Professional Documents

Culture Documents

Ball Valve Seat

Uploaded by

mrkadu_61Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ball Valve Seat

Uploaded by

mrkadu_61Copyright:

Available Formats

Flo-Tite, Inc.

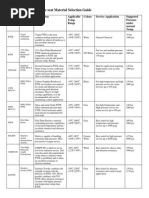

Valve Seat Material Selection Guide

Tech Bulletin Page 180-07

Valves & Controls

Choosing The Right Seat Material is the Most Challenging Decision in Ball Valve Selection

Flanged End

Valve Seat (2)

3 PC Valves

Body Seal (2)

Body Seal (1) Spiral Wound 316 / Graphite

Valve Seat (2)

Flanged End, 2 and 3 PC Valves share the same stem packing. V-Ring Stem Seal (5)

Thrust Washer (2)

VALVE REPAIR KIT INCLUDES ALL SOFT PARTS

Seats - Body Seals - Stem Packing - Thrust Washers Our listing of seat materials has been prepared to assist the specifying engineer and the end user in the proper seat selection. This information should be used in conjunction with the pressure temperature-rating graph found in our catalog for the applicable valve.

STANDARD SEAT SELECTIONS

Seat Code Material Technical Description SUPER-TEK TFM offers all of the properties of reinforced TFE with greater strength, toughness, and improved thermo mechanical properties offering lower coefficient of friction for lower torques and less permeability, reduced cold flow deformation and enhanced deformation recovery. Temperature Range - 50F to 550F Color Valve Torque Adder

TFM

OffWhite

+10% less Than RPTFE

Valves & Controls DESIGN & TECHNICAL DATA

Flo-Tite, Inc.

Tech Bulletin Page 181-07

OPTIONAL SEAT SELECTIONS

Seat Code Material Reinforced TFE Technical Description 15% Glass Reinforced TFE rated suitable for temperatures -50F to 450F, chemical resistance is compatible to virgin TFE with improved cycle life and greater pressure-temperature rating than TFE. This material is the basic seat material used in most Ball Valves. Its chemical compatibility is excellent for almost all media service applications. Temperature range -50F to 400F. Super-Tek II Glass Filled TFM-25% Glass Reinforced with 75% TFM, is good for temperature ranging from -320F to 572F. This material offers a wide temperature range with better cycle life than TFM. Ideal for steam, hot gases, thermal fluids and a variety of process chemicals. Color OffWhite Valve Torque Adder Standard As indicated in literature Standard As indicated in literature

Virgin TFE

White

Reinforced TFM

OffWhite

+25%

Combines the strength of metal with the lubricity of TFE. 50% Stainless Filled 316 powder combined with 50% TFE. Offers the abrasion resistance of metal with higher pressure and temperature ratings TFE than RPTFE. -20F to 550F / Steam rating 250 SWP. Special Nylon seats are offered for higher pressure and lower temperature service. They can be used in high-pressure air, oil, and other gas media but are not suited for strong oxidizing agents. Temperature rating -30F to 200F. Ultra-High Molecular Weight Polyethylene. Ideal for use in lowlevel radiation service. This seat also meets the requirements of the tobacco industry where TFE is prohibited and it offers an excellent resistance to abrasive media. Temperature range -70F to 200F. Recommended for service with severe flashing or hydraulic shock, abrasive media or where possible trapped metal may exist. Flo-Tites metal seats are hand lapped to the ball as individually matched sets, assuring line contact between valve ball and seats, resulting in smooth operation and tight shut off class. Flo-Tite offers metal seats in different classes of Shut Off including Class IV, V and VI. Polyetheretherketone high temperature semi rigid elastomer. Best suited for high pressure and temperature service. Also offers very good corrosion resistance. Temperature rating -70F to 550F. Designed to reduce the possibility of contamination by entrapment of process fluids in the void normally found behind the ball between the valve body in conventionally designed ball valves. Ideal for application where cross contamination is a concern, such as paints and dyes.

