Professional Documents

Culture Documents

A Multi Axial Fatigue Analysis Method For

Uploaded by

Shivanand ArwatOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Multi Axial Fatigue Analysis Method For

Uploaded by

Shivanand ArwatCopyright:

Available Formats

C. Gaier and H.

Dannbauer

A MULTIAXIAL FATIGUE ANALYSIS METHOD FOR DUCTILE, SEMI-DUCTILE, AND BRITTLE MATERIALS

C. Gaier * and H. Dannbauer

Magna Powertrain, Engineering Center Steyr St. Valentin, Austria

:

. ) ( . ) ( . - - . .

:* Address for correspondence Magna Powertrain, Engineering Center Steyr 23 Steyrer Strasse A-4300 St. Valentin Austria E-mail: c.gaier@ecs.steyr.com

7002 Paper Received 18 March 2006; Revised 5 June 2007; Accepted 18 September

8002 April

The Arabian Journal for Science and Engineering, Volume 33, Number 1B

322

C. Gaier and H. Dannbauer

ABSTRACT In mechanical engineering fatigue assessment of components, where complex non-proportional loads are acting on, plays an important role to identify critical spots and to predict the lifetime till crack initiation. Todays fatigue life prediction software has to deal with stress results of huge finite element models consisting of several hundred thousands or even millions of nodes and elements. Therefore, efficient algorithms for fatigue assessment are necessary to reduce development time and costs. Nevertheless, such methods should be able to deal with randomly and nonproportionally loaded components made of ductile, semi-ductile or brittle materials. Both cyclic tension/compression (or bending) and torsion loading and their combinations should be predicted correctly. In this contribution a new method for high cycle fatigue is presented, which covers both infinite and finite life region, and which is based on a critical plane approach combined with rainflow cycle counting and linear damage accumulation. Comparisons with test results of combined in-phase bending and torsion loaded specimens show an excellent agreement. The working method for out-of-phase loading is demonstrated as well as a practical example. Key words: fatigue life prediction, non-proportional loadings, multiaxial loadings, critical plane method.

224

The Arabian Journal for Science and Engineering, Volume 33, Number 1B

April 2008

C. Gaier and H. Dannbauer

A MULTIAXIAL FATIGUE ANALYSIS METHOD FOR DUCTILE, SEMI-DUCTILE, AND BRITTLE MATERIALS

1. INTRODUCTION In mechanical engineering, computational simulations of stress and strain distributions on mechanical components with the Finite Element Method (FEM) are widely used. Nevertheless, much experience and know-how are still necessary to obtain good results of lifetime simulations, which are based on stress/strain FEM results. A lot of fatigue life calculation methods exist (e.g. a large variety of damage parameters, which are difficult to survey; stress or strainbased methods for HCF/LCF, different methods for proportional/non-proportional loadings and brittle/ductile material, see e.g. [9, 1824]), and it is not easy to select a method, which is most suitable for a specific problem. Typical complex shaped and dynamically loaded components in automotive engineering are engine blocks, connecting rods, crankshafts, gearboxes, and body in white structures, where the locations of the critical areas are not known in advance. Appropriate and efficient methods are needed for fatigue analysis of such complicated geometries. They should fulfill several requirements: They should be able to predict the fatigue life under cyclic tension/compression (or bending) and torsion loading and its combinations correctly for any kind of metallic material (ductile, semi-ductile or brittle). As basic input material data, a tension/compression S-N curve of smooth specimens, defined by its slope, cycle limit, and endurance limit fl, and the fatigue limit fl for shear should be enough.

B B B B

Application of classical cycle counting procedures as e.g. rainflow cycle counting [1]. Assessment of tri-axial stress states, which occur on surfaces under pressure. Cracking may also start below the surface, if the surface is hardened or if there are pores inside. Assessment of randomly and non-proportionally loaded components. From a practical point of view the calculation time for big finite element models consisting of more than one million nodes and elements, where several hundred load channels with several ten thousand samples are simultaneously acting on, should not exceed one night on a single processor workstation. Consideration of local plasticity by a multiaxial correction of linearly calculated FEM-stresses (e.g. Neuber, Mroz/Glinka).

In this contribution a new method will be presented, which fulfills all the above requirements. 2. MATERIAL BEHAVIOR FOR COMBINED IN-PHASE BENDING TORSION LOADING For ductile material (e.g. steel) it was found by a lot of test results [38], that the fatigue limit forms an ellipse in the normal/shear stress diagram for combined in-phase bendingtorsion loading:

a fl + a fl

2

=1

(1)

This relation represents the well-known GoughPollard ellipse. For brittle material (e.g. cast iron) the fatigue limit forms a parabola in the normal/shear stress diagram:

a a + fl fl

=1

2

(2)

Equations (1) and (2) can be combined to the following empirical formula [2, 18]:

a fl + a fl

k

=1

(3)

For the exponent k it is rather intuitive to take the ratio tensile to shear fatigue limit (which can be assumed to be equal to the ratio bending to torsion fatigue limit. The only difference is the existence of a stress gradient, which can be used for modification of the local fatigue limit [1013]) :

April 2008 The Arabian Journal for Science and Engineering, Volume 33, Number 1B

225

C. Gaier and H. Dannbauer

k=

fl fl

(4)

The k-value ranges between 1, which represents a brittle material, and 2, which represents a ductile one. By a linear combination of Equations (1) and (2) another widely used empirical expression can be obtained [9, 24]:

(k 1) a

+ (2 k ) a fl fl

+ a fl

=1 .

