5 2.2 3.3 1.5

14.5 10.4

4 2.2 8.8 4 1.65 6.6

34.3 (1.4 x 10.4) + (1.6 x 6.6) 25.1

1 25.1

8.8 6.6

34.3 1 34.3 25.1

59.437 34.3 25.11

21

B -Bending Moment

Max moment at support M

sup

= = kN/m

Max moment at mid spanM

mid

= = kN/m

C -Beam Section

b= (0.4 to 0.5)h= (0.4 to 0.5) . b= mm b= mm

Cover: C= mm ;Assume Steel Bar D

R

= mm ; D

T

= mm

d= h - C - D

R

/2 - D

T

/2 = = mm d'= mm

D- Define Steel Area

Assume fcu= N/mm ; fy v= N/mm fy = N/mm

a - Define Steel Area at Support Mmax= kNm

Compression Steel Area

Existing Steel Area T A

s

'=

mm

2

Tension Steel Area

Existing Steel Area T A

s

=

mm

2

T A

s

'=

mm

2

Total Steel Area mm

P=100(As,req / bd)= > < 4

b - Define Steel Area at Mid span Mmax= kNm

Compression Steel Area

Existing Steel Area T A

s

'=

mm

2

Tension Steel Area

Existing Steel Area T A

s

=

mm

2

Total Steel Area mm

BS8110 REF. CALCULATION OUTPUT

=

7700

h=

L

to

L

h= 550 mm

- ql/12 -293.67

ql/24 146.83

h= 400 mm

10 15 10 15

to

7700

400 247.5 200

25 8 20

400 - 25 - 4 - 10 361 35

30 250 390

293.67

2 25 981

3 25 1472

3.851 0.13 OK

3081.13

2 20 628

146.83

2 20 628

6 25 2944

3571.75

22

P=100(As,req / bd)= > < 4

c - Link or Stirrup

Convert Trapezoidal load to uniformly distributed load for bending moment

Uniformly distributed Load x = kN/m x = kN/m

Total uniformly distributed load

+ = kN/m

Max Shear at Support

= = kN

= / bd = N/mm

Max Shear Stress 0.8(f

cu

^(1/2)) = N/mm

V

capacity

= (0.79/1.25) [(100As/bd)^(1/3)] [(400/d)^(1/4)] [(fcu/25)^(1/3)]

= N/mm

N/mm

Vc+0.4 Vs < 0.8(fcu^(1/2))

A

sv

(b

v

S

v

(v

s

-v

c

))/0.87f

y

Assume 6 mm Area of link mm

2

Link SpacingS

v

(A

sv

x 0.87f

y

)/(b

v

(v

s

-v

c

)) = mm mm

Hence R6@30

Existing Link 6 mm @ 150 mm not enough

OUTPUT

4.465 0.13 OK

BS8110 REF. CALCULATION

Left Side of the beam

34.3

3.169

Right Side of the beam

34.3 1 34.3 25.1 1 25.1

V

max

25.11 59.437

Asv= 56.5

29.9 30

V

stress

V

max

1.11

4.38

V

capacity

ql/2 228.8

+0.4= 1.51

23

Shear at L/4

= = kN

= / bd = N/mm

Max Shear Stress 0.8(f

cu

^(1/2)) = N/mm

V

capacity

= (0.79/1.25) [(100As/bd)^(1/3)] [(400/d)^(1/4)] [(fcu/25)^(1/3)]

= N/mm

N/mm

Vc+0.4 Vs < 0.8(fcu^(1/2))

A

sv

(b

v

S

v

(v

s

-v

c

))/0.87f

y

Assume 6 mm Area of link mm

2

Link SpacingS

v

(A

sv

x 0.87f

y

)/(b

v

(v

s

-v

c

)) = mm mm

Hence R6@50

Existing Link 6 mm @

d - Check Deflection

x

x

5 2

8 3

- fs

(0.9+(M / bd

2

))

= ( table3.9 in Code BS8110 Part 1 1985)

BS8110 REF. CALCULATION

=

OUTPUT

150 mm not enough

+

477

0.55 modification factor =

= 5.63

bd

2

200 130321

M

max

=

147 10

6

= x

A

s,pro

390 fs = fy

A

s,req

260

0.91

(Service Stress) x

3572

=

3571.75

120

Bassic span/depth 26

V

stress

V

max

2.377

V

capacity

+0.4= 1.51

V

max

ql

l/4

/ 2 171.6

56.5

48.7 50

1.96

Asv=

1.11

24

= x =

= l / 250 = / = mm

= < =

e - Check Cracking

1/ CLear distance between horizontal tension bars

Allowable clear distance between bars

= (table 3.28)

S

1

= (b-2(cover)-2(

links

)-2(

bar

))/2

= mm <

Clear Distance between the face of the beam and nearest longitudinal bar in tension

S

2

= ((y

2

+y

2

)^(1/2))-(

bar

/2)

y = cover+

link

+(

bar

/2)

= mm

Allowable distance

= 155x0.5 = mm

S

2

= mm < bar should be provided in side faces of beam to control cracking

Distance between bars

BS8110 REF. CALCULATION

OK 155

155

OUTPUT

45.5

51.8 77.5

Refer 3.12.11.2.3 BS8110

42

77.5

250 30.8

0.907 23.5731

NO

Actual span/depth 7700

Allowable span/depth 23.573 Actual span/depth 30.8

Allowable span/depth 26

25

Sb mm

Minimum size bar > ((S

b

b/f

y

)^(1/2))

