Professional Documents

Culture Documents

3.jsa - Arc Welding-N

Uploaded by

Vivek NaikOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3.jsa - Arc Welding-N

Uploaded by

Vivek NaikCopyright:

Available Formats

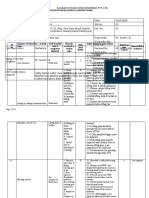

Petrofac

RISK ASSESSMENT / JOB SAFETY ANALYSIS

No JSA No.:JSA-2008-003

ARC WELDING #' No 3

1

$A TitIe: ARC WELDING Date:

3 February 2010

Project Name: IHAR DEVELOPMENT PROECT ($tage 3 ) Project No: I-191 Work Location: IHAR GTP

Permit/s Required: (circIe beIow)

AdditionaI PPE Requirements:

(list on pre-start)

$5eciaI TooIs or Equi5ment Required

(e as detection, fall protection, ventilation fans,

litin, i pressure water blastin, scaffoldin etc)

onfined Space ntry

'eicle

cavation

#adiorapy

Hot Work

old Work

lectrical work certificate

1 Safety footwear & Hat 1'entillation fan

2 Safety lasses 2 Welders sield

3 Gloves as applicable 3Gas Monitors (workin in confined space)

4 ust Mask/ #espirators 4 PTW for onfined Space

5 Spats

6

PotentiaI EnvironmentaI Hazards

(CircIe beIow)

Hazardous MateriaIs

(attac MSS)

Fire/Emergency Equi5ment Requirements

(e fire etinuiser, rescue ear etc)

X Air Pollution (dust) Fumes 1- Fire tinuiser at works area

Spills to round

X Noise

Soil erosion

Spills to water

Hazards to flora and fauna

lectrical emical Lit/ark/'isibility ter omments

Pressure (air, water, as) Heat/old ust and/or fume onduct tool bo talk

Proper housekeepIng

SImultaneous operatIons

Mecanical (crus points) nition Sources ter Trades

Manual Handlin Ground ondition Wind

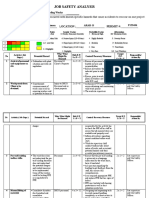

Petrofac

RISK ASSESSMENT / JOB SAFETY ANALYSIS

No JSA No.:JSA-2008-003

ARC WELDING #' No 3

2

$te5s Task/Activity Hazard

Risk Consequence

$oIution/ControI Measure

Mitigation

Res5onsibIe

Person

1 nstallin weldin Macine

in safe area

Presence of

flammable / toic

'apours or Liquid

Fire & plosion

Fatality

Burns

Place electric arc weldin

macine/enerator away from walk

ways and traffic Barricade macine

Use drip trays if oil leakae occurs

isplay i noise and daner

sinae

btain Hot Work To Permit and oter

associated permits if necessary

Keep fire etinuisers near macine

and in weldin area

onstant

supervision by

Weldin

Supervisor/

Foreman

/Welder

2 eck electrical equipment efective tools

plosion/fire

lectrical sock

Fire & plosion

Fatality

Burns

nsure tat all weldin equipment:

cable, electrode, older, plus are not

defects, Systematically ceck te

surroundin and above areas before

startin any weldin work lectrical

and weldin cables are not coiled

onstant

supervision by

Weldin

Supervisor/

Foreman

/Welder

3 Wet floors/soil lectrical Sock Serious injury/ fatal incident

Place weldin macine in dry surface

All cables ave proper insulation and

connector as well as termination joints

are safe for te purpose

Locate te emerency stop switc for

immediate power isolation

onstant

supervision by

Weldin

Supervisor/

Foreman

/Welder

4 Switc on weldin Macine

lectrical Sock Fire and eplosion lectric

sock

No open electric wirin/connections

on primary and secondary circuits

onstant

supervision by

Weldin

Supervisor/

Foreman

/Welder

5 Weldin action #adiation from

U'/# #ays ( all

eyes)

posure body parts,

Serious injury

Use weldin ood wit dark lass

and clear lass nsure proper

ventilation and fume etraction

onstant

supervision by

Weldin

Petrofac

RISK ASSESSMENT / JOB SAFETY ANALYSIS

No JSA No.:JSA-2008-003

ARC WELDING #' No 3

3

posure to weldin

fumes, flammable

as, poor ventilation

Burns

equipment in case of weldin inside

an enclosure Use full weldin PP

Place fire watc wit fire

etinuiser

Supervisor/

Foreman

/Welder

6 Arc weldin Sparks

Splinters/ sla

Harmful fumes

Poor ventilation

Fall of job piece (te

job bein welded)

