Professional Documents

Culture Documents

1 - SPWLA1975 - T - The Distribution of Shale in SS and Effect Upon Por

Uploaded by

Lewis RangelOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 - SPWLA1975 - T - The Distribution of Shale in SS and Effect Upon Por

Uploaded by

Lewis RangelCopyright:

Available Formats

SPWLA

SIXTEENTH

ANNUAL

LOGGING

SYMPOSIUM,

JUNE

4-7,

1975

THE DISTRIBUTION OF SHALE IN SANDSTONES AND ITS EFFECT UPON POROSITY

BY

E. C. Thomas Shell Oil Company New Orleans, Louisiana S. J. Stieber Butler, Miller & Lents Houston, Texas

ABSTRACT

A shale volume parameter derived from the response of the gamma ray log in shaly sands is often used to correct the responses of other logs for the effects of the shale. The correlation of a garmna ray parameter to shale volume is usually presented as one direct relationship. However, because the shale can be distributed through the sand in different ways, such as laminated, dispersed, structural, or any combination of these, one may expect vasying gamma ray responses dependent upon geometry. We show that each of these configurations can involve a different response from the gamma ray and this variable response can be used to determine the shale configuration. A gamma ray parameter vs. porosity crossplot can then be used to determine shale configuration, sand fraction and sand porosity; the derived equations can be used for implicit solution when processing digital log data. These configurational data can be combined with electric log parameters to determine the oil saturation of the net sand. These log derived parameters are herein verified by direct comparison to rubber sleeve core data.

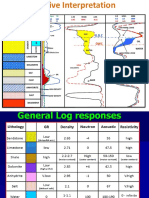

The sparcity of porosity logs in many of the older South Louisiana fields often necessitates that other available log data be correlated to porosity. One log which is generally available is the gamma ray collar log which is used to perforate the well. Thus, empirical gamma ray response Density log porosity correlations in a particular reservoir are developed using recent penetrations, and this correlation is applied to the older gamma ray logs to determine a reservoir-wide porosity distribution. This simple approach is fruitful for reservoirs which are found in Tertiary sand-shale sequences and usually will not apply to more complicated mineralogies involving carbonates. An example of this type of correlation is shown in Figure 1.

-l-

SPWLA

SIXTEENTH

ANNUAL

LOGGING

SYMPOSIUM,

JUNE

4-7,

1975

It is assumed from the above that shale is the main destroyer of sand porosity and it is therefore reasonable to expect the gamma ray to correlate to porosity. However, if sorting or mineralization are the dominant factors in sand porosity variation, then no simple gamma ray response correlation to porosity should be found because the gamma ray responds to the presence or absence of radioactive minerals. We must learn how the shale is distributed in the sand, for this distribution governs the productivity. There are three broad categories which describe how shale can be distributed in a sand: 1. 2. 3. Laminated - layers of shale within the sand. Dispersed - shale on the sand grains, or pore

filling.

Structural - sand sized shale particles in load-bearing positions within the rock.

Of course there can be any combinations of these categories. Thus, to quantitatively determine shale content and distribution we have developed a simple mathematical model which relates gamma ray response to shale distribution and concentration. The five main assumptions in the model are the following: 1. There are only two rock types, a high porosity "clean" sand and a low porosity "pure" shale. The observed in situ porosities are generated by mixing the two. Within the interval investigated, there is no change in shale type and the shale mixed in the sand is mineralogically the same as the "pure" shale sections above and below the sand. The gamma ray responds to the number of radioactive events in a material and thus its mass. The shale fractions we wish to determine are a function of volume. We assume for the Tertiary basins that both sands and shales have comparable grain densities, thus, the radioactivity will be proportional to volume. Constant background radiation will be assumed to be present in all measurements. Counting yields will not change as rock types are intermixed.

2.

3.

4.

5.