(5)

For k=2 Equation (3) as well as Equation (5) becomes Equation (1), whereas for k=1 Equation (2) is obtained. Also for other k-values Equation (3) and Equation (5) deliver almost the same results. These formulas will be used in the following to check the result quality of the proposed lifetime prediction method. 3. PROBLEMS OF CLASSICAL APPROACHES For non-proportional loadings and multiaxial stress states with rotating principal stress directions, the critical plane criterion is a widely applied and commonly accepted concept. The principle is rather simple: for all the material planes a damage analysis will be performed. The plane with maximum damage is assumed to be critical for fatigue failure. For the numerical algorithm, the angle increment must be chosen sufficiently small. For free surfaces, where the stress state is biaxial, in this paper we consider only the planes perpendicular to the surface (e.g. 18 planes with 10 degree distance). For tri-axial stress states, which occur on surfaces under pressure (e.g. bearings) or inside components, much more planes have to be considered, i.e. all the planes, whose normal vectors form a hemisphere (e.g. about 200 planes with about 10 degree distance). Damage is produced by closed load cycles in the stress-strain path. According to the Palmgren-Miner hypothesis, the damages of each load cycle can be linearly accumulated to the total damage. Although linear damage accumulation has been criticized sometimes, it is still the most common way for fatigue analysis because of its simplicity and effectiveness, and the accuracy is sufficient in technical practice. For random loads, closed cycles must be detected by a suitable cycle counting algorithm as e.g. rainflow counting [1]. The number of cycles can be economically stored in a rainflow matrix. The question arises, for which quantity a rainflow counting should be performed in combination with the critical plane criterion. A stress vector is acting on material planes, but cycle counting procedures can be applied only to scalar quantities. The easiest way is applying rainflow counting to the normal stress. Considering normal stress is good for brittle failure, but shear stress is responsible for ductile failure. Nevertheless, for tri-axial stress states it is difficult to apply rainflow counting to shear stress because of its vector nature, i.e. shear stress may rotate or even form random curves in the material plane. 4. THE METHOD OF SCALED NORMAL STRESS The main idea of the proposed method to solve the above problems is damage equivalent scaling of the normal stress in material planes in dependence on the stress state (tension torsion hydrostatic, and its combinations). To the resulting equivalent stress history, a rainflow cycle counting procedure can be applied to identify closed cycles in the stressstrain-path, which is the basis for endurance safety analysis or lifetime analysis. A suitable quantity, denoted as V (ti ) is introduced to characterize the stress state at each time step (ti ) . For a best fit to test results represented by Equation (3 5), the following procedure is proposed: (a) Calculation of the local principal stresses 1 (ti ) > 2 (ti ) > 3 (ti ) at each time step (ti ) . (b) Calculation of the ratio minimum to maximum principal stress at each time step:

(t ) V (ti ) = 3 i 1 (ti )

for 1 (t i ) > 3 (t i ) (6)

(t ) V (t i ) = 1 i 3 (t i )

for 3 (t i ) > 1 (t i ) (7)

The ratio V is a value between 1 and +1 with special meanings: o V = 1: Dominating shear stress state

226

The Arabian Journal for Science and Engineering, Volume 33, Number 1B

April 2008

C. Gaier and H. Dannbauer

o o

V = 0: Dominating normal (tension/compression) stress state V = +1: Hydrostatic stress state

It is important to note, that V (t ) is a continuous function in time, even for non-proportional and rotating principal stresses! (The first derivative V (t ) can be discontinuous, but this is not relevant in this context because V (t ) is not used.) (c) In dependence on V (t i ) the normal stress n of the considered material plane will be scaled by the following time dependent scaling factor:

B B

f (ti ) = 1 + (1 k )V (ti )

(8)

The quantity k is defined by Equation (4). Also f (t ) is a continuous function in time, even for non-proportional and rotating principal stresses. It can be easily recognized, that for brittle materials, with k = 1, the stress state will not be modified at all (f = 1). Therefore, the normal stress will be used directly, which is in accordance with the normal stress hypothesis for brittle materials. For ductile materials f depends on the stress state: for tension/compression stress (V = 0) the stress still remains unchanged, whereas for shear stress (V = 1) the normal stress will be increased by the factor k. In this way, the stronger damaging effect of shear stress is taken into consideration in a quantitatively correct manner. This behavior is in good agreement with the distortion energy criterion for ductile materials. For k = 3 the absolute value of the scaled normal stress is the same as the Von Mises stress. But in contrast to the Von Mises stress, the scaled normal stress is equipped with a sign. The scaled normal stress may change in time from positive values to negative ones and vice versa. Therefore, the scaled normal stress is accessible for rainflow cycle counting, which is the most important advantage compared to other methods. For hydrostatic stress states (V = 1) the factor f will be linearly extrapolated, i.e. the normal stress will be decreased. Also this behavior is in good agreement with the distortion energy criterion for ductile materials, where the Von Mises stress becomes zero. According to Equation (8), the factor f becomes to zero for very ductile materials, with k = 2. From a computational point of view, it is much more efficient, to scale all components of the stress tensor just before calculating the normal stress in the planes instead of scaling the normal stress directly in every plane. (d) Next, the critical plane criterion is applied: In each plane a rainflow cycle counting of the scaled normal stress history e (ti ) = f (t i ) n (ti ) is performed. The resulting equivalent stress amplitudes ea,n can be used together with a tension/compression SN curve for the calculation and linear summation of partial damages according to the Palmgren/Miner hypothesis. Before damage analysis the SN curve should be locally modified according to influences like mean stress (which can be quantified by means of a Haighdiagram), notch support effect and bending loadings (which can be considered by taking into account stress gradient [1013]), temperature, surface roughness, surface treatments, etc. The plane with maximum damage is assumed to be the most critical one. The ductility of the material has already been taken into account by scaling the normal stress or all components of the stress tensor.