Presence of

flammable as

ncorrect electrical

polarity

Fire

Severe injury/Flus

Burns/Arc eyes

#espiratory illness

Fire/ plosion

lectric sock

nsure tat tere is no combustible in

work area

Provide fire etinuiser/s

Wear proper PP,

Fire proof apron/ loves

nsure electrical polarity is correct

traction systems must be provided

to remove smoke/ fumes if natural

ventilation is inadequate

Provide proper clamp and support

nsure weldin macine is properly

earted

nsure tat electrode older is

insulated

nsure tat tere are no eposed

wires

onstant

supervision by

Weldin

Supervisor/

Foreman

/Welder

7 Weldin worksop/

confined space

Harmful fumes

Poor ventilation

Affected respiratory traction systems must be provided

to remove smoke/ fumes if natural

ventilation is inadequate /weldin

screen

onduct as test periodically

(confined space)

onstant

supervision by

Weldin

Supervisor/

Foreman

/Welder

8 Weldin equipment Fall of job piece (te

job bein welded)

njury to te personnel/ cras

injury

Provide proper clamp and support

onstant

supervision by

Weldin

Supervisor/

Foreman

/Welder

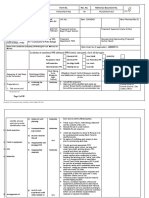

9 Unsafe tools njury and damae to ye injury Use correct tool for te job Use onstant

Petrofac

RISK ASSESSMENT / JOB SAFETY ANALYSIS

No JSA No.:JSA-2008-003

ARC WELDING #' No 3

4

equipment cippin ammer to remove sla Use

inspected cuttin and rindin

electrical/pneumatic equipment for

cuttin and rindin Use inspected

liftin equipment Use properly made,

inspected and approved equipment

supports (pipe supports)

supervision by

Weldin

Supervisor/

Foreman

/Welder

10 Fire Prevention Fire Fire occurred durin and

after work ours

Place enou inspected and fit for

work fire etinuisers in strateic

places in weldin areas/worksops

nsure all weldin services cooled

down No ot weldin electrodes

discarded on flammables ea wood,

scaffoldin planks, paper ect Stay at

work area at least 30 minutes after

work as stopped

Weldin

Supervisor/

Foreman

/Welder/ Fire

watcer

11 Trainin Not trained/un-

autorised workers

njury, damae to equipment All welders, elpers and fire watcers

done te Site HS induction trainin

one all relevant safety trainin

(onfined space/Workin at eits

ect) Supervisor/Foreman done daily

toolbo talk wit weldin crew

Weldin

Supervisor/

Foreman

/Welder

12 PP No body protection njuries Use welders PP: Weldin Helmut,

apron, fire retardant overalls, loves,

spats and face sield for rinders, site

specific PP wen not weldin

Welder Helmut will not be used as a

safety at

Weldin

Supervisor/

Foreman

/Welder

Safety

13 Housekeepin Scattered Material,

obstruction in case of

emerency Slip, trips

and falls

Multiple injuries, nsure proper ousekeepin at

worksite, Te accessories (cable,

electrode older) not bein used must

be disconnected from weldin

macine / enerator and stored

separately

Workin area sould be kept clean

Weldin

Supervisor/

Foreman

/Welder

Petrofac

RISK ASSESSMENT / JOB SAFETY ANALYSIS

No JSA No.:JSA-2008-003

ARC WELDING #' No 3

5

and free from azards suc as loose

objects, tools, oil, rease, discard

weldin electrode ends in special

olders After finisin job keep all

walk ways clear

Attacment 522

RECORD OF ACCEPTANCE PREPARED BY REVIEWED BY APPROVED BY

NAME MOHAMAD NADER AL-$EBAEE AHMAD A$$AD ANDRE L. KOLVER

PO$ITION LEAD $&PERVI$OR LEAD H$$E MANAGER PEC H$$E MANAGER

DATE

$IGNAT&RE

You might also like

- How Chin Engineering: Job Safety AnalysisDocument6 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- JSA Format Erection of Column 903-C-02,03Document5 pagesJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- JSA For Erection & Dismantling of ScaffoldingDocument4 pagesJSA For Erection & Dismantling of ScaffoldingNoe AranelNo ratings yet

