Professional Documents

Culture Documents

W201 en

Uploaded by

Aelya SanctuaryOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

W201 en

Uploaded by

Aelya SanctuaryCopyright:

Available Formats

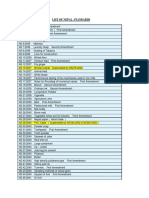

Data Sheet W201 Issue 02/08

DISPERBYK-170

DISPERBYK-171

DISPERBYK-174

High Molecular Weight Wetting and Dispersing Additives for Solvent-Borne Systems and Pigment Concentrates

Composition

DISPERBYK-170 DISPERBYK-171 DISPERBYK-174 Solutions of high molecular weight block copolymers with pigment affinic groups

Typical Properties

Acid value in mg KOH/g DISPERBYK-170 DISPERBYK-171 DISPERBYK-174 Density at 20C in g/ml Non-volatile matter in % 30,0 39,5 Flash point in C 36 > 35 24

11 1,02 Solvents: Methoxypropylacetate/Butylacetate 6/1 13 1,01 Solvents: Methoxypropylacetate/Butylacetate 4/1

22 0,97 52,5 Solvents: Xylene/Methoxypropylacetate/Butylacetate 3/2/1

Values indicated in this data sheet describe typical properties and do not constitute specification limits.

Recommended Levels

% additive (as supplied) based upon inorganic pigments DISPERBYK-170 DISPERBYK-171 DISPERBYK-174 10 - 20 10 - 18 10 - 15 titanium dioxide 5-6 4-6 3-5 organic pigments 35 - 70 30 - 60 35 - 60 carbon blacks 70 - 140 70 - 120 70 - 100

The above mentioned usage levels strongly depend on pigment particle size. Optimal levels are determined through a series of laboratory tests.

Incorporation and Processing Instructions

The additives should be incorporated into the millbase before adding the pigments.

Data Sheet W201 Issue 02/08

Applications

Coil coatings DISPERBYK-170 DISPERBYK-171 DISPERBYK-174 recommended suitable Industrial coatings Automotive coatings

Function

These additives deflocculate pigments through steric stabilization of the pigments. Due to the small particle sizes of the deflocculated pigments, high gloss is achieved and color strength improved. Additionally, transparency and hiding power are increased. These products reduce viscosity, subsequently, leveling is improved and higher pigment loading is possible.

Special Features and Benefits

DISPERBYK-170 DISPERBYK-170 has an extremely high molecular weight. Accordingly, it imparts excellent stabilization of inorganic and organic pigments. DISPERBYK-170 is used primarily in acid-catalyzed polyester/ melamine topcoats and PVdF systems. DISPERBYK-171 has a slightly lower molecular weight than DISPERBYK-170 and consequently displays a wider compatibility with many grinding polyester resins. Therefore, DISPERBYK-171 can also be utilized in highly filled pigment concentrate formulations. In some systems, DISPERBYK-171 may improve adhesion to aluminium substrates. DISPERBYK-174 is especially suitable for producing pigment concentrates. In addition to stabilizing pigments, DISPERBYK-174 reduces millbase viscosity, thus enabling the formulator to produce highly filled pigment concentrates without difficulty.

DISPERBYK-171

DISPERBYK-174

Special Note

DISPERBYK-170 DISPERBYK-171 DISPERBYK-174 When using these additives in two-component isocyanate-systems, pot-life and other parameters should be checked.

Storage and Transportation

DISPERBYK-170 DISPERBYK-171 DISPERBYK-174 Separation or turbidity may occur at temperatures below 0C. Warm to 20C and mix well. Separation or turbidity may occur at temperatures below 5C. Warm to 20C and mix well.

BYK-Chemie GmbH P.O. Box 10 0245 46462 Wesel Germany Tel +49 281 670-0 Fax +49 281 65735 info@byk.com www.byk.com/additives

ANTI-TERRA, BYK, BYK-DYNWET, BYK-SILCLEAN, BYKANOL, BYKETOL, BYKOPLAST, BYKUMEN, DISPERBYK, DISPERPLAST, LACTIMON, NANOBYK, SILBYK and VISCOBYK are registered trademarks of BYK-Chemie. AQUACER, AQUAFLOUR, AQUAMAT, CERACOL, CERAFAK, CERAFLOUR, CERAMAT, CERATIX and MINERPOL are registered trademarks of BYK-Cera. This information is given to the best of our knowledge. Because of the multitude of formulations, production and application conditions, all the above mentioned statements have to be adjusted to the circumstances of the processor. No liabilities, including those for patent rights, can be derived from this fact for individual cases. This data sheet replaces all previous issues - Printed in Germany

