Professional Documents

Culture Documents

Bandra Worli Sealink

Uploaded by

faheem_roshanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bandra Worli Sealink

Uploaded by

faheem_roshanCopyright:

Available Formats

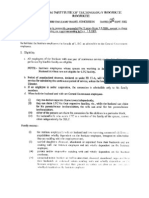

Case Study of Bandra-Worli Sea Link

Chapter 1

INTRODUCTION The construction of the Bandra-Worli Bridge is part of the Bandra-Worli Sea Link project necessitated by the exceptionally large amounts of traffic which was earlier using the Mahim Causeway travel from the western suburbs of Mumbai to the commercial hub of the island City. This affects the efficiency and links to the economic metropolis and the internationally used harbour. As an upshot of Mumbai's rapid growth in economy and population since its independence, traffic has stalled in the city center. It is thought that 120,000 PCU's use the Mahim causeway every day. Therefore for the sea link to make a substantial difference to the level of traffic on the mainland it is required to be able to accommodate large amounts of traffic. 8 lanes are provided on the sea link, out of which 2 are dedicated to city bus. It is the first bridge of its kind in India to be built in open sea, which has brought up a number of engineering issues. The infrastructure within the city is completely saturated and there is little room for expansion on the mainland, there was no other alternative than to construct over the bay. With this solution come a number of other benefits, such as reduced pollution within the city, reduced vehicle operation costs and journey times as well as the city obtaining a coastal landmark. The main part of the project is the larger two twinned tower cable stayed sections of the bridge which were designed by consultants Dar Al-Handasah. The bridge was dedicated to the public on 30 June 2009, although only 4 of 8 lanes were opened to service. All the 8 lanes were opened to traffic on 24 March 2010.

Photo no. 1.1 side view of bandra cable stayed

K.K.Wagh Polytechnic, Nashik

Page 1

Case Study of Bandra-Worli Sea Link

1.1 Purpose Mahim Causeway was the only link connecting the western suburbs to island city of Mumbai. This north-southwestern corridor would be highly congested resulting in a bottleneck at rush hours. The sea link was thus proposed to act as an alternate route between the western suburbs of Mumbai and central Mumbai, in addition to the existing Mahim Causeway, thus easing congestion. This link would also form a part of the larger West Island Freeway spanning the entire coastline. The project was initiated more than 10 years ago in 1999 and was supposed to be completed within 5 years but it was delayed due to public interest litigations. The foundation stone was laid in 1999, by Shiv Sena supremo Balasaheb Thackeray. It was to cost 300 crore and finished in 2004. The BWSL project is a part of the Western Freeway Sea Project, which, in turn, is a part of a larger proposal to upgrade the road transportation network of greater Mumbai. It is primarily meant to provide an alternative to the Mahim Causeway route that is presently the only connection between South Mumbai and the Western and Central suburbs. The project starts from the intersection of Western Express Highway and SV Road at the Bandra end, and connects it to Khan Abdul Gaffar Khan Road (Worli Seaface) at the Worli end which in turn connects to Mumbai's arterial Annie Besant Road at the Narayan Pujari Nagar corner. The MSRDC is planning to open the remaining four lanes of the sea link by March 2010. The project has been commissioned by the Maharashtra State Road Development Corporation Ltd (MSRDC), designed by DAR Consultants and is being built by Hindustan Construction Company (HCC).

Photo no. 1.2 traffic at mahim cause way

K.K.Wagh Polytechnic, Nashik

Page 2

Case Study of Bandra-Worli Sea Link

1.2 Major Components of the Sea-Link spans.

449m long embankment with 20m wide promenades for 16-lane toll plaza. 800m long Precast Segmental Approach Bridge on Bandra Side. 600m long Cable Stayed Bridge 125m high Towers including transition 200m long Precast Segmental Approach Bridge between Bandra Cable

Stayed Bridge and Worli Cable Stayed Bridge.

350m long Cable Stayed Bridge on the Worli with Pylons including

transition spans 1400m Precast Segmental Approach Bridge on Worli Side. 811m long link to Khan Abdul Ghaffar Khan Road comprising 510m Precast

Segmental Bridge and 310m Cast-in-Situ Bridge. Systems. Drainage, Street Lighting, Signage Making, Landscaping and Arboriculture. Setting up Traffic Monitoring, Surveillance, Information and Control

1.3 Benefits of project

Savings in vehicle operating cost to the tune of Rs.100 crores per annum due to

reduction in congestion in the existing roads and lower vehicle operating cost on the bridge.

Considerable savings in travel time due to increased speed and reduced delays at Ease in driving with reduced mental tension and overall improvement in the Improvement in environment especially in terms of reduction in carbon

intersections at existing roads.

quality of life.

monoxide, oxides of nitrogen and reduction in noise pollution in areas of Mahim, Dadar, Prabhadevi and Worli.

Project to have no adverse effect on fisheries, marine life and livelihood of Proper landscaping measures along the approaches and promenade along

fisherman.

waterfront to enhance environment of the area.

K.K.Wagh Polytechnic, Nashik

Page 3

Case Study of Bandra-Worli Sea Link

1.4 Various agencies involved during the construction of Package IV are listed below: Client / Owner Maharashtra State Road Development Corporation Ltd. Design Consultants Consortium of Consultants: Sverdrup Asia Ltd. (India) AGRA Earth & Environmental INC. (USA) KPMG India Pvt. Ltd. Shrikhande Consultants India Pvt. Ltd. TPG (India) with HNTB (USA) Ratan J. Batliboi Architects (India) Design Consultants (for cable stay bridges) & Project Management Consultants Dar Consultants (U.K) Ltd. in association with Dar Consultants (India) Pvt. Ltd. Design Consultants (for portion of Link Bridge) STUP Consultants India Pvt. Ltd. Proof Consultants Consortium of Consultants: Construma Consultancy Mott Mc Donald Schlaich Bergermann Proof Consultants (for cable stay bridges) T.Y. Lin International Main Contractor Hindustan Construction Company Ltd.

K.K.Wagh Polytechnic, Nashik

Page 4

Case Study of Bandra-Worli Sea Link

1.5 Construction

The entire project was originally conceived as one large project comprising, different components, but in order to accelerate the overall construction schedule, the project has been divided into five construction packages. These packages helped, to an extent, to make the project meet its deadline. Package I: Construction of flyover over Love Grove junction at Worli Package II: Construction of cloverleaf interchange at Mahim intersection Package III: Construction of solid approach road from the Mahim intersection up to the start of the Toll Plaza on the Bandra side and a public promenade Package IV: Construction of Cable-Stayed Bridges together with viaduct approaches extending from Worli up to the Toll Plaza at Bandra end, Intelligent Bridge System (IBS). Package V: Improvement to Khan Abdul Gaffar Khan Road

Package IV is the largest and main phase of Bandra-Worli Sea Link Project that has been awarded to HCC that includes cable-stayed bridge, viaduct approaches extending from Worli up to Toll Plaza at Bandra end and Modern Toll Plaza

Photo no. 1.3 Progress of construction at Bandra

K.K.Wagh Polytechnic, Nashik

Page 5

Case Study of Bandra-Worli Sea Link

Present Progress Table no. 1.1 Description Pile Pile cap Pier/Abutment Segment casting Segment erection Bandra Cable Stay P19 Worli Cable Stay P27 Worli Cable Stay P30 Finishing Works (SB) Finishing Works (NB) Finishing Works Toll plaza South carriageway opened to traffic from 01/07/09 North carriageway opened to traffic from 24/03/10 Unit Total Progress Total Progress Nos. Nos. Nos. Nos. Span Lifts Lifts Lifts % % % Scope in Nov 10 incl. Nov 10 618 Completed 139 Completed 147 Completed 2342 Completed 125 Completed 84 Completed 36 Completed 34 Completed 100 0 88 100 0 72 100 0 92

Photo no. 1.4 Construction of approach road 1.5 Form

The main cable stayed section of the bridge spans 600m in length, consisting of two 250m cable supported spans and two 50m conventional approach spans. The smaller cable stayed section is 350m in length and comprises of 2 smaller

K.K.Wagh Polytechnic, Nashik Page 6

Case Study of Bandra-Worli Sea Link

cable stayed sections with a 150m central span and 2 of 50m approach spans on either side. The design is described as follows by the designer. The overall tower configuration is an inverted Y" shape with the inclined legs oriented along the axis of the bridge". In total there are 264 cables attached to the towers, they form a semi-fan arrangement. The bridge deck is constructed of pre cast box girder sections which are identical those used for segmented concrete box girder sections". the approaches "the bridge is proposed to be built utilizing the concept of precast, post - tensioned, twin

Photo no. 1.5 Foundation of main pylon

Chapter 2

Aesthetics It was the intention of the designers to create a striking landmark in the design of this structure. Although large span cable stayed bridge design is fairly restrictive due to designs of this size being fairly standard and there being a finite

K.K.Wagh Polytechnic, Nashik Page 7

Case Study of Bandra-Worli Sea Link

number of cable layout options. There are a number of subtle design choices used for this bridge that have helped to achieve an impressive design. The 10 areas of importance in bridge aesthetics suggested by Fritz Leonhard. These are: Fulfillment of function. Proportions Order within the structure Refinement of design Integration with the environment Surface Texture Colour of components Character Complexity in variety Incorporation of nature.