The components of the system are sand and shale, thus, we have chosen to use shale rather than clay minerals, even though it is the clay

-2-

SPWLA

SIXTEENTH

ANNUAL

LOGGING

SYMPOSIUM,

JUNE

4-7,

1975

which contains the bulk of the radioactive material. We believe shaly sands and shales are mineralogically similar because both facies are derived from the same source material, carried by the same river and emptied into the same basin. The differentiation between sands and shales begins as the particles settle at differing rates according to their size and transport energy and not mineral type. (This is not rigorously true but, except for heavy minerals, very vesicular minerals, or colloids the differences in density are not dominant.) Thus, we feel the porosity destroying material introduced into a sand stratum will be of the same composition as the shales above and below the sand stratum. Of course, this will not be true for the diagenetic alteration of feldspars into clay within the sand stratum. We define the subscripts a = sand and b = shale. Take a solid block of sand material and place it near an instrument capable of measuring the gamma rays emitted, we observe a counting rate, Ra, expressed as Ra* = Ya Aa

(1)

where Y is the counting yield, A is the activity and the asterisk indicates that fla= 0. Now if we crush the solid and build a porous rock with the pieces, we introduce a void space, Ya. Express Va in terms of the fraction of the total volume of rock, Vt, then V,/Vt = @a, the pure sand rock porosity. The grain volume fraction, grainosity, is then Xa, and Xa = (l-@a). If we now repeat the gamma ray detection experiment using this new porous rock, the counting rate observed is R, = (l-@a) Ya' Aa

(2)

where the prime was added to denote a change in counting yield because of a geometry change in the material counted. If we repeat the same crushing and construction experiment using the shale material, we observe Rb = (I-&,)

Yb

fib .

Let's now mix together quantities of the porous sand and shale, and assume the counting yield will not be significantly altered (Assumption No. 5). We will elaborate on the error caused by this assumption in Appendix 1. There are three independent ways to place the shale in the sand block and these are treated separately. 1. Dispersed shale (pore filling) Place some shale in the sand's pore space. We define the fraction of the total volume occupied by this shale as Xb.

SPWLA

SIXTEENTH

ANNUAL

LOGGING

SYMPOSIUM,

JUNE

4-7,

1975

Now if we count the gamma rays, we observe R=

(1-0a)

Ya Aa + Xb (l-0b) yb' Ab.

(2) and (3) into (4) we get

(4)

If we substitute R=R,+

Xb Rb to

(5)

or simply the observed count rate increases proportional the amount of shale added to the pore systems.

If we are to apply this concept to borehole gamma ray measurements we must relate a defined parameter, y, which correlates to porosity, in terms Of Xb, the bulk volume fraction occupied by shale. The value of y in a sand stratum is defined in terms of the above parameters as

Rb -

Y=

R Rb - Ra

(6)

where Rb is observed in the "purest" nearby shale, and Ra observed in the nearest "clean" sand. Substituting (5) into (6), then Rb - (Ra + Xb Rb) Rb - Ra For simplicity lets define Rb ' = Rb - Ra which is a measure of how radioactive the sands are. y and Xb then becomes

xb =

Y=

(7)

(8)

The relation between

l-y

5

when Xb is pore filling. One point to note is that the minimum porosity available to the dispersed model is when shale completely fills all the original pore volume of the sand or when Xb = @a, 0 min, dispersed = 0, x @b.

(10)

SPWLA

SIXTEENTH

ANNUAL

LOGGING

SYMPOSIUM,

JUNE

4-7,

1975

When Xb > fla, then equation (4) for the counting rate is not valid because we must remove sand grains to add shale. We derive this equation by starting with pure shale (Xb = 1) and work back to Xb = @a. Thus, R = (1-0b) Yb'Ab - Xa (l-@b) Yb'Ab + Xa (I-8a) Ya'Aa. (11) Substituting (2) and (3) into (11) we R = Rb - XaRb + XaRa. Using Xa = 1-Xb, (12) rearranges to R Substituting 2.

get

(12) =

Rb -

(1-Xb)(Rb-Ra)'

(13) (14)

(13) into (6), y = 1-Xb = Xa .

