Professional Documents

Culture Documents

Electronic Multipoint Fuel Injection System

Uploaded by

DIPAK VINAYAK SHIRBHATEOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electronic Multipoint Fuel Injection System

Uploaded by

DIPAK VINAYAK SHIRBHATECopyright:

Available Formats

Electronic Multipoint Fuel Injection System

INTRODUCTION

Now a day, the digital revolution is taking place increasingly and

dominating the 1990's. Or rather we can call the 1990's as the digital decade.

Because much more and more advancement is taking place in the field of electronics

engineering only on the basis of a word digital.

Many examples can be quoted. LP's have been replaced by the

digitally recorded compact discs usually called as CD's. Personal computers which

works on a digital processing are becoming an essential home appliance every where

in many of the home appliances digital control units sire provided for easy control of

parameters and for convenience of users.

The word digital has a meaning behind it that to reduce any process or

input to the basic, extremely precise numerical components. The word digital had

taken a place of analogue, which is a very complicated procedure, while digital is

simplified one.

Due to the simplified operation of digital processors it had introduced

many techniques, which dominates the variety of industries & which are resulting

beneficial to the industries. In the field of music industry the digital CD's were

introduced giving finest quality of output. The recently introduced term i.e. 'surround

sound' is based on the digital processing which is again increasing the quality.

Government Polytechnic, Washim 1

Electronic Multipoint Fuel Injection System

Now the point of attention is that one digital element that touches all

of our lives daily is, in our automobiles. Near about all the automobiles are taking the

benefits of word digital. We can say every car running on the road has at least one

digital element in it. The word digital had penetrated or reached the heart of an

automotive i.e. the engine. The carburetors, which are now absolute, are being called

the 'dinosaurs' of the automobile engineering and the digitally controlled fuel ignition

system had been introduced in the engines of automotive.

Government Polytechnic, Washim 2

Electronic Multipoint Fuel Injection System

NEED OF FUEL INJECTORS

About a decade before, the mean of supply of the fuel to the engine

was the device, called carburetor. As the evolution in the automotive took place, the

carburetor became more and more complicated in structure. Since it had to handle

many of the operations. For serving the purpose five circuits were provided in it for

performing different operations. For obtaining the stricter emission requirements

catalytic converters were introduced. And for its effective working the very accurate

control over the air-fuel ratio must be there. The carburetor had failed to monitor the

exact amount of oxygen in the exhaust and thereby maintaining the correct air-fuel

ratio for it. There were electrically controlled carburetors for long time but still they

were much more complicated than the pure mechanical one. These drawbacks gave

the birth to fuel injectors.

In the beginning the throttle body fuel injection system were

introduced. Which is also called single point or central fuel injection system.

Gradually as new engines were produced this system was replaced by the Multi-

point or multiport fuel injection systems. Which are operated electronically using

performance chips.

Government Polytechnic, Washim 3

Electronic Multipoint Fuel Injection System

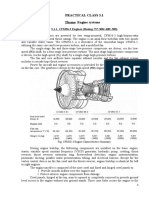

TYPES OF INJECTION SYSTEMS

1) Throttle body injection (TBI):

It is usually called as single port injector, placed before the throttle

plate. K looks more or less like a carburetor. In this system one injector feeds all the

cylinders. Some times two injectors may be used side by side. In these cases, what

happens, two injectors are placed above the throttle blades in the air valve. The fuel

sprayed by the injectors hits directly the blades of throttle valve and sticks there.

That's why the uniform distribution of the fuel in the air stream does not take place.

This uneven distribution ultimately lowers the efficiency, performance and produces

low power.

TBI systems usually runs at low pressure fuel systems i.e. 15 psi.

2) Multipoint fuel injection (MPFI):

It means the number of injectors is more than two i.e. one injector for

each cylinder for ex, 6-cylinder = 6 injectors.

Here the injector is situated at the intake plenum and pointed towards

the intake valve of a cylinder. There are two firing circuits provided in this system.