Photo no. 2.1 Front view of main cable stayed As with most cable stayed bridges its structural function is clear and the structure seems to be fulfilling its function well and efficiently. without performing calculations, when looking It is clear at the spans involved

compared to those in the approach section the purpose of the cables in taking the load of the bridge deck. Due to the structural form of cable stayed bridges

K.K.Wagh Polytechnic, Nashik

Page 8

Case Study of Bandra-Worli Sea Link

the interaction between separate functional parts is very pronounced colour and semi-fan layout blurs them when looking from

which

creates clarity and simplicity in design. Although there are a lot of cables, the a distance, do giving, in my opinion the look of a translucent surface. The bridge is well proportioned. Although the towers not appear are massive they to be disproportional when looking at the span that they have to

cater for and again from a visual point of view there appears to be little redundancy in design. The deck is very slender; the aerodynamic shape of the box girder sections allows the edges to be thin. The final design shows that the edges will be finished in a light colour, drawing attention to the deck. The width of the deck is so great it would have been easy to end up with very large towers. A graceful solution has been found whereby the 4 columns supporting the deck meet to form one column above the deck and 2 piers below, disguising the fact that there is such an expansive deck. The deck appears sufficient in completing the triangle created by the towers and the deck. There is order in the repetitive nature of this bridge and although the two cable stayed sections of the bridge are different, efforts have been made to mirror structural elements to create order. The cable stayed sections are of the same proportions, the greater span of the Bandra end bridge is created by merely increasing the number of cables, the tower height and cable spacing is similar for both cable stayed sections. The spacing of the piers for the approach section is concurrent however it could be argued that the spans could be made larger as from some angles there appears to be a forest of piers due to the bridge curving on plan. As already mentioned the order of the cables seems to work well, the semi-fan layout compliments the structural form of the towers because the density of cables connected in one plane increases as the 4 columns become one. This is an improvement of a precedent to this design in the Rion Antirion Bridge in Greece, where in my opinion the four columns which join appear too slender in comparison to the larger pier beneath the deck. There are a number of refinements that have been used to assist and improve the elegance of this structure. Most of these refinements tend to promote the simplicity of the bridge rather than adding to its complexity. The most worthwhile mentioning is the connection between the stays and the deck.

K.K.Wagh Polytechnic, Nashik

Page 9

Case Study of Bandra-Worli Sea Link

The connection is hidden beneath the deck which offers a very neat interaction between the stays and the top side of the deck. This solution is both graceful and practical as the connections are still accessible for inspection. The piers supporting the approach deck are widened at their juncture with the deck so that there is dimensional coherence between the two elements. There is a gentle taper to the columns in the towers which is continued through the deck, this is pleasing to the eye without being overly apparent. As a rule of thumb cable stayed bridges look fitting over a large expanse of water, in that sense it was a good design choice for its natural environment but the more important factor with this bridge is its sympathy to its urban environment. It is in a very prominent position and needs to look appropriate for its stage. The designers had the tricky task of designing something that would befit a business district and a harbour town. Whether this had been achieved is a matter of opinion. The designers have achieved in making something that from a distance is stylish and intricately simple in appearance but for the commuters who will use the road it will feel as though it is part of the city and merely an extension to the road network. The primary observation about texture is that the concrete in the towers is notched making it appear much darker than the concrete used in the deck. Whether this was a detail based more on practicality than aesthetics, it does serve to emphasize the much lighter cables and deck which is a virtuous property in bridge design. The piers also appear to be darker, this may be due to them being shaded by the deck, this helps in making the piers merge with the sea. It is difficult to analyse how colours will look on completion. It is also difficult to define the character of this bridge because of the nature of the large span cable structure and the similarities to many other bridges of this type. My opinion is that the character of this bridge is defined by its use and the fact that the function of this bridge says a lot about the surrounding area and the congestion in Mumbai, the fact that the solution to connecting two areas which are not separated themselves by water, using a bridge over the sea is testament to the level of traffic in Mumbai and the desperate need to relieve this with such an ambitious solution. It is important to give a separate consideration to the pylons and cables which appear to have been subject to much thought in terms of design. The pylons tend to

K.K.Wagh Polytechnic, Nashik

Page 10

Case Study of Bandra-Worli Sea Link

have a governing influence over the overall architectural layout. when considering the loads that it is carried.

However the

design appears to make structural sense and you can see that it is proportioned well Although it is an architectural statement it does not clash with the structural behaviour and therefore does not interrupt the clarity of structural form which is so often one of the most attractive features of cable stayed structures.

Chapter 3

Structure

3.1 Pylons tower legs

Pylons are arguably the most important components of a cable stayed bridge. The main span bridge has 2 pylons, each with 4 legs; each tower is inclined towards the

K.K.Wagh Polytechnic, Nashik

Page 11

Case Study of Bandra-Worli Sea Link

other by 10, eventually merging at 98m above deck to become a single tower. Transverse and longitudinal post - tensioning is provided in the tower head to resist local cable forces. The single tower is tapered towards the very top. Beneath the superstructure of the bridge the 4 legs merge to 2 points which are carried into the ground through the pile caps.

Photo no.3.1 progress in main cable stayed As with most cable stayed bridges the pylons are very stiff. An A-frame adds torsional stiffness to the bridge, this is due to the natural resistance to twisting created by the closed triangle. The stiff pylon in conjunction with the slender deck and numerous cables means that the pylon will be subjected to high longitudinal moments due to the live loads on the deck and pylon itself.

The salient characteristics of the pylon tower that make it complex and challenging from the point of view of constructability are as follows: (a) The section decreases gradually with height; (b) There are horizontal grooves at every 3m height and vertical grooves for circular portion that requires special form liners as well as it requires attention for de-shuttering;

K.K.Wagh Polytechnic, Nashik

Page 12

Case Study of Bandra-Worli Sea Link

(c) The tower legs are inclined in two directions, which creates complexities in alignment and climbing of soldiers; (d) Construction joints permitted only at 3m level. Inserts were permitted only in horizontal grooves provided at 3m height. On not being able to get immediate solution from reputed worldwide formwork manufacturers, the project design team designed an automatic climbing shutter formwork system, which was fabricated on site and employed to execute all tower leg lifts below deck level. To affect further reduction in time cycles, HCC approached Doka, Austria. Doka then devised a customized solution based on their SKE-100 automatic climbing shutter system.

3.2 Cables

Photo no.3.2 Cable cross section The arrangement of the cables is 4 planes of a semi- fan arrangement. "The Cable Stay system comprises 2,250 km of high strength galvanized steel wires which support the Cable Stay Bridge weighing 20,000 tons". Each deck section has 2 planes of inclined cables which are attached to the top of the tower in one plane. This layout of cables is suitable for the large spans as the inclined arrangement provides the lateral stiffness required. The advantage of this layout is that the deck can be slender as it does not have to account for the torsional

K.K.Wagh Polytechnic, Nashik Page 13

Case Study of Bandra-Worli Sea Link

inadequacies of a single plane of cables whilst taking advantage of the preferred aesthetics of a single plane attachment to the pylon. The cables are inclined due to A-frame pylons. "The deck and the two planes of inclined stays behave like a rigid closed section in bending" Having this apparent closed section made by the deck, the inclined stays and pylon causes the rigidities of the deck and pylons to work together to make a rigid structure which acts against rotation in the deck. The inclination of the cables is such that clearance is not an issue for the passage of vehicles across the deck due to the spans involved and the height of the pylon, it means that the level of inclination is slight. The method of lateral suspension used in this case causes transverse bending moments with a maximum in the centre of the deck. There are points of maximum shear at the edges of the deck. It was therefore important that the design took into consideration the possibility that the transverse pre- stress in the deck and the anchorage for the cables may clash. Cable spacing is 6.0 meters along the bridge deck.

