Professional Documents

Culture Documents

Conveyers - Making Our World

Uploaded by

kirstenrileyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conveyers - Making Our World

Uploaded by

kirstenrileyCopyright:

Available Formats

2

Title

1. Free-Flowing Conveyor Technologies

Page #

3

2. Types of Conveyors and Their Practical Uses

3. Popular Applications of a Belt Conveyor

4. I'll Have My Order on a Conveyor Belt, Please

5. The Value of Conveyor Systems in Today's World

11

www.robotunits.com.au

Free-Flowing Conveyor Technologies

Elementary school-level science classes have taught children about the different instances in history when man invented ways for moving objects before the wheel was formally used. Close your eyes and picture visual aids from your early education years, where Egyptians would be moving gigantic bricks used in building the giant pyramids. How are they moving those enormous blocks along? With the help of logs, laid out in a row, over which the bricks are placed. The brick is then pulled forward using ropes, with the logs rolling underneath. As the brick launches forward, the logs that get left behind it are carried and placed in front of the brick, and this process is continued until the brick reaches its destinations. They must have been at this back-breaking task for a while, but the Egyptians were surely on to something. Those laid-out logs must surely have been the inspiration for the non-powered conveyor equipment that we see in use every day. Conveyors are essential tools in materials-handling industries. Wherever there are a large number of products or items to be loaded and transported, there are sure to be conveyor systems in place to ensure that they are delivered from one area of a factory or warehouse to another. Large scale industries will call for models that can hold heavy or bulky items, such as components of a car, electronics parts, or even carcasses of livestock about to be processed for food products. In

www.robotunits.com.au

these cases, overhead conveyors will effectively carry these large items to different sections of a factory as needed. For simpler operations, however, non-powered conveyors are perfect for the job. A roller conveyor makes use of gravity to propel an object along over its cylinders, and is perfect for moving flat- and unevenbottomed items alike, such as cartons and cans. An aluminum or steel skatewheel is also a good and more lightweight option; its portability allows its use in a wide variety of locations such as shipping areas and pickand-pack stations. There is a gravity-powered version of the mechanized belt conveyor as well; it would translate to a roller conveyor belt with a rubber sheet covering, ideal for moving loads for inclines and declines. The rubber sheet prevents incidents of slipping, even for smooth-bottomed cartons and packages. Machines are valuable tools in large operations, but for simple loading and transporting needs, simple mechanisms can also work best. Remember how the Egyptians moved their bricks, and look at what they were able to create! Anything can truly be done if you have the right tools for the job.

www.robotunits.com.au

Types of Conveyors and Their Practical Uses

Do you remember the last time you packed up and moved to a new place? All those days hauling your things in big boxes and carrying them up and down several flights of stairs were surely exhausting. And that was before you got to your new apartment, on the 11th floor. When it comes to heavy loads, we always wish that there were better solutions to help us. There is only so much weight a single person can carry by himself. Carrying large and heavy objects with the help of other people would require plenty of strength and endurance, too, before the group would have to stop for some much-needed rest. If your day job involves a lot of heavy lifting, there is a limit to how much work you can take. This would not be a very ideal work arrangement for you, as the job requires heavy physical labor. The productivity of the day would rely on your physical well-being at the moment; this is not good news to your employer, either, who may need several heavy loads moved in a day. Out of this sort of necessity came the introduction of machinery that can help men with lifting and transporting heavy materials, in large or small scales as necessary. Conveyor systems are used to move heavy or bulky items from one point to another, eliminating the need for manpower in the process of carrying and moving items. A conveyor belt can come in a wide range of shapes and sizes. Some can be as small as the common ones you see in supermarket checkout counters, for moving small objects. There are also large-scale belts to hold bigger-sized objects or larger amounts of products.

www.robotunits.com.au

The use of modular conveyors has several advantages: the tracking of the belt is secure no matter what the application; the possibility of slippage is eliminated due to the construction and resistance of the belt, thus allowing higher loads; the conveyor can run in both directions, allowing for more flexible operations. For even greater convenience, a company handling large boxes of supplies can use a timing belt conveyor. It comes with a self-tracking timer that allows for the smooth and safe delivery of loaded items. It enables even spacing between items and controls them from going forward while one item has been separated, for example, for weighing or packaging. Curved conveyors can also be useful for manufacturing facilities with limited space. They can be customized to fit specifications and will still perform as well as standard-shaped belts. With technological advances and simple mechanical tweaks, some tasks need not become back-breaking work. We can make use of machines and equipment that can make every day functions easier and simpler for us to perform. Keep that in mind the next time you're faced with another fully packed boxthere's always a better way.

