Professional Documents

Culture Documents

Manager or Director

Uploaded by

api-122238908Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manager or Director

Uploaded by

api-122238908Copyright:

Available Formats

Wendell A. Bradley Greater Atlanta Area | 678-849-1107 | wb1e3b63e@westpost.net | www.linkedi n.

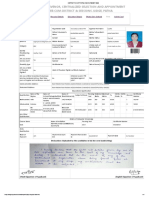

com/in/wendellbradley Vendor Manager / Director of Operations / Manager of Fulfillment Operations Confident, results-oriented operations leader and vendor advocate. Proven abilit y to thrive in extremely high volume production operations. Consistently able to leverage advanced technology to improve business results. Known for completing increasingly demanding projects on-time and under budget. An exceptional leader and trainer with a -can do- attitude whose integrity is beyond reproach. B.A., b usiness administration. Core competencies include: Vendor management. At GE, I lead a project team of six, third-party vendor and GE team members to improve the vendor invoice review process. This review requir ed a strong working knowledge of the production contract and a good client relat ionship that resulted in reducing vendor billing errors and recovering $3.7M. Quality management and process improvement. I am certified both as a Six Sigma Green Belt and TQM quality manager. I identified 400,000 consumer products that had not been fulfilled or distributed according to service agreements; this ide ntification and intervention/problem resolution prevented contractual, client pe nalties that could have escalated in the millions of dollars. Operations leadership. At DST Output, I lead a team of five direct reports and 200+ production associates that fulfilled and distributed millions of consumer p roducts annually. Over a two-year period at GE, I led a cross-functional project team that replaced out-of-date barcode technology across the enterprise that re sulted in multi-million dollar cost avoidance to the division`s profit and loss statement. Professional Experience 2004 - 2011 | GE Capital Finance | Alpharetta, Georgia Daily Production Manager / Production Vendor Manager Co-managed the production services agreement for a third-party vendor with 500+ associates. The vendor fulfilled and distributed consumer and commercial produc ts. Principal vendor manager for the daily oversight of all third-party production contracts and the personalization, fulfillment, distribution and procurement of all manufacturing materials. As problem resolution manager, all reported discrepancies were satisfied accord ing to contract specifications resulting in a 51% reduction of all escalated iss ues. Ensured that contractual production, six sigma service levels and performance m etrics were achieved for all aspects of production / fulfillment / distribution / procurement and finance. Provided production contract interpretation and pricing to include budget forec asts. Developed requests and analyzed data for Requests For Information and Proposal, selected vendors, created term sheets and negotiated / finalized master service agreements that resulted in an enterprise savings of $8,000,000. Lead a multi-disciplined project team that consisted of third-party vendor and enterprise team members whose charter was to replace the existing product barcod e technology with a more robust and universal format for all consumer and commer cial products to be in compliance; the project resulted in a multi-million dolla r P&L cost avoidance. Managed a project team of six, third-party vendor and enterprise finance team m embers to improve the vendor invoice accuracy. As team leader, I provided a stro ng working knowledge of the production contract. The project team was able to r educe billing errors and recover $3.7M. 1997 - 2003 | DST Output | Kansas City, Missouri Director, Production Operations Lead daily operations with five direct reports and 200+ associates with direct

responsibility of the production Profit and Loss Statement. As a member of the DST Output new construction team for output services, I prov ided the functional team and equipment layout for the delivery of a 300,000 squa re foot, state-of-the art production facility. I worked to compress the movemen t of 1,900+ collateral materials, 100 state-of-the-art production platforms, var ious other equipment, and personnel from the old site to the new plant in a 45-d ay window that resulted in zero impact to client service levels and quality metr ics. Provided cradle-to-grave processing for 300+ mutual fund client products and le ad production teams to achieve an overall 99% product, delivery performance for the first-time in company history. I negotiated all vendor contracts for equipment and maintenance improving up-ti me performance by 23% and reducing costs by several hundred thousand dollars. Effectively coordinated 300+ clients` production scheduling and receipt of mate rials at various off-site storage facilities and the redistribution of said mate rials throughout the production environment resulting in 11% improvement of just -in-time job kitting. Served as corporate liaison to the US Postal Service and was the corporate post al affairs subject matter expert. 1995 - 1997 | ZipDirect Presort Service Bureau | Kansas City, Missouri General Manager Responsible for the daily operation of a USPS mail sorting operation and the di rect management of 54 associates, three sales team members, effective customer r elations, postage escrow payments, technical alliances, and a $3,000,000 Profit and Loss statement. Negotiated a work share contract with USPS to become a certified vendor. Once t he new contract was completed and in six months, the marketing campaign realized 100 new clients for the business and a 500% increase in client mail volume. Enhanced national mailing distribution sort schemes to streamline machine perfo rmance. These improved plans reduced the number of times a machine scanned each mail piece by 30% and reduced the cost of annual sort machine maintenance contra cts by $200,000. Incoming mail was sorted and presented daily to the U.S. Postal Service; result ing in the successful, weekly national shipping of approximately 2,000,000 lette rs and checks. Developed a postal quality receiving program for incoming mail. Quality inspect ed all mail received by client, product, price and address integrity. Improved m ail receiving and equipment utilization process by 37%; mail accepted by the USP S improved by 29% that significantly reduced. Served as corporate liaison to the US Postal Service and was the corporate post al affairs subject matter expert. 1974-1995 | U.S. Army Military and Civilian Personnel Technician/Warrant Officer Duties and responsibilities included, but were not limited to: systems and data base management, manpower accountability and reporting; officer and enlisted rec ords management; enlisted personnel management and requisition authority; identi fication cards; world-wide reassignments and orders authority; awards and decora tions; officer and enlisted separations and discharges; officer and enlisted pro motions; officer and enlisted retirement processing; payroll and policy administ ration. Education and Certifications B.A., Business Administration | Saint Leo College | St. Leo, Florida Certifications Six Sigma, Green Belt Six Sigma Lean Manufacturing CMDSM, Certified Mail Distribution Service Manager