- JSA G20 Scaffolding Erection DismantlingDocument4 pagesJSA G20 Scaffolding Erection DismantlingemmyNo ratings yet

- 001 - JHA Survey Setting Out - REV000Document5 pages001 - JHA Survey Setting Out - REV000Venkadesh Periathambi100% (2)

- JSA Formet New Blasting & PaintingDocument5 pagesJSA Formet New Blasting & Paintingsakthi venkatNo ratings yet

- JSA For Electrical Work TCF3-HaradhDocument6 pagesJSA For Electrical Work TCF3-HaradhShaikh Abu bakarNo ratings yet

- 7105 JHRA 008 12 Pneumatic Testing ActivitiesDocument7 pages7105 JHRA 008 12 Pneumatic Testing Activitiesarnel sungkipNo ratings yet

- New Monthly SHE ReportsDocument21 pagesNew Monthly SHE ReportsGIRI BISWAS100% (1)

- JSA Confined Sapce EntryDocument1 pageJSA Confined Sapce EntryprasongNo ratings yet

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- Nasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetDocument2 pagesNasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetRaza Muhammad SoomroNo ratings yet

- Generic TPL JsaDocument83 pagesGeneric TPL JsaSanjay Kumar GhadaiNo ratings yet

- JsaDocument106 pagesJsaRoy Dwi PrasetyoNo ratings yet

- 4 HIRA Format - Sand Blasting ActivityDocument2 pages4 HIRA Format - Sand Blasting ActivityMD Abdullah100% (1)

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- Shifting of Materials by Double HydraDocument1 pageShifting of Materials by Double HydraShahid RazaNo ratings yet

- JSA For Erection of Precast..Document18 pagesJSA For Erection of Precast..Shafie ZubierNo ratings yet

- Water Proofing JSADocument9 pagesWater Proofing JSARamNo ratings yet

- Iaslc Ra 013 Working Under Direct Sun LightDocument4 pagesIaslc Ra 013 Working Under Direct Sun LightJoe PsNo ratings yet

- ARK JSA Manual ExcavationDocument8 pagesARK JSA Manual ExcavationMohammed Ali QaziNo ratings yet

- Job Safety Analysis For Civil WorkDocument9 pagesJob Safety Analysis For Civil Worksakthi venkatNo ratings yet

- Concrete Cutting JsaDocument4 pagesConcrete Cutting JsaMohammad Irfan Kiki IsmailNo ratings yet

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocument16 pagesSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda Buksh60% (5)

- Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007Document30 pagesJsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007elmsm14No ratings yet

- Health and Safety Induction ChecklistDocument2 pagesHealth and Safety Induction ChecklistYathawan Nair ThamutharamNo ratings yet

- Abrasive Wheels Risk AssessmentDocument4 pagesAbrasive Wheels Risk AssessmentAhmed El-sherpiniNo ratings yet

- HIRA 008 Height Work.Document4 pagesHIRA 008 Height Work.srinibas mohapatraNo ratings yet

- Hira - RCC Road ActivityDocument3 pagesHira - RCC Road Activitytariq1987100% (1)

- JSA - Blasting & PaintingDocument11 pagesJSA - Blasting & PaintingRajuNo ratings yet

- Job Safety Assessment (Jsa)Document19 pagesJob Safety Assessment (Jsa)Saravanan Sara0% (1)

- 3.JOB SAFETY ANALYSIS Hot Work Project Title Installation of Wet Sprinkler System at Main WarehouseDocument5 pages3.JOB SAFETY ANALYSIS Hot Work Project Title Installation of Wet Sprinkler System at Main WarehouseMuhammad Umar Gondal100% (1)

- Project JHA For Grading Compacting WorksDocument27 pagesProject JHA For Grading Compacting WorksBasker Balu100% (1)