Working pressure of fuel is about 45 psi. For the purpose of extra fuel during cold

start, an additional injector is oftenly provided.

Government Polytechnic, Washim 4

Electronic Multipoint Fuel Injection System

3) electronics multi point fuel injection (EMPFI) :

Here the word electronic stands for the electronical operation of the

injectors valves. Here the opening and closing of each injector valve is directly

controlled by the electronical circuits provided.

4) Sequential Fuel Injection (SFI) :

It's a type of multi port or multipoint fuel injection system. Here each

cylinder has one injector which is provided by individual firing circuit.

In this system each injector opens just before the intake valve of a

cylinder opens. The advantage of SFI is that, it responds more quickly to the sudden

change made by driver because from the time the change is made, the valve only has

to wait until the next intake valve opens instead of for the next complete revolution

of the engine. It results in better emissions and probably gives more power. It runs at

the same pressure as the MPFI runs.

5) Tuned port injection (TPI) :

It is same as the MPFI only the difference is that it has more number

of cylinder. Ail the MPFI and TPI injectors are physically interchangeable. Only they

have different fuel flow rates.

Government Polytechnic, Washim 5

Electronic Multipoint Fuel Injection System

CONSTITUENTS OF EMPFI SYSTEM

This system includes the following major parts :

1] Sensors:

Sensors are the sensing elements located at different places for

collecting the necessary information about current working condition of the engine.

They sense the different parameters like pressure temperature speed air flow rate etc.

Sensors send this information to the ECU.

2] ECU :

Engine control unit (ECU) uses the information collected by sensors

and make calculations and send the result towards the actuators.

3] Performance chips :

They are situated in the ECU and are the data storing elements and

may be called as a minicomputer in the fuel injection system.

4] Injector valves :

These are the actuators basically. They receives signal from ECU and

does function accordingly.

Government Polytechnic, Washim 6

Electronic Multipoint Fuel Injection System

EMFI-HOW IT WORKS ?

Here, there in starting from a gas pedal which is pushed to accelerate

the vehicle. It is connected directly to the throttle valve which has a function of

supplying oxygen rather air into the engine. So the gas pedal is actually the air pedal

regulating the amount of air being supplied to the engine. As soon as the pedal is

pressed the throttle valve opens up more, letting more amount of air in the cylinder.

Now to balance the stoichiometric ratio there must be increase in the amount of fuel

entering the engine through injector. Otherwise some air may enter without sufficient

fuel with it which will change the stoichiometric (air-fuel) ratio and may result in

lowering the efficiency. Hence an ECU, which controls all the electronic components

in the systems, is connected to the injector valve. It takes information from the

oxygen sensors. These oxygen sensors are connected to the air valve and ECU. It

decides the amount of oxygen in the engine and exhaust and sends this information

to ECU. ECU, after collecting the information opens the injector valve in specific

proportion. So that stoichiometric ratio is just maintained. These fuel injectors are

nothing but the electronically controlled valves. Whose opening time depends upon

ECU. The valves are supplied with pressurised fuel by means of fuel pump present in

the vehicle. This valve is cable of opening and closing many times in a second.

Inside fuel injector when injector is energized, a plunger which is operated by

electromagnet, opens the valve. Which allows the fuel under pressure to squirt out

through a tiny nozzle. This nozzle is designed to atomise the fuel in fine spray or

mist as possible so that its combustion will be easy.

Government Polytechnic, Washim 7

Electronic Multipoint Fuel Injection System

ECU & PERFORMANCE CHIPS

ECU controls the amount of fuel entering the engine by having the

control over the opening and closing of injector valve. There are two main types of

the control for multipoint injection systems.

1) All the fuel injectors can open at the same time.

2) Each one opens just before the opening of intake valve of its cylinder (called

sequential fuel injection).