Gray

+50%

Nylon

Translucent White

+35%

UHMWP Polyethylene

Opaque White

+35%

Metal (Stellite)

Metallic

+60%

Peek

Brown

+50%

C/F

Cavity Filler

White

+50%

Consult factory for availability of all additional seat material.

Flo-Tite, Inc.

Valves & Controls

P. O. Box 1293 Lumberton, NC 28359 Website: www.flotite.com

Tel: (910) 738-8904 Fax: (910) 738-9112 E-mail: flotite@nc.rr.com

You might also like

- Valve Seat Seal Selection GuideDocument4 pagesValve Seat Seal Selection GuideDhim131267No ratings yet

- Valve Seat Seal Selection GuideDocument2 pagesValve Seat Seal Selection Guideecovarrubias1No ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Valve Seat Selection GuideDocument4 pagesValve Seat Selection Guideim4uim4uim4uNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Valve Seat Material Selection GuideDocument1 pageValve Seat Material Selection GuideHo Minh VietNo ratings yet

- 180 - 18 Seat Selection GuideDocument4 pages180 - 18 Seat Selection GuidemolinachNo ratings yet

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Seats and Seals Selection Guide: Share ThisDocument4 pagesSeats and Seals Selection Guide: Share ThisArjed Ali ShaikhNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Valve Soft Parts: Flanged End 3 Piece C ValvesDocument4 pagesValve Soft Parts: Flanged End 3 Piece C ValvesFLOW VALVE AUTOMATIONNo ratings yet

- Seat Material Selection in Ball ValvesDocument2 pagesSeat Material Selection in Ball Valvescoolguy12345No ratings yet

- Ball Valve Seat MaterialDocument1 pageBall Valve Seat MaterialupdyneNo ratings yet

- Ball Valve TJ (21 Sep 16)Document24 pagesBall Valve TJ (21 Sep 16)TeukuJoharNo ratings yet

- Engineering Bulletin: Rev. 10/07 Page 1 of 4Document5 pagesEngineering Bulletin: Rev. 10/07 Page 1 of 4Iván López PavezNo ratings yet

- Valves Eat Seal Materials and Service TypesDocument3 pagesValves Eat Seal Materials and Service Typescoolguy12345No ratings yet

- Valve Seat Material Selection GuideDocument1 pageValve Seat Material Selection Guidemurtuza5No ratings yet

- BallValve Body Trim MaterialDocument3 pagesBallValve Body Trim Materialsabes26No ratings yet

- Valves Eat Seal Materials and Service TypesDocument3 pagesValves Eat Seal Materials and Service Typess.mladinNo ratings yet

- Worcester Controls F819/829 Full Bore Ball ValvesDocument8 pagesWorcester Controls F819/829 Full Bore Ball ValvesVăn Đình NhậtNo ratings yet

- Valve Seat Material GuideDocument1 pageValve Seat Material GuideAndresNo ratings yet

- Dezurik High Performance Butterfly Valves BHP Sales 45-00-1Document8 pagesDezurik High Performance Butterfly Valves BHP Sales 45-00-1yg89No ratings yet

- GASKETS - SrsDocument14 pagesGASKETS - SrsRanganathan SekarNo ratings yet

- Series 7400Document22 pagesSeries 7400zekha87No ratings yet

- FlowTek Ball Valve DesignDocument0 pagesFlowTek Ball Valve DesignGohilakrishnan ThiagarajanNo ratings yet

- Titeflex Transportation CatalogDocument4 pagesTiteflex Transportation Catalogkrzys10No ratings yet

- L&T Ball ValveDocument12 pagesL&T Ball ValvecdsenthilNo ratings yet

- Teflon Tubing: What You Absolutely Need To KnowDocument4 pagesTeflon Tubing: What You Absolutely Need To Knowdarsh2001patelNo ratings yet

- (Good) ChemicalResistanceGuide - Many SealsDocument13 pages(Good) ChemicalResistanceGuide - Many SealscrystaltanNo ratings yet

