Professional Documents

Culture Documents

Trouble Shooting of APFC Panel

Uploaded by

Vijay KumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trouble Shooting of APFC Panel

Uploaded by

Vijay KumarCopyright:

Available Formats

APFC

Maintenance:

1. Tighten the connections if termination is found loose. 2. Check the current of capacitor and cable connection.

Power factor is not improving:

1. Please check if required K VAr of capacitors are installed. 2. Check whether all the capacitors are operated in APFC depending upon the load operation. 3. Check the CT connection is i.e., S1 of incomer bus bar C.T. is given to S1 of capacitor bank C.T. 4. Check if the load demand in the s ystem is increased. 5. Check the type of capacitor installed is suitable for application or the capacitors are de-rated.

Taking reading of capacitor: 3-phase capacitor.

KVAr Line current@ 525V 4.3 8.7 10.9 21.7 43.5 65.2 86.9 Line current@ 440V 6.2 12.4 15.5 30.9 61.9 92.8 123.8 Line current@ 415V 7 13.9 17.4 34.8 69.6 104.3 139.1

5 10 12.5 25 50 75 100

Trouble shooting:

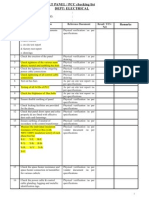

SI. No

Symptoms

Cause

Remedial action

1.

Unit does not turn on.

1. Input auxiliary supply not coming. 2. Input side fuses blown.

1. Check the input supply. 2. Check fuses in the unit are ok.

2.

Unit does not turn on any capacitors even if power factor is below lower pf limit.

1. If auto sync failure message is there at power on. 2. The load KW is too low. 3. Control connections from RLY module to contactor coils are not proper.

1. Load may be highly fluctuating so need of manual synchronization only. 2. This is expected condition. 3. Check control supply and connections from RLY to contactor. 1. Check the size of lug used and replace with suitable size. 2. Tighten the loose connection. 3. Check the cable current carrying capacity and if req. change. 4. Rectify the crimping. 5. Check the voltage and reduce it if possible. Check for any harmonic in the supply voltage. 1. Ensure cross ventilation for the installation area / inside the panel. 2. Check for any harmonic presence in the network. 3. Maintain the voltage within limits(Refer the specification of capacitor) 1. Voltage to be maintained. 2. Should be checked if the capacitor are installed and operated as per guide line given above. 3. In case of improper HRC fuse rating the capacitor element would have failed during over current condition. 1. Check the operation of capacitors. 2. Capacitor should be allowed to switch on only when it is required. 3. Transformer should be provided with fix compensation. 4. Check the rating of capacitor installed is sufficient or not.

3.

Capacitor terminal over heating

1. Proper size of lug is not used. 2. Loose connection. 3. Rating of cable is not adequate. 4. Lugs having bad crimping. 5. Capacitor drawing over current.

4.

Over heating of unit.

1. Poor ventilation. 2. Drawing excessive current. 3. Over voltage.

5.

Capacitor drawing less current.

1. Low voltage. 2. Failure of capacitor elements. 3. Improper rating of short circuit device. 4. Presence of harmonic causing.

6.

Power factor is not improved.

1. Capacitor installed is not operated as required. 2. Capacitor is permanently switched on. 3. Transformer fix compensation is not proved. 4. Capacitor installed is less than the actual requirement.

7.

Fuse blowing but the capacitor is healthy

1. Fuse rating improper. 2. Harmonic over-loading.

1. Fuse rating should be properly selected. 2. Check for harmonic over loading and if required install detuned filter banks. 1. Fuse rating should be properly selected. 2. Check for harmonic over loading and if required install detuned filter banks. 3. Replace capacitor in case it has no other problems.

8.

Leakage of capacitor

1. Fuse rating improper. 2. Harmonic over loading. 3. Over voltage. 4. Switching timer not provided (On delay timer.) 5. High ambient temperature.

