Professional Documents

Culture Documents

Phân tích hệ thống sản xuất linh hoạt

Uploaded by

vansu2790Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Phân tích hệ thống sản xuất linh hoạt

Uploaded by

vansu2790Copyright:

Available Formats

Phn tch h thng sn xut linh hot (FMS50)

I.

Khi qut v h thng v cc chc nng chnh: 1. Khi qut v h thng: - FMS50 l mt h thng c kh nng m rng lin tc gm cc trm c chc nng ring. Cc trm ny lin kt vi nhau bi h thng vn chuyn v cc tn hiu vo ra t h thng vn chuyn. - Hot ng ca mi cp trm khng ph thuc vo vic chi tit c a n t u. - C th nng cp d dng m khng nh hng nhiu ti ton b h thng v cc trm khc. 2. Cc chc nng chnh ca h thng: - Nhn cc chi tit t kho, kim tra kch thc chi tit - lp rp vi cc chi tit thch hp khc. - Sau khi c lp rp y sn phm c phn loi v a ra ngoi.

II.

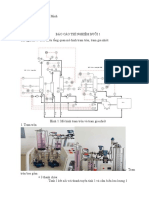

M hnh ha cc modul:

Distributing station

Testing station

Transport system consists of tranfer stations

Robot with assembly

Sorting station

Pick alfa

1. H thng vn chuyn: Input: chi tit t mt trm. Output: chi tit c chuyn n cho trm tip theo Sensor: Fiber optic unit (SOEGL-Q30-PA-S-2L) C cu chp hnh: bng ti, kh nn M hnh ng hc: M hnh ng hc: 1

4 6

Bng chuyn 2 chy lin tc y carrier 1 i theo chiu mi tn nh trn hnh. Khi carrier n mi trm g 3 (piston kh nn) c dng ln gi tm carrier li, m qup 5 (piston kh nn) qup ly tm carrier kt hp vi 2 vng m 6 nh v chnh xc carrier ti v tr tng ng lm vic vi tng trm. Tip theo g 4 c dng chn carrier n sau. Sau chi tit trn carrier s c mang vo trm hoc chi tit c a t trm ln carrier, xong vic cc b phn 3,5,4 li m ra cho carrier tip tc di chuyn sang trm tip theo. Bng chuyn c dn ng bng ng c in 3 pha.

S logic iu khin:

2. Trm cp chi tit: Input: chi tit t trong kho Output: cp chi tit cho trm testing Sensor: SOEG-SQ30-S-L(Light barrier sender)

M hnh ng hc:

1

3 2

ng cha chi tit 1 khi c chia tit s chi tit dn xung di y ng. Khi cc cm bin nhn bit kho cn chi tit piton 2 s y chia tit sang mt bn, tay quay v ng c kh nn 3 s quay sang tri dng p sut chn khng ht chi tit bm vo u 4 ri quay sang phi v th chi tit vo gi ca trm testing.

S iu khin:

3. Trm kim tra Input: chi tit t kho cha c kim tra Output: chi tit kim tra t s chuyn sang palette, khng t s loi b.

M hnh ng hc:

valid

Carrier

6 Reject 5

Sau khi nhn bit c chi tit trong gi 5 cc cm bin v b phn o c s kim tra kch thc, loi vt liu ca chi tit nu khng tha mn piton 6 s y chi tit sang mng cha ph phm. Nu chi tit t iu kin gi 5 s c nng ln ti ngang vi mng 7, piton 6 y chi tit sang mng 7, chi tit tri xung gi v c chuyn sang khu vc khc.

S iu khin

4. H thng nht chi tit (pick-alfa): Input: chi tit t palette, hoc t 1 trm no Output: chi tit c chuyn t trm ny sang trm khc

M hnh ng hc:

S iu khin:

5. Trm lp rp: Input: chi tit t palette Output: b chi tit c lp rp, th vo carrier

5 4 3 2

M hnh ng hc: Robot 5 khu (1) s nht vo gi 2, li t kho 4, piston t kho 3 v l xo t kho 5, sau nhc c b lp ghp vo carrier. Trong trn hm phi ca tay kp ca robot c sensor pht hin loi chi tit ca chi tit a n t carrier, t s nht cc chi tit ph hp lp ghp.

S iu khin:

6. Trm phn loi: Input: cc chi tit cha c phn loi Output: chi tit c vo v tr tng ng vi tng loi.

M hnh ng hc:

3

1 2

Bng ti 1 s quay lin tc vn chuyn chi tit. Khi chi tit c t vo u bng ti s c mt thit b gi, cc cm bin ti u bng ti c nhim v nhn bit v phn loi chi tit ra 3 loi da vo cc c tnh phn x nh sng/ko phn x, kim loi hoc ko phi kim loi. Sau khi phn loi c chi tit, cc tay gt 2 s ng nhng ca cho tng loi i vo mng tng ng.