The amount of fuel entering the engine depends upon the time for

which the valve remains open and this time is called the ' pulse width'. So ECU

decides the pulse width actually. ECU calculates this pulse width which varies

according to the operating conditions of the engine. For finding some factors

involving in the calculation, ECU uses the information obtained by the different

sensors located in the circuit. Some of them are listed below :

1. Mass airflow sensor :

- tells the ECU, the mass of air entering the engine.

2. Oxygen sensors :

- controls the amounts of oxygen in the exhaust so that the ECU can

determine how rich the fuel mixture should be and accordingly makes the

adjustment.

Government Polytechnic, Washim 8

Electronic Multipoint Fuel Injection System

3. Throttle Position Sensor :

-monitors the position of throttle valve (which senses how much air

into the engine) so that the ECU can respond quickly to changes, varying the fuel

flow rate.

4. Coolant temperature sensor :

-allows the ECU to determine when the engine has reached the proper

operating temperature.

5. Voltage sensor :

-monitors the system voltage in the car so the ECU can raise the idle

speed if the voltage is dropping (Which indicates the high electrical load).

6. Manifold absolute pressure sensor :

- monitors the pressure of the air in the intake manifold. The amount

of air being drawn into the engine is a good indication of how much power it is

producing as more air entering the engine, lowering the manifold pressure, so this

reading is used to gauge how much power is being produced.

7. Engine speed sensors :

- senses the engine speed which is one of the factor in calculating the

pulse width.

Government Polytechnic, Washim 9

Electronic Multipoint Fuel Injection System

ECU uses the formula for calculation of a pulse width i.e. required

pulse width = Base pulse width (rpm, Load) × factor A × factor B × --- and so on.

For this calculation the base pulse width is found out by ECU which

is a faction of engine speed in rpm and load which is calculated from the manifold

absolute pressure recorded by the respective sensors. For finding the base pulse

width and all the factors in the formula there are look up tables from which the

corresponding values are chosen for the given operating conditions sad the required

pulse width is calculated. These calculations are done by the performance chips and

all the data such as number of look up tables are Stored in the same chips we can

have an example.

In this example, for simplicity our equation will have only three

parameters i.e.

Pulse width = (Base pulse width (RJPM, Load)) × (Factor A) × (Factor B)

Let's say the engine speed is 2000 rpm and the load is 4. So the

number on the intersection of 2000 & 4 is 8 milliseconds as below :

RPM / Load 1 2 3 4 5

1000 1 2 3 4 5

2000 2 4 6 8 10

3000 3 6 9 12 15

4000 4 8 12 16 20

Government Polytechnic, Washim 10

Electronic Multipoint Fuel Injection System

Now A & Bare the parameters came from sensors. Let's say A is

coolant temperature and B is oxygen level. If A is 100 and B is 3, the following look

up tables tells us the factor A == 0.8 and factor B = 1.0.

A Factor A B Factor B

0 1.2 0 1.0

25 1.1 1 1.0

50 1.0 2 1.0

75 0.9 3 1.0

100 0.8 4 0.75

So putting the obtained values in the formula we have the overall

pulse width required.

= 8 × 0.8 × 1.0

= 6.4 milliseconds

From this example you will come to know that how the control

system makes the adjustment. This is the calculation for one pulse width. And the

injector valve has to open and close many times in a second. So for every different

working condition of an engine, there is difference in pulse width ultimately the

different calculations.

In this way we can say a small computer in the form of ECU in which

the brain called performance chips are situated works basically on the digital

processing. It has to collect the information handle the data, calculate the result and

finally is responsible for getting the proper amount of fuel inside the cylinder of an

engine by having control over the pulse width of the injector valves.

MODES OF OPERATIONS OF EMPFI

Government Polytechnic, Washim 11

Electronic Multipoint Fuel Injection System

1] Open Loop Operation :

During cold start or idle start the system works on the open loop

operation. For this purpose the starter switch is also connected to the EMPFI system.

As the key rotates over the shift lever the EMPFI system set over the open loop

mode and started. In this mode of operation the oxygen sensors are ignored by the

ECU. And the EMPFI controls to a fixed fuelling map.

