Professional Documents

Culture Documents

ISO 1579-1 (Part Only)

Uploaded by

sn200709Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ISO 1579-1 (Part Only)

Uploaded by

sn200709Copyright:

Available Formats

Document Reference: ISO/TC 44/WG 1 Underwater welding Date: April 10, 2001

ISO/TC 44/WG 1 N9

___________________________________________________________________________________

Extract from ISO 15792-1 Welding consumables Test methods Part 1: Test methods for all-weld metal test specimens in steel, nickel and nickel alloys

International Organization for Standardization Secretariat: ANSI - American National Standards Institute Handled by: AWS - American Welding Society Postal address Secretariat ISO/TC 44/WG 1 adavis@aws.org Attn: Andrew Davis 550 N.W. LeJeune Rd. Miami, FL 33126 Telephone National: Fax: International: Fax: E-mail Internet:

305-443-9353 ext. 466 305-443-5951 +1 305 443 9353 ext. 466 +1 305 443 5951

USA

INTERNATIONAL STANDARD

ISO 15792-1

First edition 2000-12-15

Welding consumables Test methods Part 1: Test methods for all-weld metal test specimens in steel, nickel and nickel alloys

Produits consommables pour le soudage Mthodes d'essai Partie 1: Mthodes d'essai pour les prouvettes de mtal fondu hors dilution pour le soudage de l'acier, du nickel et des alliages de nickel

Reference number ISO 15792-1:2000(E)

ISO 2000

INTERNATIONAL STANDARD

ISO 15792-1:2000(E)

Welding consumables Test methods Part 1: Test methods for all-weld metal test specimens in steel, nickel and nickel alloys

Scope

This part of ISO 15792 specifies the preparation of test piece and specimens. The purpose is to determine mechanical properties of all-weld metal where required by the consumable classification standard or for other purposes, in arc welding of steel, nickel and nickel alloys. This part of ISO 15792 is not applicable to single- or two-pass welding or fillet welding. For these cases, ISO 15792-2 and ISO 15792-3 apply.

Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of this part of ISO 15792. For dated references, subsequent amendments to, or revisions of, any of these publications do not apply. However, parties to agreements based on this part of ISO 15792 are encouraged to investigate the possibility of applying the most recent editions of the normative documents indicated below. For undated references, the latest edition of the normative document referred to applies. Members of ISO and IEC maintain registers of currently valid International Standards. ISO 5178, Destructive tests on welds in metallic materials Longitudinal tensile test on weld metal in fusion welded joints. ISO 9016:2000, Destructive tests on welds in metallic materials Impact tests Test specimen location, notch orientation and examination. ISO 13916:1996, Welding Guidance on the measurement of preheating temperature, interpass temperature and preheat maintenance temperature.

General requirements

Welding consumables to be tested shall be representative of the manufacturer's products to be classified or tested. Test pieces shall be prepared as described below.

Test plate material

The material to be used for the test piece shall be compatible with the weld metal provided by the welding consumable tested. Alternatively, the groove edges and the backing strip shall be built up with at least two layers using the welding consumable being tested.

ISO 2000 All rights reserved

ISO 15792-1:2000(E)

Preparation of test piece

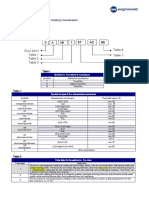

The test piece shall be prepared in the form of a single V-groove on a backing strip. The backing strip shall be tack welded to the test piece on the reverse side. See Figure 1 and Table 1. The plates of the test piece shall be pre-set or restrained in such a way that a sufficiently flat test piece is produced for extraction of specimens. The welded test piece shall not be straightened. The type of test piece defines the dimensions, see Table 1. The type selected for classification purpose is specified in the relevant consumable standard.

