Professional Documents

Culture Documents

PRV-075-020 Iom 1

Uploaded by

Ryan VaronaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PRV-075-020 Iom 1

Uploaded by

Ryan VaronaCopyright:

Available Formats

Installation and Operation Guide

5/98

BERMAD Model PRV-075 thru 150

Direct-Acting Pressure Reducing Valve

ADJUSTING SCREW & CAP ADJUSTING SCREW LOCKNUT

CONTROL VALVES

ADJUSTING SCREW & CAP

VENT HOLE VENT HOLE VENT HOLE

PRV-150 S.S ADJ. SCREW

FLOWCONTROL HANDLE

FLAT-BOTTOM W/O FLOW CONTROL HANDLE

DESCRIPTION The model PRV control valve maintains a constant downstream pressure regardless of demand or changing upstream pressure. The reducing pilot senses downstream pressure and modulates the main valve to maintain the setpoint. When downstream pressure falls below the setting of the reducing pilot, the pilot opens allowing the main valve to open to increase pressure to the setpoint. When downstream pressure rises above the setting of the reducing pilot, the pilot closes causing the main valve to throttle toward a closed postion to maintain the setpoint.

IN LINE STATIC TEST

Open Valve Static Test 1. Turn adjusting screw on the cover fully CCW. **Vice versa on PRV-150 w/long S.S adjusting screw. CAUTION: This will allow the valve to fully open. Make sure this condition wll not cause system damage! 2. Check for leaks at the threaded connections, cover, etc. Throttled-Closed-Valve Test 1. Turn adjusting screw on PRV fully clockwise (CW).**Vice versa on PRV-150 w/long S.S adjusting screw. 2. This will trap the main valve towards a throttled-closed position while the pipeline is pressurized. Check the valve cover and diaphragm area for leaks. Tighten black-plastic cover CW if necessary.

START-UP OPERATION

NOTE: There must be flow through the valve and system to check and adjust the valve. Insure that a downstream demand is created. All plastic adjusting screws should be marked + or on the top of INSTALLATION the cover/cap. All plastic adjusting screws must be turned CCW 1. Allow enough room around the valve assembly for to increase downstream pressure and CW to decrease making adjustments and for future maintenance and downstream pressure. **On PRV-150 models with the long disassembly work. adjusting screw, the adjustment is vice versa. 2. Thoroughly flush the pipeline to remove dirt, scale, and 1. Turn adjusting screw on PRV fully clockwise (CW) until all debris. Failure to perform this operation may render the spring tension is relieved. **Opposite on model PRV-150 w/long valve inoperable. adj. S.S screw. Open fully pipeline gate or butterfly valves if 3. It is recommended that isolation gate valves be installed applicable. upstream and downstream of the Bermad PRV control valve 2. Main valve will close or come towards a throttled-closed to allow for future maintenance operations. position (depending on grade of spring and system 4. Install the valve in the pipeline with the valve flow arrow pressure). Main valve should still remain towards a closed on the body casting in the proper direction. Install the position. valve horizontally with the cover up for best performance. 3. If applicable, vent trapped air in the system by loosening a Make certain the valve is positioned so the cover assembly fitting or device at the high points in the system near the PRV. can be easily removed for future maintenance requirements. 4. Slowly turn adjusting screw on PRV (CCW) until the valve just 5. After installation carefully inspect/correct any damaged begins to open or modulate. **Opposite on model PRV-150 w/long accessories, piping, tubing, or fittings within the system. adj. S.S screw. Watching a pressure gauge downstream, continue to slowly turn adjusting screw (CCW) until desired downstream ** TURN S.S ADJ. SCREW CW TO INCREASE DOWN- pressure setting is reached. Tighten the locknut (150 models w/ STREAM PRESSURE AND CCW TO DECREASE ON long S.S adj. screw). Put plastic cap back on top of the adjusting PRV-150 MODELS W/LONG S.S ADJ. SCREW ONLY. screw (some older models). On 100 models, leave in place.

CONTROL VALVES

BERMAD Model PRV-075 thru 150

Direct-Acting Pressure Reducing Valve

ADJUSTING SCREW & CAP ADJUSTING SCREW LOCKNUT VENT HOLE ADJUSTING SCREW

VENT HOLE VENT HOLE

PRV-150 S.S ADJ. SCREW

FLOWCONTROL HANDLE

FLAT-BOTTOM W/O FLOW CONTROL HANDLE

TROUBLESHOOTING SYMPTOM

Valve Fails to Open

** TURN S.S ADJ. SCREW CW TO INCREASE DOWNSTREAM PRESSURE AND CCW TO DECREASE ON PRV-150 MODELS W/LONG S.S ADJ. SCREW ONLY!

CAUSE

Insufficient inlet pressure. No downstream demand. Insufficient spring compression on PRV adjusting screw. Debris trapped in main valve. Incorrect spring in the valve cover.