3.3 Deck The deck of the Bandra Worli Sea Link consists of a hollow concrete box section with 3 cores, the dimensions of the deck varies throughout the length of the bridge. The pre-cast segments vary in length from 1.5m to 3.1m. Each section of bridge deck will be post tensioned following installation. The idea behind having a very slender and lightweight deck is to reduce the longitudinal stiffness, it is therefore advantageous to provide a very flexible deck. Because this bridge

K.K.Wagh Polytechnic, Nashik Page 14

Case Study of Bandra-Worli Sea Link

utilises a lateral suspension, bending within the deck is reduced and torsion in the deck is not normally a critical case. For flexible decks the dimensions of the deck are determined by the transverse moments and the size of the point loads at the anchorages, this is therefore governed by the separation of those cables. For the type of box section used at Bandra Worli Sea link the top slab is continuous over the webs and props. The use of webs and props creates a multi-box section allows the large width which is required for each direction of traffic.

Photo no. 3.3 Construction of Deck

3.4 Foundations The foundations were designed by Lachel Felice. The drilled shaft method of construction was used to for the shafts. The shafts vary considerably in size, highly depending on the bedrock "Rock encountered at the site included percent and unconfined compressive strengths

weathered, fractured and oxidized volcanic material with RQD's of less than 25 of 1 MPa". Foundations for the towers comprised of 52- 2m diameter piles arranged in a H shape to capably support the legs of the pylon, they are up to 34m in length. The loads on different parts of the structure vary considerably and this was reflected in the variability of the shaft sizes to accommodate loads from 2-25MN.

K.K.Wagh Polytechnic, Nashik

Page 15

Case Study of Bandra-Worli Sea Link

Photo no. 3.4 Construction of foundation below the cable stayed portion

Chapter 4

Constructions

4.1 Foundation Construction

K.K.Wagh Polytechnic, Nashik

Page 16

Case Study of Bandra-Worli Sea Link

The foundations being the most important elements of the bridge, its also one of the most challenging activities at the project due to geological conditions. All the Piles in the Project are vertical and cast-in-situ permanent steel liners and are friction and end-bearing type of Piles.

Fig. no. 4.1 Process of driving piles The piles are driven with RCD Rigs mounted on the Jack up Platforms. Construction of cofferdam followed by the placement of tremie seal after the dewatering is required for the erection of a pile. Concrete produced at the Batching Plant under controlled conditions is transported by agitator drums on concrete barges and is placed at the required location using Concrete Pumps. The number of M60 piles and its depth along with its diameter in a foundation varies from Pier to Pier, and depends mainly on the load it takes from the Sub-structure.

K.K.Wagh Polytechnic, Nashik

Page 17

Case Study of Bandra-Worli Sea Link

Photo no. 4.1 Constructed piers Each Pier is given an id as which represents its position from the Bandra end of the Bridge, the ith Pier is given id as Pi for example the first Pier from the Bandra side is given an id as P1. So, number of Piles from P1 to P18 and P20 to P60 are 4and each are of diameter 1500mm except for P17, P18, P20 and P21 which has Piles of diameter 2000mm. The number of Piles for P19 is 52 including both north and south carriageways, and the diameter for each Pile is 2000mm. Lastly, P27 and P30 have 6 Piles each of diameter 2000mm, this includes both carriageways. The depth of each Pile depends on the depth of sea at the particular place, which in general varies from 5.15m to 663.4m at P19.

Photo no. 4.2 RCD Drill Bit used in RCD Rigs for foundation construction

K.K.Wagh Polytechnic, Nashik

Page 18

Case Study of Bandra-Worli Sea Link

Photo no. 4.3 Pile Cap Reinforcement at fabrication yard

4.2 SUB STRUCTURE CONSTRUCTION

Fig. no. 4.2

K.K.Wagh Polytechnic, Nashik Page 19

Case Study of Bandra-Worli Sea Link

The Piers for the bridge are hollow but the Piercaps are solid mass of concrete. Prefabricated reinforcement cages are brought at site for the construction of the piers and sacrificial concrete lines are installed with a top cover so as to create the hollow part inside them. Once inner liners are installed the cage is aligned in the position and placed as requisite and concreting is done after installing the outer form. The recess for bearing installation is cast with Pier cap.

Photo no. 4.4 Pile Cap Reinforcement

Photo no. 4.5 A concrete pump pumping concrete in Pier Cap

K.K.Wagh Polytechnic, Nashik

Page 20

Case Study of Bandra-Worli Sea Link

Photo no. 4.6 The formwork for the Sub structure construction

Photo no. 4.7 Completion of pier cap

Photo no. 4.8 The bearing between a Pier and a Pier

K.K.Wagh Polytechnic, Nashik Page 21

Case Study of Bandra-Worli Sea Link

4.3 SUPER STRUCTURE CONSTRUCTION The segments are cast at a centralized pre-casting yard using short line method of casting, which means once a segment is casted its conjugate segment is casted right after it so as the two of them matches. Sophisticated software is used to arrive at the correct casting curves for the segments. The concrete for the segments is supplied by the Batching Plant and is pumped in each module after which the segments are transported to the construction site. The Erection Gantry, a picture of which is illustrated, does the erection of span. A typical 50m span comprises of 15 numbers of precast segments, a Pier segment and 200mm (nominal) in-situ wet joints. For the construction all the spans, all the segments are suspended from the Gantry, glued and temporarily stressed together, on completion of which span alignment to the piers is followed. After the alignment, wet joints are casted including grouting of bearings top plinth. Once the wet joints achieve the required strength, stressing of longitudinal PT is commenced followed by the load transfer of span to Piers. A complete construction of a segment takes about a month, which includes its curing as well as it is being casted by the short line method of casting. A cell is the place where a segment is casted, before casting a segment a survey team decides its position in cell. Once the survey team sets the bulkhead, the rebar setup takes place which takes different amount of time depending upon the type of segment and could be as much as 20 to 30 days. After rebar setup is done, the concrete is poured in the formwork and is allowed to set out, after which again a survey team confirms its successful casting. Then the segment is displaced from its position and it position is taken by another formwork and rebar setup which is of its conjugate segment. The two segments are being linked through a male-female joint, in the meanwhile the casted segment is allowed to gain strength and also its curing is done side by side. Once the casted has gained enough strength its initial tensioning is done with force about 30% of its maximum capacity. Then we further wait for it to gain strength of about 40Mpa or more and final testing with rest of the 70% load is done which marks the completion of the procedure. Once a segment is completed it is transferred to the stock where it is given a particular and it waits for its turn to come. As for the conjugate segment, as its concreting is completed it takes place of the completed segment and another

K.K.Wagh Polytechnic, Nashik

Page 22

Case Study of Bandra-Worli Sea Link

matching segment takes its place and so the process goes on. Here at Bandra Worli Sea Link we have 8 cells to makes all the different types of segments.

There are a number of equipments which deployed in the pre-casting yard which mainly includes the following:

1) Hydraulic Jacks of different capacities 2) Turn Buckles 3) Gantry, for lifting segments 4) Tower Crain 5) Concrete Pumps 6) Cutting and bending machines for rebar of segments.

