Professional Documents

Culture Documents

DCV - Design Notes

Uploaded by

Ankit JainOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DCV - Design Notes

Uploaded by

Ankit JainCopyright:

Available Formats

Optimise Ventilation & Energy Costs

Variable Air Quality Station - An Introduction

n Why should you monitor outdoor air volumes?

There are many significant benefits to monitoring outdoor air volumes. First, by measuring the amount of outdoor air coming into a building you can be assured that the building is complying with all applicable indoor air quality codes including ASHRAE Standard 62 and California Title 24. Meeting these minimum requirements reduces indoor airborne viruses and bacteria which can lead to Sick Building Syndrome. Studies have shown that buildings that are under ventilated suffer from reduced productivity levels. The second major advantage to monitoring outdoor air volumes is that it eliminates costly over ventilation. In addition to increased energy costs associated with heating and cooling of outdoor air, over ventilation causes in an increase in humidity that can result in mold development.

n Applications

VAV Terminal: In this application, an air measuring control damper provides the air supply at a constant temperature while individual zone thermostats vary the flow of air to each space maintaining the desired zone temperature. The specific amount of air volume required to maintain a particular zone temperature set-point is dictated by the size of the space and the internal and External heat loads. Exhaust Air: In this application an air measuring control damper is used to measure and control outdoor air intake while a second air measuring control damper is used to measure and control the exhaust flow. The set point for the exhaust air damper would track the flow of the outdoor air damper (minus a differential if positive building pressure is desired.) Mixed Air: In this application, an air measuring control damper is used to measure and control outdoor air intake while a second air measuring control damper is used to control the mixed air temperature. Normally an averaging sensor is required for mixed-air temperature control because the large temperature differences between return air and outdoor air cause stratification. The mixed air temperature is calculated from the flows and temperatures measured by each damper eliminating the measurement problem caused by stratification. Outdoor Air: In this application, an air measuring control damper provides outdoor air control based on a demand signal. The demand signal could be determined by a set schedule or by occupancy sensors. Examples of demand signals are carbon dioxide (CO2) concentration, a binary signal from a motion detector, or a manual switch.

n Presenting, the VAQ Station from Conaire

The VAQ Station combines an air measuring station with an ultralowleak, high performance control damper that is AMCA class 1A leakage and performance certified (CD50). The complete assembly is factory assembled and tested to provide effective set point monitoring and adjustment. The unit comes standard with a pressure transducer, with the output signal proportional to cfm and factory fitted standalone DDC controller. The VAQ Station can also be used with any building automation system. Multiple control options available are descibed in the following pages. .

Variable Air Quality Station - Control Strategy

n Demand Controlled Ventilation

Exhaust Air

CO2

Alternate Sensor Location

Return Air

n Applying CO2-based DCV

CO2-based demand-controlled ventilation refers to the practice of using carbon dioxide concentrations as an indicator for the per-person ventilation rate. In this context, CO2 is monitored as a byproduct of respiration rather than as an indoor contaminant. The rate at which people produce CO2 varies with diet and health, as well as with the duration and intensity of their physical activity. The more exertion an activity entails, the more carbon dioxide we produce. Appendix C of ASHRAE 62.1-2007 provides the following mass balance equation to predict the difference between indoor (Cs) and outdoor (Co) concentrations of carbon dioxide at steady-state conditions, given a constant, per-person ventilation rate (Vo) and a constant CO2 generation rate (N). where,

Outside Air

Mixed Air

CO2-based DCV in a single-zone system as per ASHRAE 62.1-2007

The proportional control approach thats described in the ASHRAE 62.12007 users manual discusses a method for implementing CO2-based DCV in a single-zone system. implementing CO2-based DCV in a single-zone system. A paraphrase of that method follows: 1) Find the required intake flow of outdoor air for the design zone population, Pz.

V ot-design = V ot =

(Rp x Pz) + (Ra x Az) Ez

Vo =

N Cs - Co

Vo = outdoor airflow rate, cfm/person N =CO2 generation rate, cfm/person Cs =CO2 concentration in the space, ppm Co =CO2 concentration in the outdoor air, ppm

2) Find the required intake flow of outdoor air when the zone is unoccupied, that is, Pz = 0. 3) Find the target indoor CO2 concentration at Vot-design.