Idle mixture adjustment :

The electronic control unit (ECU) is just in the right side of the trunk

and there is an opening in the side of ECU. In this opening there is I with one side

flat. This shaft turns a little snaps and adjusts the baseline fuelling map during the

idle which is responsible for the idle mixture.

2] Closed Loop Operation :

When the engine is connected to any drive or any gear, the system

started to operate on the closed loop mode of control. In this mode the system works

normally as the specified air-fuel ratio and using all the sensors as discussed before.

ADVANTAGES OF EMPFI

Government Polytechnic, Washim 12

Electronic Multipoint Fuel Injection System

1) More uniform Air-Fuel mixture will be supplied to each cylinder, hence the

difference in power developed in each cylinder is minimum. Vibration from the

engine equipped with this system is less, due to this there is an improvement in the

life of engine components.

2) No need to crank the engine twice or thrice in case of cold starting as happens in

the carburetor system.

3) Gives immediate response, in case of sudden acceleration / deceleration.

4) Since the engine is controlled by ECM or ECU (Engine Control Module or Unit),

more accurate amount of Air-Fuel mixture will be supplied and as a result complete

combustion will take place. This leads to effective utilization of fuel supplied and

hence low emission level.

5) The mileage of the vehicle will be improved.

CONCLUSION

Government Polytechnic, Washim 13

Electronic Multipoint Fuel Injection System

In above discussion we have understood that how the new fuel

injection system works more efficiently than the previous carbs, how the

performance chips gives us more power. After having discussion over this subject we

are quite well known about the terms like injection of fuel, air-fuel ratio and its

variation, and artificial intelligence of ECU.

This digital technology is an invention of 20th century and is apart of

an artificial intelligence. This technology is developed in 20th century and will carry

us in the 21st century along with its new forms.

May the new century give us more advanced and more comfortable

technologies other than digital one.

Government Polytechnic, Washim 14

Electronic Multipoint Fuel Injection System

REFERENCES

1. I. C. Engine

- by Mathur and Sharma

2. www.googlesearch.com

3. Automobile Engineering

- by Kirpal Singh

Government Polytechnic, Washim 15

You might also like

- Stratified Charged EngineDocument21 pagesStratified Charged EngineDeepak Gupta100% (9)

- IC Engine Exhaust Emissions RegulationDocument38 pagesIC Engine Exhaust Emissions RegulationGuru SamyNo ratings yet

- Emission Control On IC EngineDocument18 pagesEmission Control On IC Enginetarunskumar89% (19)

- Fuel InjectionDocument17 pagesFuel InjectionKler Manpreet0% (1)

- Common Rail Direct Injection ReportDocument20 pagesCommon Rail Direct Injection ReportAshish Malik100% (3)

- 10 Easy Ways To Increase Engine PerformanceDocument9 pages10 Easy Ways To Increase Engine PerformanceRajes SaraNo ratings yet

- How To Improve Internal Combustion Engine EfficiencyDocument8 pagesHow To Improve Internal Combustion Engine EfficiencyJakob LarssonNo ratings yet

- Advancement in AutomobileDocument14 pagesAdvancement in AutomobileVardhan ChipperNo ratings yet

- Cylinder DeactivationDocument6 pagesCylinder Deactivationkhanhung4184100% (1)

- Gasoline Direct InjectionDocument7 pagesGasoline Direct InjectionRavichandran GNo ratings yet

- Project HCCI EngineDocument109 pagesProject HCCI EnginePhuc Dang MinhNo ratings yet

- Variable Compression Ratio EnginesDocument24 pagesVariable Compression Ratio EnginesAzher UddinNo ratings yet

- Fuel Injection System of Diesel EngineDocument26 pagesFuel Injection System of Diesel EngineAbdul MannanNo ratings yet

- Advanced Fuel Injection Technology for Future Diesel EnginesDocument17 pagesAdvanced Fuel Injection Technology for Future Diesel EnginesDan SerbNo ratings yet