B B

For infinite lifetime evaluation the following condition must hold, otherwise the component is not safe:

ea max = max ( ea,n ) <

n fl

(9)

Therefore an endurance safety factor can be defined in this way:

SF =

fl ea max

(10)

Again the fatigue limit fl should already contain several influences like mean stress, stress gradient, temperature, etc. For proportional cyclic loading without mean stresses the scaling factor is independent from time (f = const) and n max is equal to the maximum value of 1, i.e.

B B B B B B

April 2008

The Arabian Journal for Science and Engineering, Volume 33, Number 1B

227

C. Gaier and H. Dannbauer

SF =

fl

f 1max

(11)

5. ILLUSTRATION ON SOME MULTIAXIAL LOAD CASES Here the procedure of the scaled normal stress method will be illustrated on some combined tension-shear load cases (sinusoidalsinusoidal and sinusoidalconstant). A ductile material has been taken with k=1.73. For showing both stresses and scaling factor in the same diagram, a normalized tension/compression stress amplitude a = 1 and a shear stress amplitude a = 0.577 has been chosen for sinusoidal loading, and the same values for constant loading. The Figures 15 show the resulting histories for the maximum/minimum principal stress, the scaling factor f and the scaled normal stress e from the critical plane (i.e. the plane where the scaled normal stress amplitude reaches its maximum). The x-axis denotes t = 360t/T.

B B B B B B

It has to be noticed, that in Figures 4 and 5, where a mean stress exists, the critical plane and herewith the scaled normal stress history depend slightly on the mean stress sensitivity of the material. Depending on mean stress and mean stress sensitivity (or Haigh diagram), the fatigue limit fl may be different in every plane. For simplification, in Figures 4 and 5 no mean stress influence has been considered, i.e. the used fatigue limit fl was the same in every plane.

B B B B

Figure 1. Combined sinusoidal tensionshear loading without phase shift

Figure 2. Combined sinusoidal tensionshear loading with 45 phase shift

228

The Arabian Journal for Science and Engineering, Volume 33, Number 1B

April 2008

C. Gaier and H. Dannbauer

Figure 3. Combined sinusoidal tensionshear loading with 90 phase shift

Figure 4. Combined sinusoidal tension and constant shear loading

Figure 5. Combined constant tension and sinusoidal shear loading

April 2008

The Arabian Journal for Science and Engineering, Volume 33, Number 1B

229

C. Gaier and H. Dannbauer

6. VERIFICATION FOR PROPORTIONAL BENDING/TORSION LOADING Here the proposed method of scaled normal stress will be verified for fully reversed combined in-phase bending/torsion loading on cylindrical un-notched specimens, for which a lot of test data and commonly accepted empirical formulas exist, see Equation (35). For this purpose the fatigue limit in the normal/shear stress diagram for combined in-phase bending/torsion loading will be mathematically derived and compared with the empirical formulas. On the specimens surface the plane stress state can be written as the following tensor:

a a a = a 0 0 0 0 0 . 0

(12)

Here the stress quantities are already stress amplitudes. The following principal stresses will be obtained:

1 (t = T 4) = 1max =

1 2 2 a + a + 4 a 2

(13) (14)

2 =0

3 (t = T 4) =

1 2 2 a a + 4 a 2

(15)

As it can be seen in Figure 1, these principal stresses occur both at t = 90 and the scaling factor f is constant over the whole load cycle. Now the critical plane criterion has to be applied. For proportional loading without mean stress effects the plane with maximum normal stress is critical, i.e. the principal stress according to Equation (13) acts in the critical plane. Following point c) of the proposed method of scaled normal stress, n (t ) = 1max sin t with 1 max according to Equation (13) will be multiplied by the scaling factor f according to Equation (8). Setting SF=1 in Equation (11), the fatigue limit under combined in-phase bending/torsion loading can be derived. Some simple manipulations are necessary, to obtain the fatigue limit as a function of the normal and shear stress amplitudes. Putting Equations (6), (8), (13), and (15) into (11) with SF=1, the following relationship can be derived:

(k 1)

a fl

+ (2 k )

a fl

+ a fl

=1

(16)

