Professional Documents

Culture Documents

Man 2

Uploaded by

Him SatiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Man 2

Uploaded by

Him SatiCopyright:

Available Formats

Steering Gear Manual

February 2001

STEERING GEAR MANUAL

February 2001

CONTENTS

STEERING GEARS FROM SCAN-STEERING..................................................3 1. Installation of Scan-Steering Hydraulic Steering Gear ....................................5 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 Base Plate. ...................................................................................................5 Tiller ............................................................................................................6 Cylinder .......................................................................................................6 Wheel pump ................................................................................................7 Non-Return Valve .......................................................................................7 PSU Pump Unit(s).......................................................................................8 P10 + PV20/PV30 Power unit.....................................................................8 Pipes/Flexible Hoses. ..................................................................................9 Hydraulic oil. ..............................................................................................9

2. Testing and Air Bleed procedure. ....................................................................10 3. Maintenance. ......................................................................................................11 4. Trouble-Shooting. ..............................................................................................12

SCAN-STEERING

Page 2

STEERING GEAR MANUAL

February 2001

STEERING GEARS FROM SCAN-STEERING

Scan-Steering can deliver steering gear for almost any type of vessels. The steering gears are ram type and can be delivered as hand-hydraulic or power operated with one or more pump units, or as a combination of both systems. The power units can be driven either by electrical motor or mechanically driven by Vbelt from Main Engine. Steering gears from Scan-Steering can be delivered with various types of valves. The type and numbers of valves can vary according to various demands from Classification Authorities, numbers of wheel pump, power units, oil tanks, etc. Further the type of rudder to be operated by the steering gear might influence on the type of valves used. The following types of valves can be included in scope of delivery or mounted on steering gear/power unit(s): A. Non-Return Valve. Will be delivered when steering gear is supplied with wheel pump. Depending on type of wheel pump the non-return valve will be delivered build into pump or as a separate valve to be mounted on the pipes connecting the wheel pump with the steering gear. Function: Prevent the wheel from turning when forces act on rudder and keeps rudder locked in chosen position. B. Shut-Off Valves (1) 4 pcs. of shut-off valves are mounted on steering gear distributor block (cylinder hose connection) (2-cylinder type steering gear). Function: Corresponding valves must be closed in case of internal or external leak in a cylinder, or burst hose. This will make it possible to continue operation of steering gear with 1 cylinder in operation. Note: Air bleed valves must be opened on faulty cylinder.

Shut-Off Valves (2) Shut-off valves mounted on steering gear distributor block (pump unit connection). Number of valves varies according to number of pump units. Function: To be closed in case of leakage in pipes or malfunction of pump unit(s)/wheel pump. Will prevent drainage of complete system during repair.

SCAN-STEERING

Page 3

STEERING GEAR MANUAL

February 2001

Shut-off Valves (3) Mounted on oil tank(s) Function: Same as above. C. Shock/Overload Valve Mounted on steering gear distributor block. Function: Prevents overload of system. The valve is preset according to rule of Classification Authority and will by-pass ram unit in case of chock/overload. Adjustment: Loosen nut and turn clockwise for higher pressure setting. Turn counter-clockwise for lower pressure setting. Tighten nut after adjustment. D. By-pass Valve Mounted on steering gear distributor block. Function: When opened the valve will by-pass oil flow in ram unit allowing emergency mechanical steering in case of total break down of pump unit(s). E. Solenoid Valve Mounted on PSU Power unit or PV20/30 Control Valve Unit. Function: Controls Rudder movements by means of autopilot or FFU/NFU rudder control The valve can be activated manually by pressing pin in center of solenoid. F. Counter Balance Valve Mounted on PSU Power unit or PV 20/30 Control Valve Unit. Function: Locks rudder in chosen position and controls return oil flow from ram unit. Adjustment: Loosen nut and turn clockwise for lower pressure setting. Turn counter-clockwise for higher pressure setting. Tighten nut after adjustment.

SCAN-STEERING

Page 4

STEERING GEAR MANUAL

February 2001

1. Installation of Scan-Steering Hydraulic Steering Gear

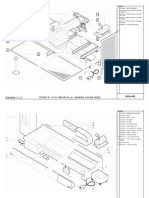

1.1 Base Plate. Scan-Steering steering gears can be delivered with either full base plate with built-in rudder stock bearing or with foundation plate for cylinder only. Install steering gear such that the angle between rudder stock and base plate will be exactly 90 degree. (Fig. No.1) The distances between Centers are to be found on assembly drawing.