> mm

Provide @

250

11.323

DB12 250

26

Check Existing Section of First Floor Beam B2a (Along Grid E from Grid 7'-9')

I/ Check Existing B2a effective span= m

A -Loading Slab Panel x m and x m and mTHK

Dead Load

Slab kN/m x x = kN/m kN/m x x = kN/m

Beam kN/m x x = kN/m

Roof Load kN/m x = kN/m kN/m x = kN/m

Wall 10cm kN/m x = kN/m kN/m x = kN/m

Wall 20cm kN/m x = kN/m kN/m x = kN/m

Floor Finished kN/m x = kN/m kN/m x = kN/m

Total Dead Load kN/m kN/m

Live Load or Imposed load

Floor LL kN/m x m = kN/m kN/m x m = kN/m

Roof LL kN/m x m = kN/m kN/m x m = kN/m

Total live Load kN/m kN/m

Triangle or Trapezoidal Design Load

= kN/m = kN/m

Convert Trapezoidal load to uniformly distributed load

Uniformly distributed Load x = kN/m x = kN/m

Total uniformly distributed load

+ = kN/m

1 26.2

38.2 26.22 64.376

38.2 1 38.2 26.2

4 2.2

8.8 6.6

(1.4 x 17.2) + (1.6 x 8.8) 38.2 (1.4 x 11.19) + (1.6 x 6.6) 26.2

0 1.7 0 0 0.83 0

8.8 4

1.65 2.48

17.2 11.2

1.65 6.6

1.5 2.2 3.3 1.5

3.3 3.96

0 0 0 0 0 0

1.2 3.3 3.96 1.2

0.83 0

24 0.25

0 1.7 0 0

BS8110 REF. CALCULATION

0.6 3.6

Left Side of the beam Right Side of the beam

24 0.12 24 0.12 1.65 4.75 2.2 6.34

OUTPUT

7.7

7.7 2.2 7.7 1.65 0.12

27

B -Bending Moment

Max moment at support M

sup

= = kN/m

Max moment at mid spanM

mid

= = kN/m

C -Beam Section

b= (0.4 to 0.5)h= (0.4 to 0.5) . b= mm b= mm

Cover: C= mm ;Assume Steel Bar D

R

= mm ; D

T

= mm

d= h - C - D

R

/2 - D

T

/2 = = mm d'= mm

D- Define Steel Area

Assume fcu= N/mm ; fy v= N/mm fy = N/mm

a - Define Steel Area at Support Mmax= kNm

Compression Steel Area

Existing Steel Area T A

s

'=

mm

2

Tension Steel Area

Existing Steel Area T A

s

=

mm

2

T A

s

'=

mm

2

Total Steel Area mm

P=100(As,req / bd)= > < 4

b - Define Steel Area at Mid span Mmax= kNm

Compression Steel Area

Existing Steel Area T A

s

'=

mm

2

Tension Steel Area

Existing Steel Area T A

s

=

mm

2

Total Steel Area mm

6 25 2944

3571.75

159.04

2 20 628

25 1472

3081.13

2.054 0.13 OK

2 20 628 3

318.07

2 25 981

600 - 25 - 4 - 10 561 35

30 250 390

600 247.5 250

25 8 20

600 mm 550 mm

10 15 10 15

to h= =

7700

ql/24 159.04

h=

7700

h=

L

to

L

BS8110 REF. CALCULATION OUTPUT

- ql/12 -318.07

28

P=100(As,req / bd)= > < 4

c - Link or Stirrup

Convert Trapezoidal load to uniformly distributed load for bending moment

Uniformly distributed Load x = kN/m x = kN/m

Total uniformly distributed load

+ = kN/m

Max Shear at Support

= = kN

= / bd = N/mm

Max Shear Stress 0.8(f

cu

^(1/2)) = N/mm

V

capacity

= (0.79/1.25) [(100As/bd)^(1/3)] [(400/d)^(1/4)] [(fcu/25)^(1/3)]

= N/mm

N/mm

Vc+0.4 Vs < 0.8(fcu^(1/2))

A

sv

(b

v

S

v

(v

s

-v

c

))/0.87f

y

Assume 8 mm Area of link mm

2

Link SpacingS

v

(A

sv

x 0.87f

y

)/(b

v

(v

s

-v

c

)) = mm mm

Hence R8@90

Existing Link 8 mm @ 125 mm not enough

Asv= 101

90.4 90

1.767

4.38

0.80

V

capacity

+0.4= 1.20

V

max

ql/2 247.8

V

stress

V

max

38.2 26.22 64.376

OUTPUT

Left Side of the beam Right Side of the beam

38.2 1 38.2 26.2 1 26.2

2.381 0.13 OK

BS8110 REF. CALCULATION

29

Shear at L/4

= = kN

= / bd = N/mm

Max Shear Stress 0.8(f

cu

^(1/2)) = N/mm

V

capacity

= (0.79/1.25) [(100As/bd)^(1/3)] [(400/d)^(1/4)] [(fcu/25)^(1/3)]

= N/mm

N/mm

Vc+0.4 Vs < 0.8(fcu^(1/2))

A

sv

(b

v

S

v

(v

s

-v

c

))/0.87f

y

Assume 8 mm Area of link mm

2

Link SpacingS

v

(A

sv

x 0.87f

y

)/(b

v

(v

s

-v

c

)) = mm mm

Hence R8@160

Existing Link 8 mm @

d - Check Deflection

x

x

5 2

8 3

- fs

(0.9+(M / bd

2

))