Comparing Equation (16) with Equation (5) it can be seen that these expressions are completely identical. This excellent agreement with empirical formulas confirms the postulated relationship for the damage equivalent scaling factor f for stresses according to Equation (8). 7. VERIFICATION FOR NON-PROPORTIONAL BENDING/TORSION LOADING Test results of specimens loaded by combined bending and torsion with phase shift have been used for comparison with calculation results [15]. The materials were one cast aluminum and one tempered steel. The correspondence was good for cast aluminum, whereas for tempered steel the calculation result was on the unsafe side. This drawback has been overcome by calculating a multiaxiality influence factor on the fatigue limit as described in [15], depending on a local degree of multiaxiality and on a newly introduced material parameter sensitivity of multiaxiality. Further investigations are still ongoing. 8. PRACTICAL APPLICATION: SIMULATION OF A DIESEL ENGINE CRANKSHAFT The proposed method of scaled normal stress was implemented in the commercial fatigue software tool FEMFAT, developed at the Engineering Center Steyr [12, 1416]. FEMFAT has been established in automotive engineering for about fifteen years now and continuously improved. Finite element stress results are taken as input data for fatigue assessment. FEMFAT can take into consideration different influences on fatigue life as stress gradient (to take into account the notch support effect), mean stress, surface roughness, surface treatment, temperature, and much more. In the following fatigue analysis of a diesel engine crankshaft is presented.

230

The Arabian Journal for Science and Engineering, Volume 33, Number 1B

April 2008

C. Gaier and H. Dannbauer

In order to perform an accurate fatigue life prediction for a crankshaft it is necessary to take a couple of different effects into account. The crankshaft itself is assumed to be a linear reacting structure embedded into a multi-body system that undergoes large nonlinear displacements. Also it can be expected, that there are only small plastic zones in notches. Local plastic stresses and strains can be approximately calculated from linear stresses by applying Neubers rule. The accuracy is usually sufficient for practical needs. Thus complex and very time consuming non-linear FEM analyses can be avoided. If surfaces are hardened, residual stresses may be induced, which substantially influence the lifetime. If residual stresses are known, their influence on fatigue can be easily quantified by a Haigh diagram. Nevertheless, to obtain residual stresses, the hardening process itself must be simulated, which is quite a complicated task and usually omitted. Additionally, an elastohydrodynamic (EHD) oil film model is required, being capable to consider the stiffness and damping properties of the oil film inside the journal bearings. An efficient computation of all these effects requires different algorithms (e.g. FEM for linear reacting structure, Multi-Body System (MBS) simulation for large nonlinear movements, and EHD software for the oil film dynamics). The FE, MBS, and EHD software contribute to this integrated simulation process with their particular advantages. The modal representation of the crankshaft (component modes, Craig Bampton Theory [17]) is imported into an MBS Software (e.g. ADAMS, RecurDyn). The reaction forces and moments of the elastohydrodynamic oil film are computed in a co-simulation process using a user-written subroutine within the MBS software. The result of the time integration of the MBS solver are, among many other result sets, the modal coordinates of the crankshaft, representing the amplitude of each mode shape at each time step. Because the crankshaft itself is a linear reacting structure analyzed by linear FEM, a superposition of all mode shapes weighted by the corresponding modal coordinates is possible and gives the total deformation of the flexible structure. Each deformation of a FE structure is related to a clearly defined stress distribution. Consequently, each component mode shape (deformation) corresponds to a clearly assigned stress distribution (modal stress), which is an output of a subsequent FE analysis. The resulting stress state of the FE structure is again computed by a linear combination of the modal stresses. The single modal stress shapes modal coordinate is the same as the modal coordinate of the corresponding component mode and a result of the MBS (Figure 6).

Figure 6. Proceeding of the durability analysis based on superposition of modal stresses

Figure 6 outlines the procedure of the multiaxial and channel-based fatigue lifetime prediction. The modal stresses and modal coordinates are the input for the durability analysis. Each channel consists of a modal stress and the time history of the corresponding modal coordinate. FEMFAT then computes the resulting stress states for each time step (stress history). It has to be mentioned, that the modal based approach provides the technique for fatigue life prediction of any vibration dominated problems or dynamic loaded parts, like components of an engine.

April 2008

The Arabian Journal for Science and Engineering, Volume 33, Number 1B

231

C. Gaier and H. Dannbauer

Figures 7 and 8 left shows the distribution of the endurance safety factor, as defined by Equation (10), on the finite element mesh, calculated by FEMFAT with the scaled normal stress approach. The minimum safety factor can be found in notches of the main bearings. The safety factor also changes with the rotational speed of the crankshaft as shown in Figure 8 right. The minimum can be found at 7000 rpm, where the safety factor still do not fall below the critical limit of one. Therefore the crankshaft is safe, and also in tests no cracks have been observed. Figure 8 also shows safety factors obtained with pure normal stress (without scaling). The difference in the safety factors between pure normal stress und scaled normal stress is rather small over the whole speed range, which indicates, that the local influence of the external torsion load at the main bearing notches seems to be small compared to other load types (tension, bending).

