Professional Documents

Culture Documents

Arduino Magnet Levitation Guide

Uploaded by

lorenaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Arduino Magnet Levitation Guide

Uploaded by

lorenaCopyright:

Available Formats

Arduino Magnet Levitation detailed tutorial Recently, I finished my first Arduino project, a magnet levitation device.

. It levitates a magnetic object under an electromagnet. What makes it different from similar projects is the position sensor for the feedback loop. I use a single Hall effect sensor placed directly on the bottom of the core of the electromagnet. This creates a problem of separating the electromagnets field from the levitating magnets field. Fortunately, this can be done in software by the microcontroller ATmega168 that is the heart of Arduino Duemilanove, the board that I use to control the levitation. This article gives a detailed description of the project together with source code at https://github.com/rekka/levitation, as I promised. This is my first attempt to describe something that I dont have much experience with. If you find an error, if there is something that is not clear or if there is something I could improve, please, leave a comment.

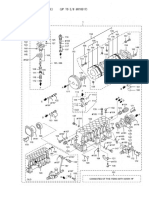

Setup Setup The general setup is quite straightforward. The main part is an electromagnet consisting of a coil on an iron core. The current through my coil from a push-type solenoid is 300mA at 12V. At the bottom of the electromagnet, there is a Hall effect sensor directly on the iron core, positioned in such a way that the sensor detection axis is aligned with the core axis (figure on the right). Components Arduino Duemilanove Switched power supply 12V Linear Hall effect sensor Honeywell SS19 Norton operational amplifier MC3401P NPN transistor MPSA06 Rectifier 1N4001 Electromagnet (I used a coil from a 12V push-type solenoid) Resistors 2x 1k, 5k6, 47k, 68k, 330k, 4x 1M Capacitors 2x 1

Since I dont have much experience, I tried to keep the circuit as simple as possible. The project consists of two quite independent parts.

The coil driver

The first part is the coil driver. I used a small transistor to turn the coil on or off, added a reverse-biased diode across the coil for protection of the transistor against fly-back currents, and put a capacitor across the supply for noise reduction. The base of the transistor is connected to a Arduino digital output through a 1k resistor, with an extra LED to indicate the pin state. The second part is a bit more involved. I used linear Hall effect sensor SS19 from Honeywell. It is a tiny black box that has 3 pins, 2 of which are connected to GND and +5V, the 3rd one is the output. The sensor translates the perpendicular (to the two largest faces of the sensor) component of a magnetic field into voltage on the output. In my case, it was 2.15V with no field and 3.0 V with the maximal field (coil on and magnet nearby). Thus I attached 2 Norton operational amplifiers (out of 4 in MC3401). The first stage subtracts ~1.5V while the second amplifies it by a factor of ~3. That gives a signal in the range 1.8 4.5V, in the working range of the amplifier. This amplified signal then connects to an Arduino analog input pin. Note that I used a Norton op amp. It amplifies current difference, unlike the usual op amp that amplifies voltage difference. Thats why the wiring is slightly different. I also had to add a load resistor 5k6 on the sensor output to make it work properly.

Sensor with amplifier circuit A bit of theory The magnetic field needed to keep a magnet from falling changes with the distance from the electromagnet. In our case, the position of the magnet is monitored by the Hall effect sensor. The closer the magnet is to the sensor the higher voltage is on the output. And the closer the magnet is the smaller field is required to keep it from falling. The situation is shown in the following figure:

General idea of how to keep magnet levitating The purple straight line represents the magnetic field required to keep a magnet from falling with respect to the reading on the sensor. In reality, it is nonlinear curve but thats not important for us. We need to produce a field that will keep a magnet at a specific position. For that we will modulate the coils power so that the field produced is given by the blue line in the previous plot. The two extreme values are the maximal field of the coil and the field when the coil is off. If we are successful, the magnet should be stable at the intersection of the two curves in the middle of the plot. If the magnet gets too close to the iron core the shear attractive force of these two is enough to attract it. That is represented by the rightmost intersection. We need to prevent this situation. That sounds quite easy, doesnt it? But there is a small complication. The reading on the sensor includes the magnetic field of the coil. In fact, because the sensor is right on the core this component will probably be bigger than

the component we are interested in, the field of the magnet itself. Fortunately for us, we know what signal we use to drive the coil. However, if we plot the driving signal and the magnetic field of the coil, we get the following plot:

Coil field This behavior is caused by the large inductance of the coil. When the transistor is open, the there is +12V on the coil. But the change in current induced magnetic field that resist this change and it takes more time for the full current to flow. When the transistor is closed, the current continues to flow through the diode in parallel. The resistance of the coil and the diode disipates the energy and the current decreases to zero. In my case, it takes around 5ms for the coil to energize or deenergize. That is way too long for us to ignore. But we can model this behavior. A coil can be approximated as a resistance R and inductance L in series. The circuit can be simplified like this:

Coil model The differential equation for the current I through the coil then reads where V is the voltage on the coil. In our case, it is +12V when the driving signal is 1 and -0.6V (the diode voltage) when the signal is 0. The magnetic field is proportional to the current. For simplicity, we rewrite the equation for dimensionless field power y and applied voltage x, x being -0.05 = -0.6/12 or 1 and y being in the range 0 1. That yields the equation is a parameter depending on the coil. But this is a equation for a low-pass filter. This continuous form can be discretized, see Low-pass filter on wikipedia. Assuming constant timesteps, t = 1, we get the final formula The parameter depends on the coil and on the timestep. It can be found using where T is the number of timesteps it take for the coil to energize from 0 to 0.632 of its maximal field. This has to be found by some experimentation. Generally, is different for the energization and deenergization phase since the diode gives rise to extra resistance in the circuit.

Control algorithm Now with some theoretical background, we can proceed to describe the algorithm that controls the output signal. First, we have to find the following parameters (field shall denote the reading on the sensor): sample frequency = how often to sample field and adjust the output signal, I use 10kHz baseline = field with no magnetic fields coilMag = the maximal strength of the coil, i.e. the difference of field with the coil on and baseline alphaInc = the constant from above for energization of the coil alphaDec = the constant from above for deenergization

We have to keep track of the following variables: signal = last signal ouput, 0 or 1 filter = value in the range 0 to 1, this is the field of the coil in the last step, the result of the discretized formula.

With these parameters, we perform the following steps with the sample frequency: 1. 2. Update the filter If ouput == 1, use filter += alphaInc(1 filter), else filter -= alphaDec(filter + 0.05). Read the sensor input, field. Based on this value, find the value of the permanent magnets field alone, mag = field coilMag * filter baseline. 3. Using the value mag that represents the distance of the magnet from the sensor, estimate the required coil power required to keep the magnet from falling, power. This is estimated based on the simple model shown in Figure 1. 4. Produce new signal. If power > filter, set signal = 1 (need to energize) else set signal = 0 (need to deenergize) Implementation I should make some remarks on my software implementation: Constant timestep To achieve a constant sampling and output rate, some constant time-base is necessary. The standard millis() method doesnt allow for the desired precision. One option is to use the build-in timers, like millis() is using, and change their resolution. But the simplest way is to use the A/D converter itself for timing purposes. The time it takes for ADC to perform a reading is constant and can be changed by changing the ADC prescaler settings. It is given by the formula clock = 16,000,000 prescaler = 2, 4, 8, 16, 32, 64 or 128 conversionCycles = 13 * clock / prescaler; The default prescaler value is 128, which gives the maximal conversion rate to be ~~9.6kHz. Im using 64 which leads to 19230.8Hz sampling rate. The ADC clock value, clock/prescaler, affects the ADC accuracy. ATMEL recommends the range 50-200kHz for maximal accuracy, with rates up to 1MHz if less accuracy is needed. My choice gives 250kHz ADC clock, thats quite close to the recommendation.

