Professional Documents

Culture Documents

Product Applications Basic System Concepts: About This Manual

Uploaded by

Mohammad TouffiqueOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Applications Basic System Concepts: About This Manual

Uploaded by

Mohammad TouffiqueCopyright:

Available Formats

Product Applications Basic System Concepts

Introduction:

ABOUT THIS MANUAL

The purpose of this manual is to acquaint you with the basics of metal building system terminology and products of the building system industry in general. Furthermore, it is designed to familiarize you with VP Building systems in particular and to give you the basic knowledge. If you already have a good working knowledge of these items this manual should serve as an excellent refresher course.

1.3 Basic System Concepts.doc 06.16.09

Page 1 of 16

Product Applications Basic System Concepts Basic Terminology

Basic metal building systems typically have four outside walls. Two of these walls are located where the roof meets the walls in a line parallel to the ground without any increase in the height of these walls. The other two walls show a rising line where the walls meet the roof and the height of the wall changes. The line where the sidewalls meet the roof is called the eave line or eave. It often has trim to enhance appearance or gutter for removal of rain water from the roof. The distance from the bottom of the base plate to the point where the roof meets the wall, or the eave, is called the eave height, measured at the back side of the wall panels and underside of roof panels.

Eave Height

Eave or Eave Line

The line where the endwall meets the roof is finished with a piece of trim known as rake fascia. The line where the sidewall s meet the endwall s is usually finished out with a piece of trim known as the corner trim. The peak receives a plastic or metal cap know as a peak cap. The peak cap includes the VP logo.

Ridge or Peak Gable

1.3 Basic System Concepts.doc 06.16.09

Page 2 of 16

Product Applications Basic System Concepts

The roof pitch or slope is usually shown as 1-in-12, 1/2-in-12, and 4-in-12 etc. When inches are used as the basic unit, for example 2-in-12 roof pitch means that the roof that rises vertically 2 inches for every 12 inches measured horizontally.

Eave Height

VP buildings are dimensioned from the outside edge of the girt, to the outside edge of the girt. The outside edge of the girt is known as the building line.

Building Line B

Building Line

VP building systems have three basic dimensions: width, length, and eave height. The width is the distance from the outside of the sidewall girt on one side to the outside of the sidewall girt on the other side. The length is the distance from the outside of the outside of the endwall girt to the outside of the endwall girt on the other end. Eave height is the distance from the Finish Floor to the point where the roof meets the wall.

Eave Height

Length Width

1.3 Basic System Concepts.doc 06.16.09

Page 3 of 16

Product Applications Basic System Concepts Systems & Components

VP building systems are built on top of a foundation. The foundation is generally a concrete slab with concrete footings. The footing is extra concrete, usually rectangular in shape, poured and formed under a column or some other structural support member of the building. A footing distributes the load carried by the VP building system support members into the supporting soil. Anchor bolts are set in the footing to "anchor" the column or structural members. A pre-punched metal plate is welded to the base of the column or structural to fit over the anchor bolts.

1.3 Basic System Concepts.doc 06.16.09

Page 4 of 16

Product Applications Basic System Concepts Primary Structural Support Systems

Primary structural support systems furnish the main support of a building. The primary structural support systems are more often called the main framing system and can be divided into two basic types, modular (Continuous Beam CB) and clear span (Rigid Frame - RF). Modular frames have one or more interior columns between the exterior columns, supporting some of the vertical load carried by the frame.

Modular

Clear Span

On modular frames, Continuous Beams (CB) and Continuous Trusses (CT), the dimensions between interior columns are measured from the outside of the sidewall girt to the centerline of the first interior column. On all other interior columns the column spacing dimension is measured from the centerline of one column to the centerline of the next column until the last interior column is reached. The column spacing on the last interior column is again measured centerline of column to the outside of the sidewall girt. Interior column spacing may vary.

C L

B L

Column Spacing

C L

Column Spacing

C L

Column Spacing

B L

1.3 Basic System Concepts.doc 06.16.09

Page 5 of 16

Product Applications Basic System Concepts Solid Web Primary Frames

The rigid frame is probably the most commonly used clear span frame. Clear span frames have no interior columns or vertical support between the exterior columns. The rigid frame has as a standard tapered vertical columns and a tapered rafter section. A cross-section through either a column or rafter section would show an I-shape. Typically, the rigid frame is deepest in the knee or haunch area where the column is connected to the rafter beam.

Rigid Frame

Welds

Flange

Web

Open Web Primary Frames

The Rigid Frame Truss (RFT or Wind Bent) is another type of clear span frame. The RFT has tapered exterior columns, but unlike the rigid frame, the web of the truss beam has open area. The RFT rafter is made up of angles welded in a specially designed pattern between the flanges.