www.robotunits.com.au

Popular Applications of a Belt Conveyor

Yesterday, you stepped on them. You may have walked all over them this afternoon. Last week, you placed a bunch of bananas, a carton of milk, and the rest of your groceries on top of them. Figured it out yet? If you're wondering what object you could possibly place both your groceries and your feet on, don't be alarmed. We're talking about a belt conveyor (or conveyor belt). It's present in more everyday applications than you'd expect! This piece of machinery is made up of two or more pulleys and a flat material, such as rubber, that is looped and rotated around them. Using it would require powering one or both of the pulleys, so that any item you place on the rubber belt will be propelled forward or backward. In industrial settings, a belt conveyor is commonly used in two ways. Materials handling would call for using a belt to move boxes of supplies from one part of a factory or warehouse to another. In bulk materials handling, however, it is often used outdoors for moving agricultural or industrial products like coal and various types of grains. Generally, this machine is designed to make transporting heavy materials from one point to another easier, and in a fixed setting, compared to using transport vehicles or manpower in carrying the supplies around. In more commercial settings, you're sure to have encountered this technology already. Grocery stores install small conveyors at their

www.robotunits.com.au

check-out counters to help shoppers and check-out personnel in moving the purchased items along. This is one convenience that we have been enjoying for quite some time now. Another example? Surely you've visited the shopping mall recently, and you have stepped onto an escalator to get to the upper floor. Or perhaps you may have entered an airport recently that features a walkalator or a moving sidewalk within its premises, to help passengers with heavy luggage. Those are types of conveyor transport, too. The main purpose of these mechanized belts is to provide a more convenient means of moving items from place to placeitems that people would otherwise have to carry themselves. In the case of escalators, on the other hand, people are provided an easier means to get from one part of a building to another without walking. Easier, and betterthere are always areas of everyday life that can be improved on, and these little luxuries are experienced by people around the world, thanks to conveyor systems.

www.robotunits.com.au

I'll Have My Order on a Conveyor Belt, Please

You may have only seen or heard about this type of machinery from the last Japanese restaurant you recently dined in. You were so fascinated about the restaurant's main attraction, a seemingly miniature "railroad track" laden with plates of sushi and bowls of rice toppings and running at a steady pace along each dining table. Diners can simply observe the motorized parade of Japanese specialties and reach out to get the dish of their choice. You thought the restaurant was so smart to have thought of a fun way to serve food, and it was so convenient to see the little dishes for yourself passing by your table. Convenient? Correct. That miniature "railroad track" is a conveyor belt, a machine that enables easier ways of moving objects from one point to another. A Japanese restaurant (sometimes, even a dim sum restaurant) is just one instance wherein a conveyor can be used for practical everyday purposes. A conveyor belt is commonly used by large-scale materials handling companies; it is used to move heavy loads such as construction equipment and sacks of cement or sand. There are also smallersized systems that are put in place in warehouses, where delivery trucks can unload their goods straight onto a belt to be carried inside, and vice-versa. A better-known use for them, however, would be in factories, with raw materials placed on the belts. As the materials pass by different sections of the factory, workers add parts piece by piece, so that by the final stage of production, a complete product is assembled and ready to pack in their dedicated packaging.

www.robotunits.com.au

10

The use of conveyors in sushi restaurants stemmed from necessity. A restaurant owner named Yoshiaki Shiriashi was facing problems with putting together a staff that would serve food to his customers, and he was generally unable to handle managing the restaurant by himself. As a solution to his dilemma, he brushed up on designs of conveyor systems and had them applied to his restaurant. Soon enough, his system replaced the need for a service crew that normally went from the kitchen to the dining tables and back. Food could simply be placed on the belt; conveyor power would bring the dishes to the tables, and customers can just reach out and get the ones that they fancied. This type of dining service is popular for customers who wish to try Japanese food but are hesitant because of the inability to read or speak Japanese, thinking that they may not be able to understand the offerings listed in a typical menu. Families with children also enjoy seeing the different types of dishes and picking something out for themselves. Technological innovations are always about making processes simpler to do, and this example is surely no exception. Try visiting a sushi restaurant like this one soon, and have a great time scooping up one dish after another off that mini "railroad track."

10

www.robotunits.com.au

11

The Value of Conveyor Systems in Todays World

Modern man has come a long way in terms of industrial innovations that simplify the way we do things today. Labor has certainly changed through time; from hundreds of men digging out tunnels and roads with their hands and shovels, we now have heavy machinery that can practically move the earth. Harvesting the fruits of the land by hand, which used to be time-consuming and laborious, can now be done with special equipment. Mechanized solutions are improving by the day, paving the way for the creation of better products, with more varieties, and in enormous quantities to enable their distribution to people all over the world. In the business of producing common necessities by the billion-fold, certain types of equipment make the entire process possible, and foremost would be solid conveyor systems. A conveyor is a piece of mechanical handling equipment designed to transport items from one location to another. It is commonly used to move heavy and bulky items around, often in large quantities, in industrial facilities. Using human labor for these tasks would be difficult and time-consuming otherwise, so packaging or bulk materials handling companies choose to use this technology in their operations. You have surely seen this machine in action. If you have ever been inside a factory or production plant of some kind, or if you have watched any television program featuring industrial processes, you're bound to have come across an example.