= ( table3.9 in Code BS8110 Part 1 1985)

= x =

= l / 250 = / = mm

= > = OK Allowable span/depth 40.145 Actual span/depth 30.8

250 30.8

Allowable span/depth 26 1.544 40.1452

Bassic span/depth 26

modification factor =

Actual span/depth 7700

x

3572

= 260

0.55 +

477

= 1.54

120

(Service Stress)

3571.75

fs = fy

A

s,req

= x

A

s,pro

390

= 2.02

bd

2

250 314721

M

max

=

159 10

6

safe enough

Asv= 101

166 160

1.96

0.80

V

capacity

+0.4= 1.20

125 mm

V

max

ql

l/4

/ 2 185.9

V

stress

V

max

1.325

30

e - Check Cracking

1/ CLear distance between horizontal tension bars

Allowable clear distance between bars

= (table 3.28)

S

1

= (b-2(cover)-2(

links

)-2(

bar

))/2

= mm <

Clear Distance between the face of the beam and nearest longitudinal bar in tension

S

2

= ((y

2

+y

2

)^(1/2))-(

bar

/2)

y = cover+

link

+(

bar

/2)

= mm

Allowable distance

= 155x0.5 = mm

S

2

= mm < bar should be provided in side faces of beam to control cracking

Distance between bars

Sb mm

45.5

77.5

51.8 77.5

250

Refer 3.12.11.2.3 BS8110

155

67 155 OK

31

Minimum size bar

> ((S

b

b/f

y

)^(1/2))

> mm

Provide @ DB12 250

12.7

32

Check Existing Section of Roof Floor Beam RB1A (Along Grid H from Grid 2-4)

I/ Check Existing RB1A effective span= m

A -Loading Slab Panel x m and x m and mTHK

Dead Load

Slab kN/m x x = kN/m kN/m x x = kN/m

Beam kN/m x x = kN/m

Roof Load kN/m x = kN/m kN/m x = kN/m

Wall 10cm kN/m x = kN/m kN/m x = kN/m

Wall 20cm kN/m x = kN/m kN/m x = kN/m

Floor Finished kN/m x = kN/m kN/m x = kN/m

Total Dead Load kN/m kN/m

Live Load or Imposed load

Floor LL kN/m x m = kN/m kN/m x m = kN/m

Roof LL kN/m x m = kN/m kN/m x m = kN/m

Total live Load kN/m kN/m

Triangle or Trapezoidal Design Load

= kN/m = kN/m

Convert Trapezoidal load to uniformly distributed load

Uniformly distributed Load x = kN/m x = kN/m

Total uniformly distributed load

+ = kN/m

OUTPUT

6.6

6.6 1.65 6.6 1.65 0.12

BS8110 REF. CALCULATION

Left Side of the beam Right Side of the beam

24 0.12

24 0.2 0.4 1.92

1.65 4.75

2.55 1.5

3.3 0

1.65 4.75 24 0.12

0.83 1.25

0 3.3 0 0

1.5 1.7

0 0 0 0 0 0

1.5 1.65 2.48 1.5

1.65 2.48 1.5 1.65

1.25

11.7 8.5

1.65 2.48

2.48 1.5

1.5 1.7 2.55 1.5

(1.4 x 11.7) + (1.6 x 5.03) 24.4 (1.4 x 8.47) + (1.6 x 3.72)

0.83

17.8

1 17.8

5.03 3.72

24.4 1 24.4 17.8

42.229 24.4 17.81

33

B -Bending Moment

Max moment at support M

sup

= = kN/m

Max moment at mid spanM

mid

= = kN/m

C -Beam Section

b= (0.4 to 0.5)h= (0.4 to 0.5) . b= mm b= mm

Cover: C= mm ;Assume Steel Bar D

R

= mm ; D

T

= mm

d= h - C - D

R

/2 - D

T

/2 = = mm d'= mm

D- Define Steel Area

Assume fcu= N/mm ; fy v= N/mm fy = N/mm

a - Define Steel Area at Support Mmax= kNm

Compression Steel Area

Existing Steel Area T A

s

'=

mm

2

Tension Steel Area

Existing Steel Area T A

s

=

mm

2

T A

s

'=

mm

2

Total Steel Area mm

P=100(As,req / bd)= > < 4

b - Define Steel Area at Mid span Mmax= kNm

Compression Steel Area

Existing Steel Area T A

s

'=

mm

2

Tension Steel Area

Existing Steel Area T A

s

=

mm

2

Total Steel Area mm

BS8110 REF. CALCULATION OUTPUT

=

6600

h=

L

to

L

mm

- ql/12 -153.29

ql/24 76.64

h=

10 15 10 15

to

6600

h= 471.429 400 mm

400 212.143 200

25 8 20

400 - 25 - 4 - 10 361 35

30 250 390

2 20 628

2 20 628

2.072 0.13 OK

153.29

2 16 402

1657.92

76.64

2 20 628

4 20 1256

1884

34

P=100(As,req / bd)= > < 4

c - Link or Stirrup

Convert Trapezoidal load to uniformly distributed load for bending moment

Uniformly distributed Load x = kN/m x = kN/m

Total uniformly distributed load

+ = kN/m

Max Shear at Support

= = kN

= / bd = N/mm

Max Shear Stress 0.8(f

cu

^(1/2)) = N/mm

V

capacity

= (0.79/1.25) [(100As/bd)^(1/3)] [(400/d)^(1/4)] [(fcu/25)^(1/3)]