Laminated model Now when we add shale to the sand stratum we must replace sand and its associated porosity, fla,with shale to keep a constant The amount of sand removed and shale total volume of material. added is Xb, the sand fraction. Thus R = (l-Ba) Ya'Aa - (l-0,) Ya'AaXb + (l-P)b)YbAbXb. Substituting (2) and (3) into (15) yields (15)

R = Ra + Xb (Rb-Ra)* If we substitute (16) into (6) then ,/= Rb - Ra - Xb (Rb-Ra) = 1-Xb = X, . Rb - Ra

(16)

(17)

Thus for the laminated model y is the sand fraction. 3. Structural When we add shale in structural positions we remove sand grains only. Thus the porosity increases with the amount of shale porosity that we add in place of the solid sand grain. Or R= (l-@a> Ya'Aa - Xb (1-@a) Ya'Aa + Xb (l-@b) 'b'% (18)

which is the same as (15). Thus, the y to Xb relationship for structural shale is identical to that for the laminated model.

T

-5-

SPWLA

SIXTEENTH

ANNUAL

LOGGING

SYMPOSIUM,

JUNE

4-7,

1975

Now that we know the relation between y and shale fraction, we can construct a theoretical y-porosity relationship based on these three models.

1.

Dispersed (pore filling) - we start with the total porosity of a or @a. We then add shale in the pore space, thus decreasing the porosity by the amount of grainosity of the shale. 0dis = @a - xb (1-gb) for Xb < @a, the available space for shale. The end points of this equation are easily fixed and are independent of any proposed relation between Xb and y. When Xb = 0, 0&& = 8a and when Xb = 8a, @&a = 0a@b. Substituting (9) into (19)

(1-Y)

5

(19)

0dj.s =

@a -

(l-f&).

(20)

A reasonable number for 5 in South Louisiana sands is 1.25.h Thus the relation between these end points is linear with y. The actual value of y at 0~1~ is difficult to define absolutely because of Assumption No. 5. The error caused by this assumption is discussed in Appendix 1. The porosity relation for the region when Xb > 0, is derived just as is the radiation relationship by starting with pure shale and adding sand grains which have no porosity, thus reducing the total porosity by the value of sand added. Ibdis = Ob - xa0b = 0b - (l-xb) @b, when Xb > fla. Substituting (14) into (21) yields

(21)

Q)dis = @b-Ylbb. The relation is linear with y. When y = 0, 0dis = 0b and this is a fixed end point. ymax in eq. (22) is limited as Ymin in eq. (20). However this number is difficult to fix as stated before. See Appendix 1. 2. Laminated - in this case we remove both the porosity and grainosity of the sand and replace it by the shale porosity and grainosity.

(22)

*This value is derived from eq. (8) using Rb = 100 API units and Ra = 20 API units.

SPWLA

SIXTEENTH

ANNUAL

LOGGING

SYMPOSIUM,

JUNE

4-7,

1975

ham = 0a - xb (8,) +

xb

(0b).

(23)

Substitute (17) into (23)

O1am =

Y@a

(1-Y)

0b-

(24)

The end points are easily fixed when y = 1, @lam T 0, and when y = 0, @Iam x P)b. These end points are independent of y-xb relation and are firm. Also equation (24) demonstrates a linear relation between the two end points. 3. Structural - in this case we remove no sand porosity, only sand grainosity, and replace it with an equivalent bulk volume fraction of shale porosity.

0str = Oa + xb @bSubstitute (18) or (17) into (25) Ostr = fla+ (l-y) 0b.

(25)

(26)

The maximum amount of structural shale which can be added equals the grainosity of the sand or Xmax = l_Ymin = l-P)a. (27) Notice that 0 increases linearly with decreasing y. This startling result is obvious upon inspection of the model and is the consequence of replacing the solid quartz grain with a corresponding volume of porous shale. The radiation at the maximum is a simple relation because no sand grains remain. However, the counting yield will be different than for pure shale. But if we use Assumption No. 5, then

R = Xa

(l-0b) Yb'Ab = (I-@a) Rb* (28) into (6) Rb (@a) Rb - R,.

(28)

Then substituting Y"

Rb - (1-qa)Rb = Rb-Ra

(29)

Substituting

Y =

(8) into (29)

*

(0,)

(30)

Thus (27) and (30) are not equal, again the consequences of Assumption No. 5. See Appendix 1.