The tensioning test that is being done here at casting yard plays a very significant role for a segment to be perfect, as it decides the that segment thus casted can be lifted at all or not. Once a segment passes this test, this means that it can be easily lifted by any gantry or through any other process during the construction of the bridge. There are many other advantages of using the process of short line method which can be tabulated as follows:

1) As already stated, it prepares a segment for lifting 2) It also gives enough time for the curing of a segment 3) It also helps to start the other segment as soon as one is completed

So, it basically less time consuming and efficient process for the building of segments. The pictures of various important components of pre-casting yard and other important processes are given below:

K.K.Wagh Polytechnic, Nashik

Page 23

Case Study of Bandra-Worli Sea Link

Photo no. 4.9 Casting Yard Stock, the lowermost and the one above it are conjugate segments

Photo no. 4.10 Post Tensioning cables are stressed using VSL multi pull jack

K.K.Wagh Polytechnic, Nashik

Page 24

Case Study of Bandra-Worli Sea Link

Photo no. 4.11 A segment on barge being taken to Derrick

Photo no. 4.12 Batching plant

K.K.Wagh Polytechnic, Nashik

Page 25

Case Study of Bandra-Worli Sea Link

Photo no. 4.13 A segment being cast and its conjugate

Photo no. 4.14 Segment being taken from the casting yard to jetty

K.K.Wagh Polytechnic, Nashik

Page 26

Case Study of Bandra-Worli Sea Link

Photo no. 4.15 The Top View of the Casting Yard

Photo no. 4.16 Erection gantry

K.K.Wagh Polytechnic, Nashik

Page 27

Case Study of Bandra-Worli Sea Link

Photo no. 4.17 The details of the Erection Gantry

Photo no. 4.18 The Asian Hercules and Erection Gantry, the Asian Hercules was

Page 28

K.K.Wagh Polytechnic, Nashik

Case Study of Bandra-Worli Sea Link

Hired to displace the Erection Gantry

Fig. no. 4.3 Different types of segments

K.K.Wagh Polytechnic, Nashik

Page 29

Case Study of Bandra-Worli Sea Link

4.4 CABLE STAYED BRIDGE

There are two Cable Stayed Bridges in the Sea Link Project with a complex geometry as one pair of the towers is inclined in two planes and the entire cross section reduces continuously over the entire height of the Towers. The other concern is the Casting and Geometry of the Bridge, as the bride has to attain reference geometry after 2000 days in the service stage which requires a detailed analysis of the time dependent factors such as creep, shrinkage and temperature. The design of the Stay Cables, anchorages and stressing forces are all governed by this parameter. The Stay Cables for the bridge were subjected to a series of quality and engineering tests to meet special requirements including Fatigue Test. The concrete for the Bridge is M60 grade and Micro silica is added to improve the quality of the concrete. The construction of a cable-stayed bridge requires high engineering skills and its the most challenging part of the whole Bridge. Its construction can be divided among following components:

Photo no. 4.19 Complete cable stayed bridge at Bandra-side of the Sea Link

K.K.Wagh Polytechnic, Nashik

Page 30

Case Study of Bandra-Worli Sea Link

4.4.1 Construction of foundation

The P19 Pylon of Bandra Worli Sea Link stands on a foundation comprising of 52 nos. M50 Piles, each of 2m diameters arranged in definite framework as illustrated in the following picture.

Fig. no. 4.4 Foundation below the Pylon

4.4.2 Construction of Tower or Pylon below deck The construction of Pylon below includes 6 lifts of M60 grade concrete each of 3.0m and 1 lift of 3.260m. The rebar layout for every leg is predesigned and the steel bars are being cut and bent as per the requirements of the prefabricated reinforcement cages at the rebar fabrication yard. These bars are then taken to the Pilecap P19 through the means of Barge where they will be fixed in the requisite fashion. Reference checks shall be made with respect to the centre line of the carriageway and control points of tower to align the cage of bars to its desired position. Then the arrangements for concreting are checked so that no interruption occurs during concreting. The concreting will be done in layers through a concrete pump placed on a temporary platform followed by vibrating with needles of appropriate diameters. Thepouring concrete is done in a peripheral

K.K.Wagh Polytechnic, Nashik

Page 31

Case Study of Bandra-Worli Sea Link

manner in which its done from the centre towards the wall. Hessian cloth rolls immersed in water are used for the curing of concrete once its initially set, or greater heights, a wet skirt of suitable length can kept in contact with the concrete. Dripping of water due to excess application should be avoided and a higher relative humidity will be maintained. The final surface will be given finishing touch by masons. The geometry of the tower is controlled by an integrated set of procedures undertaken during the construction planning and construction stages so as to ensure that any environmental or any other actions does not effects the target geometry that is to be attained by the Pylon. A stage-by-stage construction analysis of all the different types of forces and other actions is already carried out during the planning so to establish the optimum construction sequence and the requirements for temporary supports, restraints, and jacking forces. This will be helpful during the construction of the tower as it will define the target incremental and total geometry profiles at each construction stage, and estimated jacking displacements for pylons and alignment of components, together with associated jacking forces. The formwork for every lift is already preplanned and designed; also the sequence of the erection of the various lifts is predefined. A trial mock up fitting shall be conducted to check the dimensional fitting of the formwork system before installing the same at location.

Fig. no. 4.5 Construction process of pylon

4.4.3 Construction of Diaphragm

K.K.Wagh Polytechnic, Nashik Page 32

Case Study of Bandra-Worli Sea Link

The formwork of diaphragm and adjacent segments will be supported on the staging truss of pier table beneath with the help of a system of supporting brackets spanning between the tower legs. The reinforcement cage for the diaphragm will be cut and bent as per the preset design at the rebar fabrication yard from there to the desired place and tied. The cage is then aligned to its required position with respect to various survey points and all the requisite inserts shall be fixed in position and required checks shall be made. The formwork is designed in such a manner that the 8th Lift of the tower, adjacent segments and the diaphragm will be cast a single unit, and al so it shall be custom made to suit the requirements of geometry, inserts and Post tensioning. Survey Checks will be made at appropriate stages to confirm the exact posit ion of form before casting of the section. The concreting will be done with M60 Grade Concrete and will be carried out in layers. The final top surface of tower leg is given a texture finish using brooms. As early as possible after initial setting, hessian cloth will be spread and sprinkled with water. Once the casting is done prestressing will be commenced as soon as the adjacent segments are being casted. 4.4.4 Construction of Pier Table The Pire Table constitutes the cast-in-situ diaphragms, adjacent segments and segments between and outside Tower Legs.

Fig. no. 4.6

K.K.Wagh Polytechnic, Nashik

Page 33

Case Study of Bandra-Worli Sea Link

The construction of the Pier Table begins with the temporary arrangements for the Erection of Pier Table Segments and the Construction of Diaphragm explained followed by method for construction of Permanent Structures. The temporary arrangement includes five columns four of which are on the Pile cap and fifth lies in the sea. The pedestals for each column is of size 600mm X 600mm are casted at the pre marked required positions with the anchor bars positioned in them. The top levels of each pedestal are then matched before fixing of the top plates. The construction of a column starts with proper positioning and marking and followed by the lower modules. Once lower modules are completed, upper modules are erected and the top levels of all the columns are checked. Following this will be the erection of the truss modules from one end to the other. The modules of the truss resting directly over the columns will be erected using the crawler crane as weight of the module exceeds the capacity of the tower crane at desired working radius. The intermediate modules would be erected using the tower crane. The truss is then leveled and aligned for installation of the lifting device of segments. The leveling and alignment of the segments will be done by screw jacks mounted on the sliding shoe. This marks the completion of the temporary part of the Pier Table the permanent structure includes pre casted segments at the casting yard. The segments are delivered to the Pylon P19 through barge from where its lifted on the top of the truss with Strand Lifting Unit (SLU) mounted on the lifting arrangement. The segments are then sided to their positions where the longitudinal and transverse slopes would be adjusted by the combination of screw jacks and shims mounted on the sliding chair. The middle 7 segments inside the tower legs are then stressed and glued to their final position, immediately after that segments on both sides of tower legs will be placed at 6.0m distances on both sides from the end segments inside the tower legs and restrained against any movement. The procedure for the further construction of the Pier Table is already being discussed in the previous section construction of diaphragm besides that the only part left is Post Tensioning which is done once the diaphragms are being casted together with the adjacent segments. Post tensioning includes stressing the segments and transferring the load from the truss to the pylon legs and at the time of pre stressing the segments in the longitudinal direction it

K.K.Wagh Polytechnic, Nashik

Page 34

Case Study of Bandra-Worli Sea Link

would have already be seen that the horizontal props erected between the tower legs are removed. The main truss is then dismantled and modules and Pier Table for the other carriageway are then to be erected with the same procedure.