The steering gear can be installed at any angle to centerline of vessel. Please notice that keyway in rudder stock must be machined according to installation angle of steering gear. Make sure that distance from center of rudder stock to center line of pin bolts on foundation plate is correct if steering gear is delivered with cylinder foundation only.

SCAN-STEERING

Page 5

STEERING GEAR MANUAL 1.2 Tiller

February 2001

Install tiller on top of rudder stock. The tiller will be delivered wit cylindrical or conical bore according to requirement and with keyway machined according to requirement of Classification Authority.

1.3 Cylinder Mount cylinder on base plate and tiller such that air bleed valves are at top position and hose connections are pointing at center line of steering gear. Please notice that cylinder support must be mounted under cylinder bearings. Notice: The pin bolts (Fig. No. 1) for mounting cylinder(s) onto tiller/foundation plate is made in such a way that the part of the bolt fitting to the bearing is made with a very close tolerance while the parts fitting to the plates are slightly conical. Make sure that cylinder bearing is situated very precise when mounting pin bolt. If possible freeze pin bolt before mounting as this might ease installation. Mount hoses according to drawing (Fig. No. 2) and in such a way that air can escape either to cylinder or distributor block.

Fig. No. 2

SCAN-STEERING

Page 6

STEERING GEAR MANUAL

February 2001

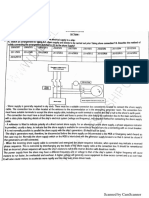

1.4 Wheel pump The wheel pump is an axial piston pump and comes in different sizes according to the size of the steering gear. The wheel pump can be used as main pump in a hand-hydraulic steering system or as an emergency pump in a power operated steering system. Connect Wheel pump to ram unit distributor block by means of steel pipes. The wheel pump is fitted with 18 mm pipe connectors.(Fig. No. 3) Connect wheel pump to power unit tank outlet if system is supplied with power unit.(Fig. No. 4) Connect top of wheel pump to tank if tank is required. Please notice that tank must be installed higher than wheel pump. The wheel pump can be mounted in a steering column or it can be panel mounted. The pump can be placed in wheel house, engine room or steering gear room. Notice: The wheel pump must be mounted higher that the steering gear.

Fig. No. 3

Fig. No. 4

1.5 Non-Return Valve The non-return valve must be mounted on the two pipes connecting wheel pump to steering gear.(Fig. No. 3) Preferable the valve should be mounted as close to the ram unit as possible. Function: Prevents steering wheel from turning when power unit(s) is in operation by locking oil flow from power unit(s) and keeps rudder locked in chosen position.

SCAN-STEERING

Page 7

STEERING GEAR MANUAL

February 2001

1.6 PSU Pump Unit(s) The steering gear can be delivered with 1, 2, or more PSU electrohydraulic pump unit(s). The PSU power unit is delivered as a complete unit with electrical motor, pump, filter, solenoid valve, and counter balance valve. The power unit can be installed in steering gear compartment or engine room. Connect Outlets on top of pump unit distributor block to ram unit and outlet on side of distributor block to wheel pump/oil tank. Connect electrical motor to starter unit according to starter unit manual and check that motor is running in correct direction (see arrow on clutch). Connect solenoids to autopilot/rudder control unit according to corresponding manual. Notice: The pump must be mounted lower thank wheel pump/oil tank and in such a way that air can escape or be bled out of the system. 1.7 P10 + PV20/PV30 Power unit. Install P10 oil pump such that pulley on main engine can be used for driving pump and make sure that revs. of pump will be between 900 3000 RPM when engine is idling/going full speed. Notice: the V-belt must not be tightened to hard as this can damage pump bearings. Check that pump is turning in correct direction (see arrow on pump). Install PV20/PV30 control valve unit above oil pump and connect to pump by means of hydraulic hoses or steel pipes avoiding unnecessary twist and bends so that no air pockets will occur in system. Connect outlets on top of control valve unit distributor block to ram unit and outlet on side of distributor block to wheel pump/oil tank. Connect solenoids to autopilot/rudder control unit according to corresponding manuals. Notice: Pump and control valve unit must be mounted so that air can escape or be bled out of the system