REMEDY

Check/create inlet pressure. Create demand/flow. Turn adjusting screw on the cover of the PRV (CCW) counter-clockwise. **Vice versa on PRV-150 long adj. Screw. Remove valve cover/main valve from line to inspect/remove debris. Replace/Verify the proper spring for the desired adjustment range. Replace/Verify the proper spring for desired adjustment range. Bleed air from pipeline at high points of the system or add air release valves to the system. Ensure flow rate is above recommended minimum. Remove valve cover/main valve from line to inspect/remove debris. *Locate the vent hole on the valves cover. If continuous flow exists from cover vent hole, diaphragm is damaged or loose.

Valve Fails to Regulate**

Incorrect spring in the valve cover/Readjust PRV. See Start-Up. Regulated pressure pulsates or hunts.

Debris trapped in main valve.

Diaphragm in main valve leaking.

*NOTE: There are only two plastic PRV models that will hold and reduce pressure to 1/3 of the inlet pressure on zero (dead-head) flow. They are the models PRV-075 LO-FLOW and PRV-100 w/FLOW CONTROL HANDLE (SEE ABOVE DRAWING-NOT FLAT BOTTOM COVER). All PRV-150 models will hold pressure to 1/3 of the inlet pressure on zero (dead-head) flow.

4070 Leaverton Court - Anaheim, CA. 92807 - (714) 666-1100

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- DNV Os C104 2014Document40 pagesDNV Os C104 2014Moe LattNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Physics For Entertainment Volume 1 (Yakov Perelman)Document211 pagesPhysics For Entertainment Volume 1 (Yakov Perelman)snath7800No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Applied Combinatorics, Second Edition by Fred S Roberts, Barry TesmanDocument889 pagesApplied Combinatorics, Second Edition by Fred S Roberts, Barry TesmanAnil kumarNo ratings yet

- A Dimensional Engineering Process For ShipbuildingDocument11 pagesA Dimensional Engineering Process For ShipbuildingWJccnNo ratings yet

- Mechanical Properties ExplainedDocument38 pagesMechanical Properties ExplainedJamaica VelascoNo ratings yet

- Basic Engineering Correlation Calculus v3 001Document3 pagesBasic Engineering Correlation Calculus v3 001Ska doosh100% (1)

- Introduction To PragmaticsDocument119 pagesIntroduction To PragmaticsIsabella IsaBella75% (4)

- MPLS QAsDocument6 pagesMPLS QAsLaxman Shrestha100% (1)

- 5-Unsymmetrical Fault AnalysisDocument5 pages5-Unsymmetrical Fault Analysisvirenpandya0% (1)

- Questions Bank On ElectrostaticsDocument2 pagesQuestions Bank On Electrostaticsashok PradhanNo ratings yet

- High-Resolution Micromachined Interferometric AccelerometerDocument75 pagesHigh-Resolution Micromachined Interferometric AccelerometerjitendraNo ratings yet

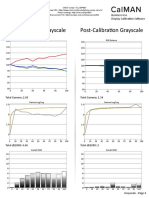

- TCL 55P607 CNET Review Calibration ResultsDocument3 pagesTCL 55P607 CNET Review Calibration ResultsDavid KatzmaierNo ratings yet

- Schottky DiodeDocument5 pagesSchottky Diodeilg1No ratings yet

- St. Michael'S High SchoolDocument5 pagesSt. Michael'S High SchoolHoniel PagoboNo ratings yet

- 0580 w13 QP 41Document20 pages0580 w13 QP 41Haider AliNo ratings yet

- Skripsi #2 Tanpa HyperlinkDocument19 pagesSkripsi #2 Tanpa HyperlinkindahNo ratings yet

- DEPP Programmer's Reference ManualDocument5 pagesDEPP Programmer's Reference ManualRaul Gil BayardoNo ratings yet

- Solubility of Caso: Major Concepts and Learning GoalsDocument6 pagesSolubility of Caso: Major Concepts and Learning GoalsNacorn PanchanawapornNo ratings yet

- XXXXX: Important Instructions To ExaminersDocument21 pagesXXXXX: Important Instructions To ExaminersYogesh DumaneNo ratings yet

- Yr 6 Maths G-6 E P-I PDFDocument168 pagesYr 6 Maths G-6 E P-I PDFdina171279No ratings yet

- Primary-Side Regulation PWM Power Switch General Description FeaturesDocument10 pagesPrimary-Side Regulation PWM Power Switch General Description FeaturespopoNo ratings yet

- L6565 DatasheetDocument17 pagesL6565 DatasheetJose BenavidesNo ratings yet

- Review For Mastery: VocabularyDocument3 pagesReview For Mastery: VocabularyHala EidNo ratings yet

- Solutions: Rise Desnita, M.Si., AptDocument41 pagesSolutions: Rise Desnita, M.Si., Aptdeput_rprNo ratings yet

- Straight Line MotionDocument12 pagesStraight Line MotionMZWAANo ratings yet

- Electric Charges and Fields All DerivationsDocument9 pagesElectric Charges and Fields All DerivationsFlame kaiserNo ratings yet

- AtmegaDocument22 pagesAtmegaMUKILANNo ratings yet

- ES Q2 Mod8Document26 pagesES Q2 Mod8maacovsNo ratings yet

- PSAB Product ManualDocument4 pagesPSAB Product ManualArnold StevenNo ratings yet

- Maths EnglishDocument26 pagesMaths EnglishmeenasarathaNo ratings yet