= N/mm

N/mm

Vc+0.4 Vs < 0.8(fcu^(1/2))

A

sv

(b

v

S

v

(v

s

-v

c

))/0.87f

y

Assume 8 mm Area of link mm

2

Link SpacingS

v

(A

sv

x 0.87f

y

)/(b

v

(v

s

-v

c

)) = mm mm

Hence R8@100

Existing Link 8 mm @

BS8110 REF. CALCULATION

1 17.8

2.355 0.13 OK

V

max

ql/2 139.4

OUTPUT

Left Side of the beam Right Side of the beam

24.4 1 24.4 17.8

24.4 17.81 42.229

0.91

V

capacity

+0.4= 1.31

V

stress

V

max

1.93

4.38

101

107 100

125 mm not enough

Asv=

35

Shear at L/4

= = kN

= / bd = N/mm

Max Shear Stress 0.8(f

cu

^(1/2)) = N/mm

V

capacity

= (0.79/1.25) [(100As/bd)^(1/3)] [(400/d)^(1/4)] [(fcu/25)^(1/3)]

= N/mm

N/mm

Vc+0.4 Vs < 0.8(fcu^(1/2))

A

sv

(b

v

S

v

(v

s

-v

c

))/0.87f

y

Assume 8 mm Area of link mm

2

Link SpacingS

v

(A

sv

x 0.87f

y

)/(b

v

(v

s

-v

c

)) = mm mm

Hence R8@200

Existing Link 8 mm @

d - Check Deflection

x

x

5 2

8 3

- fs

(0.9+(M / bd

2

))

= ( table3.9 in Code BS8110 Part 1 1985)

= x =

= l / 250 = / = mm

= > =

V

stress

V

max

1.448

V

max

ql

l/4

/ 2 104.5

1.6

0.91

V

capacity

+0.4= 1.31

101

202 200

125 mm safe enough

Asv=

M

max

=

76.6 10

6

= 2.94

bd

2

200 130321

260 (Service Stress)

1884

fs = fy

A

s,req

= x

A

s,pro

390 x

1884

=

Allowable span/depth 26 1.233 32.0652

1.23

120

Bassic span/depth 26

modification factor = 0.55 +

477

=

Actual span/depth 6600 250 26.4

OK Actual span/depth 26.4 Allowable span/depth 32.065

36

e - Check Cracking

Refer 3.12.11.2.3 BS8110

1/ CLear distance between horizontal tension bars

Allowable clear distance between bars

= (table 3.28)

S

1

= (b-2(cover)-2(

links

)-2(

bar

))/2

= mm <

Clear Distance between the face of the beam and nearest longitudinal bar in tension

S

2

= ((y

2

+y

2

)^(1/2))-(

bar

/2)

y = cover+

link

+(

bar

/2)

= mm

Allowable distance

= 155x0.5 = mm

S

2

= mm < bar should be provided in side faces of beam to control cracking

Distance between bars

Sb mm

155

47 155 OK

43

77.5

50.8 77.5

250

37

Minimum size bar

> ((S

b

b/f

y

)^(1/2))

> mm

Provide @ DB12 250

11.3

38

Check Existing Section of Roof Floor Beam RB15B (Along Grid E from Grid 1-5)