4.4.5 Construction of Tower or Pylon above deck

The construction of the Pylon above the deck includes steps starting from the making of kickers to the top of the Pylon. The Kicker for the Bandra Tower Legs will be cast using custom made formwork to suit for kickers of each leg of the Pylon. These forms shall be lined with those, which would be there already after the casting of the diaphragms and 8th lift of the Tower. Once the kickers are set the DOKA formwork is positioned and aligned according to the pre calculated theoretical values. Followed by which concreting is done and the data for the position is again taken and matched with the theoretical values, in case of any discrepancy the corrections are made to the following lift. This cycle is continued till the 24 Lifts of the Tower are complete. the Pylon P19. Meanwhile Compression struts and cross bracings are provided at the required and pre calculated positions if

Fig. no. 4.7 Cross section of pier

K.K.Wagh Polytechnic, Nashik

Page 35

Case Study of Bandra-Worli Sea Link

Fig. no. 4.8 Bandra cable stayed

The operations of DOKA Formwork are subject to the conditions mentioned below. In no case, these operating conditions will be overruled. The Following wind speeds are binding according to the static calculations: During Working and climbing process:

K.K.Wagh Polytechnic, Nashik

Page 36

Case Study of Bandra-Worli Sea Link

Max Wind Speed = 70kmph Wind speed-exceeding 70kmph: ALL WORKING AND CLIMBING PROCESS TO BE STOPPED Wind speed-exceeding 100kmph: CLOSE FORMWORK Wind speed-exceeding 164kmph: FORM SYSTEM MUST BE TIED TO REINFORCEMENT

4.4.6 Erection of Deck and Stay Cables

The Bandra Cable Stayed Bridge spans for 600m comprising of the main bridge with a 500m Cable stayed span and 50m transition spans on either side. The cables used in the construction of the Bridge are multi-strand parallel wire cables; the number of wires in each cable varies with the amount of tension it carries. These cables are prefabricated which also includes the anchorages provided on the both sides and these are being imported from China. These cables are imported in exactly pre-calculated length and nos. of wire containing; the length also includes that of anchorages at the two ends of the cable. A detail drawing of cross-section of a cable used in the bridges is given below: The transition spans together with the cantilever segments will be erected using launching girder, whereas the segments between the pier table and the closure pour shall be erected using balance cantilever construction method. The construction of the deck is carried out with the Derrick as shown in the picture, the segments are carried from the casting yard beneath derrick from where it picks it up and places it. The detail working of this is shown below.

K.K.Wagh Polytechnic, Nashik

Page 37

Case Study of Bandra-Worli Sea Link

STAGE: 1

Open the Support Bracket and Lift the Segment. Close the Support Bracket, Slide in the Trolley and Lower the Segment on Sliding Trolley.

K.K.Wagh Polytechnic, Nashik

Page 38

Case Study of Bandra-Worli Sea Link

STAGE: 2

Open the Lifting Boom & Strut, Slide out the Segment and Close the Lifting Boom and & Strut.

3-D VIEW OF LIFTING FRAME

K.K.Wagh Polytechnic, Nashik

Page 39

Case Study of Bandra-Worli Sea Link

Note: The above Derrick is used for the Pier Table Erection.

4.4.7 Operation of Derrick

K.K.Wagh Polytechnic, Nashik

Page 40

Case Study of Bandra-Worli Sea Link

Derrick used for the Deck Erection of Cable-Stayed Deck As illustrated above the derrick places a segment in two stages, but before placing the segment its being dry matched with the previous segment and then epoxy glue is applied, followed by which its stressed. Once the epoxy is dried Post Tensioning (PT) cables with very high Ultimate Tensile Strength (UTS) are applied at the joint. The segment is then released from the derrick so that it moves forward to take the next one.

This process can be explained in detail as follows: Let us consider that we have to erect Nth segment on the Deck which is a segment without blister that is, which is not a cable-stayed segment. So, we go through following procedure:

1) Advance the segment erection derrick from Segment N-3 to Segment N-1 (cable stayed segment). 2) Load the Segment N on the Segment Carrying Barge (Segment without stay pipe) and Haul and park the barge below the Derrick lifting points, from where the segment is lifted. 3) Dry match segment N with Segment N-1, apply epoxy, stress for gluing and wait for epoxy to dry. 4) Apply Temporary PT at Joint between Segment N and N-1 for cantilever construction and release the segment from the derrick. 5) Stress the cable anchored in Segment N-1 to second stage. 6) Forward the Segment Lifting Beam on the derrick and position for lifting of Segment N+1, after which Load the Segment N+1 on the Segment Carrying Barge (Segment with stay pipe). 7) Haul and Park the barge below the Lifting Point, from where it is lifted and dry match with Segment N+1is done, apply epoxy, stress for gluing and wait for epoxy to dry. 8) Apply Temporary PT at Joint between Segment N and N+1 for cantilever construction and release the segment from the derrick. 9) Stress the stay cable anchored in segment N+1 to first stage installation force. 15. Survey the predetermined survey points on the deck at dawn.

K.K.Wagh Polytechnic, Nashik Page 41

Case Study of Bandra-Worli Sea Link

10) Repeat the above steps for further segments

The segments used here are pre-casted segments, which are already fabricated and are kept at the Casting yard; once a segment is casted it is given an id number. When its turn comes the is loaded on the trailer only after all the accessories such as connection beams, steel shoes have been fitted and post concreting inspection have cleared the same. The segment is then loaded on a barge at jetty and is hauled to the point where the Derrick will lift it. Before the Nth segment is glued, a dry matching of the segment is done. After dry matching the segment is taken back by 400mm, and then epoxy is applied on the face of the same. Once the epoxy is applied the segment is glued with the N1 segment and then the segments are stressed with the PT bars. Before Lifting the Segment N + 1, the stay cable anchored in the Segment N-1 shall be stressed to the provisional tension force as per the values based on the required deformation to be achieved by the segment N1, as per the data given in Construction Manual. Therefore, in order not to bring the survey in the critical path of the operations (as stressing could occur of any time of day and survey has to be necessarily carried out in the dawn), the cable shall be stressed according to the expected deformation of deck. The corresponding force (F) shall be computed and applied to the cable in the steps. Now, process of erection of the N+1 segment is similar to that of N but with a difference that once the tensioning of the segment is done, the erection of a stay cable comes into picture. Therefore the process is kept repeating in a Balanced Cantilever fashion and every time when a segment is brought under the derrick and as its lifted up from the barge it also has to avoid any possible collision with the barge. To avoid any such collisions small wooden planks of pre calculated thickness, on the basis of swell in sea, would be kept under the segment as soon as its lifted up from the barge.

The process cable erection like derrick also follows a particular methodology, which is as follows: a) Uncoil the cable on the bridge deck using an Uncoiled and Winch b) Fix the upper (fixed) anchorage into the tower top using a deviator device

K.K.Wagh Polytechnic, Nashik

Page 42

Case Study of Bandra-Worli Sea Link

c) Pull the lower end of the cable near anchorage using an winch and then guide into anchorage d) Stress the cable from the deck and adjust the force with hydraulic jacks As already stated once the cable is erected it will be stressed to the installation force only, a detail illustrative procedure is given as follows:

K.K.Wagh Polytechnic, Nashik

Page 43

Case Study of Bandra-Worli Sea Link

Fig. no. 4.9 Erection process of Cables

4.4.8 Wet Joint Construction The main span of the Cable-Stayed bridges would be consisted of proposed 50mm joints at specific predefined locations. The segments at these locations are first slided by the derrick and a gap of 50mm is made which is surveyed for final adjustments. On completing the final adjustments temporary PT bars are placed in the gap so as to keep the segment in place, after which the steel form is placed at specified position and M60 Grade concrete is poured into it. When the concrete gains strength temporary PT bars are removed and the required PT bars are

K.K.Wagh Polytechnic, Nashik Page 44

Case Study of Bandra-Worli Sea Link

installed to get the required fore for cantilever construction. After carrying the Prestressing of temporary PT Bars to the required force release the segment from the derrick and continue further with main span erection as per normal procedure.