S iu khin:

III. IV.

Chng trnh iu khin PLC (trn Step 7). Thc hnh mt s modul.

You might also like

- (123doc) - He-Thong-Tan-Bulong-Plc-S7-1200Document37 pages(123doc) - He-Thong-Tan-Bulong-Plc-S7-1200Minh Tiến100% (1)

- Hộp số tự độngDocument17 pagesHộp số tự độngThanh BìnhNo ratings yet

- Robotdoline 1Document12 pagesRobotdoline 1Tai Bui TriNo ratings yet

- Đề Tài: Dự Án Thiết Kế Robot Xe Dò Line: Báo Cáo Đồ ÁnDocument25 pagesĐề Tài: Dự Án Thiết Kế Robot Xe Dò Line: Báo Cáo Đồ ÁnViệt NguyễnNo ratings yet

- Báo cáo bài tập lớn môn Trang bị điệnDocument42 pagesBáo cáo bài tập lớn môn Trang bị điệnLoc Do VanNo ratings yet

- Phân Tích Hệ Thống Sản Xuất Linh Hoạt (FMS50)Document11 pagesPhân Tích Hệ Thống Sản Xuất Linh Hoạt (FMS50)Tieu Ngoc LyNo ratings yet

- BTL Nhóm 8Document26 pagesBTL Nhóm 8Nguyễn SiêuNo ratings yet

- 1.Trạm cấp phôi-tr2Document4 pages1.Trạm cấp phôi-tr2dat vuNo ratings yet

- Ly Thuyet Cac Tram Mps CDT PDFDocument55 pagesLy Thuyet Cac Tram Mps CDT PDFLê Sơn67% (3)

- Phương Pháp GrafcetDocument16 pagesPhương Pháp GrafcetBảo MạnhNo ratings yet

- Xây dựng bộ điều khiển mờ cho Robot bám đườngDocument5 pagesXây dựng bộ điều khiển mờ cho Robot bám đườngpvdaiNo ratings yet

- 4 - TR M Gia CôngDocument25 pages4 - TR M Gia CôngQuốc Thọ TrầnNo ratings yet

- HỆ THỐNG SẢN XUẤT LINH HOẠT FMSDocument8 pagesHỆ THỐNG SẢN XUẤT LINH HOẠT FMSTong Hai100% (6)

- Bai Tap Lon FMS - CIM - K52Document19 pagesBai Tap Lon FMS - CIM - K52Phan Duy KỳNo ratings yet

- Line Follower Robot With PIDDocument21 pagesLine Follower Robot With PIDThắng NguyễnNo ratings yet

- Nguyên lý hoạt động FMSDocument2 pagesNguyên lý hoạt động FMSMinh ChiếnNo ratings yet

- 2021.1.Đề 4-Tay Gap Sp- Btl Plc Va Mang CnDocument4 pages2021.1.Đề 4-Tay Gap Sp- Btl Plc Va Mang Cntiến nam nguyễnNo ratings yet

- 62. Lê Công Tuyền - 2018600313Document9 pages62. Lê Công Tuyền - 2018600313letuyen08102000No ratings yet

- 20dota2 - Bao Cao Cam Bien - 2011252973Document90 pages20dota2 - Bao Cao Cam Bien - 20112529732973Hồ Dương Bảo PhúcNo ratings yet

- FILE - 20220419 - 135323 - Tài liệuDocument19 pagesFILE - 20220419 - 135323 - Tài liệu95Tuan Huynh NgocNo ratings yet

- [123doc] - do-an-dieu-khien-logic-va-plc-de-tai-uon-kim-loai-bang-cac-xylanh-khi-nenDocument31 pages[123doc] - do-an-dieu-khien-logic-va-plc-de-tai-uon-kim-loai-bang-cac-xylanh-khi-nenquenteen16No ratings yet

- Đề cương LTĐKTĐDocument17 pagesĐề cương LTĐKTĐNguyễn Duy TháiNo ratings yet

- Báo Cáo Đ Án 2Document26 pagesBáo Cáo Đ Án 2Nguyễn Công HảiNo ratings yet

- báo cáo điều khiển động cơDocument12 pagesbáo cáo điều khiển động cơĐông NguyễnNo ratings yet

- Nhóm 4 - G T Mưa - R A KínhDocument9 pagesNhóm 4 - G T Mưa - R A KínhDang Minh TruongNo ratings yet