- BS 5351 Ball Valves CatalogDocument10 pagesBS 5351 Ball Valves CatalogcatalineulaNo ratings yet

- Ptfe HosesDocument33 pagesPtfe Hosesvitet412759No ratings yet

- Gasket RefDocument21 pagesGasket Refjun_bucayuNo ratings yet

- Teflone (PTFE) Seat SuggetionDocument1 pageTeflone (PTFE) Seat SuggetionBharat PrajapatiNo ratings yet

- Icon Process ControlsDocument2 pagesIcon Process Controlsllinda999No ratings yet

- GasketDocument45 pagesGasketSathish RajanNo ratings yet

- Flange Insulating Kits TGCD CpiDocument13 pagesFlange Insulating Kits TGCD CpiblackbriaruyjvhvjNo ratings yet

- Teflon Based GasketsDocument2 pagesTeflon Based GasketsAndroidNo ratings yet

- ASME Class 150 and 300Document12 pagesASME Class 150 and 300pca97No ratings yet

- Sure Seal LBF Series Lined Butterfly Valves for Demanding ApplicationsDocument8 pagesSure Seal LBF Series Lined Butterfly Valves for Demanding ApplicationsbbmokshNo ratings yet

- Earing Ournal: Best Polymer Selection For Quality UpgradesDocument2 pagesEaring Ournal: Best Polymer Selection For Quality UpgradesImaduddin ShaNo ratings yet

- Polytetra - Heatshrinkable Tubing (Ingles)Document12 pagesPolytetra - Heatshrinkable Tubing (Ingles)Cesar Muñoz OssesNo ratings yet

- Gasket Documents PDFDocument66 pagesGasket Documents PDFramnadh803181No ratings yet

- 2WS21ENDocument8 pages2WS21ENcibocrisNo ratings yet

- 2.2. PBM Serie ANSI EriksDocument8 pages2.2. PBM Serie ANSI EriksmguisseNo ratings yet

- Viton PropertiesDocument23 pagesViton PropertiesClaudia MmsNo ratings yet

- Butterfly Valves (300 Psi/2065 Kpa) : Series 706Document8 pagesButterfly Valves (300 Psi/2065 Kpa) : Series 706SUNIL BINDNo ratings yet

- Chemical Resistance Guide For Valves: Val-Matic Valve and Manufacturing CorpDocument13 pagesChemical Resistance Guide For Valves: Val-Matic Valve and Manufacturing CorpEdinsonNo ratings yet

- GASKETDocument8 pagesGASKETKun KunNo ratings yet

- Temperature Limits of High Temperature SystemsDocument7 pagesTemperature Limits of High Temperature SystemsCarlosAlbertoRibeiroRuyNo ratings yet

- PEEKDocument1 pagePEEKMalik DaniyalNo ratings yet

- 5.1 Pvrv-Fa - VD - Ts - Ka - 7 - GBDocument4 pages5.1 Pvrv-Fa - VD - Ts - Ka - 7 - GBSivareddy InduriNo ratings yet

- Model M26 Manifold Line For 266 Pressure TransmittersDocument24 pagesModel M26 Manifold Line For 266 Pressure TransmittersCarlos VidelaNo ratings yet

- Ball Valve GuideDocument22 pagesBall Valve GuideBalakrishna BisoyiNo ratings yet

- Cera System Catalogue 2011Document36 pagesCera System Catalogue 2011prihartono_diasNo ratings yet

- 8510 1181TeflonBack UpRings PDFDocument23 pages8510 1181TeflonBack UpRings PDFAmir Hooshang Ghadymi MahaniNo ratings yet

- 07 Polytetra Heatshrinkable Tubing 2010 PDFDocument12 pages07 Polytetra Heatshrinkable Tubing 2010 PDFNicolas AguilarNo ratings yet