SCAN-STEERING

Page 8

STEERING GEAR MANUAL

February 2001

1.8 Pipes/Flexible Hoses. Connect outlets on ram units to outlet on Power unit/ wheel pump using steel pipe of proper dimension (preferable stainless steel). The pipes must be installed in such a way that the is a smooth rise from pump unit to ram unit and from ram unit to wheel pump and no air pockets can occur in the system. It is advisable to bend pipes instead of using V-fitting where possible as this will secure a more smooth oil flow with smaller pressure drop. Make sure that pipes are properly cleaned inside before mounting Flexible hose must be mounted according to drawing.

1.9 Hydraulic oil. Fill system with oil through oil tank or wheel pump. Open air bleed valves on cylinders and leave them open until no more air is coming out of the valves. If system is supplied with wheel pump the pump must be turned from hard-over to hard-over until no more air is coming out of the bleed valves on cylinders. Loosen hoses on P 20/30 to bleed pump and filter unit if system is supplied with P10 + PV20/30 power unit system Bleed power unit by loosening pipe connections on top of distributor block if system is supplied with PSU power unit. Notice: Power units must be turned off during this bleeding procedure. Leave system 4 - 8 hours and bleed again. Recommended Type of Oil: BP: Calpham: Castrol: Esso: Shell: Statoil: Texaco: HLP50 EP Hydraulic No. 12 Hyspin AWH15 Nuto HP 15 Tellus T-15 Hydraway HVXA-15 Rando HP-15

SCAN-STEERING

Page 9

STEERING GEAR MANUAL

February 2001

2. Testing and Air Bleed procedure.

If system is supplied with wheel pump turn pump and check that rudder is turning to the correct side. Interchange pressure pipes from wheel pump on ram unit if rudder is turning to the wrong side. Turn wheel pump until steering gear is in hard over position and keep pressure on pump. Now open air bleed valves on pressure side of cylinders and keep open until no more air comes out. Turn wheel pump to the other side until steering gear is in hard over position and repeat air bleed procedure on pressure side of cylinder. Repeat the whole procedure until no more air is coming out of the bleed valves. If system is supplied with electrical power units only (without wheel pump) the following air bleed procedure must be followed: Start one of the power units and check that pump is running in correct direction (see arrow on clutch) Activate solenoid valve by pressing pin in center of solenoid until steering gear is in hard-over position. Open cylinder bleed valve until no more air is coming out. Repeat procedure to the other side. Repeat procedure using other pump unit.

SCAN-STEERING

Page 10

STEERING GEAR MANUAL

February 2001

3. Maintenance

After the first voyage all connectors must be tightened when oil is still warm. Pipes and connectors must settle in new installations and it might be necessary to tighten all connectors several times. All bearings in steering gear must be greased once every month. Check frequently that oil level in wheel pump is correct, (ap 25 mm under oil fill thread). To low oil level might result in air being pumped into the system. It is recommended that steering gear is smeared with water resistant grease if steering gear is placed such that it can be flushed by sea water.

SCAN-STEERING

Page 11

STEERING GEAR MANUAL

February 2001

4. Trouble-Shooting

A. Check that all hoses, pipes and connections are tight without any leek. B. If wheel is turning when steering gear is activated either by autopilot or steering switch this will indicate that there is air in the system or that there is a failure (leak) in non-return valve. C. Turn steering gear to hard-over position by mean of wheel pump. When in hard-over position check that there is no elastic effect when pressing wheel. If so there is air in the system and air bleed procedure must be followed. If steering wheel does not lock when steering gear is in hard-over position there might be a leak in piston gasket or in one of the non-return valves. Repeat procedure to the other side. If air is coming out of top of wheel pump there might be to much oil in pump or air in the system. Check the oil level in pump and bleed system following the above mentioned bleeding procedure. D. Turn steering gear by mean of steering switch or autopilot. If this cannot be done then try to activate solenoid valve manually by pressing the small pin in center of solenoid end. If this results in turning of steering gear the malfunction is due to electrical failure. If steering gear is not moving when activating solenoid valves: Check that all valves are set correctly. Check that pump is running in correct direction. Check that pump is working correctly. If not Repair/Replace pump. Try to turn steering gear using wheel pump or other power unit. Install new solenoid valve if steering gear can be activated by either wheel pump or other pump unit. E. Check that chock/safety valve is working properly by activating steering pressing the small pin in center of solenoid end on power unit solenoid valve.

