Professional Documents

Culture Documents

Weld Rod Selection

Uploaded by

Rads53Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weld Rod Selection

Uploaded by

Rads53Copyright:

Available Formats

SMAW & GTAW

FILLER METAL SELECTION GUIDE

(P-No. 42)

(P-No. 43)

(P-No. 45)

MONEL

400

INCONEL

600

INCOLOY

800

(P-No. 45)

(P-No. 8)

ALLOY 20

TYPE

INCOLOY 825 TYPE 321 &

(P-No. 8)

(P-No. 8)

(P-No. 8)

(P-No. 8)

(P-No. 6)

(P-No. 5B)

(P-No. 5B)

(P-No. 5B)

(P-No. 5A)

(P-No. 4)

(P-No. 3)

(P-No. 3)

(P-No. 1)

TYPE

316 SS

TYPE

310 SS

TYPE

309 SS

TYPE

304 SS

TYPE

410 SS

STEEL

9 CR

1 MO

STEEL

7 CR

1/2 MO

STEEL

5 CR

1/2 MO

STEEL

2-1/4 CR

1 MO

STEEL

1-1/4CR

1/2 MO

STEEL

1/2 CR

1/2 MO

CARBON

STEEL

1/2 MO

CARBON

STEEL

347 SS

PH1

(P-No. 1)

PH1

21

17

CARBON STEEL

PH1

17

18

HT1

(P-No. 3)

PH1

CARBON STEEL

1/2 MO

PH1

PH2

PH2

STEEL

1-1/4 CR 1/2 MO

PH3

STEEL

2-1/4 CR 1 MO

HT3

PH3

17

21

HT4

(P-No. 5B)

PH3

STEEL

5 CR 1/2 MO

HT4

PH3

STEEL

9 CR 1 MO

HT4

HT4

(P-No. 6)

PH4

TYPE

410 SS

HT5

HT1

(P-No. 8)

PH1

TYPE

309 SS

N/A

HT1

(P-No. 8)

PH1

TYPE

316 SS

17

18

PH1

TYPE

321 / 347 SS

PH1

PH1

PH1

HT1

PH1

(P-No. 43)

17

18

INCONEL 600

PH1

(P-No. 42)

N/A

17

15

HT1

21

MONEL 400

HT1

N/A

17

24

PH1

N/A

N/A

18

26

PH1

17

18

14

17

PH1

N/A

PH1

17

18

INCOLOY 800

N/A

17

18

N/A

N/A

N/A

13

17

N/A

PH1

17

18

PH1

HT1

PH1

(P-No. 45)

PH1

N/A

17

18

14

13

N/A

17

18

PH1

17

18

17

18

N/A

N/A

12

18

PH1

N/A

N/A

11

15

PH1

N/A

PH1

N/A

17

18

HT1

(P-No, 45)

N/A

17

18

N/A

13

12

N/A

HT5

10

11

PH1

10

12

PH1

14

12

PH1

N/A

17

15

ALLOY 20

INCOLOY 825

N/A

PH1

17

18

N/A

PH1

17

18

N/A

PH1

N/A

HT5

25

15

PH1

10

11

N/A

HT4

9

PH4

HT5

PH1

N/A

13

11

HT4

17

18

HT5

HT4

8

PH3

17

18

PH4

HT5

10

11

PH1

N/A

PH1

N/A

HT1

(P-No. 8)

N/A

17

18

PH1

N/A

14

11

HT4

17

18

PH1

10

13

PH1

17

18

PH1

17

18

HT5

PH1

N/A

PH1

17

18

PH1

17

15

HT5

14

10

HT5

PH4

HT4

HT4

7

PH3

8

9

HT4

HT4

6A

6

PH3

HT4

PH3

HT4

17

18

PH4

17

18

HT5

17

18

PH3

HT4

PH4

17

18

PH1

N/A

PH1

17

18

PH1

TYPE

310 SS

HT5

17

18

HT4

17

18

HT4

7

8

HT4

HT3

4A

4

PH3

6A

7

PH3

7

9

PH4

HT4

PH3

HT4

PH3

HT4

17

18

PH3

HT4

PH4

17

18

PH1

N/A

PH1

17

15

HT1

(P-No. 8)

