Professional Documents

Culture Documents

DIN 17100 Tablas

Uploaded by

anonimariumCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DIN 17100 Tablas

Uploaded by

anonimariumCopyright:

Available Formats

MEsteel - Qualities German DIN 17100 Carbon Steel & Stainless Steel

Pgina 1 de 2

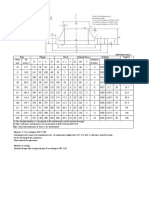

DIN 17100 Grade classification and chemical composition of the steels

Chemical composition in % by wt.

Chemical Composition in % by wt.

Ladle analysis

Sample Analysis

Steel grade

Material

Number

Type of

Deoxidation

New

30 40 < 1

Additional

Nitrogen

combining

elements

(e.g.at

least

0.02% A l

total)

>16

>40

16 30

>100

100

N

Steel

Grade

for product thicknesses in mm

>30

63

40

Max.

-

>63

>16 >30 >40

16

St.

1.0037

37-2

for Product thickness in mm

code

#

New

Max.

>63

100

Max

>100

Max

optional

0.17 0.20 0.20 0.20 0.20

0.050 0.050 0.009

0.21 0.25 0.25 0.25 0.25

0.065 0.065 0.010 St.37-2

Ust.

1.0036 1.0112

37-2

0.17 0.20 0.20 0.20 0.20

0.050 0.050 0.007

--

0.21 0.25 0.25 0.25 0.25

0.065 0.065 0.009

USt.372

Rst.

1.0038 1.0114

37-2

0.17 0.17 0.17 0.20 0.20

0.050 0.050 0.009

--

0.19 0.19 0.19 0.22 0.23

0.060 0.060 0.010

RSt.372

St.

1.0116 1.0116

37-3

RR

0.17 0.17 0.17 0.17 0.17

yes

0.19 0.19 0.19 0.19 0.19

0.050 0.050

St.37-3

--

0.24 0.24 0.24 0.25 0.25

0.060 0.060 0.010 St.44-2

by

0.040 0.040

agreement

---

St.441.0044

2

--

0.21 0.21 0.21 0.22 0.22

0.050 0.050 0.009

St.441.0144

3

--

RR

0.20 0.20 0.20 0.20 0.20

0.040 0.040

---

yes

0.23 0.23 0.23 0.23 0.23

0.050 0.050

St.44-3

St.521.0570 1.0841

3

RR

0.20 0.20 0.22 0.22 0.22

0.040 0.040

--

yes

0.22 0.22 0.24 0.24 0.24

0.050 0.050

St.52-3

St.501.0050 1.0532

2

--

--

--

--

--

--

0.050 0.050 0.009

--

--

--

--

--

--

0.060 0.050 0.010 St.50-2

St.601.0060 1.0542

2

--

--

--

--

--

--

0.050 0.050 0.009

--

--

--

--

--

--

0.060 0.060 0.010 St.60-2

St.701.0070 1.0632

2

--

--

--

--

--

--

0.050 0.050 0.009

--

--

--

--

--

--

0.060 0.060 0.010 St.70-2

Mechanical and technological properties of the steels in the as-delivered condition and/or condition of treatment according to

section 8.4.1.2

Mechanical and technological properties

Steel grade according to the above table

Tensile strength Rm

For Product thickness in mm

Upper yield point ReH

for product thickness in mm

>16 >40 >63 >80

3

<1

>100

40 63 80 100

100

Code No.

Material No.

St.33

1.0035

St.37-2

1.0037

USt.37-2

1.0036

RSt.37-2

1.0038

St.37-3

1.0116

St.44-2

1.0044

>100

16

N/mm2

N/mm2

310 up to 540 290 upto 510

185 175

235 225 215 205 195

360 upto 510 340 upto470

235 225 215 215 215

by agreemrnt

by agreement

430 upto 580 410 upto 540

275 265 255 245 235

St.44-3

1.0144

St.52-3

1.0570

510 upto 680 490 upto 630

355 345 335 325 315

St.50-2

1.0050

490 upto 660 470 upto 610

295 285 275 265 255

St.60-2

1.0060

590 upto 770 570 up to 710

335 325 315 305 295

St 70-2

1.0070

690 upto 900 670 upto 830

365 355 345 335 325

Mechanical and technological properties

Elongation at rupture

Steel

Grade

(Gauge length L=80 mm

Bending test (180 )

(Gauge length L= 5 d)

http://www.mesteel.com/info/german.htm

Notched-bar impact work

ISO V-notch specimens (longitudinal )