The main purposes of these wet joints are as follows: 1) The deck units between the wet joints can be cast in different cells independent of other units. Thus, a number of such units can be cast simultaneously in different casting cells. This will reduce the time required to complete casting of segments and allows flexibility while casting segments of Bandra and Worli Cable Stay bridges in same set of casting cells. 2) Due to the long length of the span deck erection, need some finer corrections to maintain the desired geometry. Wet joints at predetermined location will allow this flexibility to apply corrections, if any.

K.K.Wagh Polytechnic, Nashik

Page 45

Case Study of Bandra-Worli Sea Link

Fig. no. 4.10 C/S of Bandra cable stayed

K.K.Wagh Polytechnic, Nashik

Page 46

Case Study of Bandra-Worli Sea Link

Fig. no. 4.11 C/S of Worli cable stayed tower

4.4.9 Continuity PT and Grouting Once the Deck is complete Post Tensioning of all the segments is done so as to bring them to a specific predetermined geometry. This geometry was calculated during the planning of the bridge and was found with great care and precision, as it will determine the final shape and geometry of the whole bridge. The grouting of the bridge includes a major task of fill up the space left in the holes for the PT cables. It is a mixture of various kinds of available admixtures and water as a result they form slurry which is then filled to complete the holes in the segments. This is a very important process as grouting secures that rusting of PT bars does not take place at all. Therefore one can say that the life of bridge depends on the material used for grouting.

K.K.Wagh Polytechnic, Nashik

Page 47

Case Study of Bandra-Worli Sea Link

4.4.10 Cable force adjustment and Fine Tuning This is an iterative process, which is to be done as the last stage once the bridge is complete. It includes rechecking of tension forces in each cable so as to confirm that it equals the forces, which were determined theoretically at the time of planning with a least 1 to 2 percent of variation. Sometimes it may get tedious to check force in each cable again as again as a small change in one cable will bring changes to other cables as well.

K.K.Wagh Polytechnic, Nashik

Page 48

Case Study of Bandra-Worli Sea Link

Chapter 5

Construction Methods The precast concrete sections of the deck were launched incrementally between the pillars using a truss system, known as the balanced cantilever method. The bespoke girder spans between two piers with the girder being supported on the outside pier by a temporary support. This allows the central carriage to move between the two piers to install the precast deck sections by picking them up and winching them into the appropriate position. The precast sections were then made the epoxied together and given a certain degree of pre-stress to hold them in place. Once each span had completed and geometrical adjustments primary continuous tendons were stressed to the required level. Once the deck section was in its requisite position cable connection can begin, using the following method. The cables are delivered to site and uncoiled using a winch, fixed to their anchor at the upper tower, winched towards the deck connection and guided into the anchorage then stressed to the required level using hydraulic jacks. One major obstacle which had to be overcome during the construction process was how to move the large truss from the Bandra end of the bridge to the Worli end without having to dismantle the truss which would be too time consuming on such a high profile structure with a strict timescale. A decision was made to use a large sea crane to lift the truss into its new position, however the depth of the water at low tide meant that the crane could only be used at instances of high tide, this meant that the operation took a number of days. The span by span method was used for the construction of the approach sections of the bridge. Where each span was constructed up to its nearest point of contraflexure to the pier, the formwork is then shifted to the next span and the cycle is repeated. All of the rebar and formwork for the pylon, the diaphragm and the pier table were constructed off site and the pouring was carried out in stages. Due to the inclination and height of the main tower temporary longitudinal and transverse compression struts were required during construction. Geometric control is required to ensure as-built accuracy, for this reason reference points are taken at the base of towers, anchor point and completed structure, these point are used to set formwork.

K.K.Wagh Polytechnic, Nashik Page 49

Case Study of Bandra-Worli Sea Link

A programme of works for the cable stayed section of the bridge as suggested by the contractor can be seen below: Construction of Foundation Construction of Tower /Pylon below the deck Construction of Tower / Pylon above the deck Construction of Pier Table Construction of Diaphragm Construction of Tower/ Pylon above the deck Erection of Deck and Stay Stressing of Stay Cables Wet Joint Construction Continuity PT and Grouting of Cables Force adjustment and fine tuning.

Cables

Chapter 6

Loading

K.K.Wagh Polytechnic, Nashik

Page 50

Case Study of Bandra-Worli Sea Link

The following analysis of some of the primary structural considerations for this bridge will be carried out for Ultimate Limit State (ULS) and Serviceability Limit State (SLS). Dead loads for serviceability should be taken as the actual loads whereas the loads for ultimate limit state will be subject to factors for particular materials and varying load cases such as favourable and unfavourable effects, these are to be found in BS5400 - Table 7.1. Live loads must also be taken into account. . The nominal vales for traffic loads will be given using the HA and HB loading convention where. HA is the combination of the effects of a UDL over a notional lane and a knife-edge load place at the most critical point within this lane. HB loading takes account of a particularly large truck placed at the most critical point along the bridge.

6.1 Dead Loads Dead loads are taken to be just the weight of the precast deck sections, any reinforcing steel is assumed to be accounted for by the increased density of the concrete. Where dimensional information is not available conservative be considered in The deck values have been assumed. The 2 separate decks for traffic in opposite directions can isolation as the structural systems for each deck are independent.

sections considered are 3m in length along most of the bridge, there are some variations in the dimensions of the approach sections but these account for small differences and will be neglected for the purpose of analysis. Density of reinforced concrete = 2400kg/m3 =23.5kN/m3 The web thickness and the top and soffit thickness vary slightly over the sectional profile of the deck. The thickness of top and soffit can be approximated as 150mm and 200mm for the web. Cross-sectional deck area = 7.2 2 23.5 7.2 = 169.5 /

6.2 Super-imposed Dead Load The super-imposed dead load will be taken as merely the components of the road surface. In reality there will be loads incident from the services for the bridge, such

K.K.Wagh Polytechnic, Nashik Page 51

Case Study of Bandra-Worli Sea Link

as lighting and prestressing.

It is likely that these loads will be neglible in

comparison to those from the road surface. It is likely that the deck covering will consist of a waterproof layer, a sand asphalt mix and an asphalt surface. Assumed that this layer can be modeled as 200mm of asphalt with a density of 2300kg/m 3, for analysis. 2300 9.81 1000 = 22.6 22.6 22.7 0.2 = 102/

6.3 Live Traffic Loading HA is the combination of the effects of a UDL over a notional lane and a knifeedge load place at the most critical point within this lane. The primary issue which needs to be considered at this point is the number of notional lanes for the deck, BS5400 3.2.9.3; this defines how much loading there will be on the deck. Carriageway width: >19.0m and 22.8< Therefore there will be 6 notional lanes. The two types of live loads which need to be applied to the bridge separately in their most adverse form are HA and HB loading. HA is a UDL action over 2 notional lanes where all other notional lanes are loaded with 1/3 HA, in addition a KEL of 120kN per notional lane. These loads must be factored for limit state analysis. Because the loaded length is over 380m a load of 9kN/m will be used. This Needs converted into a UDL: 9 3.3 = 2.7kN/m2. 3.3m is the notional width of the loaded lanes. HB loading represents an abnormally large truck. Due to the size and function of this bridge, it is reasonable to suggest full HB loading for the bridge. This is 45 units, where each wheel carries 112.5kN.

6.4 Combination Loading There are a number of load combinations to consider in finding the worst case.

K.K.Wagh Polytechnic, Nashik

Page 52

Case Study of Bandra-Worli Sea Link

For this example look at load case 1 which includes all permanent loads and primary live loads (all traffic loads). previously and are shown below. These loads have been calculated

Table 6.1: Loading For Load Case 1 Loads Dead Superimposed Dead HA HB 1.5 1.3 13.5kN/m 45 nominally 146.3kN wheel per units, Factors ( f) 1.05 1.75 Value 177.9kN/m 178.5kN/m

The loads needs to be applied to spans in a critical manner for both hogging and sagging in order to find the bending moments in the deck. In order to display this clearly the calculations are shown for the 50m approach span sections of the bridge. For maximum sag the smallest, distance between the wheel axels will cause the critical situation for HB loading, therefore 6m separation, 9.6m in total. A possible case of maximum hogging is shown below. The largest vehicle has been chosen for HB loading to concentrate as much load as possible towards the centre of the spans adjacent to the hogging pier. An iterative process may be required in order to place the KEL in the most critical position but for simplicity assumed that it is in the centre of the span to the right of the pier. An assumption has been made for the bending and compression calculations based on this load case that there is no lengthening of the cables during normal loading conditions.