Figure 1 Test piece dimensions

Table 1 Type and dimensions of the test piece

Dimensions in millimetres

Type 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7

t 12 12 16 20 25 30 20 25

a

W 80 W 90 W 100 W 150 W 150 W 200 W 150 W 150

b 10 12 14 16 20 25 20 24

>

Degree

W6

10

+2,5 0

W 150

ISO 2000 All rights reserved

ISO 15792-1:2000(E)

Welding conditions

The test piece shall be welded in the flat position except for consumables which are designed exclusively for welding in another position in which case that position shall be used for welding. The welding shall be started after applying any preheating requirements given in the consumable standard. The interpass temperature shall also be in accordance with the consumable standard. The preheat and interpass temperatures shall be measured using temperature indicator crayons, surface thermometers or thermocouples, see ISO 13916. The welding conditions used, such as current, voltage, travel speed, weld run sequence, weld bead size, shall be in accordance with the limits specified in the relevant consumable standard.

Heat treatment

All heat treatments required for the weld metal, except hydrogen removal treatment, shall be carried out on the test piece, or on sections thereof with a machining allowance. The heat treatments are specified in standards relating to welding consumables. Hydrogen removal treatment may be carried out on the test piece for tensile testing before or after final machining. The test piece may be held at a temperature not exceeding 250 C for up to 16 h.

Position of test specimens and test specimen dimensions

Figures 2 and 3 respectively show the position of the tensile test specimen and of the notched impact specimens. The test pieces shall be divided by cutting (machining) or by thermal cutting. In the case of thermal cutting, machining allowances of 10 mm at least on either side shall be provided for the subsequent machining of the specimens.

Figure 2 Position of the tensile specimen in the test piece

Figure 3 Position of the notched bar impact specimen in the test pieces

ISO 2000 All rights reserved

You might also like

- Iso Fdis15614 13 2021Document24 pagesIso Fdis15614 13 2021arabsniperNo ratings yet

- Iso 15609-1-2019Document19 pagesIso 15609-1-2019HarikeshRana100% (2)

- Reduce Hydrogen Cracking with Proper PreheatDocument3 pagesReduce Hydrogen Cracking with Proper PreheatVJG369No ratings yet

- BS en Iso 15792-1Document12 pagesBS en Iso 15792-1Bart Ho100% (1)

- (2004) Eng.Document20 pages(2004) Eng.Zoran VlašićNo ratings yet

- En 1320-Fracture TestDocument17 pagesEn 1320-Fracture TestMadley RockNo ratings yet

- En ISO 14341-2008 Wire Electrodes MIG - MAG of Non Alloy and Fine Grain SteelsDocument4 pagesEn ISO 14341-2008 Wire Electrodes MIG - MAG of Non Alloy and Fine Grain SteelsAlessandro CamozzatoNo ratings yet

- PDFDocument15 pagesPDFkumarkk1969No ratings yet

- Iso 15614-13Document24 pagesIso 15614-13Marija IvanovskaNo ratings yet

- prEN 14700-FD-2013-11-Consumiveis para Revestimentos DurosDocument15 pagesprEN 14700-FD-2013-11-Consumiveis para Revestimentos DurosRicardo FernandesNo ratings yet

- Fracture Testing According EN 9017Document3 pagesFracture Testing According EN 9017Anil100% (1)

- ISO - TR - 15608 - Welding Guide Line PDFDocument10 pagesISO - TR - 15608 - Welding Guide Line PDFDacher DanielNo ratings yet

- CE Marking Requirements for Structural Steel PlatesDocument4 pagesCE Marking Requirements for Structural Steel PlatesSebastián Araya MoraNo ratings yet

- EN10225 Updates Steel StandardsDocument2 pagesEN10225 Updates Steel StandardsVinoth Kumar PothuvudaiNo ratings yet

- BS 709 Destructive TestingDocument17 pagesBS 709 Destructive TestingGabrieleNo ratings yet

- EN Iso 2560 - BDocument2 pagesEN Iso 2560 - Bimupathan100% (1)

- Arc Basics - FA 2009 ISO 14175 Revised StandardDocument10 pagesArc Basics - FA 2009 ISO 14175 Revised StandardCatalinNo ratings yet

- Cen TR 14633 (E)Document9 pagesCen TR 14633 (E)consssNo ratings yet

- BS en Iso 14731-2019Document20 pagesBS en Iso 14731-2019Hüseyin BuğdaycıNo ratings yet

- Section IiiDocument163 pagesSection Iiiprabhu100% (1)