Rigid Frame Truss (Wind Bent)

1.3 Basic System Concepts.doc 06.16.09

Page 6 of 16

Product Applications Basic System Concepts Bay Spacing

Frames are placed in a pattern to provide the primary support for the building, the distance between the centerline of each frame is called a Bay.

Bay Bay C L C L

C L

Bay Spacing C L C L

Spacing for the End Frame is measured from the building (girt) line to the centerline of the End Frame.

CB L L

1.3 Basic System Concepts.doc 06.16.09

Page 7 of 16

Product Applications Basic System Concepts

When a frame is located on the interior of the building, it is called an interior frame. When a frame is at an endwall, it is called an Endwall Frame or End frame.

Interior Frames

End Frames

Endwall Frames

Rake Beam

The most common endwall frame is called a Post and Beam. Post and Beam frames are comprised of Corner Posts, End Posts and Rake Beams. They are designed to support half a bay of roof.

End Posts Corner Post

End Posts Corner Post

1.3 Basic System Concepts.doc 06.16.09

Page 8 of 16

Product Applications Basic System Concepts Secondary Structural Support Systems

Purlins

The principal segments of the roof secondary support system spanning from frame line ot frame line are known as purlins. The purlins transfer roof loads to the primary structural support system, which in turn transfers the loads to the foundation.

Purlins

VP building system purlins come in a variety of material thickness and depths. VP offers two basic types of purlins: simple and continuous. The basic structural shapes used in VP building systems are 7", 8 1/2", 10, and 11 1/2" deep.

Continuous purlins overlap at frame lines making the connection stronger. The continuous purlin overlap, which can vary according to conditions, often allows the use of a lighter gage (i.e., more economical) purlin, saving the customer money while providing better structural integrity.

Continuous Purlins at Interior Frame

Simple purlins provide lap connection for alignment only. It is not a structural lap.

1.3 Basic System Concepts.doc 06.16.09

Page 9 of 16

Product Applications Basic System Concepts

Eave Strut

A C channel use as purlin, known as an eave strut, is located at the building eaves. Steep slopes (>4:12) will use additional new solution with a field attached gage angle.

1.3 Basic System Concepts.doc 06.16.09

Page 10 of 16

Product Applications Basic System Concepts

Truss Purlin (TP)

Truss purlins (TP) are economical for use when bay spacing exceeds the limits of standard purlins. Span range for use of truss purlins are typically 11 to 60 feet. Overall depths are from: 18 to 40 in 2 increments with a standard 5 seat depth. The members will bolt to the primary frames using pre-punched holes and bolts. The members are lighter than traditional bar joists and easier to erect. A foating roof system (SSR or SLR) must be used with trus purlins; a screw down roof (Panel Rib) is not permitted.

Standard WideBay members are stopped short of the frame centerline. Non-strut members have 9/16 x 7/8 slots in the seats and are connected with (2) 1/2" A325 bolts (49080) with hardened washers.

1.3 Basic System Concepts.doc 06.16.09

Page 11 of 16

Product Applications Basic System Concepts

1.3 Basic System Concepts.doc 06.16.09

Page 12 of 16

Product Applications Basic System Concepts Girts

In the wall areas, attached to the columns, are 7", 8 , 10, or 11 1/2" Zee or Cee shaped members - similar to the purlins on the roof. These are the principal segments of the wall secondary support framing system and are called girts. The girts take the loads imposed on the covering system and transfer them to the frames, which in turn transfer them to the foundation. The spacing of VP girts, like the material thickness of girts, varies with the load imposed on them. VP offers two basic girt connections continuous and simple. The most econmical girt system furnished by VP Buildings is continuous outset girt. The advantage of inset girts is an increase usable space inside the building at the column location for the same size building. It should be remembered that by definition, the building width is measured from outside of sidewall girt to outside of sidewall girt. Therefore, when using the inset girt condition the building frames are moving out into the girt line. The building does not get wider.

Girts

1.3 Basic System Concepts.doc 06.16.09

Page 13 of 16

Product Applications Basic System Concepts Diagonal Bracing

Wind exerts a force on all buildings. One of the primary design features used to resist this force is bracing. Bracing consists of sets of rods in the roof, between the rafters, and in the walls, between the columns. The specific design criteria (wind and seismic) that will govern a particular building will determine the quantity and location of bracing rods. Bracing rods are often called "X" rods, wind bracing, roof rods, wall rods, or "X" bracing. Other Bracing options are discussed in the Wind Bracing section.