I/ Check Existing RB15B effective span= m

A -Loading Slab Panel x m and x m and mTHK

Dead Load

Slab kN/m x x = kN/m kN/m x x = kN/m

Beam kN/m x x = kN/m

Roof Load kN/m x = kN/m kN/m x = kN/m

Wall 10cm kN/m x = kN/m kN/m x = kN/m

Wall 20cm kN/m x = kN/m kN/m x = kN/m

Floor Finished kN/m x = kN/m kN/m x = kN/m

Total Dead Load kN/m kN/m

Live Load or Imposed load

Floor LL kN/m x m = kN/m kN/m x m = kN/m

Roof LL kN/m x m = kN/m kN/m x m = kN/m

Total live Load kN/m kN/m

Triangle or Trapezoidal Design Load

= kN/m = kN/m

Convert Trapezoidal load to uniformly distributed load

Uniformly distributed Load x = kN/m x = kN/m

Total uniformly distributed load

+ = kN/m 31.5 17.81 49.273

31.5 1 31.5 17.8 1 17.8

5.85 3.72

(1.4 x 15.79) + (1.6 x 5.85) 31.5 (1.4 x 8.47) + (1.6 x 3.72) 17.8

1.5 1.7 2.55 1.5 0.83 1.25

15.8 8.5

1.5 2.2 3.3 1.5 1.65 2.48

1.5 2.2 3.3 1.5 1.65 2.48

0 0 0 0 0 0

0 3.3 0 0 3.3 0

1.5 1.7 2.55 1.5 0.83 1.25

24 0.25 0.6 3.6

Left Side of the beam Right Side of the beam

24 0.12 2.2 6.34 24 0.12 1.65 4.75

BS8110 REF. CALCULATION OUTPUT

9.9

9.9 2.2 9.9 1.65 0.12

39

B -Bending Moment

Max moment at support M

sup

= = kN/m

Max moment at mid spanM

mid

= = kN/m

C -Beam Section

b= (0.4 to 0.5)h= (0.4 to 0.5) . b= mm b= mm

Cover: C= mm ;Assume Steel Bar D

R

= mm ; D

T

= mm

d= h - C - D

R

/2 - D

T

/2 = = mm d'= mm

D- Define Steel Area

Assume fcu= N/mm ; fy v= N/mm fy = N/mm

a - Define Steel Area at Support Mmax= kNm

Compression Steel Area

Existing Steel Area T A

s

'=

mm

2

Tension Steel Area

Existing Steel Area T A

s

=

mm

2

T A

s

'=

mm

2

Total Steel Area mm

P=100(As,req / bd)= > < 4

b - Define Steel Area at Mid span Mmax= kNm

Compression Steel Area

Existing Steel Area T A

s

'=

mm

2

Tension Steel Area

Existing Steel Area T A

s

=

mm

2

Total Steel Area mm 3571.75

201.22

2 20 628

6 25 2944

3 25 1472

3081.13

2.054 0.13 OK

402.44

2 25 981

2 20 628

600 - 25 - 4 - 10 561 35

30 250 390

600 318.214 250

25 8 20

600 mm

10 15 10 15

to

9900

h= 707.143 mm

- ql/12 -402.44

ql/24 201.22

h= h=

L

to

L

=

9900

BS8110 REF. CALCULATION OUTPUT

40

P=100(As,req / bd)= > < 4

c - Link or Stirrup

Convert Trapezoidal load to uniformly distributed load for bending moment

Uniformly distributed Load x = kN/m x = kN/m

Total uniformly distributed load

+ = kN/m

Max Shear at Support

= = kN

= / bd = N/mm

Max Shear Stress 0.8(f

cu

^(1/2)) = N/mm

V

capacity

= (0.79/1.25) [(100As/bd)^(1/3)] [(400/d)^(1/4)] [(fcu/25)^(1/3)]

= N/mm

N/mm

Vc+0.4 Vs < 0.8(fcu^(1/2))

A

sv

(b

v

S

v

(v

s

-v

c

))/0.87f

y

Assume 8 mm Area of link mm

2

Link SpacingS

v

(A

sv

x 0.87f

y

)/(b

v

(v

s

-v

c

)) = mm mm

Hence R8@90

Existing Link 8 mm @

Asv= 101

93.1 90

125 mm not enough

V

stress

V

max

1.739

4.38

0.80

V

capacity

+0.4= 1.20

31.5 17.81 49.273

V

max

ql/2 243.9

OUTPUT

Left Side of the beam Right Side of the beam

31.5 1 31.5 17.8 1 17.8

2.381 0.13 OK

BS8110 REF. CALCULATION

41

Shear at L/4

= = kN

= / bd = N/mm

Max Shear Stress 0.8(f

cu

^(1/2)) = N/mm

V

capacity

= (0.79/1.25) [(100As/bd)^(1/3)] [(400/d)^(1/4)] [(fcu/25)^(1/3)]

= N/mm

N/mm

Vc+0.4 Vs < 0.8(fcu^(1/2))

A

sv

(b

v

S

v

(v

s

-v

c

))/0.87f

y

Assume 8 mm Area of link mm

2

Link SpacingS

v

(A

sv

x 0.87f

y

)/(b

v

(v

s

-v

c

)) = mm mm

Hence R8@170

Existing Link 8 mm @

d - Check Deflection

x

x

5 2

8 3

- fs

(0.9+(M / bd

2

))

= ( table3.9 in Code BS8110 Part 1 1985)

= x =

= l / 250 = / = mm

= < = NO

Allowable span/depth

39.6

Allowable span/depth 34.727 Actual span/depth 39.6

=

34.727

modification factor =

Actual span/depth 9900 250

120

Bassic span/depth 26

x

3572

= 260

1.34

26 1.336

0.55 +

477

(Service Stress)

3571.75

fs = fy

A

s,req

= x

A

s,pro

390

M

max

=

201 10

6

= 2.56

bd

2

250 314721

101

173 170

125 mm safe enough

1.96

0.80

V

capacity

+0.4= 1.20

Asv=

V

max

ql

l/4

/ 2 182.9

V

stress

V

max

1.304

42

e - Check Cracking

1/ CLear distance between horizontal tension bars

Allowable clear distance between bars

= (table 3.28)

S

1

= (b-2(cover)-2(

links

)-2(

bar

))/2

= mm <

Clear Distance between the face of the beam and nearest longitudinal bar in tension

S

2

= ((y

2

+y

2

)^(1/2))-(

bar

/2)

y = cover+

link

+(

bar

/2)

= mm

Allowable distance

= 155x0.5 = mm

S

2

= mm < bar should be provided in side faces of beam to control cracking

Distance between bars

Sb mm

Refer 3.12.11.2.3 BS8110

155

67 155 OK

45.5

77.5

51.8 77.5

250

43

Minimum size bar

> ((S

b

b/f

y

)^(1/2))

> mm

Provide @ DB12 250

12.7

44

Check Existing Section of First Floor Beam B1 (Along Grid G from Grid 13-15)