- SuperchargerDocument20 pagesSuperchargerrishirajtomar100% (8)

- Delphi Heavy Duty Emissions Brochure 2011 2012Document100 pagesDelphi Heavy Duty Emissions Brochure 2011 2012Younwoo NamNo ratings yet

- IC Engines & Reciprocating Machines GuideDocument73 pagesIC Engines & Reciprocating Machines Guideahmed jemalNo ratings yet

- CRDI Seminar ReportDocument19 pagesCRDI Seminar ReportBharadwaj PradhanNo ratings yet

- Designs of Input and Output Driver Circuits For 16-Bit Electronic Control Unit (Ecu) and Development of Control Strategy For Ecu Using These I o Driver CircuitsDocument5 pagesDesigns of Input and Output Driver Circuits For 16-Bit Electronic Control Unit (Ecu) and Development of Control Strategy For Ecu Using These I o Driver CircuitsesatjournalsNo ratings yet

- Using PWM With Code WarriorDocument14 pagesUsing PWM With Code WarriorGowrishankar Gupta100% (1)

- Powertrain & Calibration 101Document85 pagesPowertrain & Calibration 101babermughalNo ratings yet

- Ic EngineDocument72 pagesIc Enginekedirabduri88No ratings yet

- Turbo Engine: Mechfest 06 A Technical Paper Presentation On " " Submitted byDocument19 pagesTurbo Engine: Mechfest 06 A Technical Paper Presentation On " " Submitted byDeepak Satpathy0% (1)

- MED Motronic Case StudyDocument13 pagesMED Motronic Case StudyÃmit Řajgadkar100% (1)

- Airflow FormulasDocument11 pagesAirflow FormulasVicky GilangNo ratings yet

- Air Pollution Emission Ic EngineDocument27 pagesAir Pollution Emission Ic EngineBagus PraseyoNo ratings yet

- Diesel Engine ImprovementDocument12 pagesDiesel Engine Improvementkumail raza100% (1)

- High-Pressure Common-Rail Fuel InjectionDocument6 pagesHigh-Pressure Common-Rail Fuel InjectionAndi Anzar0% (1)

- ME-Motronic System Controls Cylinder Charge and Fuel DeliveryDocument12 pagesME-Motronic System Controls Cylinder Charge and Fuel DeliveryKanagasundram JathursajanNo ratings yet

- Bosch Gasoline Systems Product InformationDocument27 pagesBosch Gasoline Systems Product InformationГеворг АлексанянNo ratings yet

- MPFI System ExplainedDocument20 pagesMPFI System ExplainedYazala PrakashNo ratings yet

- Holset Turbo Parts DatabaseDocument428 pagesHolset Turbo Parts Databasenetemma97No ratings yet

- Mo TronicDocument2 pagesMo TronicdromakiNo ratings yet

- EHVSDocument24 pagesEHVSCochintu RaduNo ratings yet

- MPFI System ExplainedDocument15 pagesMPFI System Explainedಶಿವರಾಜ್ ಎನ್No ratings yet

- Marine DieselDocument12 pagesMarine DieselNafi AnnurNo ratings yet

- Engine Performance With Variable Valve TimingDocument4 pagesEngine Performance With Variable Valve TimingWilliam KibbeNo ratings yet

- Pizzo InjiDocument3 pagesPizzo InjiprakashNo ratings yet

- VTEC Engine: Variable Valve TimingDocument11 pagesVTEC Engine: Variable Valve TimingSarthakChikaraNo ratings yet

- Common RailDocument3 pagesCommon RailKariem R Noweer100% (1)

- AFM To MAF ConversionDocument11 pagesAFM To MAF ConversionRonnie Peterson100% (1)

- Bosch Motorsport - 2009Document341 pagesBosch Motorsport - 2009Андрей ТатаренковNo ratings yet

- Gasoline Direct InjectionDocument20 pagesGasoline Direct InjectionLalith Kumar100% (1)