You might also like

- Apfc Panel DrawingDocument14 pagesApfc Panel DrawingPRATIKPATELNo ratings yet

- Manual For APFC Panels Installation and Commissioning PDFDocument15 pagesManual For APFC Panels Installation and Commissioning PDFArvind KumawatNo ratings yet

- Sample Template - Distribution Panel Board ScheduleDocument1 pageSample Template - Distribution Panel Board Schedulemusleh19100% (4)

- Power Supplies PDFDocument292 pagesPower Supplies PDFAsadNo ratings yet

- Checklist of Panels - 00047 NewDocument6 pagesChecklist of Panels - 00047 NewKarthick NatrajanNo ratings yet

- Switchboard Schematic and BOM TitleDocument45 pagesSwitchboard Schematic and BOM Titlewaveengg.coNo ratings yet

- SOP - DG SynchronizatiDocument3 pagesSOP - DG SynchronizatiFrank RogerNo ratings yet

- Automatic Power Factor Correction Panel Technical DetailsDocument0 pagesAutomatic Power Factor Correction Panel Technical DetailsVp SreejithNo ratings yet

- MCC Panel Wiring Diagram and Panel Ga Sample PDFDocument15 pagesMCC Panel Wiring Diagram and Panel Ga Sample PDFBerkah Jaya Panel60% (5)

- MCC Panel Technical DrawingDocument1 pageMCC Panel Technical DrawingMahidhar TalapaneniNo ratings yet

- 110 KW VFD With DOL BypassDocument9 pages110 KW VFD With DOL BypassShashikant Jaisingha100% (1)

- Pages From L&T APFC Troubleshooting ManualDocument3 pagesPages From L&T APFC Troubleshooting Manualrajpre1213No ratings yet

- Design Basis For 850kVAR 440V 7% CSC APFC PanelDocument10 pagesDesign Basis For 850kVAR 440V 7% CSC APFC Panelchitra rameshNo ratings yet

- Electrical BoqDocument29 pagesElectrical BoqPaulthiyagaraj SNo ratings yet

- LT Panel SOP For Test ProcedureDocument5 pagesLT Panel SOP For Test ProcedureShrikanth Sola100% (2)

- Vacuum Circuit BreakerDocument12 pagesVacuum Circuit Breakerherovhung12100% (1)

- 6.6kv Apfc PanelDocument4 pages6.6kv Apfc PanelMohan KNo ratings yet

- PLC Panel Check ListDocument6 pagesPLC Panel Check ListPATEL AKASHNo ratings yet

- Commissioning Standard Test FormatsDocument7 pagesCommissioning Standard Test FormatsAmr ElkadyNo ratings yet

- 11kv 630a 25ka Outdoor VCB PanelDocument3 pages11kv 630a 25ka Outdoor VCB PanelSharafat AliNo ratings yet

- Prok DVs - ACCL - CatalougeDocument3 pagesProk DVs - ACCL - CatalougekapilNo ratings yet

- System Study of 220Kv Switchyard For Phase - Iiib Project: Petronet LNG, DahejDocument34 pagesSystem Study of 220Kv Switchyard For Phase - Iiib Project: Petronet LNG, DahejBrijesh BhadauriaNo ratings yet

- HT Panel ChecklistDocument1 pageHT Panel ChecklistMahfuza MansuraNo ratings yet

- LT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateDocument3 pagesLT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateVelmurugan Chakkravarthy100% (4)

- 30 - DE - GA, BOM, SLD & Wiring Diagram For PMCC (21 Sheets)Document21 pages30 - DE - GA, BOM, SLD & Wiring Diagram For PMCC (21 Sheets)kishoredata100% (1)

- Switchboards, Distribution Boards and Control PanelsDocument45 pagesSwitchboards, Distribution Boards and Control PanelsRachel IngramNo ratings yet

- BC 023 Electrical Drgs.Document68 pagesBC 023 Electrical Drgs.srabani dashNo ratings yet

- Capacitor Step Size Selection Guidelines in APFC PanelsDocument4 pagesCapacitor Step Size Selection Guidelines in APFC PanelsAditya Pandey100% (1)

- Technial Specification of Panel .Wiring, SwitchgearDocument19 pagesTechnial Specification of Panel .Wiring, SwitchgearkiroNo ratings yet

- MCC Panel Drawing - R1Document22 pagesMCC Panel Drawing - R1Sagar Mohapatra100% (1)

- Guide Installation Commissioning Operation Maintenance Oil Filled TransformersDocument31 pagesGuide Installation Commissioning Operation Maintenance Oil Filled Transformers2003vinay60% (5)

- Check List For Testing: Equipment Needed To Be TestedDocument2 pagesCheck List For Testing: Equipment Needed To Be TestedKarthik EvilordNo ratings yet