Now for the synchronization. When a conversion is finished, an interrupt flag in the ADC registers is set. Waiting for this flag provides the necessary synchronization. To ensure that the next conversion is started as soon as one is finished, the ADC is configured to work in a free running mode with an auto-trigger enabled. The functions analogSetup and analogStart configure the ADC and start the first conversion while analogNext waits for a conversion to finish and thus provides the synchronization for the program. Multiplication code The coil simulation is done by fixed-point integer math. That means that values of filter, alphaDec and alphaInc in the range 0 1 are multiplied by 2^16 = 65536. When a multiplication such as coilMag * filter is performed, the actual code is result = coilMag * filter >> 16; Since AVG GCC is adding extra unnecessary instructions for multibyte multiplications like this, I implemented my own assembler routines. This is not really required for this simple code, but I also experiment with additional digital signal processing to achieve greater stability of the magnet, and this processing is quite costly in terms of multiplications. Also, my own multiplication routine allows me to perform rounding of the result of >> 16 and that adds extra precision to the computation. Computer interface The Arduino performs all computations but the code is written in such a way that it is necessary for it to be connected to the computer. The levitation routine is initiated when Arduino receives 32 bytes from the computer. These 32 bytes must contain 16 integers and are written in the array ap. The significance of the individual fields is ap[0] = alphaInc * 2^16 ap[2] = alphaDec * 2^16 ap[3] = 0.05 * 2^16 ap[4] = lowestMag ap[5] = powerDecay ap[15] = counter alphaInc and alphaDec are the constants from above, 0.05 = 0.6/12 is the diode voltage. lowestMag and powerDecay are two parameters of the linear function used to compute the power of the coil magnetic field using the formula power = 255 + (ap[4] - (mag)) * ap[5]; The levitation routine is stopped when a byte 0 is received by Arduino. Finding the constants Since the constants alphaInc, alphaDec and diode voltage seem fixed, I enter them by hand. To find their value, I simply guess, it is not that hard. To control the Arduino code and to monitor the performance, I use a simple Mathematica program. It looks like this:

Mathematica 6 interface The plots allow me to see the sensor reading, the signal output and the computed field of the permanent magnet (the three lines from top to bottom). To find a value alphaDec, for example, I guess some value and use the counter setting (ap[15]) to be 10. This causes the signal to be a simple square wave. Then I take a look at the computed magnets field. With no permanent magnet around, it should be constant and the plots should look like this:

Correct value of alphaDec If I guess the value too low or too high, I see some bumps like:

alphaDec too low alphaDec too high Code Finally, here is the code: https://github.com/rekka/levitation To make it work with the 1Mbaud communication, you will also have to download check my optimized Serial library, wiring_serial.c (the library is too outdated now. Fortunately, the official Arduino libraries have been updated and the issue has been fixed, it seems.) Final thoughts With the current implementation, the project faces a serious problem, instability. It works well for levitating a magnet for short time, minutes at most. After a while, oscillations develop and a magnet eventually falls. The reason for this is the lack of energy dissipation, or damping. The magnet under an electromagnet can be approximated by the equation where y is the distance from an equilibrium. In words, the higher the magnet is, the closer it is to the electromagnets core and the stronger it is attracted. The lower it is, the further from the core, the less attraction there is. This system is unstable, the solutions of the equation diverge. By applying power to the electromagnet, we are trying to modify the equation to have the form where c is some positive constant. Now this equation is stable, it is a harmonic oscillator. If there is a oscillation, it will be preserved, but it wont grow. The problem appears when there is a delay between reading of the sensor and producing new output. And this will be there in every real system. This translates into appearance of a new term in the equation

Again, a is a positive constant. Since -a indicates how much oscillations are damped, this term will increase the osciallations. The question is how to fight this term. I experimented with a couple ideas that I had, like diferentiation or integration of the signal, or using some other more involved filters. So far, I wasnt able to produce a consistent oscillation damping. But research continues.