T

7 -

SPWLA

SIXTEENTH

ANNUAL

LOGGING

SYMPOSIUM,

JUNE

4-7,

1975

In reality we do not have any of these pure models but rather we have a combination of the three. One simplification is to assume the amount of structural shale is too small to be significant and remove this possibility from the model. This simplification permits the response of a gamma ray-density log to be solved (graphically or algebraically) for sand fraction, sand porosity and shale distribution. As an example we choose a Miocene reservoir in South Louisiana, where clean sand porosity is 33% and pure shale porosity is 15%. This is the same reservoir shown in Figure 1. We can then construct a y-density porosity crossplot triangle limited by these data, using eq.(20), (22), and(24), shown in Figure 2. Eq. (26) is also presented. This is done by fixing the y = 1 point at 8 = 33%, y = 0 at 15%. A line drawn between these points is the laminated model limit expressed by eq. 24. The minimum flfor the dispersed is given by eq. 10 as 8, x @b or 0.0495. Solution of eq. 20 for y, using 5 = 1.25, yields y = 0.588. A line connecting this point to the y = 1 point is the graphical approximation of eq. 22. Isolaminous lines are added to Figure 2 by constructing lines parallel to the dispersed shale model line. The percent laminations is then read from the laminated model line as the percentage of the laminated model line substended by the isolaminous line measured from the y = 1.0 apex. Isoporous lines are added to Figure 2 by constructing lines which connect the y = 0 apex to the dispersed shale model line. The porosity of the sand laminae anywhere along a given line is read at its intercept on the dispersed shale model line. For a specific example, a FDC log in a thick sand reads 0 = 28% and y = 0.85. Using Figure 2, we start at the o- 28, y = .85 point, which is on an isolam corresponding to 10% shale laminations, then proceed up an isopor to the intercept on the dispersed shale model line of Id= 29.4. Thus, for this example the bed is composed of 10% shale laminations and the porosity of the interbedded sand is 29.4%. We have illustrated this solution graphically, but of course it can be done algebraically. We recently had the opportunity to test this hypothesis when we cored a well in South Louisiana which penetrated this same reservoir. Figure 3 shows the petrophysical log section across the reservoir. Figure 4 shows the oil saturation and porosity calculated for the entire interval. Figure 5 shows some of the core photographs, demonstrating the laminated nature of the sand. Note the good sand at the top and the extremely laminated material at the bottom. Figure 6 shows the corresponding FDC 8 plotted versus stressed core porosity. The FDC 8 is calculated using measured grain densities and fluid densities from the core adjusted to reservoir temperature and pressure. The good agreement in the clean sand is apparent, while a corresponding disparity appears in the lower laminated section. This is an artifact of biased sampling. Only the sand between the laminations was plugged for core analysis, thus giving misleading results.

SPWLA

SIXTEENTH

ANNUAL

LOGGING

SYMPOSIUM,

JUNE

4-7,

1975

Using the core photographs, the amount of sand and shale can be counted precisely and when a clean sand porosity of 31% (the average 0 from stressed core analysis) and pure shale porosity of 15% are assigned to the laminations, the average porosity as seen by the density log is reproduced. Conversely, from the gamma ray-density log porosity crossplot, the sand fraction and sand porosity matches that counted from the photographs and measurements in the lab. Thus, if one knows he is in a laminated environment he can apply the laminated resistivity model; 1 fsd b - = R,d x R,h Ra The value of R, is read from the induction log, f,d and fsh are obtained from the crossplot, and Rsh takes from the induction log in a nearby shale zone. Then the actual value percent of Rsd and Rt of the sand can be calculated. The effect of using the true sand 0 and Rt to calculate So is shown in Figure 7. This is a repeat of Figure 4, with an overlay showing the change in calculated So in the heavily laminated zones. In most cases, the oil saturation increases. The effect shown here increases as the percent laminations increase to the point where the shale resistivity dominates the apparent resistivity, thereby condemning a zone which could produce hydrocarbons.

ACKNOWLEDGMENT The authors wish to thank Shell Oil Company for granting permission to publish this work. We also thank B. E. Ausburn of Shell Oil Company who allowed us to use Figure 4 which he had prepared earlier. We appreciate the many discussions with our collegues who helped solidify many of the concepts presented.