V s-design = Co =

N (V ot-design /P z-design )

Implementing CO2-based DCV is a matter of estimating the CO2 generation rate of the occupants (N), measuring the concentration difference in the space versus outdoors (Cs Co), and then using this difference to determine the rate at which ventilation air (Vo), on a per-person basis, is delivered to the space. In most locations, the outdoor concentration (Co) of carbon dioxide seldom varies by more than 100 ppm from the nominal value. Because of this and in lieu of installing an outdoor CO2 sensor, most designers use either a one-time reading of the outdoor CO2 concentration at the building site or a conservative value from historical readings. This simplifies control, lowers the installed cost, and usually increases accuracy because it avoids the potential inaccuracy of an outdoor sensor.

4) Set the target indoor CO2 concentration at Vot-min equal to the outdoor CO2 concentration, Co. When the indoor CO2 concentration equals Cs-design, Vot should equal Vot-design. When the concentration of CO2 indoors equals Cs-min, Vot should equal Vot-min. When the indoor CO2 concentration is between Cs-min and Cs-design, a controller should adjust outdoor-air intake flow Vot proportionally between Vot-min and Vot-design.

n CO2-based DCV in a multiple-zone VAV system

In a multiple-zone VAV system, the ventilation system delivers fresh outdoor air to several, individually controlled spaces. CO2-based DCV alone: One approach for implementing CO2-based DCV in multiple-zone VAV system is to install a CO2 sensor in every zone. A building automation system (BAS) monitors all the sensors, determines how much outdoor air must be brought in at the air handler to satisfy the critical zone (and thus overventilate all other zones), and then repositions the outdoor air damper

n CO2-based DCV in a single-zone system

In an application where the ventilation system delivers fresh outdoor air to a single zone, the CO2 sensor typically is installed on the wall in the breathing zone, just like the thermostat. Its usually expedient to assume that the outdoor CO2 concentration is constant, so the indoor concentration (rather than the outdoors) is measured and used to modulate the position of the outdoor-air damper and thereby provide the space with the proper amount of ventilation air on a per-person basis.

Heating Coil

Cooling Coil

Supply Air

There are several ways to assess ventilation demand: Occupancy schedules, which allow a building automation system to predict the current population based on the time of day Occupancy sensors, which detect the presence or number of people in each monitored zone Carbon dioxide (CO2) sensors, which monitor the concentration of CO2 that is produced continuously by the occupants and diluted by the outdoor air Regardless of which method is used, DCV strategies attempt to vary the outdoor-air intake in response to the current population.

CO2

ZONE

Variable Air Quality Station - Control Strategy

accordingly. However, its costly to install a CO2 sensor in every zone. Especially when you consider that most of the zones will always be overventilated, regardless of operating conditions. Installing a sensor in those noncritical zones offers no added value. In some applications, you may know that only a handful of zones will ever be critical, and you could choose to locate CO2 sensors only in those potentially critical zones. The users manual for ASHRAE 62.1-2007 discusses this approach further. Alternatively, some designers opt to install a single CO2 sensor in the returnair duct of a multiple-zone system, and then use this single sensor to vary the amount of outdoor air brought in at the air handler. However, this CO2 sensor measures the average CO2 concentration, so its likely that some spaces will be underventilated while others are overventilated. Whether this approach provides adequate ventilation is a matter of debate among designers. Ventilation reset alone: Another control strategy for multiple-zone VAV systemscalled ventilation reset resets intake airflow in response to variations in system ventilation efficiency, current primary airflow (Vpz) and calculates its outdoor-air fraction (Zd). The building automation system totals the primary airflows and required outdoor airflows from all boxes, and determines the highest outdoor-air fraction reported. Then it solves the equations from Appendix A of ASHRAE 62.1-2007, calculating the system ventilation efficiency (Ev) and the system-level intake flow of outdoor air (Vot) thats required at the current operating condition. The new intake-flow setpoint is communicated to the air handler controller, which then adjusts the OA damper accordingly to bring in the required amount of outdoor air. In DDC/VAV systems, this strategy is fairly easy to implement because all of the necessary real-time information is already available digitally (so no new sensors are required). All of the equations are defined in Appendix A of the standard and can be solved dynamically to find the outdoor-air intake flow thats currently required. CO2-based DCV combined with ventilation reset: In most multiple-zone VAV systems, the best approach often combines CO2-based DCV with ventilation reset. Using this strategy, CO2 sensors are installed only in those zones (conference rooms, for example) that are densely occupied and experience widely varying patterns of occupancy. The sensors in these zones are used to reset the ventilation requirement (Voz) for their respective zones. The other zoneswhich either are not densely occupied or do not experience significant variations in occupancy are assumed to require their design ventilation rates whenever theyre occupied. The BAS then uses the ventilation reset equations to determine how much outdoor air must be brought in at the air handler to satisfy all of the zones served. Combining CO2-based DCV with ventilation reset provides two benefits: It can assure that each zone receives the proper amount of ventilation without requiring a CO2 sensor in every zone. CO2 sensors are used only in those zones where they will bring the most benefit. When the other zones are unoccupied, time-of day schedules or occupancy sensors are used to reduce ventilation. It enables documentation of actual ventilation-system performance by communicating the ventilation airflows for every zone to the BAS.