You might also like

- LevitationDocument4 pagesLevitationJorge CordeiroNo ratings yet

- Electronics 3 Checkbook: The Checkbooks SeriesFrom EverandElectronics 3 Checkbook: The Checkbooks SeriesRating: 5 out of 5 stars5/5 (1)

- Ball LevitationDocument7 pagesBall LevitationsumlusemloNo ratings yet

- Achieving Stable Magnetic Levitation On The Arduino PlatformDocument15 pagesAchieving Stable Magnetic Levitation On The Arduino Platformzub12345678No ratings yet

- Ultrasonic Levitation Machine Using Arduino: T He Object Oat SDocument8 pagesUltrasonic Levitation Machine Using Arduino: T He Object Oat SJose A Perez Delgado100% (1)

- Magnetic Circuits Question AnswersDocument3 pagesMagnetic Circuits Question AnswersAtul WadhaiNo ratings yet

- Magnetic LevitationDocument19 pagesMagnetic LevitationJayDon100% (1)

- All The Mathematics You Missed 16aug2023 Thomas A. GarrityDocument375 pagesAll The Mathematics You Missed 16aug2023 Thomas A. Garrityocorner2000No ratings yet

- MagneticsDocument84 pagesMagneticsFuad MudesirNo ratings yet

- 500-lb Lifting Electromagnet Runs on D Cell BatteriesDocument9 pages500-lb Lifting Electromagnet Runs on D Cell BatteriessudeepjosephNo ratings yet

- LevitronDocument38 pagesLevitronFatima RubabNo ratings yet

- Solar Power Charge ControllerDocument61 pagesSolar Power Charge Controllerzubair100% (1)

- typically in the low kilohertz range, through a transmit coil.New Computer-based Ferromagnetic Metal Detector These pulses induce eddy currents in any nearby conductiveDocument8 pagestypically in the low kilohertz range, through a transmit coil.New Computer-based Ferromagnetic Metal Detector These pulses induce eddy currents in any nearby conductiveJalalNo ratings yet

- The Detection of Electromagnetic Processes in The Ionosphere Caused by Seismic ActivityDocument12 pagesThe Detection of Electromagnetic Processes in The Ionosphere Caused by Seismic Activityclaudiocastillo@gmail.comNo ratings yet

- Magnetic Levitatio1Document26 pagesMagnetic Levitatio1Shambhavi VarmaNo ratings yet

- Physics of Dielectrics and DRAMDocument31 pagesPhysics of Dielectrics and DRAMUdai SinghNo ratings yet

- 1W and 5W Power AmplifierDocument4 pages1W and 5W Power AmplifierMikeViveNo ratings yet

- Frequency Locked Loop DC Motor Speed ControlDocument47 pagesFrequency Locked Loop DC Motor Speed ControlRakesh Kumar50% (2)

- Topics in Environmental Physiology and Medicine: Edited Karl E. SchaeferDocument339 pagesTopics in Environmental Physiology and Medicine: Edited Karl E. SchaeferAna GujabidzeNo ratings yet

- Calculating Magnetic FieldDocument24 pagesCalculating Magnetic Fieldcristilyn pangosfianNo ratings yet

- GBPPR 'Zine - Issue #62Document76 pagesGBPPR 'Zine - Issue #62GBPPRNo ratings yet

- Remote Sensing 2Document64 pagesRemote Sensing 2Yogesh SharmaNo ratings yet

- 6360 LV User InstructionsDocument11 pages6360 LV User InstructionsPrasanth MenonNo ratings yet

- Tesla Coil ProjectDocument58 pagesTesla Coil Projectvdahiya007No ratings yet

- Electronic Ballast Control: Fig. 1 Shows The Basic Building Blocks Found in Most ElecDocument6 pagesElectronic Ballast Control: Fig. 1 Shows The Basic Building Blocks Found in Most Elecrda103No ratings yet

- Application of Magnetic Levitation: Hamid YaghoubiDocument16 pagesApplication of Magnetic Levitation: Hamid YaghoubiLalitSisodiaNo ratings yet