I/ Check Existing B1 effective span= m

A -Loading Slab Panel x m and x m and mTHK

Dead Load

Slab kN/m x x = kN/m kN/m x x = kN/m

Beam kN/m x x = kN/m

Roof Load kN/m x = kN/m kN/m x = kN/m

Wall 10cm kN/m x = kN/m kN/m x = kN/m

Wall 20cm kN/m x = kN/m kN/m x = kN/m

Floor Finished kN/m x = kN/m kN/m x = kN/m

Total Dead Load kN/m kN/m

Live Load or Imposed load

Floor LL kN/m x m = kN/m kN/m x m = kN/m

Roof LL kN/m x m = kN/m kN/m x m = kN/m

Total live Load kN/m kN/m

Triangle or Trapezoidal Design Load

= kN/m = kN/m

Convert Trapezoidal load to uniformly distributed load

Uniformly distributed Load x = kN/m x = kN/m

Total uniformly distributed load

+ = kN/m

OUTPUT

6.6

6.6 2.2 6.6 0 0.12

BS8110 REF. CALCULATION

Left Side of the beam Right Side of the beam

24 0.12

24 0.2 0.3 1.44

0 0

0 0

3.3 0

2.2 6.34 24 0.12

0.83 0

0 3.3 0 0

0 1.7

2.3 4.3 9.89 2.3 0 0

4 2.2 8.8 4

0 0 1.5 2.2

0

21.0 0.0

0 0

3.3 1.5

0 1.7 0 0

(1.4 x 20.97) + (1.6 x 8.8) 43.4 (1.4 x 0) + (1.6 x 0)

0.83

0.0

1 0

8.8 0

43.4 1 43.4 0.0

43.432 43.4 0

45

B -Bending Moment

Max moment at support M

sup

= = kN/m

Max moment at mid spanM

mid

= = kN/m

C -Beam Section

b= (0.4 to 0.5)h= (0.4 to 0.5) . b= mm b= mm

Cover: C= mm ;Assume Steel Bar D

R

= mm ; D

T

= mm

d= h - C - D

R

/2 - D

T

/2 = = mm d'= mm

D- Define Steel Area

Assume fcu= N/mm ; fy v= N/mm fy = N/mm

a - Define Steel Area at Support Mmax= kNm

Compression Steel Area

Existing Steel Area T A

s

'=

mm

2

Tension Steel Area

Existing Steel Area T A

s

=

mm

2

T A

s

'=

mm

2

Total Steel Area mm

P=100(As,req / bd)= > < 4

b - Define Steel Area at Mid span Mmax= kNm

Compression Steel Area

Existing Steel Area T A

s

'=

mm

2

Tension Steel Area

Existing Steel Area T A

s

=

mm

2

Total Steel Area mm

BS8110 REF. CALCULATION OUTPUT

=

6600

h=

L

to

L

mm

- ql/12 -157.66

ql/24 78.83

h=

10 15 10 15

to

6600

h= 471.429 300 mm

300 212.143 200

25 8 20

300 - 25 - 4 - 10 261 35

30 250 390

2 16 402

4 20 1256

2.763 0.13 OK

157.66

0 25 0

1657.92

78.83

2 16 628

3 16 603

1230.88

46

P=100(As,req / bd)= > < 4

c - Link or Stirrup

Convert Trapezoidal load to uniformly distributed load for bending moment

Uniformly distributed Load x = kN/m x = kN/m

Total uniformly distributed load

+ = kN/m

Max Shear at Support

= = kN

= / bd = N/mm

Max Shear Stress 0.8(f

cu

^(1/2)) = N/mm

V

capacity

= (0.79/1.25) [(100As/bd)^(1/3)] [(400/d)^(1/4)] [(fcu/25)^(1/3)]

= N/mm

N/mm

Vc+0.4 Vs < 0.8(fcu^(1/2))

A

sv

(b

v

S

v

(v

s

-v

c

))/0.87f

y

Assume 8 mm Area of link mm

2

Link SpacingS

v

(A

sv

x 0.87f

y

)/(b

v

(v

s

-v

c

)) = mm mm

Hence R8@70

Existing Link 8 mm @

BS8110 REF. CALCULATION

1 0

2.051 0.13 OK

V

max

ql/2 143.3

OUTPUT

Left Side of the beam Right Side of the beam

43.4 1 43.4 0.0

43.4 0 43.432

1.09

V

capacity

+0.4= 1.49

V

stress

V

max

2.746

4.38

101

66.2 70

125 mm not enough

Asv=

47

Shear at L/4

= = kN

= / bd = N/mm

Max Shear Stress 0.8(f

cu

^(1/2)) = N/mm

V

capacity

= (0.79/1.25) [(100As/bd)^(1/3)] [(400/d)^(1/4)] [(fcu/25)^(1/3)]

= N/mm

N/mm

Vc+0.4 Vs < 0.8(fcu^(1/2))

A

sv

(b

v

S

v

(v

s

-v

c

))/0.87f

y

Assume 8 mm Area of link mm

2

Link SpacingS

v

(A

sv

x 0.87f

y

)/(b

v

(v

s

-v

c

)) = mm mm

Hence R8@100

Existing Link 8 mm @

d - Check Deflection

x

x

5 2

8 3

- fs

(0.9+(M / bd

2

))

= ( table3.9 in Code BS8110 Part 1 1985)

= x =

= l / 250 = / = mm

= < =

V

stress

V

max

2.059

V

max

ql

l/4

/ 2 107.5

1.39

1.09

V

capacity

+0.4= 1.49

101

113 100

125 mm not enough

Asv=

M

max

=

78.8 10

6

= 5.79

bd

2

200 68121

260 (Service Stress)