K.K.Wagh Polytechnic, Nashik

Page 53

Case Study of Bandra-Worli Sea Link

6.5 Wind Loading From BS5400 5.3.2.1, the maximum gust that could strike the bridge is: = 112 The height of the deck is 74m from sea level The loaded length is 500m S1=1 S2=1.66 K2=1.42 The average wind speed was found to be 4.5m/s Therefore, = 4.5 1.42 1 1.66 = 10.6/ The horizontal wind load acting on the deck = qA1Cd. Where q is the dynamic pressure head, 0.613Vc And A1 is the solid horizontal projected area C d is a function of b/d. In the case of the Bandra Worli sea link, the depth of the deck with a 1m parapet is greater than the height of the largest vehicle. assumption assume that the bridge has a solid parapet. Therefore b/d=22700/4000=5.675 and C d= 1.3 = 0.613 10.6 2 4 1.3 = 358/ This is not a large force; this is largely due to the relatively low maximum gust. These calculations do not take into account the aerodynamic shape of the deck. This force is taken to act at the centroid. This force will have been taken into account for stability of the parapet. Vertical wind can also be considered for live loading and may be part of the critical load situation, both upwards and downwards wind need to be considered. A similar equation for horizontal loading is used: = 3 68.9 22.7 0.4 = 625.6/ As the depth of the deck and parapet is greater than the largest expected vehicle the depth of 4m will be used again. For uplift the depth without vehicles is always considered as the critical case would always occur when the bridge had no vehicle loading. For a conservative

K.K.Wagh Polytechnic, Nashik

Page 54

Case Study of Bandra-Worli Sea Link

6.6 Seismic Loading Mumbai is in a geographically sensitive area for earthquakes. In general cable stayed structures are extremely effective at coping with ground displacements due to them "resting on a limited number of point supports" [walther]. However differential movement of the supports can cause damage to the structure, this is fairly common with a bridge of this size due to the separation and therefore geological variation between the ground beneath them, particularly affecting the junctions between piers and the deck. For this reason horizontal affects are much more hazardous than vertical movements. The Bandra-Worli Sea link design fulfils the criteria laid out in the Indian standard for earthquake design in bridges IS 1893 (1984). In the introduction to the codes it is stated that all earthquake resistant structures should have good structural configuration, good lateral stability, stiffness and ductility. The structural form of a cable stayed structure delivers adequate ductility and the A- frame shape of the piers along with the generous sizing of the foundations provides a certain degree of stiffness and lateral stability. There are a number of other minor features which contribute to the bridges seismic design such directions. as using DISKTRON bearings which allow complete rotation in both longitudinal and transverse

6.7 Natural Frequency The effects of vibration on the structure of a bridge can be great. Examples of where natural frequency issues of a bridge have caused problems are the Tacoma Narrows Bridge and the Millennium Bridge crossing the Thames. These two examples highlight how the frequency of live loads, apart from wind have to be considered. It demonstrates that the bridge should be analyzed bearing in mind not only collapse but the comfort of the users. Therefore a range of frequencies should be considered to confirm that the bridge will not suffer excessive movement due to having a natural frequency which matches the frequency of any oscillatory loads applied to the bridge. "Without damaging the structure, the vibrations due to wind and traffic can inconvenience users. These physiological effects are generally very subjective experiences". These physiological effects are acceptable when the natural frequency of the bridge is:

K.K.Wagh Polytechnic, Nashik

Page 55

Case Study of Bandra-Worli Sea Link

< < 75

Using: = 2/ 2

x /

The value of C is because the 2 spans on opposite sides of the piers are equal. L = 250m - the longest span occurs at Worli end suspension section. E = 30GPa I = 17m So: = / (2 250) (30 106 9.81 17)/272.5 = 26.9 This is within acceptable bounds

6.8 Cable Sizing The spacing of the cables at the deck is every 6 meters. There is a cable connection at every other precast section of deck. The load carried by each cable will include the live loads and the dead loads of the bridge. The worst case will be when there is full HA loading on two lanes and a third HA loading on the other 4 notional lanes. There will also be a KEL of 120kN per notional lane. There are 2 inclined planes per deck; for the purpose of this analysis the cables will feel the entire load. These calculations therefore conservatively neglect any support from the piers in the cable section. Calculations for the worst case cable will just be display. This is assumed to be where the angle of the cable to the plane of the bridge is least. It should be born in mind when looking at these calculations The critical angle is 26. tan = 120 /250 = 26 The total load over 6 meters of the bridge with the aforementioned vertical loading is 3.03MN. This is split evenly between 2 planes, therefore 1.515MN. This will be the vertical load in the cable; the tension in the cable is therefore: = 1.514 /sin 26

K.K.Wagh Polytechnic, Nashik Page 56

using operational

loads that the worst loading case for the cables may be during construction.

Case Study of Bandra-Worli Sea Link

= 3.46

Using technical information from cable contractors, Shanghai Pujyang Cable Company, we have found that the strength of the steel used is 1860N/mm. This is 64mm diameter of solid steel or 19 cables with a diameter of 15.7mm diameter.

Chapter 7

Compression and Bending

7.1 Deck Compression

K.K.Wagh Polytechnic, Nashik

Page 57

Case Study of Bandra-Worli Sea Link

Some of the horizontal force in the cable will be carried as compression in the deck. Calculate the horizontal force for all of the cables to find the compression in the deck. The total compression in the deck due to cable forces is 200MN. To check this value against the strength of the concrete deck, a stress value needs to be obtained. = / = (7.2 106)/ (200 106) = 27.7 This compression is acceptable as the compressive strength of concrete is between 50 and 60Mpa. If we consider the section between the cables as simply supported, = 2 / 12 = (505000 62)/ 12 = 1515kNm To check in tension, minimum compression in the deck of the suspended bridge section will occur for a in the deck section furthest away from the pier, it has a stress of: = 6.2/ 7.2 = 0.86/2 The compression due to bending moments is shown below: = (1515 106 2000)/(7 x 1012) = 0.176/2 This level of stress seems fairly low for the size of load we are looking at. This seems to be due to the particularly high second moment of area value for the deck. These calculations show that the whole section of the deck will be in compression due to the force transferred by the cables and tensile considerations can be ignored.

7.2 Compression in the Tower The vertical force in each cable will be equal to the weight of the section of deck that the cable carries and any live loads that this section of the deck may be subjected to. This has been calculated to be 3.03MN. For all of the cables, the total compressive force carried into the tower is around 242.4MN. Due to the

K.K.Wagh Polytechnic, Nashik

Page 58

Case Study of Bandra-Worli Sea Link

changing cross section of the tower it is difficult to easily see where the maximum stress will occur without more in depth analysis. For this purpose, as we do not have dimensional information for the tower, we will calculate the area of C50 concrete required to safely carry this load and make visual comparisons to the profile of the tower. = 242.4/ 50 = 4.85 The actual area of concrete appears to be much greater than this throughout the whole profile of the tower. The most critical condition for the tower may be uneven loading, for instance full HA and HB on only one side, this will cause considerable moments at the base of the tower.