SYMBOLS ARYXY-

activity, number of radioactive events counting rate observed at a detector or the Resistivity. void space volume fraction of material counting yield, an experimental constant which relates the true activity to the number of events counted by the detector

a - subscript for clean sand

T

9 -

SPWLA

SIXTEENTH

ANNUAL

LOGGING

SYMPOSIUM,

JUNE

4-7,

1975

bfY-

subscript for pure shale fraction of bulk volume, used in Resistivity models defined by eq. 6 using counting rates in pure shales and clean sands. It is often the sand fraction. defined by eq. 8 and is a measure of sand radioactivity. porosity, the void space of a rock expressed as a volume fraction of the total bulk volume. grainosity, the solid.part of a rock expressed as a volume fraction of the total bulk volume.

<-

0X-

APPENDIX1 We realize that errors have been introduced to the model by However, these assumptions are necessary to many of our assumptions. arrive at the simple equations presented in the text. We feel justified in using assumption (5) because we are also assuming no fluid radioactivity and constant background in spite of unknown changes in borehole size and rugosity, cement type. and placement, and detector type and size. By assigning a few numbers to the equations we can explore the potential errors caused by assumption (5) and demonstrate the small error introduced by its acceptance. Let's refer to Figure 2. The y = 1 point is fixed by the uncertainty in determining 0a from field measurements. But for the theoretical model we can set this number exactly, thus the y = 1, 0 = @a apex is firm. Similarly for the y = 0, 8 = t$, apex. Equation (24) demonstrated that the equation which connects these two apexes is linear, thus the posi ion of this line is firm within the confines of the other The minimum 0 available is fixed at @a&. However, the assumptions. value of y at this point is less well known. Eq. (20) predicts y = -59 while Eq. (22 predicts y = .67. The actual value is probably between t ne two, thus the max error for fldis in the working area of the triangle (8 apparent > @b) is +1.5 and the mean error about +.5. We feel this is acceptable for any practical application. For the structural shale model we have similar uncertainties in y at the @max point. The value of @max iS fixed at 8a + Xa@b or 0a + (l-oa) fib = .43. We can calculate y = .33 from eq. (27) and y = .41 from eq. (30). The Ib error introduced by uncertainty in y is less than +.5.

10

SPWLA

SIXTEENTH

ANNUAL

LOGGING

SYMPOSIUM,

JUNE

4-7,

1975

'0

12 -

API 0 I

UNITS 60 I

jo I

011 SATURATION, FRAC. PV

20 -30 I .40 I .50 I I

.60 I

.?O I

2 0

0

.32 I

.30 I

POROSITY. .2B I

FRAC. BV .2b .24 I I

.22 I

20 1

.z i %

rl

I

I

I

87950 _J

I

+

Boo0 ,,.,S.,t

5

PROFILE

FIGURE 4 - OIL SATURATION-POROSITY DENSITY LOGS.

FROM DEEP INDUCTION

AND

151 mv

FIGURE

0.1

ohm-meters

1.0

PETROPHYSICAL SECTION FOR RESERVOIR IN SOUTH LOUISIANA, CORED INTERVAL SHOWN BY BAR IN TRACK I.

.lO

OIL SATURATION, .20 .30 .40

FRAC PV .M .6O I I

POROSITY, .70 I -----I _-_...a 1 .80 1 34 I .32 .30 I r ----,-

FRAC BV .28 1 .26 I .24 I

r.___-

7900

l------l I r___*____-_

I I I

L__ :----

! I

L__.-_

JAND EFFECTS

FIGURE

OIL SATURATION-POROSITY PROFILE FROM DEEP INDUCTION DENSITY LOGS, SOLID LINE. CORRECTED FOR SHALY SAND ON INDUCTION & DENSITY SHOWN DOTTED LINE.

FIGURE

FDC POROSITY DISCREPANCY

& STRESSED CORE BETWEEN ANALYSIS

POROSITY METHODS

DEMONSTRATING APPARENl CAUSED BY LAMINATIONS.