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Method Statement Pressure TestingDocument15 pagesMethod Statement Pressure TestingAkmaldeen AhamedNo ratings yet

- Tensile TestDocument23 pagesTensile TestHazirah Achik67% (3)

- Cursos Link 2Document3 pagesCursos Link 2Diego Alves100% (7)

- Guidelines To MAS Notice 626 April 2015Document62 pagesGuidelines To MAS Notice 626 April 2015Wr OngNo ratings yet

- Attribute Achievement FormDocument15 pagesAttribute Achievement FormMiguel MenesesNo ratings yet

- Aluminium FOil SearchDocument8 pagesAluminium FOil SearchAtul KumarNo ratings yet

- Site AnalysisDocument15 pagesSite Analysismaanik005No ratings yet

- Biometric SecurityDocument495 pagesBiometric SecurityPlay100% (1)

- Nistha Tamrakar Chicago Newa VIIDocument2 pagesNistha Tamrakar Chicago Newa VIIKeshar Man Tamrakar (केशरमान ताम्राकार )No ratings yet

- Raj Priya Civil Court Clerk FinalDocument1 pageRaj Priya Civil Court Clerk FinalRaj KamalNo ratings yet

- Chiller Carrier - 30gn-9siDocument28 pagesChiller Carrier - 30gn-9siZJ Limited (ZJLimited)No ratings yet

- Data Structures LightHall ClassDocument43 pagesData Structures LightHall ClassIwuchukwu ChiomaNo ratings yet

- High Volume InstrumentDocument15 pagesHigh Volume Instrumentcario galleryNo ratings yet

- Communication in Application: WhatsappDocument18 pagesCommunication in Application: WhatsappNurul SuhanaNo ratings yet

- The Meaning of Solar CookerDocument4 pagesThe Meaning of Solar CookerJaridah Mat YakobNo ratings yet

- Berserker - Lifting Wood and Stone Like A Viking Strongman Bodybuilding Functional StrengthDocument10 pagesBerserker - Lifting Wood and Stone Like A Viking Strongman Bodybuilding Functional Strengthluciferr71No ratings yet

- Electronic Throttle ControlDocument67 pagesElectronic Throttle Controlmkisa70100% (1)

- New Microsoft Word DocumentDocument1 pageNew Microsoft Word Documentshubhangiw17No ratings yet

- MCS Adopts Milyli Software Redaction Tool BlackoutDocument3 pagesMCS Adopts Milyli Software Redaction Tool BlackoutPR.comNo ratings yet

- Chenab Railway Bridge Project ReportDocument50 pagesChenab Railway Bridge Project ReportPreet Chahal100% (1)

- The Act of Proclamation of The Independence of The Filipino PeopleDocument33 pagesThe Act of Proclamation of The Independence of The Filipino PeopleJULIANA RAE CONTRERASNo ratings yet

- Ferain Et Al, 2016 - The Fatty Acid Profile of Rainbow Trout Liver Cells Modulates Their Tolerance To Methylmercury and CadmiumDocument12 pagesFerain Et Al, 2016 - The Fatty Acid Profile of Rainbow Trout Liver Cells Modulates Their Tolerance To Methylmercury and Cadmiumarthur5927No ratings yet

- PENGARUH CYBERBULLYING BODY SHAMING TERHADAP KEPERCAYAAN DIRIDocument15 pagesPENGARUH CYBERBULLYING BODY SHAMING TERHADAP KEPERCAYAAN DIRIRizky Hizrah WumuNo ratings yet

- Tips For Effective Presentation Design and DeliveryDocument2 pagesTips For Effective Presentation Design and DeliveryJames Manrique100% (1)

- Product Data Sheet: Eas Configurator: Easy Online Configuration Ekv1+1 120 Vg4Gxhq (Vg4Gxhq)Document1 pageProduct Data Sheet: Eas Configurator: Easy Online Configuration Ekv1+1 120 Vg4Gxhq (Vg4Gxhq)Attila HorvathNo ratings yet

- Simple Present 60991Document17 pagesSimple Present 60991Ketua EE 2021 AndrianoNo ratings yet

- Wicks Angela, Roethlein Christopher - A Satisfaction - Based Definition of QualityDocument1 pageWicks Angela, Roethlein Christopher - A Satisfaction - Based Definition of Qualityalfdjole0% (1)

- DRUG LISTDocument45 pagesDRUG LISTAmitKumarNo ratings yet

- 2-STM Answers SokhaDocument6 pages2-STM Answers SokhamenghokcNo ratings yet

- Reasons for Conducting Qualitative ResearchDocument12 pagesReasons for Conducting Qualitative ResearchMa. Rhona Faye MedesNo ratings yet