(Thickness of

28/09/2011

MEsteel - Qualities German DIN 17100 Carbon Steel & Stainless Steel

specimen) for

product thickness in

mm

for product specimen in mm

Position of

0,5 1 1,5 2 2,5 3 >40 >63

Specimen

Code

Number

< 1 < 1,5 < 2 <2,5 < 3 40 63 100

>100

Position of

Specimen

<3

% min

St 33

10

11

12

13

14

18

10

11

12

16

For Product thickness in

mm

Condition Temperature

of

3 >63

10 >16 >63

treatment

C

>100

>100

63 100

16 63 100

Mandrel diameter

J min

2.5a 3a

--

St 37-2

USt 372

RSt 372

Pgina 2 de 2

--

--

--

--

U, N

---

---

--

--

--

U, N

U, N,

U, N

+20

+20

+20

27

27

27

---------

------

+/- 0

27

27

23

-20

27

27

23

U,N

+ 20

27

27

---

+/- 20,

27

27

23

-20

27

27

23

+/- 0

27

27

23

- 20

27

27

23

by

agreement

3 a 3.5a

17

18

19

20

21

26

25

24

15

16

17

18

19

24

23

22

0,5a

1a 1,5a

1.5a

2a 2,5a

0,5a 1a 1a

Longitudinal

transverse 1a

1,5a 1,5a

-------

by

agreement

St 37-3

St 44-2

Longitudinal

St 44-3 transverse

St 52-3

by

agreement

15

16

17

18

22

21

20

12

13

14

15

16

20

19

18

2.5a 3a

14

12

15

16, 17

18

22

21

20

2a

13

14

15

16

20

19

18

2.5a 3a

3,5a

12

13

14

15

16

20

19

18

--

---

--

---

U, N

---

--

--

--

---

10

11

12

13

14

18

17

16

10

11

12

16

15

14

---

--

--

--

U, N

---

--

--

--

--

10

14

13

12

11

10

9

---

--

--

--

U, N

---

--

--

--

--

10

St 50-2

St 60-2

St 70-2

2a

2.5a 3a

---

14

U, N

3.5a

2,5a 3a

by

agreement

If you are no member yet, please fill registration form

(basic fee AED 1000/- or USD 275/- year only)

MEsteel.com, contact address : P.O.Box 57040, Dubai, United Arab Emirates, info@mesteel.com , Tel:+971-4-3494995 Fax:+971-4-3494997

MEsteel.com Home Page

Copyright 2000 mesteel.com. All rights reserved. Read Our Disclaimer

http://www.mesteel.com/info/german.htm

28/09/2011

You might also like

- Din 17100Document4 pagesDin 17100Sheby SandyNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Din Flange Din 2627: (Dimensions in MM.)Document12 pagesDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönNo ratings yet

- Welding of Dissimilar Ferritic Joints For New Power Plant SteelsDocument21 pagesWelding of Dissimilar Ferritic Joints For New Power Plant SteelsspinpinNo ratings yet

- Stainless Steel Alloys Comparsion ChartDocument3 pagesStainless Steel Alloys Comparsion Chartsengcyan100% (1)

- Filler Wires PDFDocument7 pagesFiller Wires PDFJayaram MVNo ratings yet

- S275JRDocument1 pageS275JRpsaayoNo ratings yet

- GMAW Guide for Welding Copper-Base AlloysDocument2 pagesGMAW Guide for Welding Copper-Base AlloysMaulana Mufti MuhammadNo ratings yet

- Equivalent Material Cross Valve CastDocument2 pagesEquivalent Material Cross Valve CastsviswaNo ratings yet

- Add02 1060.1Document14 pagesAdd02 1060.1Diego Calderón AlvaradoNo ratings yet

- JIS G3452 PipeDocument0 pagesJIS G3452 PipefaridyeniNo ratings yet

- P355NL2 50mmDocument5 pagesP355NL2 50mmslowmosquitoNo ratings yet

- Nip Material ComparsionDocument1 pageNip Material ComparsionRob WillestoneNo ratings yet

- 250L Air Compressor 8 Bar 1.6kWDocument1 page250L Air Compressor 8 Bar 1.6kWmih4iNo ratings yet

- Oliver Equation Paper-1928Document38 pagesOliver Equation Paper-1928dps32100% (1)

- Metal Chemical CompositionDocument1 pageMetal Chemical CompositionprathmeshNo ratings yet

- Public-: Rev. D E English 03 / 2014Document33 pagesPublic-: Rev. D E English 03 / 2014xaviereduardoNo ratings yet