You might also like

- Seg 2009 1965Document5 pagesSeg 2009 1965ArmandoEsquivelNo ratings yet

- 1 IntroductionDocument14 pages1 Introductionbayoakac100% (1)

- WELL LOG ANALYSISDocument14 pagesWELL LOG ANALYSISFadh At-Tarf100% (1)

- DFIT Report Mamba 2Document13 pagesDFIT Report Mamba 2bartbrocaNo ratings yet

- Mud Gas and WL Log InterpretationDocument16 pagesMud Gas and WL Log Interpretationaaytp govtr100% (1)

- Dual water model explainedDocument3 pagesDual water model explainedDwiki Ramadhani100% (1)

- Waxman Smiths EquationDocument17 pagesWaxman Smiths EquationNikolay Moor100% (1)

- DFIT Example - High PermDocument54 pagesDFIT Example - High Permamramazon88No ratings yet

- Sloughing Shale: by Anuj BhatiaDocument9 pagesSloughing Shale: by Anuj BhatiaANUJ BHATIA100% (1)

- 10 - Shaly SandDocument31 pages10 - Shaly SandLyn KenNo ratings yet

- George Stewart - Well Test Design and Analysis-PennWell Corp (2011) - 2Document20 pagesGeorge Stewart - Well Test Design and Analysis-PennWell Corp (2011) - 2Turtas Agrutas100% (1)

- Limitations of Seismic Pore Pressure PredictionDocument2 pagesLimitations of Seismic Pore Pressure Predictionabdounou100% (1)

- Electrical Petrophysics LectureDocument40 pagesElectrical Petrophysics Lecturefreebookie88No ratings yet

- Open and Case Hole LoggingDocument33 pagesOpen and Case Hole LogginggattNo ratings yet

- Dan 3Document14 pagesDan 3Adanenche Daniel EdohNo ratings yet

- Matrix Acidizing of SandstonesDocument24 pagesMatrix Acidizing of SandstoneslapinNo ratings yet

- Wellbore Stability - SLBDocument30 pagesWellbore Stability - SLBjacek_sawiczNo ratings yet

- Cuttings Analysis During Mud LoggingDocument6 pagesCuttings Analysis During Mud LoggingMuhammad MufarridNo ratings yet

- Formation Evaluation Exercise 1 ReportDocument2 pagesFormation Evaluation Exercise 1 ReportTajul Rijal Annuar100% (1)

- Rock/Oil Interactions and Core Handling Effects on WettabilityDocument97 pagesRock/Oil Interactions and Core Handling Effects on WettabilityMARCO100% (1)

- Aguilera Pickett PlotDocument23 pagesAguilera Pickett PlotFryan GreenhousegasNo ratings yet

- Sensor Manual V2 PDFDocument3 pagesSensor Manual V2 PDFsalvepramod99No ratings yet

- Coring Oprations Alun Whittaker PDFDocument184 pagesCoring Oprations Alun Whittaker PDFalvaro_massimoNo ratings yet

- Reservoir Petrophysics ExamDocument17 pagesReservoir Petrophysics Examhusnainzaidi100% (2)

- Petrophysics IntroDocument28 pagesPetrophysics Introabhishek bhardwaj100% (1)

- Ongc Academy Welcomes TO All Graduate TraineesDocument70 pagesOngc Academy Welcomes TO All Graduate TraineesDebajyoti SarkarNo ratings yet

- YastrebDocument2 pagesYastrebSantanu SarmahNo ratings yet

- Eaton - The Equation For Geopressure Prediction From Well Logs PDFDocument11 pagesEaton - The Equation For Geopressure Prediction From Well Logs PDFSebastianChinomeNo ratings yet

- Caliper & Temperature LoggingDocument23 pagesCaliper & Temperature Loggingsdb158100% (1)

- Quantitative Log Interpretation Techniques for Reservoir EvaluationDocument45 pagesQuantitative Log Interpretation Techniques for Reservoir EvaluationWSG SARIRNo ratings yet

- Geomechanics for Safer DrillingDocument11 pagesGeomechanics for Safer DrillingScurt MIhaiNo ratings yet

- Sonic Logging While Drilling-Shear Answers: Jeff Alford Matt Blyth Ed TollefsenDocument12 pagesSonic Logging While Drilling-Shear Answers: Jeff Alford Matt Blyth Ed TollefsenJuan Juan MoraNo ratings yet

- Hydrocarbon EvaluationDocument35 pagesHydrocarbon EvaluationMohamad TayeaNo ratings yet