- pp67-72 MS06 PDFDocument6 pagespp67-72 MS06 PDFmrkadu_61No ratings yet

- pp67-72 MS06 PDFDocument6 pagespp67-72 MS06 PDFmrkadu_61No ratings yet

- ConveyorDocument14 pagesConveyorchenkok_90No ratings yet

- Principles of Electrical GroundingDocument43 pagesPrinciples of Electrical GroundingSaber HussainiNo ratings yet

- TDS WirelessNotebookOpticalMouse 0602ADocument2 pagesTDS WirelessNotebookOpticalMouse 0602Amrkadu_61No ratings yet

- How To Manage Cooling Tower Water QualityDocument4 pagesHow To Manage Cooling Tower Water QualityTony_Black99100% (1)

- Dear Customer,: Ticket ConfirmationDocument1 pageDear Customer,: Ticket Confirmationmrkadu_61No ratings yet

- pp67-72 MS06 PDFDocument6 pagespp67-72 MS06 PDFmrkadu_61No ratings yet

- Axial Thrust in Centrifugal PumpsDocument14 pagesAxial Thrust in Centrifugal PumpsAndré Da Cunha SilveiraNo ratings yet

- Closed CoolingDocument9 pagesClosed Coolingmrkadu_61No ratings yet

- Closed CoolingDocument9 pagesClosed Coolingmrkadu_61No ratings yet

- Centrifugal Pump Cooling and Lubricant ApplicationDocument11 pagesCentrifugal Pump Cooling and Lubricant ApplicationLeon SanchezNo ratings yet

- Corrosion and Water ParameterDocument7 pagesCorrosion and Water Parametermrkadu_61No ratings yet

- Procedure For ITI OpeningDocument12 pagesProcedure For ITI Openingbraj87No ratings yet

- 123Document38 pages123mrkadu_61No ratings yet

- Conveyor Belt ElastomersDocument4 pagesConveyor Belt Elastomersmrkadu_61No ratings yet

- Pump TrainingDocument15 pagesPump TrainingdalayeliNo ratings yet

- Top 10 Products by Yearly TurnoverDocument3 pagesTop 10 Products by Yearly Turnoverarunasagar_2011No ratings yet

- Piping Material Selection StandardDocument425 pagesPiping Material Selection StandardJitendra Bhosale100% (3)

- Butterfly ValveDocument3 pagesButterfly Valvemrkadu_61No ratings yet

- Ball ValvesDocument7 pagesBall ValvesRizal FalevyNo ratings yet

- CFE Product CatalogDocument12 pagesCFE Product Catalogmrkadu_610% (1)

- Nominal Pipe SizeDocument4 pagesNominal Pipe Sizemrkadu_61No ratings yet

- IT DeclerationDocument2 pagesIT Declerationmrkadu_61No ratings yet

- NTN Bearing en AllDocument411 pagesNTN Bearing en Allbhupinder85No ratings yet

- Basic Fundas and Useful Tips On Grease LubricationDocument4 pagesBasic Fundas and Useful Tips On Grease Lubricationmrkadu_61No ratings yet

- Everything about case hardening steelDocument2 pagesEverything about case hardening steelFrancisco Botelho Carlos100% (1)

- Retaining: Securing Cylindrical AssembliesDocument1 pageRetaining: Securing Cylindrical Assembliesmrkadu_61No ratings yet

- Nut Bolt SpareDocument14 pagesNut Bolt Sparemrkadu_61No ratings yet

- Installation & Start Up of Axial Piston PumpDocument14 pagesInstallation & Start Up of Axial Piston Pumpmrkadu_61No ratings yet

- A Reconfigurable Wing For Biomimetic AircraftDocument12 pagesA Reconfigurable Wing For Biomimetic AircraftMoses DevaprasannaNo ratings yet

- Embryology-Nervous System DevelopmentDocument157 pagesEmbryology-Nervous System DevelopmentGheavita Chandra DewiNo ratings yet

- WWW - Commonsensemedia - OrgDocument3 pagesWWW - Commonsensemedia - Orgkbeik001No ratings yet

