Professional Documents

Culture Documents

Flexovit Abrasives - PSA Sanding Discs

Uploaded by

Flexovit AbrasivesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flexovit Abrasives - PSA Sanding Discs

Uploaded by

Flexovit AbrasivesCopyright:

Available Formats

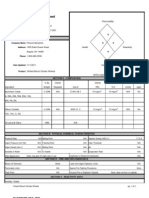

FLEXOVIT USA, INC

Material Safety Data Sheet

Used to comply with OSHA's Hazard Communication Standard, 29 CFR 1910.1200

Flammability

0 SECTION I - NAME AND PRODUCT

Company Name: Flexovit Abrasives Address: 1305 Eden-Evans Road

0 Health 0

0 Reactivity

Angola, NY 14006

Phone: 800-689-3539 Date Updated: 11/1/2011 Product: Pressure Sensitive Adhesive

Hazard Rating NFPA HAZARD RATING CODE SECTION II - COMPOSITION

Sanding Discs

Ingredient Synthetic Aluminum Oxide Glue (natural material derived from plant or animal) Kaolin-filler Paper backing Stearate coating as a supersize

% By Weight N/A N/A

OSHA Regulate N/A N/A

Cas # N/A N/A

OSHA PEL N/A N/A

ACGIH TLV N/A N/A

Other Limits N/A N/A

Carcinogen No No

N/A N/A N/A

N/A N/A N/A

N/A N/A N/A

N/A N/A N/A

N/A N/A N/A

N/A N/A N/A

No No No

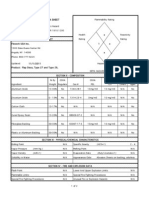

SECTION III - PHYSICAL/CHEMICAL CHARACTERISTICS

Physical State Vapor Pressure (mm HG) Vapor Density (Air=1) Solubility in Water Odor/Appearance Not defined Solid Boiling Point N/A Freezing Point N/A Melting Point % Volatile N/A N/A N/A N/A Specific Gravity (H2O=1) Odor Threshold pH Evaporation Rate N/A N/A N/A N/A N/A

May give off non-specific odor in use

Coefficient of Water/Oil Distribution

SECTION IV - FIRE AND EXPLOSION DATA

Means Of Extinction Flammable Limits Flash Point Water, powder, foam, sand CO2, etc. N/A N/A Lower And Upper Explosion Limits Special Fire Fighting Procedures Unusual Fire or Explosion Hazards N/A N/A N/A

SECTION V - REACTIVITY DATA Coated abrasives are stable and non-reactive when handled or stored. Conditions to avoid: N/A Material to avoid: Strong acids, strong bases and strong oxidizing agents may modify the mechanical characteristics of the products

& create safety hazards when used on machines.

Decomposition products: If used in accordance with instructions, no hazardous decomposition products are created.

Flexovit PSA Sanding Discs

pg 1 of 2

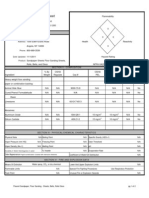

FLEXOVIT USA, INC

SECTION VI - HEALTH HAZARD DATA Coated abrasives are inert products which do not create any risk when handled or stored. When used on grinding machines they require specific measures to protect the operators. During the grinding operation 90 % or more of the particulates of the dust come from the material being ground and, for wet grinding, from aerosols generated by the grinding fluid. Specific attention must therefore be given to the nature of the part and of the fluid and the appropriate protection devices must be installed. Route(s) of Entry Inhalation Signs and Symptoms of Exposure

N/A

Emergency & First-Aid Procedures

Remove from exposure. Seek medical advice, if needed.

Eyes

N/A

Remove from exposure and flush with clean water. Seek medical advice if needed.

Skin

No hazardous effect known

N/A

Ingestion

No hazardous effect known

N/A

SECTION VII- STORAGE HANDLING AND USE PROCEDURES Follow recommendations for machines and federal, state, and local regulations. Store coated abrasives in moderate, constant temperature and humidity conditions.