11

www.robotunits.com.au

12

Overhead conveyors with automotive components hanging from them are a common sight inside factories that put vehicles together. Printing presses use a belt conveyor to carry out newspapers to the delivery area. Virtually any mass-produced product would be sorted or transported around a factory at some point using a beltpencils, pills, powders, you name it. The food processing industry also uses this equipment in various applications. Beverage and sauce-producing plants use a conveyor belt to line up bottles and jars for filling. You may have also heard about a belt with rows upon rows of chocolate truffles and bars being passed under a powdered sugar-dusting section or caramel-drizzling area of a candy factory. Canned products can also be loaded and passed through a labeling or heat sealing section. For the mass-production arm of any manufacturing company, conveyor systems are valuable tools in getting their job done. Without them, it would be more difficult to receive and send out the supplies and tools that make production possible, and we wouldn't have access to many of the products we enjoy today.

12

www.robotunits.com.au

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- By: Chhavi Bajaj Priya VermaDocument33 pagesBy: Chhavi Bajaj Priya VermaAkashVermaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- IkeaDocument8 pagesIkeaNirnay Prakhar100% (2)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Katalog New Biskuit 2022 - New + BarcodeDocument34 pagesKatalog New Biskuit 2022 - New + BarcodeEbie NaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Tugas BING FDocument7 pagesTugas BING FEmilyNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Warsash Private AccommodationDocument8 pagesWarsash Private AccommodationLovepreet ShahNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Past Tense FceDocument7 pagesPast Tense FcebralecriNo ratings yet

- Colocasia GiganteaDocument5 pagesColocasia GiganteaRonald Deck YamiNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Begin Goat Farming with DVBF's Profitable PackageDocument16 pagesBegin Goat Farming with DVBF's Profitable PackageGiacenNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Delivery Man ScriptDocument14 pagesDelivery Man ScriptJayhze DizonNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Organic PotDocument33 pagesOrganic PotAnonymous 7hVvWKNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- DRP ENGLISH Skill C Exercise 1 13Document7 pagesDRP ENGLISH Skill C Exercise 1 13rossana rondaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Growth MonitoringDocument44 pagesGrowth MonitoringPrakash C Raavudi100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Narrative Writing For UPSRDocument41 pagesNarrative Writing For UPSRLetchumy MaripanNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Sex and Studies: Working As An Escort To Pay TuitionDocument20 pagesSex and Studies: Working As An Escort To Pay Tuitionnexusnewspaper100% (2)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- BAR OPERATIONS GUIDEDocument11 pagesBAR OPERATIONS GUIDERishabh ChawdaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- ABV Calculator (Scribd Preview)Document2 pagesABV Calculator (Scribd Preview)ScotchHobbyistNo ratings yet

- TRIBEDocument17 pagesTRIBEAmor Ladera-OrchidaceaeNo ratings yet

- Feeding Program Activity DesignDocument2 pagesFeeding Program Activity DesignCAMILLE RAMOSNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Number 6 Pack - 2020Document16 pagesNumber 6 Pack - 2020Jorg SchumacherNo ratings yet

- Chippiparai Breed of Dogs in Tamil Nadu: An Assessment of Physical and Performance CharacteristicsDocument6 pagesChippiparai Breed of Dogs in Tamil Nadu: An Assessment of Physical and Performance CharacteristicsDrRameem BlochNo ratings yet

- Tugas: Bahasa Inggris: SMK Negeri 1 Unaaha 2017/2018Document6 pagesTugas: Bahasa Inggris: SMK Negeri 1 Unaaha 2017/2018Eko ServoNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

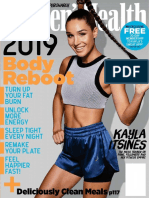

- Women's Health - February 2019 AU PDFDocument140 pagesWomen's Health - February 2019 AU PDFIsabellaVoyerNo ratings yet

- Verbals MetodichkaDocument106 pagesVerbals MetodichkaAnyaKazakovaNo ratings yet

- Midsummer Woman at the WellDocument7 pagesMidsummer Woman at the WellSarah Jik-ismNo ratings yet

- READING AND WRITING - Q1 - W2 - Mod2Document13 pagesREADING AND WRITING - Q1 - W2 - Mod2Gabriel CabansagNo ratings yet

- Basic Water RequirementsDocument10 pagesBasic Water RequirementsdimaomarNo ratings yet

- Bridges - June 2012Document9 pagesBridges - June 2012ppranckeNo ratings yet

- The Present Perfect Is Used To Talk About An Event That Began in The Past and Continues Up To The PresentDocument17 pagesThe Present Perfect Is Used To Talk About An Event That Began in The Past and Continues Up To The PresentRodinei VieiraNo ratings yet

- COLD MERCHANDISING SOLUTIONS DELIVERING EXCELLENCEDocument2 pagesCOLD MERCHANDISING SOLUTIONS DELIVERING EXCELLENCEMa. Rodiza DayocNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Clen And T3 Vs. DNP - Which Is Better For Fat LossDocument15 pagesClen And T3 Vs. DNP - Which Is Better For Fat LossAnonymous CUOZmdNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)