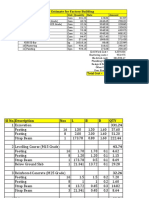

ZONE1 ZONE2 VENTILATION RESET ONLY PRIMARY AIRFLOW CFM Vpz 3000 3000 = 6000 CFM ZONE OUTDOOR AIRFLOW CFM Voz 700 550 = 1250 CFM OA FRACTION Zd 0.233333 0.183333 ZONE VENTILATION EFFICIENCY Xs =1250/6000=0.2, Ev=0.975, Vot=1300 CFM VENTILATION RESET PLUS CO2 BASED DCV PRIMARY AIRFLOW CFM Vpz 3000 3000 = 6000 CFM ZONE OUTDOOR AIRFLOW CFM Voz 700 300 = 1000 CFM OA FRACTION Zd 0.233333 0.1 ZONE VENTILATION EFFICIENCY Xs =1000/6000=0.167, Ev=0.94, Vot=1050 CFM

Effect of ventilation control strategies in a single-duct VAV system at part load

n Closing thoughts

DCV with VAQ Station can reduce the cost of operating the HVAC systemespecially in applications where contaminant levels result primarily from people (or their activities) and where population varies significantly. The most common applications include gymnasiums, meeting rooms, and auditoriums. The 2007 standard also complicates implementation of CO2-based DCV. Thats because the effective cfm/ person, and (therefore) the desired indoor-to-outdoor difference in CO2 concentrations, vary as the zone population changes. CO2-based DCV is most commonly used in single-zone systems that serve densely occupied spaces with varying populations. In multiple-zone VAV systems, combining CO2-based DCV with ventilation resetusing CO2 sensors only in densely occupied zones with widely varying populationsprovides a cost-effective,reliable, and energy-efficient system. For more details on product and applications please contact:

Exhaust Air

Return Air

Zone 1

(Using Ventilation Reset)

Zone 2

(Variable Occupied Space)

CO2 T0 C

VP1 VP2

T0 C

Heating Coil

Outdoor Air

Mixed Air

Cooling Coil

An ISO 9001:2000 Company

Supply Air

n B-23A, Udyog Kendra Extn. - 1, Greater Noida (U.P.) - 201 308 Telefax - 0120 - 2350450, E-mail : info@caireconsult.com Visit: www.caireconsult.com n Contact Person : ANKIT JAIN, +91-9911243399

CO2-based DCV with ventilation reset as per ASHRAE 62.1-2007

You might also like

- 2016-Applying Demand-Controlled Ventilation Multiple-Zone VAV Systems in BuildingsDocument7 pages2016-Applying Demand-Controlled Ventilation Multiple-Zone VAV Systems in BuildingsZoidberg12No ratings yet

- IJETR021107Document6 pagesIJETR021107erpublicationNo ratings yet

- Single Zone, CO2 Based Demand Controlled VentilationDocument7 pagesSingle Zone, CO2 Based Demand Controlled VentilationeimrehNo ratings yet

- A Study of Demand-Controlled VentilationDocument8 pagesA Study of Demand-Controlled Ventilationas3ateNo ratings yet

- ASHRAE Journal - CO2-Based DCV Using 62.1Document7 pagesASHRAE Journal - CO2-Based DCV Using 62.1Gustavo ChavesNo ratings yet