HT5

17

18

HT4

17

18

HT5

17

18

PH3

HT4

6A

8

HT4

HT3

3A

PH2

4A

6

PH2

HT4

PH3

4A

7

PH3

6A

9

PH4

HT4

17

18

PH3

HT4

PH4

17

18

PH1

17

18

HT4

17

18

HT4

17

18

PH3

HT4

PH3

17

18

PH3

HT4

17

18

PH3

HT4

PH4

17

24

PH1

17

18

HT4

17

18

HT4

17

18

PH3

*HT5

PH4

17

18

PH3

HT4

17

18

PH3

HT4

PH4

17

18

PH1

TYPE

304 SS

HT4

17

18

HT4

17

18

PH3

HT3

PH3

17

18

PH3

HT4

17

18

PH3

HT4

PH4

17

15

HT5

(P-No. 8)

HT4

17

24

HT4

17

18

PH3

HT3

PH3

17

18

PH3

HT4

17

18

PH3

17

18

HT4

17

18

PH3

HT3

PH3

17

18

PH3

HT4

17

24

PH3

17

21

HT4

17

18

PH3

HT3

PH3

17

18

PH3

HT4

17

18

HT4

(P-No. 5B)

HT4

17

24

PH3

17

21

HT3

PH3

17

18

PH3

17

18

PH3

STEEL

7 CR 1/2 MO

HT3

PH3

17

24

PH3

17

21

HT4

(P-No. 5B)

HT3

PH3

17

18

HT3

3A

4

HT3

2

1

HT2

PH1

3

PH2

HT4

PH3

4A

8

PH2

HT4

3A

6

PH1

2

3

*HT3

3

4

PH3

HT4

PH3

4A

9

PH2

HT4

3A

7

PH1

2

3

*HT3

3

6

PH3

HT4

PH3

17

18

PH3

HT4

3A

8

PH2

2

4

*HT4

3

7

PH3

*HT5

PH4

17

18

PH3

HT4

3A

9

PH2

2

6

*HT4

3

8

PH3

HT3

PH2

17

18

PH3

*HT5

17

18

PH3

2

7

*HT4

3

9

PH4

HT3

PH2

17

18

PH3

HT1

17

18

PH3

2

8

*HT4

17

18

PH2

HT3

PH2

17

18

PH4

HT1

17

18

PH3

2

9

*HT5

17

18

PH2

HT3

PH2

17

18

PH1

HT1

17

18

PH3

25

17

HT1

17

18

PH2

HT3

PH2

17

18

PH1

HT1

17

18

PH4

11

12

HT1

17

18

PH2

HT3

PH2

17

24

PH1

HT1

17

18

PH1

11

17

HT1

17

18

PH2

HT3

PH2

17

18

PH1

HT1

17

18

PH1

11

17

HT1

17

18

PH2

HT3

PH2

17

21

PH1

HT1

17

24

PH1

11

18

HT1

17

18

PH2

HT3

(P-No. 5A)

PH1

HT1

PH1

17

18

HT1

17

24

17

18

HT3

(P-No. 4)

17

18

PH1

PH2

17

21

PH1

HT1

17

18

HT1

(P-No.3)

17

24

HT1

17

21

STEEL

1/2 CR 1/2 MO

PH1

HT3

HT1

HT1

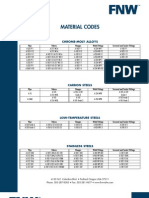

WELDING ELECTRODE/FILLER METAL CODES

CODE

1

2

3

3A

4

4A

5

6

6A

7

8

9

Notes:

ELECTRODE

COMP

CODE

E6010

CS

10

E7018

CS

11

E7018-A1

Mo

12

E8016,18-B1

Cr-Mo

13

E8015,16,18-B2

1Cr-Mo 14

E7015,16,18-B2L

1Cr-Mo 15

-16

E9015,16,18-B3

2Cr-Mo 17

E8015,18-B3L

2Cr-Mo 18

E8015,16,18-B6/B6L

5Cr-Mo

E8015,16,18-B7/B7L

7Cr-1/2Mo

E8015,16,18-B8/B8L

9Cr-1Mo

1. The L designation indicates low carbon

ELECTRODE

E308(L)-15,16

E309(L)-15,16

E310-15,16

E316(L)-15,16

E347-15,16

ENiCrFe-3

-ENiCrFe-2

ENiCrMo-3

COMP

308(L) SS

309(L) SS

310 SS

316(L) SS

347 SS

Alloy 600 / Inconel 182

-Alloy 800 / Inco Weld A

Alloy 625 / Inconel 112

CODE

19

20

21

22

23

24

25

26

27

ELECTRODE

ENiCrFe-1

ENi-1

ENiCu-7

-ENiCrMo-14

ENiCrCoMo-3

E410-15,16

E320LR-15,16

E16-8-2-15,16

COMP

Inconel 132

Alloy 200 / Nickel 141

Alloy 400 / Monel 190

Alloy 825 / Inco 686CPT

Alloy 617/ Inconel 117

410 SS

Alloy 20

2. For GTAW filler metal and shielding gas selection, position curser over tag on appropriate SMAW electrode.

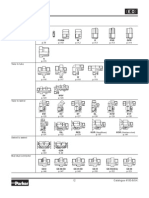

Legend

PH1

PH2

PH3

PH4

PREHEAT REQUIREMENTS

ASME VIII, Div. 1

ASME B31.3

50-175 deg F

50-175 deg F

250 deg F

300 deg F

400 deg F

350 deg F

400 deg F

300 deg F

POSTWELD HEAT TREATMENT REQUIREMENTS

Soak Temperature Deg. F

Legend

ASME VIII, Div. 1

ASME B31.3

BHN Max.

N/A

None

None

N/A

HT1

1100 - 1200

1100 - 1200

200

HT2

1100 - 1200

1100 - 1325

225

HT3

1100 - 1200

1300 - 1375

225

HT4

1300 - 1375

1300 - 1400

241

HT5

1250 - 1350

1350 - 1450

241

*Indicates that PWHT temperature may enter the lower critical temperature

range thereby affecting the essential variables of the WPS.

You might also like

- Electrode SelectionDocument15 pagesElectrode SelectionkarthikeyanNo ratings yet

- Filler Metal Selection GuideDocument2 pagesFiller Metal Selection GuideMehta Mehul100% (1)

- Garcia Welding: Filler Metal Selection GuideDocument8 pagesGarcia Welding: Filler Metal Selection GuideGustavo MorilloNo ratings yet

- Welding RodDocument368 pagesWelding Rodjrod91586% (29)

- Electrode Selection ChartDocument4 pagesElectrode Selection Chartsunitbhaumik100% (2)

- P numbers welding guideDocument20 pagesP numbers welding guideMOHANNo ratings yet

- Welding Rod SelectionDocument1 pageWelding Rod Selectionbikas_sahaNo ratings yet

- Electrodes ConsumablesDocument2 pagesElectrodes Consumablesranjith_007100% (2)

- Welding Electrode SelectionDocument1 pageWelding Electrode SelectionNadeemNo ratings yet

- Welding Rod Selection 2 PDFDocument1 pageWelding Rod Selection 2 PDFPrior Drake89% (9)

- Weld Filler Metal SelectionDocument7 pagesWeld Filler Metal SelectionsusanwebNo ratings yet

- Electrode Selection Excel SheetDocument1 pageElectrode Selection Excel Sheetchandrakit047No ratings yet

- Welding Rod For c5 & f5 - Er 80s-b6Document1 pageWelding Rod For c5 & f5 - Er 80s-b6SatyamEngNo ratings yet

- Electrode SelectionDocument85 pagesElectrode SelectionShaheen Andre Chikku100% (2)

- Electrode selection guide for welding carbon and alloy steelsDocument1 pageElectrode selection guide for welding carbon and alloy steelsRachel ThompsonNo ratings yet

- Metrode Dissimilar Consumable SelectorDocument7 pagesMetrode Dissimilar Consumable SelectorClaudia MmsNo ratings yet