Portal Brace:

Portal Frame

Eave

Floor

1.3 Basic System Concepts.doc 06.16.09

Page 14 of 16

Product Applications Basic System Concepts Covering Systems

VP Buildings offers a variety of covering systems available for both the roof and walls to match an owner's needs and budget. The gauge, finish, configuration, width, and fastening systems can all vary.

Primary Wall Panel Types

Panel Rib

Vee Rib

Stran Loc

Reverse Roll Panel Rib

Primary Roof Panel Types

Standing Seam

Panel Rib

1.3 Basic System Concepts.doc 06.16.09

Page 15 of 16

Product Applications Basic System Concepts

SLR

Other components such as insulation, trim and accessories will be discussed later in this manual.

Basic System Tips

It is usually most economical to make least dimension the width. Gable buildings usually more economical than single-sloped buildings.

1.3 Basic System Concepts.doc 06.16.09

Page 16 of 16

You might also like

- Virginia Reatining Wall PDFDocument6 pagesVirginia Reatining Wall PDFLeviNo ratings yet

- Design of a 4m Cantilever Retaining WallDocument9 pagesDesign of a 4m Cantilever Retaining WallSaiSowmithGoudNaramalaNo ratings yet

- Cantilever Retaining Wall - Metric PDFDocument16 pagesCantilever Retaining Wall - Metric PDFJebin JacobNo ratings yet

- Method StatementDocument12 pagesMethod StatementSeifeldinNo ratings yet

- Design of Underground Reservoir - 03Document21 pagesDesign of Underground Reservoir - 03Engr SwapanNo ratings yet

- ACI 117 (R2002) Specs-Tolerances-Concrete Construction & MaterialsDocument23 pagesACI 117 (R2002) Specs-Tolerances-Concrete Construction & MaterialsManmade TulipNo ratings yet

- PS 18 Concrete Tolerance CoordinationDocument1 pagePS 18 Concrete Tolerance CoordinationSeifeldinNo ratings yet

- Reinforcement To Control Cracking To BS8007: FCT / FBDocument1 pageReinforcement To Control Cracking To BS8007: FCT / FBSeifeldinNo ratings yet

- Al Rashed Preliminary Facade Material SelectionDocument6 pagesAl Rashed Preliminary Facade Material SelectionSeifeldinNo ratings yet

- Watertank 2Document41 pagesWatertank 2venkatesh19701No ratings yet

- Torsion in Girders Design and ReinforcementDocument9 pagesTorsion in Girders Design and ReinforcementExtra TerrestrialNo ratings yet

- Architectural - Drawing ListDocument3 pagesArchitectural - Drawing ListSeifeldin100% (1)

- 1464 3270 1 SMDocument11 pages1464 3270 1 SMSeifeldinNo ratings yet

- Hollowblockandribbedslabs 130702183359 Phpapp01Document38 pagesHollowblockandribbedslabs 130702183359 Phpapp01SeifeldinNo ratings yet

- 3 SG StrengthDocument38 pages3 SG StrengthSeifeldinNo ratings yet

- Is800 Steel Design Chap1Document43 pagesIs800 Steel Design Chap1yhproNo ratings yet

- Crack in Concrete Basements FloorsDocument2 pagesCrack in Concrete Basements Floorsibrahim tarekNo ratings yet

- 69 FernerDocument9 pages69 FernerSeifeldinNo ratings yet

- Shortening Cracking Crack Evaluation TN451Document64 pagesShortening Cracking Crack Evaluation TN451SeifeldinNo ratings yet

- Seepage Analysis of Earth Dams and FiltersDocument30 pagesSeepage Analysis of Earth Dams and FiltersSeifeldinNo ratings yet

- APP20140001 - 014 0001 Method StatementsDocument10 pagesAPP20140001 - 014 0001 Method StatementsSeifeldinNo ratings yet

- Design of Crane Track GirdersDocument30 pagesDesign of Crane Track GirdersSeifeldinNo ratings yet

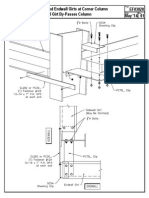

- Flush Sidewall and Endwall Girts at Corner Column Endwall Girt By-Passes Column EF03020 May '14 01Document1 pageFlush Sidewall and Endwall Girts at Corner Column Endwall Girt By-Passes Column EF03020 May '14 01SeifeldinNo ratings yet

- Aduo - Ro 23456 23456 Homework1 PDFDocument3 pagesAduo - Ro 23456 23456 Homework1 PDFDragos MafteiNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)