- Demand Control VentilationDocument28 pagesDemand Control Ventilationmnt6176100% (1)

- Ashrae Paper On IAQ PPMDocument3 pagesAshrae Paper On IAQ PPMHadi AbdulkaderNo ratings yet

- Workshop On Demand Controlled Ventilation at CLIMA 20131Document6 pagesWorkshop On Demand Controlled Ventilation at CLIMA 20131hb_scribNo ratings yet

- 2013 Symposiums SYMP003-2 Optimizing Ventilation Calculations 3-25-2013Document25 pages2013 Symposiums SYMP003-2 Optimizing Ventilation Calculations 3-25-2013edsonleviNo ratings yet

- CO2 Based Demand Controlled Ventilation: Do The Risks Outweigh The Rewards?Document6 pagesCO2 Based Demand Controlled Ventilation: Do The Risks Outweigh The Rewards?Trang NgoNo ratings yet

- Variable Air Volume & Constant Air: by CH - Sandeep Dattu (2019H1480152H) A.Chaithanya (2019H1480151H)Document13 pagesVariable Air Volume & Constant Air: by CH - Sandeep Dattu (2019H1480152H) A.Chaithanya (2019H1480151H)chitta sandeep dattuNo ratings yet

- Tranee LetterDocument8 pagesTranee Letterimecc ingenieriaNo ratings yet

- Articles About HVAC - Fresh Air and OccupancyDocument13 pagesArticles About HVAC - Fresh Air and OccupancyAnonymous DjWqKpZ1No ratings yet

- Minimum indoor air quality performance EQp1Document2 pagesMinimum indoor air quality performance EQp1Gustavo ChavesNo ratings yet

- cp038 PDFDocument12 pagescp038 PDFsoma AlmasoodyNo ratings yet

- Ventilation in HAP: QB Tip 001Document6 pagesVentilation in HAP: QB Tip 001Abdul RaheemNo ratings yet

- Percent Outdoor Air (%OA) Calculation and Its Use: Application NoteDocument7 pagesPercent Outdoor Air (%OA) Calculation and Its Use: Application NoteAce Glen GarciaNo ratings yet

- RP 1819. Energy and Ventilation Performance Analysis For CO2 Demand-Comtrolled Ventilation in Multiple-Zone VAV Systems With Fan-Powered Terminal UnitsDocument20 pagesRP 1819. Energy and Ventilation Performance Analysis For CO2 Demand-Comtrolled Ventilation in Multiple-Zone VAV Systems With Fan-Powered Terminal UnitsEduardoNo ratings yet

- Objective: To Understand Operation of Air Quality Monitor and Compare Air Quality (CO, CODocument2 pagesObjective: To Understand Operation of Air Quality Monitor and Compare Air Quality (CO, COSuri BabuNo ratings yet

- % Outdoor Air CalculationDocument6 pages% Outdoor Air Calculationamirin_kingNo ratings yet

- EDR DesignBriefs DemandcontrolledventilationDocument28 pagesEDR DesignBriefs DemandcontrolledventilationjmlengrNo ratings yet

- 3-Emission Monitoring and SamplingDocument77 pages3-Emission Monitoring and SamplingFarah SyaheyraNo ratings yet

- Optimized SOP for NOx MeasurementsDocument17 pagesOptimized SOP for NOx MeasurementsDienNo ratings yet

- ASHRAE 62.1 Ventilation Rate Procedure Calculations - Cove - Tool Help CenterDocument13 pagesASHRAE 62.1 Ventilation Rate Procedure Calculations - Cove - Tool Help CenterdavignapeNo ratings yet

- Fault-tolerant ventilation control using neural networksDocument14 pagesFault-tolerant ventilation control using neural networksKhuleedShaikhNo ratings yet

- HVAC - Guide To Demand Control VentilationDocument39 pagesHVAC - Guide To Demand Control VentilationDavid GeniacNo ratings yet

- HVAC - Guide To Demand Control Ventilation PDFDocument39 pagesHVAC - Guide To Demand Control Ventilation PDFFredie UnabiaNo ratings yet

- Project Report2 PDFDocument40 pagesProject Report2 PDFRamin ShabNo ratings yet

- IAQ performance standardsDocument2 pagesIAQ performance standardsgarycwkNo ratings yet