- APFC O&M ManualDocument54 pagesAPFC O&M ManualTarun Godiyal100% (1)

- ALL AMF Panel DrawingsRev B05082008Document15 pagesALL AMF Panel DrawingsRev B05082008amitdhamija100% (3)

- 11KV Kiosk Panel DrawingDocument12 pages11KV Kiosk Panel Drawingerkamlakar223483% (6)

- Commissioning Test Report For Circuit Breaker SiteDocument3 pagesCommissioning Test Report For Circuit Breaker SiteGuru MishraNo ratings yet

- 3M Jointing Kits PricelistDocument10 pages3M Jointing Kits PricelistEdward EduNo ratings yet

- Masibus-8208 Manual PDFDocument36 pagesMasibus-8208 Manual PDFfaisal2106No ratings yet

- COMMNG-ELEC-043 HT Motor PrecommissioningDocument6 pagesCOMMNG-ELEC-043 HT Motor PrecommissioningsantoshkumarNo ratings yet

- Busbar Selection ChartDocument4 pagesBusbar Selection ChartArvind KumawatNo ratings yet

- APFC Panel BOQDocument2 pagesAPFC Panel BOQbuntysuratNo ratings yet

- Drawout Type VCB Panel GA DrawingDocument1 pageDrawout Type VCB Panel GA DrawingsaifulNo ratings yet

- 1.6 Kva Transformer Testing ReportDocument5 pages1.6 Kva Transformer Testing ReportVikrant DeshmukhNo ratings yet

- PNTDocument2 pagesPNTnnabyendu.sahaNo ratings yet

- PanelDraw 4.1 Manual PDFDocument18 pagesPanelDraw 4.1 Manual PDFAkula VeerrajuNo ratings yet

- Backed by experience and commitment: Reliable AC drives seriesDocument52 pagesBacked by experience and commitment: Reliable AC drives seriesDhawal Patel100% (1)

- Transformer Inspection and Test FormsDocument6 pagesTransformer Inspection and Test FormsEdmar BataqueNo ratings yet

- Electrical Protection SystemDocument34 pagesElectrical Protection SystemGanti1977No ratings yet

- C Power ACB ManualDocument9 pagesC Power ACB ManualanilerNo ratings yet

- A.Circuit Breaker Test: Maintenance Test Report For 11Kv SwitchgearDocument4 pagesA.Circuit Breaker Test: Maintenance Test Report For 11Kv SwitchgearIdhaya Chandiran Vignesh100% (1)

- SOP for 3x625 Kva DGs with Auto Sync PanelDocument2 pagesSOP for 3x625 Kva DGs with Auto Sync PanelAshish M50% (2)

- AC Motor Inspection/Testing & Commissioning Check ListDocument9 pagesAC Motor Inspection/Testing & Commissioning Check ListAdnan AhmadNo ratings yet

- Porject Submitted By-: Project MentorDocument37 pagesPorject Submitted By-: Project MentorPritam100% (2)

- System: 3 Phase 4 Wire: MSP Electromech EngineerDocument19 pagesSystem: 3 Phase 4 Wire: MSP Electromech EngineerrajkumarNo ratings yet

- Stelmec 11kv VCB DiagramDocument2 pagesStelmec 11kv VCB Diagramsandeep kumar pattnaik100% (5)

- 11 KV HT Panel ReportDocument66 pages11 KV HT Panel ReportVishakha PandeyNo ratings yet

- Schedule Factory Inspection Low Voltage SwitchgearDocument4 pagesSchedule Factory Inspection Low Voltage SwitchgearMagicneering PredictNo ratings yet

- Hand Book by PrasanthDocument9 pagesHand Book by PrasanthPrasanth100% (1)

- JX NIPPON OIL & GAS LOW VOLTAGE SWITCHBOARD INSPECTIONDocument2 pagesJX NIPPON OIL & GAS LOW VOLTAGE SWITCHBOARD INSPECTIONAmyNo ratings yet

- Marine Electrical Systems ExplainedDocument8 pagesMarine Electrical Systems Explainedsunil1237No ratings yet

- SQL Server 2008 Failover ClusteringDocument176 pagesSQL Server 2008 Failover ClusteringbiplobusaNo ratings yet

- General Separator 1636422026Document55 pagesGeneral Separator 1636422026mohamed abdelazizNo ratings yet