- Welding Essential Variables - en ISO 15614Document2 pagesWelding Essential Variables - en ISO 15614NS QCNo ratings yet

- ISO-15792-1-2000. Test Vật Liệu HànDocument9 pagesISO-15792-1-2000. Test Vật Liệu HànLã Hải ĐăngNo ratings yet

- Iso 17640 2017 en PDFDocument11 pagesIso 17640 2017 en PDFTanveer Ahmed Quadri100% (1)

- ISO 3690-2000 Welding & Allied ProcessesDocument29 pagesISO 3690-2000 Welding & Allied Processesranggarang100% (1)

- Cen Iso 17844 - 2004 PDFDocument80 pagesCen Iso 17844 - 2004 PDFANNo ratings yet

- Iso 9606 4 1999Document11 pagesIso 9606 4 1999Lino Alves InácioNo ratings yet

- BS en Iso 9606-4 - 1999Document26 pagesBS en Iso 9606-4 - 1999jesoneliteNo ratings yet

- Guide To ISO14731Document8 pagesGuide To ISO14731scandalthegoodNo ratings yet

- BS en 756-96 PDFDocument13 pagesBS en 756-96 PDFAhmet Memiş100% (1)

- Equivalences Certified Welder According ASME EN ISO 14732 - 2013 - GleDocument1 pageEquivalences Certified Welder According ASME EN ISO 14732 - 2013 - Gleer_wenNo ratings yet

- EN 760 (Flux-SAW)Document2 pagesEN 760 (Flux-SAW)HoangNo ratings yet

- Iso 3452-1 PDFDocument2 pagesIso 3452-1 PDFMuhamad Richard MenarizkiNo ratings yet

- Filler Materials TestingDocument34 pagesFiller Materials TestingSunilNo ratings yet

- PED 2014-68-EU Guidelines EN PDFDocument218 pagesPED 2014-68-EU Guidelines EN PDFMali MedoNo ratings yet

- ISO 9606-1 Cor1-2012Document1 pageISO 9606-1 Cor1-2012Flaah92No ratings yet

- EN 1090 Compliance for Structural SteelDocument42 pagesEN 1090 Compliance for Structural Steelbharani dharanNo ratings yet

- Clarification On CE Marking With EN 1090-1 PDFDocument5 pagesClarification On CE Marking With EN 1090-1 PDFAMGConsultadoriaNo ratings yet

- BS en 10306 - 2002Document18 pagesBS en 10306 - 2002subbarao100% (1)

- BS en 10016-2 1995Document12 pagesBS en 10016-2 1995Irfan YararNo ratings yet

- BS en 12668-1-2010Document48 pagesBS en 12668-1-2010lamhuu quangNo ratings yet

- EN ISO 17639: European Standard Norme Européenne Europäische NormDocument17 pagesEN ISO 17639: European Standard Norme Européenne Europäische NormИван ИвановNo ratings yet

- ISO 24373 - 2018 FullDocument20 pagesISO 24373 - 2018 FullSunil RishiNo ratings yet

- Iso 3834 2 2005 en PDFDocument6 pagesIso 3834 2 2005 en PDFRamamoorthy SundarNo ratings yet

- International Standard: Metallic Materials - Determination of Plane-Strain Fracture ToughnessDocument8 pagesInternational Standard: Metallic Materials - Determination of Plane-Strain Fracture ToughnessPaquita LonddonNo ratings yet

- Iso 14344 2010Document9 pagesIso 14344 2010MOHAMEDNo ratings yet

- BS en 440-95 PDFDocument14 pagesBS en 440-95 PDFAhmet Memiş100% (2)

- BS en Iso 9606-5 - 2000Document26 pagesBS en Iso 9606-5 - 2000jesoneliteNo ratings yet

- BS en Iso 9013 - 2003Document4 pagesBS en Iso 9013 - 2003OteloElMoroNo ratings yet

- Electron Beam Welding Process - Equipment's, Working Principle With DiagramDocument7 pagesElectron Beam Welding Process - Equipment's, Working Principle With DiagramDr.S.Ravi CITNo ratings yet