- Ashrae STD 62-11Document35 pagesAshrae STD 62-11Silva NumaNo ratings yet

- Ashrae STD 62 11Document35 pagesAshrae STD 62 11djtruquitosNo ratings yet

- Hap Ehelp 025Document17 pagesHap Ehelp 025Abed NaemNo ratings yet

- Ventilation Fan Pressure OptimizationDocument11 pagesVentilation Fan Pressure OptimizationchoibeNo ratings yet

- Understanding and Applying Ashrae Standards With LG Multi V Rev 0812091Document4 pagesUnderstanding and Applying Ashrae Standards With LG Multi V Rev 0812091Leo2pbNo ratings yet

- Demand Based VentilationDocument10 pagesDemand Based VentilationSadiya IqbalNo ratings yet

- Outdoor Ventilation Airflow Calculations: ControlDocument6 pagesOutdoor Ventilation Airflow Calculations: ControlAli HabibNo ratings yet

- I E Q C C: Ndoor Nvironmental Uality Redit AtegoryDocument29 pagesI E Q C C: Ndoor Nvironmental Uality Redit AtegorypratheeshNo ratings yet

- Addendum 62n Breathes New Life Into ASHRAE 62Document8 pagesAddendum 62n Breathes New Life Into ASHRAE 62majortayNo ratings yet

- Natural Ventilation in BuildingsDocument11 pagesNatural Ventilation in BuildingsAlessandro GorgoglioneNo ratings yet

- Guide to Applying Variable Speed Drives for Energy SavingsDocument7 pagesGuide to Applying Variable Speed Drives for Energy SavingsVinit JoryNo ratings yet

- Design and AnalysisDocument5 pagesDesign and AnalysiscliveNo ratings yet

- A Study On A Control Method With A Ventilation Req PDFDocument17 pagesA Study On A Control Method With A Ventilation Req PDFEslam ElsayedNo ratings yet

- RB1-5 (3) CO Sensor CatalogueDocument10 pagesRB1-5 (3) CO Sensor CataloguedimchienNo ratings yet

- Some Design GuidelinesDocument3 pagesSome Design GuidelinesAntonio LebrunNo ratings yet

- Sustainability Schematic ReportDocument5 pagesSustainability Schematic ReportsakhrNo ratings yet

- Seidl NCBC08 Paper TR CorrectedDocument10 pagesSeidl NCBC08 Paper TR CorrectedsajuhereNo ratings yet

- Lit Review Industrial ExampleDocument6 pagesLit Review Industrial ExampleMuhamad ZahinNo ratings yet

- HVAC Design For High Performance PharmaceuticalsDocument13 pagesHVAC Design For High Performance PharmaceuticalsMuhammadSaqibNo ratings yet

- Telstar Case Study Smart CR 25mar20Document8 pagesTelstar Case Study Smart CR 25mar20Whisnu AlbertusNo ratings yet

- ASHRAE Journal - September 2007Document7 pagesASHRAE Journal - September 2007caliche_362447No ratings yet

- Lab7part2 Air Lab ManualDocument8 pagesLab7part2 Air Lab ManualMehul RanaNo ratings yet

- Measure CO2 Levels to Ensure Proper Building VentilationDocument5 pagesMeasure CO2 Levels to Ensure Proper Building VentilationhustrobinNo ratings yet

- Measuring Airflow Using Simplified Fan Curve MethodDocument7 pagesMeasuring Airflow Using Simplified Fan Curve MethodBRYAN ANDRADENo ratings yet

- Revision of EN 15251 Indoor CriteriaDocument14 pagesRevision of EN 15251 Indoor CriteriaTofan Bogdan AndreiNo ratings yet

- 1 - Extraction #3 - VA HVAC Design ManualDocument4 pages1 - Extraction #3 - VA HVAC Design ManualAmr HeshamNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- The Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationFrom EverandThe Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationRating: 1 out of 5 stars1/5 (1)

- Diagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceFrom EverandDiagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Features: Compact Embedded Box PC With Lan X 4, Hdmi X 2, Intel® Celeron® J1900/N2807 Processor SocDocument2 pagesFeatures: Compact Embedded Box PC With Lan X 4, Hdmi X 2, Intel® Celeron® J1900/N2807 Processor SocAnkit JainNo ratings yet