- Welding Guidelines CuNiDocument8 pagesWelding Guidelines CuNiRadu-Gabriel GhergheNo ratings yet

- NPT Threaded and Socket Welding Fittings ANSI Standard 3000lbsDocument10 pagesNPT Threaded and Socket Welding Fittings ANSI Standard 3000lbsdandan29No ratings yet

- ASTM A131 Steel, Grade DDocument1 pageASTM A131 Steel, Grade DjulianmorantesNo ratings yet

- Calculate Weld Metal VolumeDocument7 pagesCalculate Weld Metal VolumeChris De La Torre0% (1)

- ESAB Consumable PDFDocument165 pagesESAB Consumable PDFbond8031No ratings yet

- Materials Guide for Over 50 AlloysDocument8 pagesMaterials Guide for Over 50 AlloysMark RomeroNo ratings yet

- Welding Bevel Design 3.1 Bevels For Other Than GTAW Root PassDocument2 pagesWelding Bevel Design 3.1 Bevels For Other Than GTAW Root PassaezeadNo ratings yet

- Steel Specification-Kalyani ForgeDocument8 pagesSteel Specification-Kalyani ForgedramiltNo ratings yet

- Fillet Weld Gauges: Phased Array Technology Writing WpssDocument44 pagesFillet Weld Gauges: Phased Array Technology Writing WpssKenshin HimuraNo ratings yet

- Welding Manual SummaryDocument18 pagesWelding Manual SummarycastmatamorosNo ratings yet

- Design and Analysis of Disc Plate in Hot Blast Valve #DN1800Document8 pagesDesign and Analysis of Disc Plate in Hot Blast Valve #DN1800MounicaRasagyaPallaNo ratings yet

- C43Document1 pageC43rudramansingh123No ratings yet

- Welding Procedure Standards and Qualification CodesDocument4 pagesWelding Procedure Standards and Qualification CodesBalkishan DyavanapellyNo ratings yet

- Flange Face Surface FinishDocument2 pagesFlange Face Surface FinishJoel Ashley D'SouzaNo ratings yet

- Tigweldarc Alloys: Certification of TestsDocument1 pageTigweldarc Alloys: Certification of TestsArunNo ratings yet

- G12MF TypeDocument1 pageG12MF Typeosto72No ratings yet

- Saisc Structural Steel Section PropertiesDocument12 pagesSaisc Structural Steel Section PropertiesAnantPawarNo ratings yet

- Omni Block - BrochureDocument2 pagesOmni Block - BrochureJames100% (1)

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- Steel EquivalentDocument1 pageSteel EquivalentGhantex TradNo ratings yet

- Impact AR500 PlateDocument2 pagesImpact AR500 PlateMario Diez100% (1)

- 2019 Product Catalog WebDocument104 pages2019 Product Catalog WebIan Niko100% (1)

- Triple Eccentric Metal Seated ValvesDocument4 pagesTriple Eccentric Metal Seated ValvesFelipe Gamboa GálvezNo ratings yet

- AISI 12L14 Steel Analysis and PropertiesDocument2 pagesAISI 12L14 Steel Analysis and PropertiessyuepiNo ratings yet

- Voestalpine Heavy Plate TTD DUROSTAT E 10042015Document16 pagesVoestalpine Heavy Plate TTD DUROSTAT E 10042015Ella Byla SaraNo ratings yet

- PED Compliance for Pressure Equipment ComponentsDocument7 pagesPED Compliance for Pressure Equipment ComponentsEymen KulNo ratings yet

- Thermanit MTS 3 - GTAWDocument1 pageThermanit MTS 3 - GTAWdnageshm4n244No ratings yet

- Casting Material WCBDocument8 pagesCasting Material WCBYusri WyeuserieyNo ratings yet

- En 10025-2 ExtractDocument1 pageEn 10025-2 Extractpalani.djpNo ratings yet

- Boq For AS BoilerDocument1 pageBoq For AS BoilerGayan ChathurangaNo ratings yet

- Flanges & Pipe Fittings SpecificationsDocument3 pagesFlanges & Pipe Fittings Specificationsmcoswald83No ratings yet

- DIN EN ISO 9013 - Angular Deviation PDFDocument1 pageDIN EN ISO 9013 - Angular Deviation PDFflorinelvvNo ratings yet

- Carbon Steel Specifications and ApplicationsDocument2 pagesCarbon Steel Specifications and ApplicationsRajendraNo ratings yet

- Welding ElotrodeDocument3 pagesWelding ElotrodeNiranjan khatuaNo ratings yet

- Pulleys - Sole Plates - Standard Sole Plate DataDocument3 pagesPulleys - Sole Plates - Standard Sole Plate DataWaris La Joi Wakatobi0% (1)