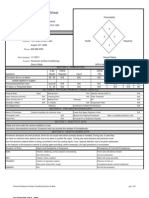

SECTION VIII- CONTROL MEASURES Protection Respiratory Ventilation Protective Gloves Eye Protection Hearing Protection Hygienic Practices Other Requirements and Referrals Use appropriate dust mask N/A Use barrier cream or protective gloves Machine guarding and safety goggles or face shield Recommended No specific requirements Use suitable protective clothing COMPANY USE The information and recommendations set forth herein are taken from sources and references believed to be accurate and complete as of the date hereof. However, Flexovit U.S.A., Inc. makes no expressed or implied warranty with respect to the accuracy of the information or the suitability of the recommendations, and assumes no liability to any user thereof.

Flexovit PSA Sanding Discs

pg 2 of 2

You might also like

- Flexovit Abrasives - Label Specification ChartDocument1 pageFlexovit Abrasives - Label Specification ChartFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Bench Grinder WheelsDocument2 pagesFlexovit Abrasives - Bench Grinder WheelsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Grinding Cutoff Wheels Reinforced ResinoidDocument2 pagesFlexovit Abrasives - Grinding Cutoff Wheels Reinforced ResinoidFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Vitrified Mounted PointsDocument2 pagesFlexovit Abrasives - Vitrified Mounted PointsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Quick Change Sanding DiscsDocument1 pageFlexovit Abrasives - Quick Change Sanding DiscsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Flap DiscsDocument2 pagesFlexovit Abrasives - Flap DiscsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Floor Sanding Sheets Rolls Belts DiscsDocument3 pagesFlexovit Abrasives - Floor Sanding Sheets Rolls Belts DiscsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Cupstone Hand Rubs Floor StonesDocument2 pagesFlexovit Abrasives - Cupstone Hand Rubs Floor StonesFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Resinoid Bonded Plugs and ConesDocument2 pagesFlexovit Abrasives - Resinoid Bonded Plugs and ConesFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Carbide BursDocument4 pagesFlexovit Abrasives - Carbide BursFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Resin Fiber Sanding DiscsDocument2 pagesFlexovit Abrasives - Resin Fiber Sanding DiscsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Resin Fiber Discs Ceramic GrainDocument2 pagesFlexovit Abrasives - Resin Fiber Discs Ceramic GrainFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Cartridge Rolls Spiral Bands PadsDocument2 pagesFlexovit Abrasives - Cartridge Rolls Spiral Bands PadsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Nylon Pads and Mesh ScreensDocument2 pagesFlexovit Abrasives - Nylon Pads and Mesh ScreensFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Mounted Flap WheelsDocument2 pagesFlexovit Abrasives - Mounted Flap WheelsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Sandpaper and Floor Sanding Sheets Rolls Belts DiscsDocument2 pagesFlexovit Abrasives - Sandpaper and Floor Sanding Sheets Rolls Belts DiscsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Steel Wool PadsDocument1 pageFlexovit Abrasives - Steel Wool PadsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Sanding BeltsDocument1 pageFlexovit Abrasives - Sanding BeltsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Shop and Plumber RollsDocument1 pageFlexovit Abrasives - Shop and Plumber RollsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Clean Strip DiscsDocument2 pagesFlexovit Abrasives - Clean Strip DiscsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Unmounted Flap WheelsDocument1 pageFlexovit Abrasives - Unmounted Flap WheelsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Trim Kut Sanding DiscsDocument1 pageFlexovit Abrasives - Trim Kut Sanding DiscsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Nylon Floor PadsDocument2 pagesFlexovit Abrasives - Nylon Floor PadsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Hand-PadsDocument1 pageFlexovit Abrasives - Hand-PadsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Troubleshooting Diamond AbrasivesDocument4 pagesFlexovit Abrasives - Troubleshooting Diamond AbrasivesFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives Overview (English)Document6 pagesFlexovit Abrasives Overview (English)Flexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Surface Conditioning Discs BeltsDocument2 pagesFlexovit Abrasives - Surface Conditioning Discs BeltsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Diamond BladesDocument3 pagesFlexovit Abrasives - Diamond BladesFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives CatalogDocument92 pagesFlexovit Abrasives CatalogFlexovit AbrasivesNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Methodologies For Sign Language Recognition A SurveyDocument4 pagesMethodologies For Sign Language Recognition A SurveyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Linux - Notes by Jitendra SirDocument125 pagesLinux - Notes by Jitendra SirgoyaltarunNo ratings yet

- Macro To Roll Exalted 3e Die in Foundry VTTDocument5 pagesMacro To Roll Exalted 3e Die in Foundry VTTtcherban100% (1)