- The Diesel Engine 2nd EditionDocument84 pagesThe Diesel Engine 2nd Edition33angleNo ratings yet

- Traffic Emission Controls: DR - Wesam Al MadhounDocument52 pagesTraffic Emission Controls: DR - Wesam Al MadhounVikram PuriNo ratings yet

- Mechanical Project TurbochargerDocument12 pagesMechanical Project Turbochargerinduscad100% (6)

- Managing Power and Traction with TORSEN Traction ControlDocument2 pagesManaging Power and Traction with TORSEN Traction ControlwadafackaNo ratings yet

- SSP 222 Electronically Mapped Cooling SystemDocument28 pagesSSP 222 Electronically Mapped Cooling Systemภูเก็ต เป็นเกาะNo ratings yet

- Bosch Fuel - TechDocument3 pagesBosch Fuel - TechMoaed KanbarNo ratings yet

- Garrett Turbo System OptimizationDocument11 pagesGarrett Turbo System OptimizationlaaliautoNo ratings yet

- Bosch Paper On Fuel Injection 2005 PDFDocument9 pagesBosch Paper On Fuel Injection 2005 PDFiocsachinNo ratings yet

- Supercharging and TurbochargingDocument15 pagesSupercharging and Turbochargingmhawan104No ratings yet

- MEEM 4220 GT-POWER Final Project Requirements and DeliverablesDocument7 pagesMEEM 4220 GT-POWER Final Project Requirements and DeliverablesMustafa OzcelikNo ratings yet

- Intake Manifold DesignDocument13 pagesIntake Manifold Designshubhaastro2827100% (1)

- Structural Health MonitoringFrom EverandStructural Health MonitoringDaniel BalageasNo ratings yet

- Progress in Biomass Conversion: Volume 3From EverandProgress in Biomass Conversion: Volume 3Kyosti V. SarkanenNo ratings yet

- Power Electronics and Electric Drives for Traction ApplicationsFrom EverandPower Electronics and Electric Drives for Traction ApplicationsNo ratings yet

- Multi Point Fuel Injection SystemDocument12 pagesMulti Point Fuel Injection Systemashwini yewaleNo ratings yet

- Unit 2Document49 pagesUnit 2Ramanathan DuraiNo ratings yet

- MPFIDocument18 pagesMPFI09gamb4005No ratings yet

- New File ListDocument2 pagesNew File ListDIPAK VINAYAK SHIRBHATENo ratings yet

- Aahan's BirthdayDocument22 pagesAahan's BirthdayDIPAK VINAYAK SHIRBHATENo ratings yet

- Educational Multimedia On Hydraulics and PneumaticsDocument89 pagesEducational Multimedia On Hydraulics and PneumaticsDIPAK VINAYAK SHIRBHATENo ratings yet

- Dipak Vinayak Shirbhate VSRDIJCSIT 3479 Research Communication June 2014Document4 pagesDipak Vinayak Shirbhate VSRDIJCSIT 3479 Research Communication June 2014DIPAK VINAYAK SHIRBHATENo ratings yet

- Quality Circles For Vikramshila StudentsDocument22 pagesQuality Circles For Vikramshila StudentsDIPAK VINAYAK SHIRBHATENo ratings yet

- Dipak Vinayak Shirbhate VSRDIJMCAPE 3631 Set PPRDocument6 pagesDipak Vinayak Shirbhate VSRDIJMCAPE 3631 Set PPRDIPAK VINAYAK SHIRBHATENo ratings yet

- 2 Dipak Vinayak Shirbhate VSRDIJMCAPE 3631 Research Paper 4 8 August 2014Document8 pages2 Dipak Vinayak Shirbhate VSRDIJMCAPE 3631 Research Paper 4 8 August 2014DIPAK VINAYAK SHIRBHATENo ratings yet

- Quality Circle A Case Study: Prof. D.V. Shirbhate Principal, Vikramshila Polytechnic DarapurDocument34 pagesQuality Circle A Case Study: Prof. D.V. Shirbhate Principal, Vikramshila Polytechnic DarapurDIPAK VINAYAK SHIRBHATENo ratings yet