SCAN-STEERING

Page 12

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Mercury Parts Guide 2019Document280 pagesMercury Parts Guide 2019Farhad Ghaffar100% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- SLICK L-1318G Text PDFDocument170 pagesSLICK L-1318G Text PDFNorberto IglesiasNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Quick Setup Guide V1.2.1Document29 pagesQuick Setup Guide V1.2.1Jordan100% (1)

- Audi Engine Management SystemsDocument185 pagesAudi Engine Management SystemsHri Vitalion100% (12)

- RV-30 2Document94 pagesRV-30 2Francois LandryNo ratings yet

- Surveyor Guide Notes On Tail Shaft Survey: 1. Propeller Shafts 1.1 Propeller Shaft Clearances - MeasurementDocument9 pagesSurveyor Guide Notes On Tail Shaft Survey: 1. Propeller Shafts 1.1 Propeller Shaft Clearances - MeasurementHim SatiNo ratings yet

- Surveyor Guide Notes On Tail Shaft Survey: 1. Propeller Shafts 1.1 Propeller Shaft Clearances - MeasurementDocument9 pagesSurveyor Guide Notes On Tail Shaft Survey: 1. Propeller Shafts 1.1 Propeller Shaft Clearances - MeasurementHim SatiNo ratings yet

- 87 Test Plan EZF and LHDocument53 pages87 Test Plan EZF and LHjelliott48278100% (1)

- Timing Light With Advance Feature PDFDocument8 pagesTiming Light With Advance Feature PDFstevencychenNo ratings yet

- Workshop Manual Datsun 1300 1600Document104 pagesWorkshop Manual Datsun 1300 1600Aldher Sama100% (1)

- Maxis Autel ScanerDocument300 pagesMaxis Autel Scanerengel cqNo ratings yet

- Linde Forklift H12 14 1618 20 Parts ManualDocument517 pagesLinde Forklift H12 14 1618 20 Parts ManualVăn Duyên Phạm100% (1)

- MAS-1 Charging, Starting and Ignition Systems PDFDocument25 pagesMAS-1 Charging, Starting and Ignition Systems PDFmanojNo ratings yet

- Daewoo Matiz 2000-2013 Engine Electrical 19-42Document24 pagesDaewoo Matiz 2000-2013 Engine Electrical 19-42Hector Osorio100% (3)

- L-1363J - Corrected 20210420Document77 pagesL-1363J - Corrected 20210420Juan TapiaNo ratings yet

- Engine RT-flex Practical & Operation Advanced (5 Days) - Tailor Made (Rev1)Document7 pagesEngine RT-flex Practical & Operation Advanced (5 Days) - Tailor Made (Rev1)Him SatiNo ratings yet

- Jenbacher Type-6 EngineDocument24 pagesJenbacher Type-6 EngineAb Hannan chowdhury100% (1)

- Global Warming Effects of Greenhouse GasesDocument5 pagesGlobal Warming Effects of Greenhouse GasesHim SatiNo ratings yet

- IS Code Chapter 2 - General Precautions Against CapsizingDocument1 pageIS Code Chapter 2 - General Precautions Against CapsizingHim SatiNo ratings yet

- Earth on Fire! What is Global WarmingDocument4 pagesEarth on Fire! What is Global WarmingHim SatiNo ratings yet

- ME Vs FlexDocument12 pagesME Vs FlexHim SatiNo ratings yet

- LiftsDocument1 pageLiftsHim SatiNo ratings yet

- Motor Set 2Document8 pagesMotor Set 2Him SatiNo ratings yet

- MET September 2017Document2 pagesMET September 2017Him SatiNo ratings yet

- ME Vs FlexDocument2 pagesME Vs FlexHim SatiNo ratings yet

- Mep 8Document2 pagesMep 8RachitNo ratings yet

- JANUARY 2017: SECTION - 1: Answer at Least TWO Questions SECTION - 2: Answer at Least TWO QuestionsDocument2 pagesJANUARY 2017: SECTION - 1: Answer at Least TWO Questions SECTION - 2: Answer at Least TWO QuestionsHim SatiNo ratings yet