- ChironDocument13 pagesChironGP100% (1)

- 9 Little Translation Mistakes With Big ConsequencesDocument2 pages9 Little Translation Mistakes With Big ConsequencesJuliany Chaves AlvearNo ratings yet

- Computers & Industrial Engineering: Guohui Zhang, Xinyu Shao, Peigen Li, Liang GaoDocument10 pagesComputers & Industrial Engineering: Guohui Zhang, Xinyu Shao, Peigen Li, Liang Gaocloud69windNo ratings yet

- Build Ubuntu for Ultra-96 FPGA DevelopmentDocument5 pagesBuild Ubuntu for Ultra-96 FPGA Developmentksajj0% (1)

- Ipc2012 90095Document11 pagesIpc2012 90095Marcelo Varejão CasarinNo ratings yet

- United Kingdom & Ireland TelevisionDocument328 pagesUnited Kingdom & Ireland TelevisionPcnhs SalNo ratings yet

- This Study Resource Was: Question AnswersDocument3 pagesThis Study Resource Was: Question AnswerskamakshiNo ratings yet

- Draft User Manual MISDocument306 pagesDraft User Manual MISkhajuriaonlineNo ratings yet

- Rule 4 - Types of Construction (Book Format)Document2 pagesRule 4 - Types of Construction (Book Format)Thea AbelardoNo ratings yet

- 130nm Techbrief01Document3 pages130nm Techbrief01Gilang Mardian KNo ratings yet

- WTAC Study-NotesDocument9 pagesWTAC Study-NotesBillNo ratings yet

- Summary of FindingsDocument3 pagesSummary of FindingsshairaNo ratings yet

- Milgrams Experiment On Obedience To AuthorityDocument2 pagesMilgrams Experiment On Obedience To Authorityapi-233605868No ratings yet

- Head Barista Job DescriptionDocument2 pagesHead Barista Job Descriptionbarber rocxNo ratings yet

- Altair's Student Guides - CAE and Design Optimization - AdvancedDocument70 pagesAltair's Student Guides - CAE and Design Optimization - AdvancedKFourMetrics100% (11)

- Reading Skills Practice: Your Digital Footprint - ExercisesDocument2 pagesReading Skills Practice: Your Digital Footprint - ExercisesagnaldopedroNo ratings yet

- International Journal of Project Management: Lavagnon A. Ika, Jonas Söderlund, Lauchlan T. Munro, Paolo LandoniDocument11 pagesInternational Journal of Project Management: Lavagnon A. Ika, Jonas Söderlund, Lauchlan T. Munro, Paolo LandoniWarda IshakNo ratings yet

- Brochure DRYVIEW 5700 201504 PDFDocument4 pagesBrochure DRYVIEW 5700 201504 PDFRolando Vargas PalacioNo ratings yet

- GeneralMusic synthesizer service manual section titlesDocument16 pagesGeneralMusic synthesizer service manual section titlesAnonymous Syjpyt4Mo100% (1)

- Corning® LEAF® Optical Fiber: Product InformationDocument0 pagesCorning® LEAF® Optical Fiber: Product Informationhcdung18No ratings yet

- Registration Form: National Hospital Insurance FundDocument5 pagesRegistration Form: National Hospital Insurance FundOgweno OgwenoNo ratings yet

- 7 Basic Qualty Tools & Root Cause AnalysisDocument42 pages7 Basic Qualty Tools & Root Cause AnalysisRamonS.FernandezOrozco100% (1)

- Ultra-Deepwater Semi-Submersible: General Description Storage CapacitiesDocument2 pagesUltra-Deepwater Semi-Submersible: General Description Storage CapacitiesFrank CloseNo ratings yet

- 120.anti Theft Alerting System For Vehicle (2 Wheeler)Document3 pages120.anti Theft Alerting System For Vehicle (2 Wheeler)Basha BashaNo ratings yet

- Rohtak:: ICT Hub For E-Governance in HaryanaDocument2 pagesRohtak:: ICT Hub For E-Governance in HaryanaAr Aayush GoelNo ratings yet

- Reportte Cambios CPC 2a1Document1 pageReportte Cambios CPC 2a1FERNANDO FERRUSCANo ratings yet

- Nist Technical Note 1297 SDocument25 pagesNist Technical Note 1297 SRonny Andalas100% (1)