1230.88

fs = fy

A

s,req

= x

A

s,pro

390 x

1231

=

Allowable span/depth 26 0.897 23.3288

0.9

120

Bassic span/depth 26

modification factor = 0.55 +

477

=

Actual span/depth 6600 250 26.4

NO Actual span/depth 26.4 Allowable span/depth 23.329

48

e - Check Cracking

1/ CLear distance between horizontal tension bars

Allowable clear distance between bars

= (table 3.28)

S

1

= (b-2(cover)-2(

links

)-2(

bar

))/2

= mm <

Clear Distance between the face of the beam and nearest longitudinal bar in tension

S

2

= ((y

2

+y

2

)^(1/2))-(

bar

/2)

y = cover+

link

+(

bar

/2)

= mm

Allowable distance

= 155x0.5 = mm

S

2

= mm < bar should be provided in side faces of beam to control cracking

Distance between bars

Sb mm

Refer 3.12.11.2.3 BS8110

155

51 155 OK

41

77.5

50 77.5

250

49

Minimum size bar

> ((S

b

b/f

y

)^(1/2))

> mm

Provide @ DB12 250

11.3

50

You might also like

- Slab DesignDocument6 pagesSlab DesignJonasIrvinGallegoNo ratings yet

- BEAM DesignDocument45 pagesBEAM DesignJoseph Cloyd L. LamberteNo ratings yet

- Steel ColumnDocument2 pagesSteel ColumnNikki Roberts100% (2)

- Beam Design - at Design OfficeDocument59 pagesBeam Design - at Design OfficeShamen AmarasekaraNo ratings yet

- Calculation On Sizing of SlabDocument20 pagesCalculation On Sizing of SlabazhimsyammelNo ratings yet

- Tourism Office Building Computations: Truss 2Document32 pagesTourism Office Building Computations: Truss 2Jesselle CelestialNo ratings yet

- StaircaseDocument2 pagesStaircaseMAGED MOHMMED AHMED QASEMNo ratings yet

- Swimming Pool Structural CalcsDocument7 pagesSwimming Pool Structural CalcsFrederick QuintoNo ratings yet

- Eddie Naldoza Engineering Design Beam AnalysisDocument5 pagesEddie Naldoza Engineering Design Beam AnalysisBong-Bong Rodriguez Bianzon100% (1)

- Design BookDocument53 pagesDesign BookmollikaminNo ratings yet

- Slab Design ACI With Reinforcment (Sketch)Document7 pagesSlab Design ACI With Reinforcment (Sketch)chemtahir100% (1)

- Conc Short ColDocument13 pagesConc Short ColEngDbtNo ratings yet

- Monolithic Staircase DesignDocument5 pagesMonolithic Staircase DesignAzraiAzizNo ratings yet

- 6.2 Beam DesignDocument12 pages6.2 Beam DesignShamen Amarasekara100% (2)

- Load Combination and Flexural Design of Roof Deck BeamsDocument123 pagesLoad Combination and Flexural Design of Roof Deck BeamsMarkNo ratings yet

- One Way Slab ProgramDocument140 pagesOne Way Slab ProgramRachelle CapulNo ratings yet

- Design of PurlinsDocument8 pagesDesign of PurlinsLa BeamNo ratings yet

- Design of Rectangular Columns with Biaxial BendingDocument21 pagesDesign of Rectangular Columns with Biaxial BendingBhaskar BabiNo ratings yet

- Design of Square Footing F2Document18 pagesDesign of Square Footing F2Mohammed Sumer100% (1)

- Design of Isolated FootingDocument10 pagesDesign of Isolated Footingramdev panditNo ratings yet

- 2way Slab DesignDocument10 pages2way Slab DesignHari Amudhan IlanchezhianNo ratings yet

- Design of Footing (Isolated)Document2 pagesDesign of Footing (Isolated)Rian Ibayan89% (9)

- Combined FootingDocument18 pagesCombined Footingjklo12No ratings yet

- RC One Way Slab Design (ACI318-05)Document2 pagesRC One Way Slab Design (ACI318-05)emoriderNo ratings yet

- Analysis and Design of One Way Slab with BeamsDocument25 pagesAnalysis and Design of One Way Slab with Beamsklynchelle100% (4)

- Design of Shear Wall FootingDocument11 pagesDesign of Shear Wall FootingJohn Paul Hilary EspejoNo ratings yet

- RC Footing Design FinalDocument39 pagesRC Footing Design Finalmegget100% (10)

- 10.0design of Baseplate and Anchor BoltsDocument7 pages10.0design of Baseplate and Anchor BoltsklynchelleNo ratings yet

- RCC71 Stair Flight & Landing - SingleDocument4 pagesRCC71 Stair Flight & Landing - SingleCioabla BogdanNo ratings yet

- Slab DesignDocument11 pagesSlab DesignCarmel Buniel Sabado100% (22)

- Spreadsheets To BS 8110: The Concrete CentreDocument14 pagesSpreadsheets To BS 8110: The Concrete CentreCioabla BogdanNo ratings yet

- Design of PurlinsDocument2 pagesDesign of PurlinsFeri Noviantoro57% (7)

- 1.0 Beam DesignDocument17 pages1.0 Beam DesignklynchelleNo ratings yet

- Beam Design. DaanDocument11 pagesBeam Design. DaanJonasIrvinGallegoNo ratings yet

- Single RC Staircase DesignDocument4 pagesSingle RC Staircase Designezarul fitri100% (4)

- Cantilever CanopyDocument2 pagesCantilever Canopyapi-19753598No ratings yet

- Chap6 Stair Design MDMDocument33 pagesChap6 Stair Design MDMJordan Allen BarriosNo ratings yet