- Ensuring Compliance of Structural Steelwork - Regardless of OriginDocument10 pagesEnsuring Compliance of Structural Steelwork - Regardless of OriginStephen HicksNo ratings yet

- En 10164Document5 pagesEn 10164Merk Erik0% (1)

- Iso 9606-3Document30 pagesIso 9606-3Aleksandar StojanovicNo ratings yet

- Astm f136 Rev ADocument4 pagesAstm f136 Rev AAhmad BrianNo ratings yet

- Astm B705Document4 pagesAstm B705Maram NasraweenNo ratings yet

- F1713 1479757-1Document5 pagesF1713 1479757-1Thaweekarn ChangthongNo ratings yet

- Iso 19879-2005Document27 pagesIso 19879-2005Márcio Fraga0% (1)

- En Iso 17642 - 1 (E)Document5 pagesEn Iso 17642 - 1 (E)mustafa gözüaçıkNo ratings yet

- MMAW SMAW Carbon Steel Electrodes ClassificationDocument10 pagesMMAW SMAW Carbon Steel Electrodes Classificationsn200709No ratings yet

- CR Loss or Gain in FluxDocument1 pageCR Loss or Gain in Fluxsn200709No ratings yet

- X15CrNiMn18 8 PDFDocument1 pageX15CrNiMn18 8 PDFsn200709No ratings yet

- Flux-Cored Arc Welding: A. Process PrinciplesDocument3 pagesFlux-Cored Arc Welding: A. Process Principlessn200709No ratings yet

- SAW Process Explained in DetailDocument21 pagesSAW Process Explained in DetailPhani KumarNo ratings yet

- Weld-Metal Property OptimizationDocument5 pagesWeld-Metal Property Optimizationsn200709No ratings yet

- Prediction of Element Transfer in Submerged Arc WeldingDocument12 pagesPrediction of Element Transfer in Submerged Arc Weldingsn200709No ratings yet

- Material Number 1.4370 - X15Crnimn18-8: Composition in %Document1 pageMaterial Number 1.4370 - X15Crnimn18-8: Composition in %sn200709No ratings yet

- January 2019 February 2019 March 2019 April 2019: WN WN WN WNDocument1 pageJanuary 2019 February 2019 March 2019 April 2019: WN WN WN WNsn200709No ratings yet

- Esab's Ok Autrod 19.30Document1 pageEsab's Ok Autrod 19.30sn200709No ratings yet

- WJ 1992 09 PDFDocument10 pagesWJ 1992 09 PDFsn200709No ratings yet

- Bostrand 308LSiDocument1 pageBostrand 308LSisn200709No ratings yet

- Welding of Ferritic Creep-Resistant SteelsDocument3 pagesWelding of Ferritic Creep-Resistant Steelssn200709No ratings yet

- WJ 2009Document132 pagesWJ 2009sn200709No ratings yet

- Health, Safety and Accident PreventionDocument5 pagesHealth, Safety and Accident Preventionsn200709No ratings yet

- 压力容器ASME/ASTM与中国PV用材料对照Document2 pages压力容器ASME/ASTM与中国PV用材料对照sn200709No ratings yet

- Conversion Units, SI and Metric TableDocument1 pageConversion Units, SI and Metric TablebstfrndyrNo ratings yet

- Slide Chpt03Document34 pagesSlide Chpt03kt rajaNo ratings yet

- Natural DyeDocument21 pagesNatural Dyesanjay shettiNo ratings yet

- Score Higher On The Ukcat, 5Th Edition - 2019 UpdateDocument2 pagesScore Higher On The Ukcat, 5Th Edition - 2019 UpdateNikki Fish0% (1)

- III International Congress on Teaching Cases Related to Public and Nonprofit Marketing: Nestlé's CSR in Moga District, IndiaDocument8 pagesIII International Congress on Teaching Cases Related to Public and Nonprofit Marketing: Nestlé's CSR in Moga District, IndiaIshita KotakNo ratings yet

- Course 1 Introduction To SIMS: Student Information Management System (SIMS) Office of The RegistrarDocument28 pagesCourse 1 Introduction To SIMS: Student Information Management System (SIMS) Office of The RegistrarWeijia WangNo ratings yet