- Domestic Water Heater PDFDocument39 pagesDomestic Water Heater PDFDIPAK VINAYAK SHIRBHATENo ratings yet

- Boys Hostel FormDocument1 pageBoys Hostel FormDIPAK VINAYAK SHIRBHATE100% (1)

- Kirti Polytechnic Prospectus Part ADocument5 pagesKirti Polytechnic Prospectus Part ADIPAK VINAYAK SHIRBHATENo ratings yet

- Salary Slip - May 2014Document5 pagesSalary Slip - May 2014DIPAK VINAYAK SHIRBHATENo ratings yet

- Girls Hostel FormDocument1 pageGirls Hostel FormDIPAK VINAYAK SHIRBHATENo ratings yet

- Kaizan Presentation 11092012Document12 pagesKaizan Presentation 11092012DIPAK VINAYAK SHIRBHATENo ratings yet

- Domestic Water Heater PDFDocument39 pagesDomestic Water Heater PDFDIPAK VINAYAK SHIRBHATENo ratings yet

- Prospectus For 14-15Document44 pagesProspectus For 14-15DIPAK VINAYAK SHIRBHATENo ratings yet

- Creativity & The Business IdeaDocument12 pagesCreativity & The Business IdeaDIPAK VINAYAK SHIRBHATENo ratings yet

- Importance of Diploma Education For Rural StudentsnnDocument55 pagesImportance of Diploma Education For Rural Studentsnnvspd2010No ratings yet

- Pramod Naik's Letter Director MsbteDocument1 pagePramod Naik's Letter Director MsbteDIPAK VINAYAK SHIRBHATENo ratings yet

- Ad Draft Approved by MsbteDocument1 pageAd Draft Approved by MsbteDIPAK VINAYAK SHIRBHATENo ratings yet

- Mobile Number of StudentsDocument4 pagesMobile Number of Studentsvspd2010No ratings yet

- Prospectus Data 2013-14Document12 pagesProspectus Data 2013-14DIPAK VINAYAK SHIRBHATENo ratings yet

- Vikramshila Polytechnic DarapurDocument1 pageVikramshila Polytechnic DarapurDIPAK VINAYAK SHIRBHATENo ratings yet

- Equivalence of Discipline Praposed Draft For Tech InstitutesDocument14 pagesEquivalence of Discipline Praposed Draft For Tech InstitutesDIPAK VINAYAK SHIRBHATENo ratings yet

- Prospectus For 13-14Document42 pagesProspectus For 13-14DIPAK VINAYAK SHIRBHATENo ratings yet

- Inplant TrainingDocument1 pageInplant TrainingDIPAK VINAYAK SHIRBHATENo ratings yet

- Vikramshila Poly Prospectus MarathiDocument29 pagesVikramshila Poly Prospectus MarathiDIPAK VINAYAK SHIRBHATENo ratings yet

- Pragati Ahawal, 2010 11Document9 pagesPragati Ahawal, 2010 11DIPAK VINAYAK SHIRBHATENo ratings yet

- Performance ApprisalDocument12 pagesPerformance ApprisalDIPAK VINAYAK SHIRBHATENo ratings yet

- Classification of EnterprenuersDocument12 pagesClassification of EnterprenuersDIPAK VINAYAK SHIRBHATE100% (2)

- Intake ProcessDocument9 pagesIntake ProcessHizanorhuda ZurghibaNo ratings yet

- Crankcase Removal (4JK1) TIEMPOSDocument67 pagesCrankcase Removal (4JK1) TIEMPOSTALLER DE MECATRONICA100% (2)

- Powerpoint Fuel Injection SystemsDocument17 pagesPowerpoint Fuel Injection SystemsShivanandNo ratings yet

- DDR Export Nov16 2Document243 pagesDDR Export Nov16 2rajesh_talwar_3No ratings yet