- ME Vs FlexDocument2 pagesME Vs FlexHim SatiNo ratings yet

- MEP June-2017 PDFDocument2 pagesMEP June-2017 PDFHim SatiNo ratings yet

- Man 2Document12 pagesMan 2Him SatiNo ratings yet

- November 2016Document2 pagesNovember 2016Arun SNo ratings yet

- Ssep 4 PDFDocument1 pageSsep 4 PDFArun SNo ratings yet

- New Doc 13Document6 pagesNew Doc 13Him SatiNo ratings yet

- CamScanner Scans Docs QuicklyDocument6 pagesCamScanner Scans Docs QuicklyHim SatiNo ratings yet

- General Set 1Document10 pagesGeneral Set 1Him SatiNo ratings yet

- Propeller SingingDocument1 pagePropeller SingingHim SatiNo ratings yet

- Multiple CamScanner ScansDocument17 pagesMultiple CamScanner ScansHim SatiNo ratings yet

- CC Relief DoorDocument7 pagesCC Relief DoorHim SatiNo ratings yet

- Electrical Set 2 PDFDocument17 pagesElectrical Set 2 PDFHim SatiNo ratings yet

- CamScanner ScansDocument8 pagesCamScanner ScansHim SatiNo ratings yet

- MEP Set 2Document10 pagesMEP Set 2Him SatiNo ratings yet

- Sulzer RT Flex Slow SpeedDocument8 pagesSulzer RT Flex Slow SpeedHim SatiNo ratings yet

- CamScanner Scans - Multiple PagesDocument13 pagesCamScanner Scans - Multiple PagesHim SatiNo ratings yet

- Ringleman Chart FlareDocument12 pagesRingleman Chart FlareguhadebasisNo ratings yet

- Bosch Terminal Designations GuideDocument7 pagesBosch Terminal Designations GuideJozsefNo ratings yet

- Optronic Technical BulletinsDocument18 pagesOptronic Technical BulletinsAlexander StollznowNo ratings yet

- P0340Document5 pagesP0340Freddie Kemp100% (1)

- Rotary Joint Unit: Supplementary Instruction ManualDocument17 pagesRotary Joint Unit: Supplementary Instruction ManualAntonio Montesinos ChavarríaNo ratings yet

- Timing Advance Processor NewDocument42 pagesTiming Advance Processor NewPhonthep YimsukananNo ratings yet

- 1955 Chevy 235 (123 HP)Document5 pages1955 Chevy 235 (123 HP)Mikey3airNo ratings yet

- Chirisler, JeepDocument24 pagesChirisler, JeepManuel SuarezNo ratings yet

- Ignition Coil DiagnosticsDocument5 pagesIgnition Coil Diagnosticsjorge rioboNo ratings yet

- Unit 2Document49 pagesUnit 2Ramanathan DuraiNo ratings yet

- Troubleshooting - Brgs.Document6 pagesTroubleshooting - Brgs.Sanjoy deyNo ratings yet

- Compression Test Kit MODEL ©MV5530: Form 824255 JAN - 08 SectionDocument18 pagesCompression Test Kit MODEL ©MV5530: Form 824255 JAN - 08 SectionCarlos CuellarNo ratings yet

- Luxi Insurance Policy Coverage DetailsDocument13 pagesLuxi Insurance Policy Coverage DetailsrcpretoriusNo ratings yet

- SNSCT Ignition SystemsDocument30 pagesSNSCT Ignition SystemsRajesh KumarNo ratings yet

- Limited Warranty: Installation Instructions Part # 1247Document2 pagesLimited Warranty: Installation Instructions Part # 1247Manuel ĆulibrkNo ratings yet

- 303-01 - 2.3L EcoBoost - Disassembly - EngineDocument88 pages303-01 - 2.3L EcoBoost - Disassembly - EngineCARLOS LIMADANo ratings yet

- FG 19R3 ManualDocument2 pagesFG 19R3 ManualtitanwlxNo ratings yet