- Super Duplex Stainless SteelDocument3 pagesSuper Duplex Stainless SteelNisa_nisheNo ratings yet

- Specification For Piping FabricationDocument24 pagesSpecification For Piping FabricationSanjay SenNo ratings yet

- SMAW & GTAW Filler Metal Selection GuideDocument2 pagesSMAW & GTAW Filler Metal Selection GuideShanmuga Navaneethan100% (1)

- SURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPSDocument2 pagesSURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPSsuria qaqcNo ratings yet

- Welding Electrode Specification ChartDocument2 pagesWelding Electrode Specification ChartMahesh Kumar100% (2)

- Material and electrode selection guideDocument1 pageMaterial and electrode selection guideVijayabaraniNo ratings yet

- ELECTRODE SelectionDocument11 pagesELECTRODE SelectionDheeraj E MohananNo ratings yet

- WPS PQR 12Document9 pagesWPS PQR 12Ranjan KumarNo ratings yet

- Filler Metal SelectionDocument7 pagesFiller Metal SelectionMidhun K ChandraboseNo ratings yet

- Welding Table WPS & PQR Check List (Sheet, 2 Pages)Document2 pagesWelding Table WPS & PQR Check List (Sheet, 2 Pages)abomanar100486375% (4)

- Torque Values B7 Studs PDFDocument1 pageTorque Values B7 Studs PDFipsthethiNo ratings yet

- Astm Table Commonly Used Materials: PipesDocument1 pageAstm Table Commonly Used Materials: PipesHarsh TiwariNo ratings yet

- Material With Electrode SelectionDocument2 pagesMaterial With Electrode SelectionJithuJohn100% (3)

- API Welding Procedure Specification PDFDocument3 pagesAPI Welding Procedure Specification PDFBob LeeNo ratings yet

- WPS API1104 A516 GR 70Document1 pageWPS API1104 A516 GR 70Erick HoganNo ratings yet

- Imp-Comparison of SpecificationsDocument7 pagesImp-Comparison of SpecificationsKetan PatelNo ratings yet

- PIPING MATERIALS COMPARISON TABLEDocument12 pagesPIPING MATERIALS COMPARISON TABLEJay Vinoth100% (2)

- Welding BisplateDocument12 pagesWelding BisplateLim Senglin100% (1)

- Welded Joint DesignDocument5 pagesWelded Joint Designscott2355No ratings yet

- ElectrodosDocument14 pagesElectrodosanon-635614100% (6)

- What Weld Rod To UseDocument2 pagesWhat Weld Rod To Usesatgk0% (1)

- Pamela Anderson's SMAW and GTAW filler metal selection guideDocument10 pagesPamela Anderson's SMAW and GTAW filler metal selection guideJames RodriguezNo ratings yet

- Material Specifications: P-No. / Group No. Nominal Steel Designation Forgings Wrought Fittings Pipe Plate RemarksDocument1 pageMaterial Specifications: P-No. / Group No. Nominal Steel Designation Forgings Wrought Fittings Pipe Plate RemarksSIVAPATHASEKARAN100% (2)

- JIS-ASTM contrast list of relative materials standardsDocument1 pageJIS-ASTM contrast list of relative materials standardsSrhosseini30% (1)

- Welding Electrodes SelectionDocument19 pagesWelding Electrodes SelectionjerickNo ratings yet

- AWS Classifications of ElectrodesDocument2 pagesAWS Classifications of ElectrodesJorge SobrevillaNo ratings yet

- Valves GaugeDocument2 pagesValves GaugeAbu Bilal AbdillahNo ratings yet

- Specification Comparison ChartDocument1 pageSpecification Comparison ChartRoberto_PrrNo ratings yet

- Pipe Fittings: 1/16 To 1 In. Sizes 316 Stainless Steel, Brass, and Carbon Steel NPT, ISO/BSP, and SAE ThreadsDocument16 pagesPipe Fittings: 1/16 To 1 In. Sizes 316 Stainless Steel, Brass, and Carbon Steel NPT, ISO/BSP, and SAE ThreadsMehmet YılmazNo ratings yet