- CAT CT13 Vocational Truck Engine BrochureDocument10 pagesCAT CT13 Vocational Truck Engine BrochurerodizianoNo ratings yet

- IFP Integrated Offer: Direct Injection Diesel Engine DevelopmentDocument4 pagesIFP Integrated Offer: Direct Injection Diesel Engine DevelopmentbdaspetNo ratings yet

- SSP-112-11 Index of SB SL and SIDocument80 pagesSSP-112-11 Index of SB SL and SISerrana ManutencaoNo ratings yet

- Lista de ToberasDocument42 pagesLista de ToberasBraulio Choque PomaNo ratings yet

- Merc Service Manual 23 454 502 EnginesDocument1,027 pagesMerc Service Manual 23 454 502 EnginesHayduke them90% (10)

- An Internship Report On Diesel Power Plant of Liz Fashion Industry LimitedDocument42 pagesAn Internship Report On Diesel Power Plant of Liz Fashion Industry LimitedSunday Joy LaduNo ratings yet

- D13-MH (FE) - AUX 290a500HP MarinoDocument3 pagesD13-MH (FE) - AUX 290a500HP MarinoClaudioNo ratings yet

- Marine Version 3: 2020 Engine Support and Adapter ReferenceDocument1 pageMarine Version 3: 2020 Engine Support and Adapter ReferenceTran PhuocNo ratings yet

- TR50D Optimizing Maintenance ManualDocument436 pagesTR50D Optimizing Maintenance ManualMuhammad NovanNo ratings yet

- Navistar, Inc.: 2701 Navistar Drive, Lisle, IL 60532 USADocument1,725 pagesNavistar, Inc.: 2701 Navistar Drive, Lisle, IL 60532 USATim Workman0% (1)

- Massey Ferguson 2012Document220 pagesMassey Ferguson 2012Jukiuz100% (1)

- Xv1700 2008-2012 Service Repair ManualDocument413 pagesXv1700 2008-2012 Service Repair ManualIgor LukNo ratings yet

- DI16083M 662kWDocument2 pagesDI16083M 662kWMaria Gabriela BusteloNo ratings yet

- S12H-engine - PDF SPECSDocument3 pagesS12H-engine - PDF SPECSMarcos Vinicio StizzioliNo ratings yet

- Tuning spark ignition engines with the ECUMaster EMU BlackDocument230 pagesTuning spark ignition engines with the ECUMaster EMU Blacksxp100% (1)

- 2Uz-Fe Engine 1. General: 4runner - New Features 317Document5 pages2Uz-Fe Engine 1. General: 4runner - New Features 317goNo ratings yet

- Denso CR - Hp2 NissanDocument31 pagesDenso CR - Hp2 NissanMarcelo Diesel86% (7)

- C9 Injection Actuation Pressure TestDocument18 pagesC9 Injection Actuation Pressure Testharikrishnanpd3327100% (1)

- KL-0369-46 K EngDocument4 pagesKL-0369-46 K EngkallatisNo ratings yet

- On-Board Diagnostics Ii SystemDocument266 pagesOn-Board Diagnostics Ii Systemvadim vadimNo ratings yet

- Auto MechanicsDocument6 pagesAuto MechanicsdrrebaNo ratings yet

- LIWEI CatalogeDocument22 pagesLIWEI Cataloge3orwa HajNo ratings yet

- Tafe Report andDocument59 pagesTafe Report andsuryaa patilNo ratings yet

- 01 - Motores CAT - MUI - MEUI - HEUI - COMMON RAIL - Dois Slide Por Pagina - Frente e Verso - Treinamento Corporativo 2010Document122 pages01 - Motores CAT - MUI - MEUI - HEUI - COMMON RAIL - Dois Slide Por Pagina - Frente e Verso - Treinamento Corporativo 2010eder100% (2)

- Spare Parts FG - Wilson - enDocument43 pagesSpare Parts FG - Wilson - enAros Isaias100% (1)