- PTA - Fekete - PTA - Course - (Mattar - 2004) Well Test Interpretation PDFDocument459 pagesPTA - Fekete - PTA - Course - (Mattar - 2004) Well Test Interpretation PDFAngel HaroNo ratings yet

- Example Mudlog XDocument13 pagesExample Mudlog XValentina GarcíaNo ratings yet

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsFrom EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsNo ratings yet

- Basic Well Logging by Mandeep Kumar: Page No. List of AbbreviationsDocument43 pagesBasic Well Logging by Mandeep Kumar: Page No. List of AbbreviationsMohammed Zubair AhmedNo ratings yet

- Blowout: PreventionDocument25 pagesBlowout: PreventionlcremaschiNo ratings yet

- Chapter 5 Well Testing (IIDocument36 pagesChapter 5 Well Testing (IISanna JorgeNo ratings yet

- Wire Line LoggingDocument81 pagesWire Line LoggingMuhammad Waqas100% (1)

- Petroleum Engineering Question Paper: 180 Marks, Medium DifficultyDocument34 pagesPetroleum Engineering Question Paper: 180 Marks, Medium DifficultyAAADSFDVSDVNo ratings yet

- Chapter-8 Sonic Logs: by Dr. Jorge Salgado GomesDocument20 pagesChapter-8 Sonic Logs: by Dr. Jorge Salgado GomesbrunoNo ratings yet

- Calculation of Formation Resistivity of Water From SP LogDocument10 pagesCalculation of Formation Resistivity of Water From SP LogSushant Barge100% (1)

- TSO Fracturing SPEDocument7 pagesTSO Fracturing SPESkolastikaPradiptaNo ratings yet

- Lithology Identification Using Resistivity and Porosity LogsDocument20 pagesLithology Identification Using Resistivity and Porosity LogsMohammed AmerNo ratings yet

- Volumes, Types, and Distribution of Clay Minerals in Reservoir Rocks Based On Well Logs PDFDocument14 pagesVolumes, Types, and Distribution of Clay Minerals in Reservoir Rocks Based On Well Logs PDFBangsawan AriefNo ratings yet

- Practical Petroleum Geochemistry for Exploration and ProductionFrom EverandPractical Petroleum Geochemistry for Exploration and ProductionNo ratings yet

- Depositional History of Franchthi Cave: Stratigraphy, Sedimentology, and Chronology, Fascicle 12From EverandDepositional History of Franchthi Cave: Stratigraphy, Sedimentology, and Chronology, Fascicle 12No ratings yet

- Reservoir Engineering in Modern Oilfields: Vertical, Deviated, Horizontal and Multilateral Well SystemsFrom EverandReservoir Engineering in Modern Oilfields: Vertical, Deviated, Horizontal and Multilateral Well SystemsNo ratings yet

- Applied Gaseous Fluid Drilling Engineering: Design and Field Case StudiesFrom EverandApplied Gaseous Fluid Drilling Engineering: Design and Field Case StudiesNo ratings yet

- Thermal Properties and Temperature-Related Behavior of Rock/Fluid SystemsFrom EverandThermal Properties and Temperature-Related Behavior of Rock/Fluid SystemsNo ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Determination of Alcohol Content in WineDocument5 pagesDetermination of Alcohol Content in WineAna María Vallejo TorresNo ratings yet

- Bronze Castings For Bridges and TurntablesDocument4 pagesBronze Castings For Bridges and TurntablesmatiullahNo ratings yet

- Temperature Distribution in Concrete Bridges by E C Hambly PDFDocument6 pagesTemperature Distribution in Concrete Bridges by E C Hambly PDFAnonymous dxsNnL6S8hNo ratings yet

- Closures Technical Manual 14nov2008Document37 pagesClosures Technical Manual 14nov2008jjescudero100% (1)

- Neil Dominic C. Mahusay Bsme-3 Module 1 Assignment: Military Body ArmorDocument4 pagesNeil Dominic C. Mahusay Bsme-3 Module 1 Assignment: Military Body ArmorMahusay Neil DominicNo ratings yet