- Swagelok CatalogueDocument16 pagesSwagelok CatalogueZacharia JohnNo ratings yet

- FNW MaterialCodesDocument2 pagesFNW MaterialCodessenioor2004No ratings yet

- Equivalencia de Matariales (Material Class For Stainless Steel)Document15 pagesEquivalencia de Matariales (Material Class For Stainless Steel)juancparra20No ratings yet

- Hard CoatingsDocument1 pageHard Coatingskutts76No ratings yet

- International Standard ReferenceDocument14 pagesInternational Standard ReferenceKARTHIGEYAN.RNo ratings yet

- Especificacion de Materiales Y Tabla de Compatibilidad Base Comercial SAE AstmDocument4 pagesEspecificacion de Materiales Y Tabla de Compatibilidad Base Comercial SAE AstmFrancisco VillaNo ratings yet

- A - General IndexDocument24 pagesA - General IndexzargeenaNo ratings yet

- Material Reference ListDocument7 pagesMaterial Reference ListionijhonnieNo ratings yet

- 150lb Style T (316ss) StrainerDocument1 page150lb Style T (316ss) StrainerLuis GarciaNo ratings yet

- JC Catalogue Gate Valves BBDocument24 pagesJC Catalogue Gate Valves BBMahdi DalyNo ratings yet

- Steel - Equivalent GradesDocument23 pagesSteel - Equivalent GradesSowmen Chakroborty100% (1)

- Cat 4160-SC A00 ParkerDocument8 pagesCat 4160-SC A00 ParkerFabian Antonio RoldanNo ratings yet

- IntroductionDocument7 pagesIntroductionAshapuri Engineering vapi (Ashapuri Engineering Vapi)No ratings yet

- erm3.CHAPTER 13 - Flow Controls and Flow DividersetoDocument17 pageserm3.CHAPTER 13 - Flow Controls and Flow DividersetoVinod YbNo ratings yet

- 20F2041 Pick ListDocument9 pages20F2041 Pick Listvio_tani4812No ratings yet

- Code of Practice for Safe Handling and Disposal of Radioactive WasteDocument17 pagesCode of Practice for Safe Handling and Disposal of Radioactive WasteRads53No ratings yet

- Safe Handling Nuclear GaugesDocument7 pagesSafe Handling Nuclear GaugesRads53No ratings yet

- GCSE in Mathematics LinearDocument85 pagesGCSE in Mathematics LinearRads53100% (1)

- The ManualDocument216 pagesThe ManualRads53No ratings yet

- Fanr Reg 24 EngDocument53 pagesFanr Reg 24 EngRads53No ratings yet

- AWS Model QuestionsDocument30 pagesAWS Model QuestionsRads53100% (9)

- Welding Inspection HandbookDocument7 pagesWelding Inspection HandbookDeepak Malhotra0% (1)

- 027Document2 pages027Rads53No ratings yet

- Asme b31-9 (Building Services Piping)Document86 pagesAsme b31-9 (Building Services Piping)Rads53No ratings yet

- Basics of Reinforced Concrete Design: OutlineDocument10 pagesBasics of Reinforced Concrete Design: OutlineariNo ratings yet

- In-Situ Rock StressesDocument16 pagesIn-Situ Rock StressesAslam KhanNo ratings yet

- Pre-AP Unit 10 Homework PacketDocument13 pagesPre-AP Unit 10 Homework PacketTrish lamNo ratings yet

- Materials for shoes, optical lenses and water bottlesDocument3 pagesMaterials for shoes, optical lenses and water bottlesJpricarioNo ratings yet

- Equilibrium Constants and Le Chatelier's PrincipleDocument20 pagesEquilibrium Constants and Le Chatelier's Principlekrishna100% (1)

- FailureEnvelopesNEW 11Document41 pagesFailureEnvelopesNEW 11Osama AshourNo ratings yet

- An Alternative To Additional SO3 Injection For Fly Ash ConditioningDocument7 pagesAn Alternative To Additional SO3 Injection For Fly Ash ConditioningmsoyoralNo ratings yet