- Advert-Manager-Operational Risk and ComplianceDocument4 pagesAdvert-Manager-Operational Risk and ComplianceRashid BumarwaNo ratings yet

- Diesel Fuel Injection Pump Test Bench ANS12PSBDocument5 pagesDiesel Fuel Injection Pump Test Bench ANS12PSBseyden viaNo ratings yet

- Marty Schwartz Blues TipsDocument25 pagesMarty Schwartz Blues TipsEuCelNouNo ratings yet

- Accounting 26th Edition Warren Test BankDocument13 pagesAccounting 26th Edition Warren Test Bankmellow.duncical.v9vuq100% (28)

- RLE Journal CoverDocument2 pagesRLE Journal Coverrchellee689No ratings yet

- Service 31200800 11-13-13 CE-AUS English PDFDocument262 pagesService 31200800 11-13-13 CE-AUS English PDFduongpn100% (1)

- Politische StrategiesEnd 2012 de en FINALDocument405 pagesPolitische StrategiesEnd 2012 de en FINALFomeNo ratings yet

- Isuzu Libro 2 PDFDocument802 pagesIsuzu Libro 2 PDFjulia_23_22100% (2)

- The Cucumber Book Behaviour-Driven Development For Testers and DevelopersDocument28 pagesThe Cucumber Book Behaviour-Driven Development For Testers and DevelopersGursharan AulakhNo ratings yet

- 131b0314 - Im Danffos VLT ManualDocument108 pages131b0314 - Im Danffos VLT ManualMery Helen Barraza DelgadoNo ratings yet

- Data Sheet Sylomer SR 28 ENDocument4 pagesData Sheet Sylomer SR 28 ENlpczyfansNo ratings yet

- Asiignment 1 in TAX ADocument3 pagesAsiignment 1 in TAX ARonna Mae DungogNo ratings yet

- G.R. No. 208393, June 15, 2016Document3 pagesG.R. No. 208393, June 15, 2016jeliena-malazarteNo ratings yet

- Delta Ia-Mds VFDB I TC 20070719Document2 pagesDelta Ia-Mds VFDB I TC 20070719homa54404No ratings yet

- QRHDocument12 pagesQRHNwe OoNo ratings yet

- Mid-Term Test RemedialDocument2 pagesMid-Term Test RemedialgaliihputrobachtiarzenNo ratings yet

- Literature Review Economics SampleDocument8 pagesLiterature Review Economics Sampleafmzynegjunqfk100% (1)

- Completing The Accounting Cycle: © 2009 The Mcgraw-Hill Companies, Inc., All Rights ReservedDocument57 pagesCompleting The Accounting Cycle: © 2009 The Mcgraw-Hill Companies, Inc., All Rights ReservedPham Thi Hoa (K14 DN)No ratings yet

- Gobenciong v CA ruling on preventive suspensionDocument3 pagesGobenciong v CA ruling on preventive suspensionBambi GumbanNo ratings yet

- Operation Check: Check Panel & Steering SwitchDocument20 pagesOperation Check: Check Panel & Steering SwitchJack CardiagNo ratings yet

- The Puppet Masters: How The Corrupt Use Legal Structures To Hide Stolen Assets and What To Do About ItDocument284 pagesThe Puppet Masters: How The Corrupt Use Legal Structures To Hide Stolen Assets and What To Do About ItSteve B. SalongaNo ratings yet

- Set Up A Mail Server On LinuxDocument56 pagesSet Up A Mail Server On Linuxammurasikan6477No ratings yet

- Covid-19 Vaccine (Argumentative Essay) By: Karr GelladoDocument2 pagesCovid-19 Vaccine (Argumentative Essay) By: Karr GelladoKesha May GelladoNo ratings yet

- Ngos' Due Diligence and Risk Mitigation: A Holistic ApproachDocument54 pagesNgos' Due Diligence and Risk Mitigation: A Holistic ApproachMichel KozahNo ratings yet

- Google Inc 2014Document19 pagesGoogle Inc 2014Archit PateriaNo ratings yet