- Hệ thống nâng hạ kính xe ô tô conDocument7 pagesHệ thống nâng hạ kính xe ô tô con20145618No ratings yet

- DKTD Full Bài FixedDocument136 pagesDKTD Full Bài FixedLong TrầnNo ratings yet

- AutomaticDocument22 pagesAutomaticBắc Trần vănNo ratings yet

- NHOM4_HETHONGDIENPHUDocument29 pagesNHOM4_HETHONGDIENPHULâm Thế VinhNo ratings yet

- Báo Cáo Nhóm 1Document12 pagesBáo Cáo Nhóm 1Vũ Mạnh CườngNo ratings yet

- PLC EndDocument30 pagesPLC End51. Lê Xuân TùngNo ratings yet

- Báo Cáo Bài Tập Lớn Internet of ThingsDocument23 pagesBáo Cáo Bài Tập Lớn Internet of ThingsLâm Đỗ TràngNo ratings yet

- Bao Cao Tuan 1 Nhom 1Document21 pagesBao Cao Tuan 1 Nhom 1tai0707141843No ratings yet

- Đe Tai Cuoi Ky - Final - 2 - 6Document8 pagesĐe Tai Cuoi Ky - Final - 2 - 6quangthanhlop10a9No ratings yet

- Bai Tap PLC K19Document8 pagesBai Tap PLC K19caoxom7No ratings yet

- BAITAPTHUCHANHDocument17 pagesBAITAPTHUCHANHpham van duNo ratings yet

- Đồ án thiết kế hệ thống điều khiển thang máy chở hàngDocument33 pagesĐồ án thiết kế hệ thống điều khiển thang máy chở hàngvhungdx100% (1)

- HỆ THỐNG BÀI TẬP PLC CƠ BẢNDocument11 pagesHỆ THỐNG BÀI TẬP PLC CƠ BẢNLyly Nguyen0% (1)

- Danh sách chia nhóm và chủ đề tiểu luận Hp Điều khiểnlogic và PLCDocument28 pagesDanh sách chia nhóm và chủ đề tiểu luận Hp Điều khiểnlogic và PLChoangk3dzofficialNo ratings yet

- đồ án cấp phôi tự độngDocument6 pagesđồ án cấp phôi tự độngQuang HuyNo ratings yet

- Xe tránh vật cảnDocument14 pagesXe tránh vật cảnTy CoonNo ratings yet

- Ly Thuyet HPTNC CKDocument4 pagesLy Thuyet HPTNC CKNguyễn ĐôngNo ratings yet

- Bùi Trọng Kiên - 20173998 - ReportDocument10 pagesBùi Trọng Kiên - 20173998 - ReportKiên BùiNo ratings yet

- Nhóm 2Document20 pagesNhóm 2Thọ VũNo ratings yet

- Đồ Án Điện Khí Nén - Nhóm 5Document9 pagesĐồ Án Điện Khí Nén - Nhóm 5nhutminh2k2No ratings yet

- Dong Co BuocDocument10 pagesDong Co BuocQuy QuyNo ratings yet

- Huong Danc Aid at Mach 3Document20 pagesHuong Danc Aid at Mach 3Nhan LeNo ratings yet

- Bài tập mở rộng Kỹ thuật điều khiển tự độngDocument8 pagesBài tập mở rộng Kỹ thuật điều khiển tự độngNGUYÊN NGUYỄN THỊ THANHNo ratings yet

- Đe Tai Gi A K Ky - Final - 11!3!2024Document9 pagesĐe Tai Gi A K Ky - Final - 11!3!2024Nguyễn Thị Diễm ThúyNo ratings yet

- Bản sao của PLCDocument40 pagesBản sao của PLCThiên ĐoànNo ratings yet

- BTL KhiNenDocument15 pagesBTL KhiNenFarewell Hi100% (1)

- Lý-thuyết-LMSDocument5 pagesLý-thuyết-LMSMinh ChiếnNo ratings yet

- Báo Cáo Bu I 1Document4 pagesBáo Cáo Bu I 1Tuyền HoàngNo ratings yet

- đồ án tốt nghiệpDocument16 pagesđồ án tốt nghiệpLễNo ratings yet

- Chương 4Document9 pagesChương 4Nguyễn Hải ĐăngNo ratings yet

![[123doc] - do-an-dieu-khien-logic-va-plc-de-tai-uon-kim-loai-bang-cac-xylanh-khi-nen](https://imgv2-2-f.scribdassets.com/img/document/720316248/149x198/62a0f6df19/1712323566?v=1)