- Pramod - Target - Sheet1Document2 pagesPramod - Target - Sheet1Ankit JainNo ratings yet

- Kaze ReidanDocument3 pagesKaze ReidanAnkit JainNo ratings yet

- Purchase Details - Dell India 2Document4 pagesPurchase Details - Dell India 2Ankit JainNo ratings yet

- Ec Centrifugal Module - Radipac: K3G280-Au06-B2Document5 pagesEc Centrifugal Module - Radipac: K3G280-Au06-B2Ankit JainNo ratings yet

- Quotation Quote FP KASP 11-19-102Document2 pagesQuotation Quote FP KASP 11-19-102Ankit JainNo ratings yet

- First Name Last Name Company Industry Function DesignationDocument149 pagesFirst Name Last Name Company Industry Function DesignationAnkit JainNo ratings yet

- ECDocument48 pagesECAditya PatilNo ratings yet

- Trackdart - Tracking Details: Shipped in Transit DeliveredDocument1 pageTrackdart - Tracking Details: Shipped in Transit DeliveredAnkit JainNo ratings yet

- Purchase Details - Dell India 2Document4 pagesPurchase Details - Dell India 2Ankit JainNo ratings yet

- Purchase Details - Dell IndiaDocument2 pagesPurchase Details - Dell IndiaAnkit JainNo ratings yet

- Instructions From Discount Bazaar IndiaDocument2 pagesInstructions From Discount Bazaar IndiaAnkit JainNo ratings yet

- BACnet - IP PICS ServerDocument8 pagesBACnet - IP PICS ServerAnkit JainNo ratings yet

- ECDocument48 pagesECAditya PatilNo ratings yet

- Compact High-accuracy MEMS Differential Pressure SensorDocument3 pagesCompact High-accuracy MEMS Differential Pressure SensorAnkit JainNo ratings yet

- DCVDocument8 pagesDCVShabbir AliNo ratings yet

- TM4000 Series Data Sheet 1.8Document59 pagesTM4000 Series Data Sheet 1.8Ankit JainNo ratings yet

- BACnetSupervisor DataSheetDocument2 pagesBACnetSupervisor DataSheetAnkit JainNo ratings yet

- ccs811 ds000459 2-00-1098798Document37 pagesccs811 ds000459 2-00-1098798api-474821388No ratings yet

- NikhilDocument339 pagesNikhilAnkit JainNo ratings yet

- Graphics Certification Table 2020 0604 Tcm27 77702Document57 pagesGraphics Certification Table 2020 0604 Tcm27 77702Ankit JainNo ratings yet

- Niagara 4 DriversDocument2 pagesNiagara 4 DriversAnkit JainNo ratings yet

- BACnetSupervisor DataSheetDocument2 pagesBACnetSupervisor DataSheetAnkit JainNo ratings yet

- Tgs5141-p00 Technical Infomation (En) Rev08Document16 pagesTgs5141-p00 Technical Infomation (En) Rev08Ankit JainNo ratings yet

- JDC Ball Transfer Unit Catalog 181019Document4 pagesJDC Ball Transfer Unit Catalog 181019Ankit JainNo ratings yet

- TM4000 Series Data Sheet 1.8Document59 pagesTM4000 Series Data Sheet 1.8Ankit JainNo ratings yet

- Delhi Goa: Aqusxb CompleteDocument3 pagesDelhi Goa: Aqusxb CompleteAnkit JainNo ratings yet

- Runtimeos: Software Product Solid Edge 2020Document10 pagesRuntimeos: Software Product Solid Edge 2020Ankit JainNo ratings yet

- TM4000 Series Data Sheet 1.8Document59 pagesTM4000 Series Data Sheet 1.8Ankit JainNo ratings yet

- BACnetSupervisor DataSheetDocument2 pagesBACnetSupervisor DataSheetAnkit JainNo ratings yet

- Estimate For Factory Building: SI No Description Unit Quantity Rate AmountDocument3 pagesEstimate For Factory Building: SI No Description Unit Quantity Rate AmountkanagarajodishaNo ratings yet

- Item Unit Qty Rate AmountDocument17 pagesItem Unit Qty Rate AmountvinujohnpanickerNo ratings yet

- Bill of Quantities for 37 sqm SA House ModelDocument9 pagesBill of Quantities for 37 sqm SA House ModelJuryl ZacariasNo ratings yet