Figure 7. Finite element mesh of the crankshaft together with distribution of safety factor against endurance limit; whole crankshaft (left), detail at main bearing (right)

Figure 8. Endurance safety factor distribution at notch (left), endurance safety factors against rotational speed of crankshaft (right), comparison of pure normal stress and scaled normal stress

Nevertheless, the question arises, why the safety factors obtained by the scaled normal stress are slightly higher than the safety factors obtained by pure normal stress, although the difference is quite small. In theory, on the surface a biaxial stress state is acting, therefore V(t) 0 must be valid (according to Equations (6) and (7)). It follows that f(t) 1 (according to Equation (8)) should be true. This discrepancy to the obtained results of the crankshaft can be explained by the limited accuracy of the finite element method. The surface at the notches of the main bearings cannot be absolute exactly modeled by finite elements, because there remain folds between the faces of finite elements. Therefore the

232

The Arabian Journal for Science and Engineering, Volume 33, Number 1B

April 2008

C. Gaier and H. Dannbauer

normal stress perpendicular to the surface is not exactly zero. A further refinement of the FE mesh at the notches of the main bearings would reduce the differences between pure normal stress and scaled normal stress almost to zero. 9. CONCLUSIONS A fast and reliable stress based fatigue life prediction method has been presented for both high cycle finite and infinite life applications. The method uses an extended critical plane criterion and can be applied to all kind of metals (ductile, semi-ductile, and brittle). For random loading classical cycle counting procedures like rainflow can be used. For combined in-phase bending and torsion loading exact results compared to empirical formulas are obtained. It has been shown, that the method can be easily combined with the finite element method for fatigue analysis of large and complicated shaped structures (e.g. automotive parts like crankshafts, engine blocks, cylinder heads etc.). The critical areas need not to be known in advance. Future efforts take aim to investigate the result quality for combined out of phase bending and torsion loading. REFERENCES

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] [17] [18] M. Matsuishi and T. Endo, Fatigue of Metals Subjected to Varying Stress, Proc. Kyushi Branch JSME, 1968, pp. 37 40. H. Dietmann, Werkstoffverhalten unter mehrachsiger schwingender Beanspruchung, Teil 1: Berechnungsmglichkeiten, J. of Materials Technology, 5(1973), pp. 255263. H. Dietmann, Werkstoffverhalten unter mehrachsiger schwingender Beanspruchung, Teil 2: Experimentelle Untersuchungen, J. of Materials Technology, 6(1973), pp. 322333. H. J. Gough and H. V. Pollard, The Strength of Metals Under Combined Alternating Stresses, Proc. of the Inst. of Mechanical Engineers, 131(1935), pp. 3103. H. J. Gough and H. V. Pollard, The Effect of Specimen Form on the Resistence of Metals to Combined Alternating Stresses, Proc. of the Inst. of Mech. Eng., 132(1935), pp. 549573. H. J. Gough and H. V. Pollard, Properties of Some Materials for Cast Crankshafts, with Special Reference to Combined Stresses, Proc. Inst. Autom. Eng. 31(1937), pp. 821893. H. J. Gough, Engineering Steels under Combined Cyclic and Static Stresses, The Engineer, 1949, pp. 497499, 510 514, 540543, 570573. H. J. Gough, Engineering Steels under Combined Cyclic and Static Stresses, J. of Applied Mechanics, 50(1950), pp. 113125. D. F. Socie and G. B. Marquis, Multiaxial Fatigue. Warrendale, U.S.A.: SAE 2000. M. Hueck, L. Thrainer, and W. Schuetz, Berechnung von Woehlerlinien fuer Bauteile aus Stahl, Stahlguss und Grauguss Synthetische Woehlerlinien. Dsseldorf: VBFEh, Bericht Nr. ABF 11, 1983. W. Eichlseder, Rechnerische Lebensdaueranalyse von Nutzfahrzeugkomponenten mit der Finite Elemente Methode, Dissertation, University of Technology Graz, Austria, (1989). W. Eichlseder and B. Unger, Prediction of the Fatigue Life with the Finite Element Method, SAE Paper 940245, 1994. FKM-Guideline, Analytical Strength Assessment. Frankfurt am Main, Germany: Forschungskuratorium Maschinenbau, VDMA Verlag, 5th Edition, 2003.

P P

C. Gaier, B. Unger, and J. Vogler, Theory and Application of FEMFAT - a FE-Postprocessing Tool for Fatigue Analysis, Proc. 7th Int. Fatigue Congress, Beijing, 1999, pp.821826.

P P

C. Gaier and H. Dannbauer, Fatigue Analysis of Multiaxially Loaded Components with the FE-Postprocessor FEMFAT-MAX. ESIS Publication 31, 2003, pp. 223240. H. Dannbauer, C. Gaier, and M. Steinbatz, A Statistical Measure of the Non-Proportionality of Stresses Investigations and Applications, Proc. 7th ICBMFF Berlin, DVM, 2004, pp. 623628.

P P

M. Prandsttter, H. Riener, and M. Steinbatz, Simulation of an Engine Speed-UP Run: Integration of MBS FE EHD - Fatigue, ADAMS User Conference 2002 - Europe. W. N. Findley and P. N. Mathur, Modified Theories of Fatigue Failure under Combined Stress, Proc. SESA, XIV, 1, (1956), pp. 3546.

April 2008

The Arabian Journal for Science and Engineering, Volume 33, Number 1B

233

C. Gaier and H. Dannbauer

[19] [20] [21] [22] [23] [24]

T. Itoh, A. Karolczuk, C. T. Lachowicz, and E. Macha, Energy Models of Fatigue Life of Steels and an Aluminium Alloy under Nonproportional Loading, Proc. 7th ICBMFF Berlin, DVM, 2004, pp. 5762.