- A338 Steel StandardDocument2 pagesA338 Steel StandardguilhermehsssNo ratings yet

- Applied Metrology for Manufacturing EngineeringFrom EverandApplied Metrology for Manufacturing EngineeringRating: 5 out of 5 stars5/5 (1)

- Geo Servic PDFDocument3 pagesGeo Servic PDFSamiyonoNo ratings yet

- EffectOfThermo PhysicalpropertDocument17 pagesEffectOfThermo Physicalproperthache eseeseNo ratings yet

- Brayton Cycle (Or Joule Cycle) PDFDocument19 pagesBrayton Cycle (Or Joule Cycle) PDFhozipek5599No ratings yet

- Grade 7 Science Unified Test 1 QuarterDocument6 pagesGrade 7 Science Unified Test 1 QuarterMichael Deliva100% (1)

- Experiment 4: Effect of Concentration and Temperature On Rate of Reaction (Dissappearing Cross)Document24 pagesExperiment 4: Effect of Concentration and Temperature On Rate of Reaction (Dissappearing Cross)Malini RajeshNo ratings yet

- Chryso - MCSWMPDocument21 pagesChryso - MCSWMPkasun89No ratings yet

- Pirs509a BeamnrcDocument289 pagesPirs509a BeamnrcskcomhackerNo ratings yet

- Chapter 8 Multiple-Choice QuestionsDocument11 pagesChapter 8 Multiple-Choice Questionsteresa tsoiNo ratings yet

- MSDSDocument3 pagesMSDSr1robbynNo ratings yet

- System Chroma 21Document28 pagesSystem Chroma 21Omar CaruanaNo ratings yet

- Eb MandilDocument2 pagesEb MandilCorporación JolucavaNo ratings yet

- Lesson 1.1 The Formation of The Light Elements in The Big Bang TheoryDocument9 pagesLesson 1.1 The Formation of The Light Elements in The Big Bang TheoryAimee MarangaNo ratings yet

- Radiopharmaceutical Design and DevelopmentDocument111 pagesRadiopharmaceutical Design and Developmentarun231187No ratings yet

- Ger 3928c Uprate Options Ms9001 Heavy Duty Gas TurbineDocument58 pagesGer 3928c Uprate Options Ms9001 Heavy Duty Gas Turbineamir moniriNo ratings yet

- Concentration of SolutionDocument3 pagesConcentration of SolutionJoon Bok NamleeNo ratings yet

- Fundamentals ThoughtsDocument21 pagesFundamentals ThoughtsNicole Casanova0% (1)

- Local and Post-Local Buckling of Fabricated High-Strength Steel and Composite Columns, 2019 (Zhichao Huang) PDFDocument15 pagesLocal and Post-Local Buckling of Fabricated High-Strength Steel and Composite Columns, 2019 (Zhichao Huang) PDFPhan Đào Hoàng HiệpNo ratings yet

- CRSO Meeting Shielding Calculations PresentationDocument34 pagesCRSO Meeting Shielding Calculations PresentationJared Medina BlanquicettNo ratings yet

- Chemistry ProjectDocument28 pagesChemistry ProjectVikramjeet Singh82% (11)

- Tech Spec - SLPB120255255 - 75ahDocument12 pagesTech Spec - SLPB120255255 - 75ahMuhammadWaqarButtNo ratings yet

- Adv Compressor ControlsDocument8 pagesAdv Compressor Controlspartha6789No ratings yet

- Geethanjali ResumeDocument6 pagesGeethanjali ResumeGeetha AnjaliNo ratings yet

- Calibration, Validation, Qualification and System Suitability Tests in The ElectrochemistryDocument29 pagesCalibration, Validation, Qualification and System Suitability Tests in The ElectrochemistryVision2011100% (1)

- Well Test Course NotesDocument522 pagesWell Test Course NotesBulan BintangNo ratings yet

- Engine Fault Code Diagnostic GuideDocument6 pagesEngine Fault Code Diagnostic Guidehs421100% (2)

- Chapter 1.1Document103 pagesChapter 1.1Shubham RathiNo ratings yet

- AQAGloss X 8 AnDocument59 pagesAQAGloss X 8 AnArturo Ibarra MonfónNo ratings yet

- Tegomer Da 640 0419 en Oi PiDocument2 pagesTegomer Da 640 0419 en Oi Piهیمن مNo ratings yet

- Code Bright GiDDocument81 pagesCode Bright GiDjoserommariobarbozas0% (1)