- Chapter 2Document22 pagesChapter 2Okorie Chinedu PNo ratings yet

- BPO UNIT - 5 Types of Securities Mode of Creating Charge Bank Guarantees Basel NormsDocument61 pagesBPO UNIT - 5 Types of Securities Mode of Creating Charge Bank Guarantees Basel NormsDishank JohriNo ratings yet

- Instagram Dan Buli Siber Dalam Kalangan Remaja Di Malaysia: Jasmyn Tan YuxuanDocument13 pagesInstagram Dan Buli Siber Dalam Kalangan Remaja Di Malaysia: Jasmyn Tan YuxuanXiu Jiuan SimNo ratings yet

- Electrosteel Castings Limited (ECL) - Technology That CaresDocument4 pagesElectrosteel Castings Limited (ECL) - Technology That CaresUjjawal PrakashNo ratings yet

- Honors Biology Unit 2 - Energy Study GuideDocument2 pagesHonors Biology Unit 2 - Energy Study GuideMark RandolphNo ratings yet

- Term Sheet: Original Borrowers) Material Subsidiaries/jurisdiction) )Document16 pagesTerm Sheet: Original Borrowers) Material Subsidiaries/jurisdiction) )spachecofdz0% (1)

- Boiler Check ListDocument4 pagesBoiler Check ListFrancis VinoNo ratings yet

- EASA TCDS E.007 (IM) General Electric CF6 80E1 Series Engines 02 25102011Document9 pagesEASA TCDS E.007 (IM) General Electric CF6 80E1 Series Engines 02 25102011Graham WaterfieldNo ratings yet

- Identifying The TopicDocument2 pagesIdentifying The TopicrioNo ratings yet

- Department of Education: Weekly Home Learning Plan Grade Ii Fourth Quarter Week 8Document8 pagesDepartment of Education: Weekly Home Learning Plan Grade Ii Fourth Quarter Week 8Evelyn DEL ROSARIONo ratings yet

- Transformer Oil Testing MethodsDocument10 pagesTransformer Oil Testing MethodsDEE TOTLVJANo ratings yet

- Afu 08504 - International Capital Bdgeting - Tutorial QuestionsDocument4 pagesAfu 08504 - International Capital Bdgeting - Tutorial QuestionsHashim SaidNo ratings yet

- WassiDocument12 pagesWassiwaseem0808No ratings yet

- IP68 Rating ExplainedDocument12 pagesIP68 Rating ExplainedAdhi ErlanggaNo ratings yet

- Environment ManagerDocument234 pagesEnvironment ManagerAbhishek kumarNo ratings yet

- Job Description Support Worker Level 1Document4 pagesJob Description Support Worker Level 1Damilola IsahNo ratings yet

- Computer Portfolio (Aashi Singh)Document18 pagesComputer Portfolio (Aashi Singh)aashisingh9315No ratings yet

- Failure Analysis Case Study PDFDocument2 pagesFailure Analysis Case Study PDFScott50% (2)

- Waves and Thermodynamics, PDFDocument464 pagesWaves and Thermodynamics, PDFamitNo ratings yet

- Piping MaterialDocument45 pagesPiping MaterialLcm TnlNo ratings yet

- Bandung Colonial City Revisited Diversity in Housing NeighborhoodDocument6 pagesBandung Colonial City Revisited Diversity in Housing NeighborhoodJimmy IllustratorNo ratings yet

- Budget ControlDocument7 pagesBudget ControlArnel CopinaNo ratings yet

- Wacker Neuson RTDocument120 pagesWacker Neuson RTJANUSZ2017100% (4)

- Elmeasure Solenoid Ates CatalogDocument12 pagesElmeasure Solenoid Ates CatalogSEO BDMNo ratings yet

- Miami Police File The O'Nell Case - Clemen Gina D. BDocument30 pagesMiami Police File The O'Nell Case - Clemen Gina D. Barda15biceNo ratings yet

- Device Interface Device Type (Router, Switch, Host) IP Address Subnet Mask Default GatewayDocument2 pagesDevice Interface Device Type (Router, Switch, Host) IP Address Subnet Mask Default GatewayRohit Chouhan0% (1)

- Cisco CMTS Feature GuideDocument756 pagesCisco CMTS Feature GuideEzequiel Mariano DaoudNo ratings yet

- Practice Like-Love - Hate and PronounsDocument3 pagesPractice Like-Love - Hate and PronounsangelinarojascnNo ratings yet