7.3 Bending To calculate the bending moments in the bridge assume that the bridge is continuous over piers and has non moment carrying connection at both ends. Due to the scale of the bridge it would be difficult to clarify the distribution of moments for the bridge as a whole. For this reason we can display those for just the cable stayed section. The deck is continuous and is supported by cables which are assumed to take all of the loads, any support from piers has been neglected. There are movements at each end of the cable stayed section of the bridge and there is no moment carried. The bending and shear diagram above shows just a small section but due to the symmetrical and orthotropic nature of the cable stayed section of this bridge the values will be concurrent for the whole length of the cable stayed section. The maximum sagging moment is 2.27MNm and the maximum hogging is 9.09NMm. This produces a stress of: = / = (9.09 109 1500) / (17 1012 ) = 0.8/ 2 < 1

Chapter 8

8.1 Temperature Effects Effective temperature fluctuations and a severe temperature gradient over the profile of a bridge can cause deformations in the members. These deformations

K.K.Wagh Polytechnic, Nashik

Page 59

Case Study of Bandra-Worli Sea Link

must be accommodated in design to avoid high levels of stress being induced in the structure. For example, the designer needs to provide bearings with adequate displacement and rotation capacities. For cable stayed bridges it is

extremely important that temperature changes will not cause the cables to slacken thus reducing their tension and load carrying capacity resulting in the large span section acting more as a beam bridge than a cable stayed bridge, giving unexpected load conditions. BS5400 5.4 dictates that the bridge must be analysed for 2 conditions, overall temperature increases and variations in temperature through the profile of the bridge. We will initially look at the stresses caused by overall temperature increases. The design values for the temperature variation are unknown but for the climate in India we will take a conservative value of 25. Concrete has a thermal expansion of 12106 /C. expansion joints is 500m. = = (12 10 25 6) = 300 = = 300 10 500000 = 150 6 The apparent stress in the deck can then be found: = = 210000 300 10 6 = 63/ Using Fig. 9 in BS5400 to obtain the expected temperature gradient over the depth of the bridge. Clearly these values will have to be adapted somewhat to allow for the different temperatures in India. The corresponding values for strain are also shown. Stress in the deck can also be found and used to confirm the capacity of the deck. The maximum stress due to temperature effects will occur when the strain is 240. In this instance the associated stress, assuming E of concrete is 30GPa is 7.2N/mm2 . The greatest distance between

K.K.Wagh Polytechnic, Nashik

Page 60

Case Study of Bandra-Worli Sea Link

8.2 Creep Effects One of the most critical factors in the assessment of a bridge is how the structure will perform and change with time. There are a number of parameters which can affect the loading on the bridge such as, stress relaxation, settlement and earth pressure. Possible shrinkage and creep effects are two of the most important and need to be incorporated into the design. The effects of creep are inevitable in concrete structures, to a certain degree. "Due to the effect of creep, a structure tend to amplify its deformation under a given load condition over time. These changes can substantially affect the stresses and strains calculated throughout this paper, which have neglected the effects of creep. The interaction between deformations of different portions of the structural system can cause difficulties in design, for example "increase in the deformations of the deck and pylons over time leads to an increase in the initial tension in the stays". It is therefore important to counter these effects by putting some initial prestress into the cables to reduce the effect that the creep in the concrete has on the cables. The amount of creep must be known in order to be able to adjust the level of prestress accordingly. At the Bandra Worli Sea Link O-Cells are used which are able to output data about creep behaviour at various points along these can remain in-situ post construction. the bridge, "The bridge will be tested for

reference geometry after 200 days in service stage which requires a detailed analysis of the time dependant factors."

Chapter 9

Durability and Maintenance Due to this bridge being a new build it is unlikely that there will be any durability or serious maintenance issues for some time, however the these issues must be

K.K.Wagh Polytechnic, Nashik

Page 61

Case Study of Bandra-Worli Sea Link

accounted for and any possible inadequacies in durability highlighted so that there is a prior awareness of any shortfalls. It is useful to look to precedents prior to design to see if there is a trend in the type of damage caused to cable stayed structures over time which can be alleviated through design. It is important to undertake comprehensive inspections both periodically and after extreme events such as floods or storms. In cable structures critical damage to the cables themselves must be prevented. The cable anchorages at Bandra Worli have been designed to allow full access and a thorough inspection. The design must also allow inspection of the cables passage into the socket using an endoscope. electromagnetic inspection. Mitigation is a more effective solution but is not wholly reliable in all cases and does not remove the need for inspection. A number of measures have been taken in this case to improve durability and reduce the amount of required maintenance such as having galvanized strands with a protective coating and covering the whole cable with a polyethylene sheath. Microsillica and other admixtures have been added to the concrete creating a denser, stronger and less permeable material which is less likely to require maintenance during construction. The bridge has been designed with contingency for increase in traffic anticipated in Mumbai and no changes are anticipated in the near future. Other methods of inspection are and available such as x-ray inspection which allow for examination of internal

steel. The sockets for the cables are located on the soffit of the deck to aid

Chapter 10 Bandra-Worli Sea links Effect on the Environment

10.1 Merits of BWSL

K.K.Wagh Polytechnic, Nashik

Page 62

Case Study of Bandra-Worli Sea Link

Savings in vehicle operating cost to the tune of Rs.100 crores per annum due to

reduction in congestion in the existing roads and lower vehicle operating cost on the bridge ultimately reducing pollution.

Considerable savings in travel time due to increased speed and reduced delays at

intersections at existing roads. Which results in lower fuel burn ultimately saving precious fuels like Petrol, Diesel and LPG?

The bridge would result in lower traffic congestions thereby improving

the

environment especially in terms of reduction in carbon monoxide, oxides of nitrogen and reduction in noise pollution in areas of Mahim, Dadar, Prabhadevi and Worli.

Project to have no adverse effect on fisheries, marine life and livelihood of Proper landscaping measures along the approaches and promenade along

fisherman.

waterfront to enhance environment of the area.

10.2 Demerits of BWSL Bandra-Worli sea link wrecks shoreline Land Reclamation and construction of a bund for the Bandra-Worli Sea Link in the downstream region of Mahim creek have caused erosion along the Worli shoreline, endangering the lives of thousands of fishermen-says an recent ecological assessment. Startling facts came to light in a survey conducted by scientists of the Bombay Natural History Society (BNHS) since August this year. The blocking of tidal water near the mouth of Mahim Creek has already resulted in changes on the level of sea water in the area. BNHS Principal Scientist Sanjay Deshmukh, who conducted the survey, told Express Newsline that the sea water which used to enter Mahim Creek is now diverted towards the Mahim-Worli coastal belt and is contributing to erosion along the beaches. ``The compound walls of some of the buildings along the shoreline in the region are constantly hit by tidal waves and the frequency has increased after the bund has been build. The walls of some of the buildings have cracked threatening the safety of the residential houses in the neighbourhood,''Deshmukh pointed out.

K.K.Wagh Polytechnic, Nashik Page 63

Case Study of Bandra-Worli Sea Link

The Bombay Sewage Disposal Project of Brihanmumbai Mumbai Municipal Corporation between 1995-96 had reclaimed land for construction of bund on the mouth of Mahim Creek reducing the width to about 100 meters affecting the flow of incoming tides from moving upstream. Construction in the region for the proposed Worli-Bandra Sea link has further reduced the mouth of the creek to a mere 30-40 meters, the ecological assessment. ``The lives of several fishing villages are threatened due to frequent tidal effect in the region. Some of the house has been regularly hit by the waves causing fear among the residents in the area, said local resident and environmental activist Girish Raut. Apart from shoreline changes, unsustainable reclaimation has also led to degradation of the mangroves in the region and wetland conditions. The size of mangroves has reduced to 50 per cent of its original size in the last few years, investigations have revealed. Also, the freshwater flow from the erstwhile Mithi river, which originates from the forest in Sanjay Gandhi National Park and flows through the central suburbs, has completely dried up. This is mainly due to reclaimation of land and unbriddled dumping of garbage along its shores. The scientist during field visits have observed that some of the upstream regions of Mahim Creek, which is currently under mangrove cover, is drying up due to paucity of flushing by tidal waters. Constant inundation of the intertidal regions is one of the prerequisites for the very existence of mangrove habitats, said environmentalists. An Ecological Assessment of Mangrove Environment of Mahim with Reference to Current Anthropogenic Pressure has been recently submitted to Mumbai Metropolitian Region Development Authority (MMRDA). This is in view of degraded wetland conditions caused due to reclamation of land for the BandraWorli Sea Link. In 1999, when the Maharashtra State Road Development Corporation Ltd (MSRDC) gained permission to start construction on the Bandra-Worli Sealink, reclamation work at the mouth of the Mahim Creek began. In 2001, the Indian People's Tribunal on Environment and Human Rights was requested to conduct an investigation into the feasibility of the Bandra Worli Sealink. During the

K.K.Wagh Polytechnic, Nashik

Page 64

Case Study of Bandra-Worli Sea Link

investigation numerous experts and environmentalists deposed before the Tribunal objected that reclamation and blockage of the Mahim Creek could lead to increased flooding. By disturbing the natural course of events and redrawing the geography of the Mahim Creek the link has gradually upset the flow of effluents and floodwaters that drain into the Arabian Sea Areas.

10.3 No Effect of BWSL Project on the traffic