- HVAC SystemsDocument4 pagesHVAC SystemsSyed Shafaat Ali JafferyNo ratings yet

- 34.01.01-BOQ For Bres 20 RevDocument3 pages34.01.01-BOQ For Bres 20 Revvigil vigilNo ratings yet

- Fighter 1330 Manual enDocument88 pagesFighter 1330 Manual enpikermiNo ratings yet

- Residential Design PlansDocument5 pagesResidential Design Plansmichelle995No ratings yet

- Design For Thermal Comfort During Summer & Psychometry Tool For Human ComfortDocument8 pagesDesign For Thermal Comfort During Summer & Psychometry Tool For Human ComfortSwapan Kumar SarkerNo ratings yet

- Annex BDocument28 pagesAnnex BpspqsNo ratings yet

- Common Problems (Complete)Document26 pagesCommon Problems (Complete)junreymorales100% (1)

- Concrete BUildings Scheme Design Manual PDFDocument142 pagesConcrete BUildings Scheme Design Manual PDFAnilMohanK67% (3)

- Eastinate of ESRDocument139 pagesEastinate of ESRPradeepta PatraNo ratings yet

- FLOATING COLUMN LIMITATIONS FOR SEISMIC ZONESDocument3 pagesFLOATING COLUMN LIMITATIONS FOR SEISMIC ZONESkamakshiNo ratings yet

- Vel-Kaec Gha PMT Mom It Requirement 00 2023-02-19Document2 pagesVel-Kaec Gha PMT Mom It Requirement 00 2023-02-19姜逸飞(jeffery)No ratings yet

- M.03.1 Roof Eave DetailDocument1 pageM.03.1 Roof Eave DetailGkou DojkuNo ratings yet

- Restoring the Historic St. John the Baptist ChurchDocument50 pagesRestoring the Historic St. John the Baptist ChurchKathleen Celine D SamsonNo ratings yet

- Construction Techniques and Equipment and Practice - Lecture Notes, Study Material and Important Questions, AnswersDocument5 pagesConstruction Techniques and Equipment and Practice - Lecture Notes, Study Material and Important Questions, AnswersM.V. TVNo ratings yet

- 09-28-2018 Architectural Plans and ExhibitsDocument55 pages09-28-2018 Architectural Plans and ExhibitsNone None NoneNo ratings yet

- The Comprehensive Land Use Plan (CLUP) Vol. II (Zoning - Ordinance)Document44 pagesThe Comprehensive Land Use Plan (CLUP) Vol. II (Zoning - Ordinance)Jeffrey DiazNo ratings yet

- Bahay Na Bato at Kahoy Architectural and Home Furnishing Terms PDFDocument4 pagesBahay Na Bato at Kahoy Architectural and Home Furnishing Terms PDFAnne ReyesNo ratings yet

- Min. Reinforcement in ColumnsDocument58 pagesMin. Reinforcement in ColumnsBhaskar ReddyNo ratings yet

- Lecture 2 - Case Study On Sustainable Architecture PDFDocument41 pagesLecture 2 - Case Study On Sustainable Architecture PDFSaliha Kabeer100% (1)

- Natrani AmphitheaterDocument10 pagesNatrani AmphitheaterA-07 MIHIR BHUVANo ratings yet

- Building Fabric 2 Insulation MaterialsDocument9 pagesBuilding Fabric 2 Insulation MaterialsRomocea BogdanNo ratings yet

- Act 2 2 3 Heat Loss GainDocument4 pagesAct 2 2 3 Heat Loss Gainapi-247437088No ratings yet

- 072-73rate AnalysisKTMDocument388 pages072-73rate AnalysisKTMAmok BajracharyaNo ratings yet

- ANH House by Sanuki + NishizawaDocument13 pagesANH House by Sanuki + NishizawabatcavesNo ratings yet

- Cold Formed Steel Structures Around The World PDFDocument9 pagesCold Formed Steel Structures Around The World PDFTito MuñozNo ratings yet

- SMACNA Architecturalmanual PPDocument74 pagesSMACNA Architecturalmanual PPRonald Kahora50% (4)

- Installation of Timber Suspended CeilingDocument73 pagesInstallation of Timber Suspended CeilingKarthick SNo ratings yet