- Steel Rafter Section For Eave Roof Section ReductionsDocument25 pagesSteel Rafter Section For Eave Roof Section ReductionsJanaka KarunarathnaNo ratings yet

- Hassanal Bagundang BSCE-5Document5 pagesHassanal Bagundang BSCE-5D MNo ratings yet

- Slab Design-@ Design OfficeDocument40 pagesSlab Design-@ Design OfficeShamen AmarasekaraNo ratings yet

- Ractangular Under Ground Water Tank1Document28 pagesRactangular Under Ground Water Tank1Ali Khan100% (1)

- Slab CantileverDocument1 pageSlab CantileveramitkuknaNo ratings yet

- 7 Slab Design 1503Document32 pages7 Slab Design 1503Er Mohd NoshadNo ratings yet

- RC Beam Analysis & Design (En1992-1) : TEDDS Calculation Version 2.0.03Document5 pagesRC Beam Analysis & Design (En1992-1) : TEDDS Calculation Version 2.0.03Natasha WyneNo ratings yet

- DeckDocument9 pagesDeckSamuel AntobamNo ratings yet

- Steel Staircase DesignDocument6 pagesSteel Staircase DesignMario FeghaliNo ratings yet

- 8.0 Slab Design (Aci)Document4 pages8.0 Slab Design (Aci)klynchelleNo ratings yet

- Beam DesignDocument37 pagesBeam DesignYinka Akinkunmi100% (1)

- RC Column Design BS8110Document5 pagesRC Column Design BS8110dantevariasNo ratings yet

- Plate Girder DesignDocument8 pagesPlate Girder Designkalpanaadhi100% (1)

- Retaining WallDocument41 pagesRetaining Wallp_ignatiusNo ratings yet

- Week 11 Lecture Material - WatermarkDocument57 pagesWeek 11 Lecture Material - WatermarkVaibhav SharmaNo ratings yet

- Steel Design To Eurocode 3 - University of Sheffield Structural Engineering MastersDocument13 pagesSteel Design To Eurocode 3 - University of Sheffield Structural Engineering Mastersfatabass100% (13)

- Design Gantry Girder Industrial Building CraneDocument28 pagesDesign Gantry Girder Industrial Building Cranes_bharathkumar75% (12)

- Design CalculationDocument23 pagesDesign CalculationKathir VelNo ratings yet

- Auditorium Building DesignDocument28 pagesAuditorium Building DesignChandra Sekar100% (1)

- Structrual Concrete Design To Eurocode 2 University of Sheffield Structural Engineering MastersDocument12 pagesStructrual Concrete Design To Eurocode 2 University of Sheffield Structural Engineering Mastersfatabass100% (3)

- 2 Design of Beam Ledges 23052014Document2 pages2 Design of Beam Ledges 23052014Ahmad Badsha QuadriNo ratings yet

- Design For Reinforcement in Pier: Slenderness RatioDocument2 pagesDesign For Reinforcement in Pier: Slenderness RatioPreetam SundarayNo ratings yet

- 02 Values and Heritage ConservationDocument100 pages02 Values and Heritage ConservationMihaela NadasanNo ratings yet

- Analysis of Bearing Capacity Driven PileDocument22 pagesAnalysis of Bearing Capacity Driven PileGEOMAHESHNo ratings yet

- ElasticityDocument3 pagesElasticityaazz1No ratings yet

- Use of Building Regulation in Designing BuildingDocument38 pagesUse of Building Regulation in Designing BuildingmonirithneangNo ratings yet

- Use of Building Regulation in Designing BuildingDocument38 pagesUse of Building Regulation in Designing BuildingmonirithneangNo ratings yet

- 911 TrussesDocument4 pages911 Trussesapi-3831908No ratings yet

- Use of Building Regulation in Designing BuildingDocument38 pagesUse of Building Regulation in Designing BuildingmonirithneangNo ratings yet

- ElasticitiesDocument46 pagesElasticitiesrageofangels48100% (1)

- Use of Building Regulation in Designing BuildingDocument38 pagesUse of Building Regulation in Designing BuildingmonirithneangNo ratings yet

- 911 TrussesDocument4 pages911 Trussesapi-3831908No ratings yet

- Design BeamDocument50 pagesDesign BeammonirithneangNo ratings yet

- Architect Graphic - IDocument30 pagesArchitect Graphic - ImonirithneangNo ratings yet

- ArcGIS Telecom Data DictionaryDocument59 pagesArcGIS Telecom Data Dictionaryoussamatique100% (2)

- Design of Spread FootingDocument14 pagesDesign of Spread Footingghulamqader100% (1)

- Man and ColourDocument4 pagesMan and Colourahm0ahmNo ratings yet

- New Khmer ArchitectureDocument50 pagesNew Khmer ArchitecturemonirithneangNo ratings yet

- Timer Highway BridgeDocument19 pagesTimer Highway BridgemonirithneangNo ratings yet

- Tall StructrureDocument20 pagesTall StructruremonirithneangNo ratings yet

- New Khmer ArchitectureDocument50 pagesNew Khmer ArchitecturemonirithneangNo ratings yet

- Design Slab-ShortDocument2 pagesDesign Slab-ShortmonirithneangNo ratings yet

- Design Slab-ShortDocument2 pagesDesign Slab-ShortmonirithneangNo ratings yet