P P

H. Zenner, R. Heidenreich, and I. Richter, Fatigue Strength under Nonsynchronous Multiaxial Stresses, Z. Werkstofftech, 16(1985), pp. 101112. H. Zenner, A. Simbuerger, and J. Liu, On the Fatigue Limit of Ductile Metals under Complex Multiaxial Loading, Int. J. of Fatigue, 22(2000), pp. 137145. C. C. Chu, F. A. Conle, and A. Huebner, An Integrated Uniaxial and Multiaxial Fatigue Life Prediction Method, VDI Berichte, 1283(1996), pp. 337348. I. V. Papadopoulos, P. Davoli, C. Gorla, M. Filippini, and A. Bernasconi, A Comparative Study of Multiaxial HighCycle Fatigue Criteria for Metals, Int. J. Fatigue, 19(3)(1997), pp. 219235. High-cycle Metal Fatigue, from Theory to Applications. CISM Courses and Lectures 392, 1999, Dang Van and I.V. Papadopoulos. New York: Springer, 1994.

234

The Arabian Journal for Science and Engineering, Volume 33, Number 1B

April 2008

C. Gaier and H. Dannbauer

NOMENCLATURE

1 Maximum principal stress

B B

2 Middle principal stress

B B

3 Minimum principal stress

B B

a Fully reversed tensile stress amplitude

B B

e

B B B

Equivalent stress (= scaled normal stress)

B

ea Equivalent stress amplitude (= scaled normal stress amplitude) fl Alternating tension/compression (or bending) fatigue limit on smooth specimen

B B

i

B B B B

Principal stresses

n Normal stress in material planes a Fully reversed shear stress amplitude

B B

f l Alternating shear (or torsion) fatigue limit on smooth specimen

B

k f V

Ratio fully reversed tensile to shear fatigue limit Damage equivalent scaling factor for normal stress or stress tensor components Ratio minimum to maximum principal stress

April 2008

The Arabian Journal for Science and Engineering, Volume 33, Number 1B

235

You might also like

- Voltage Drop and Short CircuitDocument39 pagesVoltage Drop and Short CircuitMinerva Abanto100% (1)

- SAE ARP 5429-2001 (R2006) Landing Gear Fatigue Tests With Equivalent Damage SpectraDocument15 pagesSAE ARP 5429-2001 (R2006) Landing Gear Fatigue Tests With Equivalent Damage Spectraabo029100% (1)

- Metal Fatigue Analysis Handbook: Practical Problem-solving Techniques for Computer-aided EngineeringFrom EverandMetal Fatigue Analysis Handbook: Practical Problem-solving Techniques for Computer-aided EngineeringRating: 3.5 out of 5 stars3.5/5 (5)

- Spectral method for fatigue damage estimation with non-zero mean stressFrom EverandSpectral method for fatigue damage estimation with non-zero mean stressNo ratings yet

- Fatigue Analyses of Offshore StructuresDocument64 pagesFatigue Analyses of Offshore Structuresgeeawhiz55100% (4)

- Lifting AnalysisDocument14 pagesLifting Analysisruhul72No ratings yet

- Fad Analytic PDFDocument13 pagesFad Analytic PDFMalik Beta100% (1)

- Stress ConcentrationDocument9 pagesStress ConcentrationPuneet BahriNo ratings yet

- Multiple Choice Question Material ScienceDocument2 pagesMultiple Choice Question Material Sciencemanish_agr8567% (3)

- Table 6-Peak Solar Heat Gain Thru Ordinary GlassDocument1 pageTable 6-Peak Solar Heat Gain Thru Ordinary GlassADsuperman100% (1)

- ME0403 Ch2 Gear MeasurementDocument42 pagesME0403 Ch2 Gear MeasurementMANOJ M100% (1)

- Mech4620 Group 12 Report PDFDocument12 pagesMech4620 Group 12 Report PDFAaron Hoytash100% (1)

- Concepts of Fracture MechanicsDocument18 pagesConcepts of Fracture Mechanicsjs kalyana rama100% (1)

- Stochastic Fatigue, Fracture and Damage AnalysisDocument37 pagesStochastic Fatigue, Fracture and Damage AnalysisVinayaga Murthy GNo ratings yet

- Paper Spectral Leoben 2012 PDFDocument11 pagesPaper Spectral Leoben 2012 PDFashish38799No ratings yet

- A Load History Generation Approach For Full-Scale Accelerated Fatigue TestsDocument18 pagesA Load History Generation Approach For Full-Scale Accelerated Fatigue TestsBilu VargheseNo ratings yet

- Effects of Thermal LoadsDocument12 pagesEffects of Thermal LoadshamadaniNo ratings yet

- Astm D1250 Table 56Document7 pagesAstm D1250 Table 56Frankie Nguyen100% (4)

- nb-3216.2 MIT 2007Document23 pagesnb-3216.2 MIT 2007adel_izadbakhshNo ratings yet

- Shaft Fatigue - 11838-44955-1-PBDocument8 pagesShaft Fatigue - 11838-44955-1-PBgammaprimeNo ratings yet

- 06 1999fatigue BeijingDocument7 pages06 1999fatigue BeijingTech MitNo ratings yet

- Theory and Applications of FEMFAT - A FE-Postprocessing Tool For Fatigue AnalysisDocument7 pagesTheory and Applications of FEMFAT - A FE-Postprocessing Tool For Fatigue AnalysisMNo ratings yet

- MF Da Ac Notch2 Ijf2010Document31 pagesMF Da Ac Notch2 Ijf2010albertofgvNo ratings yet