- AOCS Recommended Practice Ca 12-55 Phosphorus PDFDocument2 pagesAOCS Recommended Practice Ca 12-55 Phosphorus PDFMaximino Alvarez100% (1)

- Ds Oil and Grease TypesDocument2 pagesDs Oil and Grease TypesIsaias BarbaNo ratings yet

- A Study of The Effect of Magnetite Additions To Shell Molds On THDocument106 pagesA Study of The Effect of Magnetite Additions To Shell Molds On THneel gajNo ratings yet

- China's First Ministry of Machine-Building Standard for Radiography of WeldsDocument133 pagesChina's First Ministry of Machine-Building Standard for Radiography of Weldsmsiddique1No ratings yet

- Hapter: Occurrence of Noble GasesDocument10 pagesHapter: Occurrence of Noble GasesSandipan SahaNo ratings yet

- Estimation of Undrained Shear Strength For Peat Using CPTDocument4 pagesEstimation of Undrained Shear Strength For Peat Using CPTLaura RossNo ratings yet

- Mro Products and Oem Adhesives Catalog 2021Document44 pagesMro Products and Oem Adhesives Catalog 2021piyush1124No ratings yet

- Balancing Chemical Equations: For Advanced Chemistry Special Science High School in Grade 10 Quarter 3/ Week 2Document9 pagesBalancing Chemical Equations: For Advanced Chemistry Special Science High School in Grade 10 Quarter 3/ Week 2Venice Gwyn ChavezNo ratings yet

- 2019 Y5 Work Book 1 (Practical 3) SolutionsDocument9 pages2019 Y5 Work Book 1 (Practical 3) SolutionsChenluyingNo ratings yet

- Department of Civil Engineering Test Report of Concrete Mix DesignDocument3 pagesDepartment of Civil Engineering Test Report of Concrete Mix Designsupreetha k sNo ratings yet

- CH 4034 Comprehensive Design Project II Interim Report 1: Production of Ammonia From NaphthaDocument21 pagesCH 4034 Comprehensive Design Project II Interim Report 1: Production of Ammonia From NaphthaAlfonso BlancoNo ratings yet

- DEGASSING AGENT AF 100 - Ind1 - AngDocument1 pageDEGASSING AGENT AF 100 - Ind1 - AngFrench Corvette50% (2)

- The Optical Properties of Magnesium Oxide ContainiDocument6 pagesThe Optical Properties of Magnesium Oxide ContainiAbdulbar kelilNo ratings yet

- Load Rate: Test ReportDocument1 pageLoad Rate: Test ReportluvfearNo ratings yet

- Neutrophiles and ElectrophilesDocument2 pagesNeutrophiles and Electrophileswhydaspam joeNo ratings yet

- 3466Document8 pages3466sk m hassanNo ratings yet

- Feng 2020Document9 pagesFeng 2020Gerapi EraNo ratings yet

- Welding Consumable Nominal Chemical Composition, Wt. Pct. Other Designation SystemsDocument1 pageWelding Consumable Nominal Chemical Composition, Wt. Pct. Other Designation SystemsLLNo ratings yet

- Foundry Engineering MSE-316 Course OverviewDocument25 pagesFoundry Engineering MSE-316 Course OverviewMuhammad AsimNo ratings yet

- SIGMADUR 550 BASE RAL7035 EnglishDocument14 pagesSIGMADUR 550 BASE RAL7035 Englishbuitems11No ratings yet

- About Welding Process 47Document1 pageAbout Welding Process 47XerexNo ratings yet

- Group No 6 - Boge 2 Well Logging and FormationDocument26 pagesGroup No 6 - Boge 2 Well Logging and FormationAlhaj MassoudNo ratings yet

- Application of Permeable Pavements in Highways ForDocument15 pagesApplication of Permeable Pavements in Highways ForYEGAR SAHADUTA HEBZIBAH K 08211942000015No ratings yet

- Metallurgical Characterization of Electrical Discharge Textured Roll SurfaceDocument8 pagesMetallurgical Characterization of Electrical Discharge Textured Roll Surfacevishalbhojak vishalbhojakNo ratings yet

- AP Chemistry Summer Assignment 2017Document44 pagesAP Chemistry Summer Assignment 2017John SmithNo ratings yet