- Rmdjv-pj74-Hiradc-subc 03 (Hoisting & Rigging)Document1 pageRmdjv-pj74-Hiradc-subc 03 (Hoisting & Rigging)myn maliQueNo ratings yet

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisDocument2 pagesBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechNo ratings yet

- Z - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Document3 pagesZ - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Din JalilNo ratings yet

- JSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Document15 pagesJSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Habib ur rahmanNo ratings yet

- JSA For Blower Cyclone and Duct Installation - Revision 004Document8 pagesJSA For Blower Cyclone and Duct Installation - Revision 004WilsonNo ratings yet

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNo ratings yet

- Job Safety Analysis (JSA) : Description Hazard ControlDocument3 pagesJob Safety Analysis (JSA) : Description Hazard ControlRidha BennasrNo ratings yet

- Rock BreakingDocument1 pageRock BreakingGyanendra Narayan NayakNo ratings yet

- Job Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety PersonnelDocument2 pagesJob Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety Personnelmahammed saleemNo ratings yet

- Hira RCC Cement MillDocument2 pagesHira RCC Cement MillRajuNo ratings yet

- Risk Assess JSA Bolt Tightening 012Document7 pagesRisk Assess JSA Bolt Tightening 012Abdeldjalil Ferhati100% (2)

- Ra FormDocument5 pagesRa FormEngrHazrat MaazNo ratings yet

- 19.hydro Pressure Testing.Document8 pages19.hydro Pressure Testing.Mohammad Fazal KhanNo ratings yet

- JSA For Civil Work and MDocument22 pagesJSA For Civil Work and MSyed Yousuf Ali100% (1)

- Safety Check (Please Put Tick ( ) Mark in The Appropriate BoxDocument8 pagesSafety Check (Please Put Tick ( ) Mark in The Appropriate BoxAntony JebarajNo ratings yet

- PTA-JSA-003-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-003-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- PTW JHA Electrical Wiring Installation Work at Air Dryer RoomDocument4 pagesPTW JHA Electrical Wiring Installation Work at Air Dryer RoomPHH9834No ratings yet

- 19.17 (SWMS) All Work HvacDocument17 pages19.17 (SWMS) All Work Hvacsyed khaja misbhuddinNo ratings yet

- 4.cutting Grinding WeldingDocument5 pages4.cutting Grinding WeldingMohammad Fazal KhanNo ratings yet

- Job Safety & Environment Analysis (Jsa) : Activity or TaskDocument3 pagesJob Safety & Environment Analysis (Jsa) : Activity or TaskLusy Gusti EfendiNo ratings yet

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- Job Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentDocument6 pagesJob Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentMoaatazz NouisriNo ratings yet

- RA-Suspended Gypsum, Metallic Tiles Celling WorksDocument4 pagesRA-Suspended Gypsum, Metallic Tiles Celling Worksfaizan khanNo ratings yet

- JSA-Using A Type Ladder 2015Document1 pageJSA-Using A Type Ladder 2015nishanthNo ratings yet

- Project: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control MeasuresDocument3 pagesProject: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control Measureskhaja asifuddin100% (1)

- JSA-Steel Structure Erection-NDocument4 pagesJSA-Steel Structure Erection-NVivek Naik100% (2)

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDocument1 pageJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingalekyaNo ratings yet

- Three Ways To Battle ComplacencyDocument2 pagesThree Ways To Battle ComplacencyVivek NaikNo ratings yet

- H2S QuizDocument2 pagesH2S QuizVivek Naik100% (1)

- Collapse of CraneDocument3 pagesCollapse of CraneVivek NaikNo ratings yet

- Germs Get Handed AroundDocument2 pagesGerms Get Handed AroundVivek NaikNo ratings yet

- Bed Bugs-FFDocument2 pagesBed Bugs-FFVivek NaikNo ratings yet

- JSA-Steel Structure Erection-NDocument4 pagesJSA-Steel Structure Erection-NVivek Naik100% (2)

- 3.jsa - Arc Welding-NDocument5 pages3.jsa - Arc Welding-NVivek NaikNo ratings yet

- ATEX Poster-ISDocument1 pageATEX Poster-ISVivek NaikNo ratings yet