- Determination of the Crack Resistance ParametersDocument7 pagesDetermination of the Crack Resistance ParametersВладислав КиричокNo ratings yet

- Unit 14: Aircraft Structutal Integrity Outcome 1Document19 pagesUnit 14: Aircraft Structutal Integrity Outcome 1Rezve AhmedNo ratings yet

- Riser TestDocument22 pagesRiser TestAbraham RojasNo ratings yet

- Nuclear Engineering and Design: Numerical Simulation of Impact and Fast Transient Phenomena Using and 3DDocument7 pagesNuclear Engineering and Design: Numerical Simulation of Impact and Fast Transient Phenomena Using and 3DvenkatesanjsNo ratings yet

- Fatigue Analysis of Welding Seams and Spot Joints in Automotive StructuresDocument9 pagesFatigue Analysis of Welding Seams and Spot Joints in Automotive StructuresAndreyNo ratings yet

- Durability Analysis From FEA Models Incorporating High Temperature and Creep EffectsDocument15 pagesDurability Analysis From FEA Models Incorporating High Temperature and Creep Effectsklomps_jrNo ratings yet

- Design and Demonstration of A Low-Cost Small-Scale Fatigue Testing Machine For Multi-Purpose Testing of Materials, Sensors and StructuresDocument13 pagesDesign and Demonstration of A Low-Cost Small-Scale Fatigue Testing Machine For Multi-Purpose Testing of Materials, Sensors and StructuresFergus GardnerNo ratings yet

- The Yield-Line Method For Concrete Slabs: Automated at LastDocument11 pagesThe Yield-Line Method For Concrete Slabs: Automated at LastMudassar KhanNo ratings yet

- Fatigue Crack Initiation Life Prediction For A Flat Plate With A Central HoleDocument14 pagesFatigue Crack Initiation Life Prediction For A Flat Plate With A Central HoleMona AwadNo ratings yet

- Mean Load EffectsDocument12 pagesMean Load EffectsPier FrancescoNo ratings yet

- Numerical Simulation of Coupled Uid Solid Problems: Michael SCH Afer, Ilka TeschauerDocument23 pagesNumerical Simulation of Coupled Uid Solid Problems: Michael SCH Afer, Ilka TeschauerBahadır HarmancıNo ratings yet

- ANSYS Creep-Fatigue Assessment Tool For EUROFER97 ComponentsDocument2 pagesANSYS Creep-Fatigue Assessment Tool For EUROFER97 ComponentshemantcabhaleNo ratings yet

- Ziemian Et Al-2018-Steel ConstructionDocument6 pagesZiemian Et Al-2018-Steel ConstructionHicham Said BoukhalkhalNo ratings yet

- Efficient Calculation of Transverse Stresses in Composite PlatesDocument17 pagesEfficient Calculation of Transverse Stresses in Composite PlatesKalpana BharatNo ratings yet

- Rapid Crack Propagation in Plastic Pipe: Predicting Full-Scale Critical Pressure From S4 Test ResultsDocument16 pagesRapid Crack Propagation in Plastic Pipe: Predicting Full-Scale Critical Pressure From S4 Test ResultsE.s. BinbillahNo ratings yet

- Total Life Approach For Fatigue Life Estimation of Welded StructuresDocument8 pagesTotal Life Approach For Fatigue Life Estimation of Welded StructuresAishik SahaNo ratings yet

- Fatigue Damage Analysis of Offshore Structures Using Hot Spot Stress and Notch Strain ApproachesDocument9 pagesFatigue Damage Analysis of Offshore Structures Using Hot Spot Stress and Notch Strain ApproachesnapoleonmNo ratings yet

- A New Approach To Ductile Tearing Assessment of Pipelines Under Large-Scale YieldingDocument12 pagesA New Approach To Ductile Tearing Assessment of Pipelines Under Large-Scale YieldingAndrea De CintiNo ratings yet

- 3D Fracture Mechanics in ANSYSDocument20 pages3D Fracture Mechanics in ANSYSFadillah Nur RahmanNo ratings yet

- y.garud Multiaxial FatigueDocument27 pagesy.garud Multiaxial FatiguebazookavnitNo ratings yet

- Renewable and Sustainable Energy Reviews: ArticleinfoDocument10 pagesRenewable and Sustainable Energy Reviews: ArticleinfoRyann MengNo ratings yet

- Fatigue Under Mean ConditionsDocument6 pagesFatigue Under Mean Conditionsrizzo8No ratings yet

- Planning of Inspection and Repair For Ship Operation: SchallDocument8 pagesPlanning of Inspection and Repair For Ship Operation: Schallchwinboss85No ratings yet

- The Estimation of Oil Leakage in Hydraulic Cylinders Using FemDocument8 pagesThe Estimation of Oil Leakage in Hydraulic Cylinders Using FemsunilNo ratings yet

- Determination of Fragments of Multiaxial Service Loading Strongly Influencing The Fatigue of Machine ComponentsDocument10 pagesDetermination of Fragments of Multiaxial Service Loading Strongly Influencing The Fatigue of Machine Componentspaulocouceiro100% (1)

- 0142 1123 (92) 90041 A PDFDocument1 page0142 1123 (92) 90041 A PDFSwapnil NarnavareNo ratings yet