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Permanence and Care of Color PhotographsDocument24 pagesThe Permanence and Care of Color PhotographschioqueNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- PET Plastic (Polyethylene Terephthalate) - Uses, Properties & StructureDocument7 pagesPET Plastic (Polyethylene Terephthalate) - Uses, Properties & StructureFITIWI100% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The EFFECT of PH, RESIN PROPERTIES, and Manufacturing Process On Laboratory Degradation of Polyester GeosyntheticsDocument32 pagesThe EFFECT of PH, RESIN PROPERTIES, and Manufacturing Process On Laboratory Degradation of Polyester GeosyntheticsAnnie LauNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Textile AuxillaryDocument6 pagesTextile AuxillaryVinay GuptaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- ACI 503.5 (R2003) Guide For The Selection of Polymer Adhesives With ConcreteDocument16 pagesACI 503.5 (R2003) Guide For The Selection of Polymer Adhesives With ConcretephilipyapNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Introduction of Indonesia and Master Research: FakhruddinDocument21 pagesIntroduction of Indonesia and Master Research: FakhruddinFakhruddin UdinNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- PD PMD CadcamDocument20 pagesPD PMD CadcamVinay MishraNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- List of NSDocument22 pagesList of NSPujan NeupaneNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Rigging Safety Training: 4 Types of Slings and Inspection RequirementsDocument92 pagesRigging Safety Training: 4 Types of Slings and Inspection RequirementsD Srinivasa RaoNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Bamboo+Alumina CompositeDocument5 pagesBamboo+Alumina CompositeAmmineni Syam PrasadNo ratings yet

- Adeso MembranesDocument28 pagesAdeso MembranesSankar CdmNo ratings yet

- 2537 Data Sheet Lok FixDocument4 pages2537 Data Sheet Lok FixkamalxdNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Colpoly - 7166 - ISO-NPG Unsaturared Polyester resinTDSDocument2 pagesColpoly - 7166 - ISO-NPG Unsaturared Polyester resinTDStrường phạmNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Development of Nonwoven Fabric From Recycled Fibers 2165 8064 1000289Document3 pagesDevelopment of Nonwoven Fabric From Recycled Fibers 2165 8064 1000289Ronak JoshiNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Factura para Liquidacion de Importacion 21-04-20Document2 pagesFactura para Liquidacion de Importacion 21-04-20Juan Pablo EstradaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Types of PlasticsDocument13 pagesTypes of PlasticsSander100% (1)

- What Are Synthetic Resins Applications and UsesDocument11 pagesWhat Are Synthetic Resins Applications and UsesBansal Trading CompanyNo ratings yet

- Design For Snapfit Revi-10Document26 pagesDesign For Snapfit Revi-10Arasu Pandian100% (1)

- Automobile Paints Manufacturing ReportDocument26 pagesAutomobile Paints Manufacturing ReportPraveen BanThia100% (1)

- Vipel Chemical Resistance Guide: Corrosion Resistant Resins For The Harshest EnvironmentsDocument32 pagesVipel Chemical Resistance Guide: Corrosion Resistant Resins For The Harshest EnvironmentsCésar AreinamoNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Identification of FibersDocument17 pagesIdentification of FibersJazib KhanNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- RSH Qam11 Ch08 GEDocument75 pagesRSH Qam11 Ch08 GEFahad MehmoodNo ratings yet

- Market Potential For Selected Platform ChemicalsDocument173 pagesMarket Potential For Selected Platform ChemicalsMohamad Pazlin100% (1)

- Fiber Reinforced Polymer (FRP) MaterialsDocument35 pagesFiber Reinforced Polymer (FRP) MaterialskirtikamjhjhsgcssNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Fiber TestingDocument11 pagesFiber TestingSandy YansikuNo ratings yet

- Insulating Systems For Repair Industry in AmericasDocument16 pagesInsulating Systems For Repair Industry in AmericasElafanNo ratings yet

- MS00070925 SF05 Polyols A4 0315 ESDocument14 pagesMS00070925 SF05 Polyols A4 0315 ESΣταύρος Βουγιουκλίδης100% (1)

- Reduce Styrene Migration from UP ResinsDocument2 pagesReduce Styrene Migration from UP Resinsgunawan refiadi0% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- CEM-001 CelaneseQuickRefTrifold AM 0913Document3 pagesCEM-001 CelaneseQuickRefTrifold AM 0913cesaroleinikNo ratings yet

- Assignment: Polyester Fiber Production ProcessDocument8 pagesAssignment: Polyester Fiber Production ProcesstojinboNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)