- Managerial EconomicsDocument3 pagesManagerial EconomicsGuruKPONo ratings yet

- Simba s7d Long Hole Drill RigDocument2 pagesSimba s7d Long Hole Drill RigJaime Asis LopezNo ratings yet

- Get Oracle Order DetailsDocument4 pagesGet Oracle Order Detailssiva_lordNo ratings yet

- Factors of Active Citizenship EducationDocument2 pagesFactors of Active Citizenship EducationmauïNo ratings yet

- Learning Activity Sheet: 3 Quarter Week 1 Mathematics 2Document8 pagesLearning Activity Sheet: 3 Quarter Week 1 Mathematics 2Dom MartinezNo ratings yet

- Peran Dan Tugas Receptionist Pada Pt. Serim Indonesia: Disadur Oleh: Dra. Nani Nuraini Sarah MsiDocument19 pagesPeran Dan Tugas Receptionist Pada Pt. Serim Indonesia: Disadur Oleh: Dra. Nani Nuraini Sarah MsiCynthia HtbNo ratings yet

- Corporate Governance, Corporate Profitability Toward Corporate Social Responsibility Disclosure and Corporate Value (Comparative Study in Indonesia, China and India Stock Exchange in 2013-2016) .Document18 pagesCorporate Governance, Corporate Profitability Toward Corporate Social Responsibility Disclosure and Corporate Value (Comparative Study in Indonesia, China and India Stock Exchange in 2013-2016) .Lia asnamNo ratings yet

- Todo Matic PDFDocument12 pagesTodo Matic PDFSharrife JNo ratings yet

- Guide To Raising Capital From Angel Investors Ebook From The Startup Garage PDFDocument20 pagesGuide To Raising Capital From Angel Investors Ebook From The Startup Garage PDFLars VonTurboNo ratings yet

- Staffing Process and Job AnalysisDocument8 pagesStaffing Process and Job AnalysisRuben Rosendal De Asis100% (1)

- HSSC English Model PaperDocument32 pagesHSSC English Model PaperMaryam Abdus SalamNo ratings yet

- Why Choose Medicine As A CareerDocument25 pagesWhy Choose Medicine As A CareerVinod KumarNo ratings yet

- Techniques in Selecting and Organizing InformationDocument3 pagesTechniques in Selecting and Organizing InformationMylen Noel Elgincolin ManlapazNo ratings yet

- LegoDocument30 pagesLegomzai2003No ratings yet

- Qad Quick StartDocument534 pagesQad Quick StartMahadev Subramani100% (1)

- Galaxy Owners Manual Dx98vhpDocument10 pagesGalaxy Owners Manual Dx98vhpbellscbNo ratings yet

- Be It Enacted by The Senate and House of Representatives of The Philippines in Congress AssembledDocument2 pagesBe It Enacted by The Senate and House of Representatives of The Philippines in Congress AssembledCesar ValeraNo ratings yet

- IELTS Speaking Q&ADocument17 pagesIELTS Speaking Q&ABDApp Star100% (1)

- There Is There Are Exercise 1Document3 pagesThere Is There Are Exercise 1Chindy AriestaNo ratings yet

- C4 ISRchapterDocument16 pagesC4 ISRchapterSerkan KalaycıNo ratings yet

- Cab&Chaissis ElectricalDocument323 pagesCab&Chaissis Electricaltipo3331100% (13)

- ITP Exam SuggetionDocument252 pagesITP Exam SuggetionNurul AminNo ratings yet

- WindSonic GPA Manual Issue 20Document31 pagesWindSonic GPA Manual Issue 20stuartNo ratings yet

- Bula Defense M14 Operator's ManualDocument32 pagesBula Defense M14 Operator's ManualmeNo ratings yet

- PowerPointHub Student Planner B2hqY8Document25 pagesPowerPointHub Student Planner B2hqY8jersey10kNo ratings yet

- Tutorial 1 Discussion Document - Batch 03Document4 pagesTutorial 1 Discussion Document - Batch 03Anindya CostaNo ratings yet