- To Simple Operations Like Addition and SubtractionDocument36 pagesTo Simple Operations Like Addition and SubtractionsonalighareNo ratings yet

- Web Catalog 2006Document32 pagesWeb Catalog 2006scribedeanNo ratings yet

- Magnetostrictive TransducersDocument17 pagesMagnetostrictive TransducersPrathamesh BhutraNo ratings yet

- Labview Daq Hands On ExercisesDocument40 pagesLabview Daq Hands On ExercisesTony GilesNo ratings yet

- Future Devices 2Document13 pagesFuture Devices 2ramjidrNo ratings yet

- Fundamental Understanding of Piezoelectric Strain SensorsDocument5 pagesFundamental Understanding of Piezoelectric Strain SensorsNemoz ZrNo ratings yet

- PPF4 - Ultrasonic Phaser Pain Field Generator: Basic Device DescriptionDocument16 pagesPPF4 - Ultrasonic Phaser Pain Field Generator: Basic Device DescriptionAndreas KNo ratings yet

- Design of A Rogowski Coil With A Magnetic Core Used For Measurements of Nanosecond Current PulsesDocument4 pagesDesign of A Rogowski Coil With A Magnetic Core Used For Measurements of Nanosecond Current PulsesRavishankar PmNo ratings yet

- Solar Sun Seeker1Document20 pagesSolar Sun Seeker1Yogen MohanNo ratings yet

- Elf Circuit DesignDocument5 pagesElf Circuit DesignKatja GoiteNo ratings yet

- Tesla Levitating SphereDocument4 pagesTesla Levitating Spheremathias455No ratings yet

- RF Controlled ApplianceDocument14 pagesRF Controlled ApplianceNEX456No ratings yet

- Quantum AntennasDocument33 pagesQuantum AntennasmuteflikaNo ratings yet

- Malaviya National Institute of Technology: Submitted byDocument22 pagesMalaviya National Institute of Technology: Submitted byArpit JakarNo ratings yet

- Virtual Sensors Improve Vehicle Safety SystemsDocument11 pagesVirtual Sensors Improve Vehicle Safety Systemscristi_pet4742No ratings yet

- Control of Magnetic Levitation SystemDocument15 pagesControl of Magnetic Levitation SystemordekNo ratings yet

- Project Proposal Plasma SpeakerDocument3 pagesProject Proposal Plasma Speakerapi-283530338No ratings yet

- Design and Implementation of A Quantum True Random Number GeneratorDocument24 pagesDesign and Implementation of A Quantum True Random Number Generatormercurio11No ratings yet

- Magnetic Levitation AbstractDocument6 pagesMagnetic Levitation Abstractkkkoundi0% (1)

- Power Semiconductor Devices ThyristorsDocument140 pagesPower Semiconductor Devices ThyristorsNomanNo ratings yet

- LLC Transformer CalculationDocument49 pagesLLC Transformer CalculationDanut StanciuNo ratings yet

- Dsa 9062Document8 pagesDsa 9062Christian TadeoNo ratings yet

- Parametric ExcitationDocument14 pagesParametric ExcitationSolomanTrismosinNo ratings yet

- Energy HarvestingDocument120 pagesEnergy Harvestinghermas67No ratings yet

- ProposalDocument13 pagesProposalHafizAfizal0% (1)

- E CoreDocument68 pagesE CoreSaiman ShettyNo ratings yet

- WHITEPAPER - Veronica Valeros and Sebastian Garcia - A Modern Study of Microphone BugsDocument14 pagesWHITEPAPER - Veronica Valeros and Sebastian Garcia - A Modern Study of Microphone BugsTina BillingsleyNo ratings yet

- 0000 Design by Optimization of An Axial-Flux Permanent-Magnet Synchronous MotorDocument5 pages0000 Design by Optimization of An Axial-Flux Permanent-Magnet Synchronous MotorAnonymous hWj4HKIDOF100% (1)