- 3363 - Problem - 5-6 Material Balance High Press Gas Reservoir - Jun07Document2 pages3363 - Problem - 5-6 Material Balance High Press Gas Reservoir - Jun07Charles PabaneNo ratings yet

- Painting Procedure For Structural Steel Rev 00Document13 pagesPainting Procedure For Structural Steel Rev 00Ranjan KumarNo ratings yet

- HHD-S Cavity anchor installation guideDocument2 pagesHHD-S Cavity anchor installation guideIngeniero Miguel VillarroelNo ratings yet

- Advanced Nanotechnology Unlocks Potential of Thermoelectric GeneratorsDocument3 pagesAdvanced Nanotechnology Unlocks Potential of Thermoelectric GeneratorsmarijpotNo ratings yet

- Aramco US Vendors For P F FDocument1 pageAramco US Vendors For P F Fhemantmech099200No ratings yet

- Exp. 4 LipidsDocument6 pagesExp. 4 LipidsAna LuisaNo ratings yet

- Corrosion of Cast Aluminum Alloys in Engine Coolants Under Heat-Rejecting ConditionsDocument4 pagesCorrosion of Cast Aluminum Alloys in Engine Coolants Under Heat-Rejecting ConditionsInsumos GygNo ratings yet

- Slurry Shield AdditivesDocument8 pagesSlurry Shield AdditivesfabiodbdbNo ratings yet

- Carbofill Dec08Document4 pagesCarbofill Dec08Cristian Andres Araya CisternasNo ratings yet

- Group No 6 - Boge 2 Well Logging and FormationDocument26 pagesGroup No 6 - Boge 2 Well Logging and FormationAlhaj MassoudNo ratings yet

- VERITAS PHARMACEUTICALS LIMITED MICROCRYSTALLINE CELLULOSE SPECIFICATIONDocument1 pageVERITAS PHARMACEUTICALS LIMITED MICROCRYSTALLINE CELLULOSE SPECIFICATIONShagorShagorNo ratings yet

- X17CrNi16 2Document2 pagesX17CrNi16 2madodandembeNo ratings yet

- Quality Tests RequirementDocument6 pagesQuality Tests RequirementSandip PaulNo ratings yet

- Heraklith CatalogueDocument54 pagesHeraklith CatalogueN P SrinivasaraoNo ratings yet

- Accurate Self-Damage Detection by Electrically Conductive Epoxy/graphene Nanocomposite FilmDocument12 pagesAccurate Self-Damage Detection by Electrically Conductive Epoxy/graphene Nanocomposite FilmAaron ChandNo ratings yet

- Astm A-6 PDFDocument1 pageAstm A-6 PDFFrank Berrios GarcesNo ratings yet

- Liquid Penetrant Testing Chapter 4: Emulsification, Penetrant Removal and Developer ApplicationDocument11 pagesLiquid Penetrant Testing Chapter 4: Emulsification, Penetrant Removal and Developer ApplicationRajendrasinh PuvarNo ratings yet

- Applied Thermodynamics For Marine Systems Prof. P. K. Das Department of Mechanical Engineering Indian Institute of Technology, KharagpurDocument19 pagesApplied Thermodynamics For Marine Systems Prof. P. K. Das Department of Mechanical Engineering Indian Institute of Technology, KharagpurTommyVercettiNo ratings yet

- Kingspan Logstor Handling and Installation Manual User Installation Guide en EurDocument290 pagesKingspan Logstor Handling and Installation Manual User Installation Guide en Eurvalentin.gomez-valadesNo ratings yet

- Welding Consumable Nominal Chemical Composition, Wt. Pct. Other Designation SystemsDocument1 pageWelding Consumable Nominal Chemical Composition, Wt. Pct. Other Designation SystemsLLNo ratings yet

- k3) Luxatherm5600 7954Document2 pagesk3) Luxatherm5600 7954Syed FaridNo ratings yet

- ICC-ES-AC 86-0619-AltDocument10 pagesICC-ES-AC 86-0619-AltrcNo ratings yet

- Gyproc Plasters: Product CatalogueDocument24 pagesGyproc Plasters: Product CatalogueFariz AbdullaNo ratings yet