- Schumann Resonator - Fabio's Blog About ElectronicsDocument2 pagesSchumann Resonator - Fabio's Blog About ElectronicsStellaEstel0% (1)

- Project Report On Dna Computing: Information Technology For ManagersDocument12 pagesProject Report On Dna Computing: Information Technology For Managersanshu002No ratings yet

- CST Magic Tee Workflow1Document19 pagesCST Magic Tee Workflow1trsureshNo ratings yet

- High Field Magnetism: Proceedings of the 2nd International Symposium on High Field Magnetism, Leuven, Belgium, 20-23 July 1988From EverandHigh Field Magnetism: Proceedings of the 2nd International Symposium on High Field Magnetism, Leuven, Belgium, 20-23 July 1988No ratings yet

- Juliane Turcovic Guedes Banco de Dados Exercícios Práticos Capitulo 3Document5 pagesJuliane Turcovic Guedes Banco de Dados Exercícios Práticos Capitulo 3lorenaNo ratings yet

- Exam Final 1 PDFDocument1 pageExam Final 1 PDFlorenaNo ratings yet

- Juliane Turcovic Guedes Banco de Dados Exercícios Práticos Capitulo 3Document5 pagesJuliane Turcovic Guedes Banco de Dados Exercícios Práticos Capitulo 3lorenaNo ratings yet

- Comp NetworkDocument2 pagesComp NetworklorenaNo ratings yet

- CEE225 Lab09 Guedes 20141117Document1 pageCEE225 Lab09 Guedes 20141117lorenaNo ratings yet

- Reading Worksheet FundamentalsDocument2 pagesReading Worksheet FundamentalslorenaNo ratings yet

- CEE225 Lab09 Guedes 20141117Document1 pageCEE225 Lab09 Guedes 20141117lorenaNo ratings yet

- Reading Worksheet: R1 (Introducing Nano) and R2 (Size Matters)Document2 pagesReading Worksheet: R1 (Introducing Nano) and R2 (Size Matters)lorenaNo ratings yet

- CEE225 Lab08 Guedes 20141104Document1 pageCEE225 Lab08 Guedes 20141104lorenaNo ratings yet

- CEE425 Lab2 Guedes 20140923Document11 pagesCEE425 Lab2 Guedes 20140923lorenaNo ratings yet

- Reading Worksheet: R1 (Introducing Nano) and R2 (Size Matters)Document2 pagesReading Worksheet: R1 (Introducing Nano) and R2 (Size Matters)lorenaNo ratings yet

- Reading Worksheet: R1 (Introducing Nano) and R2 (Size Matters)Document2 pagesReading Worksheet: R1 (Introducing Nano) and R2 (Size Matters)lorenaNo ratings yet

- Circuitos Pratica 12Document6 pagesCircuitos Pratica 12lorenaNo ratings yet

- DR 07251 Heat Treatment of Ferrous Metals - Guidelines For Specifications, Quality, Purchasing, Inspection AnDocument44 pagesDR 07251 Heat Treatment of Ferrous Metals - Guidelines For Specifications, Quality, Purchasing, Inspection AnjonathangoodheadNo ratings yet

- Partial Stroke Test Yokogawa A.F.M. Prins PDFDocument42 pagesPartial Stroke Test Yokogawa A.F.M. Prins PDFWalter Ruiz AstoNo ratings yet

- Sample Assessment Material International Gcse in Information and Communication TechnologyDocument80 pagesSample Assessment Material International Gcse in Information and Communication TechnologyRaj ChandaranaNo ratings yet

- Western Railway Recruitment 2020Document24 pagesWestern Railway Recruitment 2020Sana Zaidi100% (4)

- Electrochemical Methodsof Real Surface Area Determinationof Noble Metal Electrodesan OverviewDocument28 pagesElectrochemical Methodsof Real Surface Area Determinationof Noble Metal Electrodesan OverviewJBertrandNo ratings yet

- Sim Check Reviewer (Revision April 2016) 2-1Document720 pagesSim Check Reviewer (Revision April 2016) 2-1Devdatt Sonde100% (5)

- Access To Space ISRODocument23 pagesAccess To Space ISROGanesan SNo ratings yet

- Soal Bahsa Inggris PAS XI GenapDocument22 pagesSoal Bahsa Inggris PAS XI GenapDwi LestariNo ratings yet

- Liquid Nitrogen Filled Power TransformerDocument6 pagesLiquid Nitrogen Filled Power TransformerHamayoun MurtazaNo ratings yet

- Simplifying Cranes PDFDocument69 pagesSimplifying Cranes PDFJorge Cruz ParkerNo ratings yet

- Development of Auxiliary Automobile Air Conditioning System by Solar EnergyDocument7 pagesDevelopment of Auxiliary Automobile Air Conditioning System by Solar EnergyRivhan NugrohoNo ratings yet

- TM 55-1510-215-10 PDFDocument367 pagesTM 55-1510-215-10 PDFdddoty100% (1)

- User Manual - Sorvall - RC 6 - Rev 0 - EnglishDocument70 pagesUser Manual - Sorvall - RC 6 - Rev 0 - Englishluroguita-1No ratings yet

- Mac InstallDocument2 pagesMac InstallOrhon Can DağtekinNo ratings yet

- Reducing Patient Waiting Time in OPD Using LSS MethodologyDocument2 pagesReducing Patient Waiting Time in OPD Using LSS MethodologyjessicaNo ratings yet

- PCH Series: Btu/h Kcal/h Watt TR Btu/h Kcal/h Watt TR % Btu/h.WattDocument1 pagePCH Series: Btu/h Kcal/h Watt TR Btu/h Kcal/h Watt TR % Btu/h.WattrianartoNo ratings yet

- C-Steel Composited (E70C-3M, E70C-6M) PDFDocument2 pagesC-Steel Composited (E70C-3M, E70C-6M) PDFborovniskiNo ratings yet

- Chapter01 Solutions 10eDocument12 pagesChapter01 Solutions 10equsayNo ratings yet

- Spreaderbar design analysisDocument2 pagesSpreaderbar design analysisRraffrizal ChandsNo ratings yet

- Help Mla GFXDocument374 pagesHelp Mla GFXonafets100% (1)

- MNNIT Job Notification FormDocument3 pagesMNNIT Job Notification FormShashank PandeyNo ratings yet

- Fuel System 4Document5 pagesFuel System 4Falgon IslamNo ratings yet

- Forensic Geotechnical Engineering: V.V.S. Rao G.L. Sivakumar Babu EditorsDocument30 pagesForensic Geotechnical Engineering: V.V.S. Rao G.L. Sivakumar Babu EditorsKikieKirana AndMeNo ratings yet

- 100 Imp PointsDocument18 pages100 Imp Pointsfarhan poya100% (1)

- Bk19-007-Ts-Ec10-Dw-027.02 - 1 - Hoang Sa Crane Barge - Anchor Handling Sequence For Offshore Installation Crane - Sheet 2Document1 pageBk19-007-Ts-Ec10-Dw-027.02 - 1 - Hoang Sa Crane Barge - Anchor Handling Sequence For Offshore Installation Crane - Sheet 2đoàn lêNo ratings yet

- Miranda Kaleido Alto-Quad Installation ManualDocument24 pagesMiranda Kaleido Alto-Quad Installation ManualFloydChuangNo ratings yet

- B767 ATA 46 Student BookDocument17 pagesB767 ATA 46 Student BookElijah Paul Merto100% (2)

- Interior Fluid Resistant Epoxy Primer: Technical Data SheetDocument5 pagesInterior Fluid Resistant Epoxy Primer: Technical Data SheetLeonard Ngiam YkNo ratings yet

- Main specs for FD10, FD15, FD18 forkliftsDocument2 pagesMain specs for FD10, FD15, FD18 forkliftsMA TotalforkliftNo ratings yet