- Chen HF Strathprints Lower and Upper Bound Shakedown Analysis of Structures With Temperature Dependent Yield Stress Feb 2010Document27 pagesChen HF Strathprints Lower and Upper Bound Shakedown Analysis of Structures With Temperature Dependent Yield Stress Feb 2010Othman BouazizNo ratings yet

- FatigueDocument12 pagesFatigueOmid Razavi ZadehNo ratings yet

- FatigueDocument32 pagesFatigueNicolau Morar33% (3)

- Fatigue of Grouted Joint ConnectionsDocument5 pagesFatigue of Grouted Joint Connectionsscrane@No ratings yet

- Sena CilamceDocument7 pagesSena CilamceJoãoPedroSenaNo ratings yet

- Administrator,+toms Vol9no1 Doi001 v2Document17 pagesAdministrator,+toms Vol9no1 Doi001 v2ashwagandyNo ratings yet

- 1 s2.0 S1877705811002499 MainDocument6 pages1 s2.0 S1877705811002499 MainanuNo ratings yet

- Multiaxial Fatigue Under Variable Amplitude Loads: K. S. Kim J. C. Park J. W. LeeDocument8 pagesMultiaxial Fatigue Under Variable Amplitude Loads: K. S. Kim J. C. Park J. W. LeeJithendra KumarNo ratings yet

- (2012) Analysis of Jacking Force For Rectangular Pipe-Jacking Machine (Przeglad Elektrotechniczny) Scopes Volume 88, Issue 9 B, Pages 200 - 203Document4 pages(2012) Analysis of Jacking Force For Rectangular Pipe-Jacking Machine (Przeglad Elektrotechniczny) Scopes Volume 88, Issue 9 B, Pages 200 - 203Rajesh WanwadeNo ratings yet

- Proceedings of the 6th International Workshop on Hydro Scheduling in Competitive Electricity MarketsFrom EverandProceedings of the 6th International Workshop on Hydro Scheduling in Competitive Electricity MarketsArild HelsethNo ratings yet

- Final Imp GK Ques - CompressedDocument15 pagesFinal Imp GK Ques - CompressedRajesh MachchaNo ratings yet

- (Course Code:18ME36B) : Mechanical Measurements and MetrologyDocument27 pages(Course Code:18ME36B) : Mechanical Measurements and MetrologyShivanand ArwatNo ratings yet

- Prof. UPADHE SUDEEP N.Document1 pageProf. UPADHE SUDEEP N.Shivanand ArwatNo ratings yet

- KSRTC Technical Assistant QPDocument14 pagesKSRTC Technical Assistant QPShivanand ArwatNo ratings yet

- Abstracts Received Till Date Agpit Other Institutes Full Papers Till Date AGPIT Department Wise Abstracts Mechanical ElectronicsDocument2 pagesAbstracts Received Till Date Agpit Other Institutes Full Papers Till Date AGPIT Department Wise Abstracts Mechanical ElectronicsShivanand ArwatNo ratings yet

- List of Appointments - Oct19-1Document6 pagesList of Appointments - Oct19-1Shivanand ArwatNo ratings yet

- List of Imp Consititutional Posts CM Gov CJI NewDocument7 pagesList of Imp Consititutional Posts CM Gov CJI NewShivanand ArwatNo ratings yet

- SSC CGL Previous Year GK Questions E-bookDocument12 pagesSSC CGL Previous Year GK Questions E-bookShivanand ArwatNo ratings yet

- 6308FE04Document2 pages6308FE04Shivanand ArwatNo ratings yet

- New Doc 2020-09-28 10.28.04Document6 pagesNew Doc 2020-09-28 10.28.04Shivanand ArwatNo ratings yet

- LessonPlan ListblankDocument4 pagesLessonPlan ListblankShivanand ArwatNo ratings yet

- Syllabus DBATUDocument88 pagesSyllabus DBATUShivanand ArwatNo ratings yet

- MQC SyllabusDocument2 pagesMQC SyllabusShivanand ArwatNo ratings yet

- 01 Introduction To MetrologyDocument138 pages01 Introduction To MetrologyShivanand ArwatNo ratings yet

- Mech Property TestingDocument103 pagesMech Property TestingShivanand ArwatNo ratings yet

- InterferometryDocument11 pagesInterferometryShivanand ArwatNo ratings yet

- Indexing PDFDocument5 pagesIndexing PDFShivanand ArwatNo ratings yet

- Chapter4 150109005052 Conversion Gate02Document56 pagesChapter4 150109005052 Conversion Gate02زهديابوانسNo ratings yet

- World Distribution of WindDocument15 pagesWorld Distribution of WindShivanand ArwatNo ratings yet

- IndexingDocument5 pagesIndexingShivanand ArwatNo ratings yet

- Wind Speed StatisticsDocument8 pagesWind Speed StatisticsShivanand ArwatNo ratings yet

- Crystal structure overviewDocument58 pagesCrystal structure overviewShivanand ArwatNo ratings yet

- World Distribution of WindDocument15 pagesWorld Distribution of WindShivanand ArwatNo ratings yet

- Atmospheric Stability PDFDocument9 pagesAtmospheric Stability PDFShivanand ArwatNo ratings yet

- SlipDocument4 pagesSlipShivanand ArwatNo ratings yet

- Wind Energy SyllabusDocument3 pagesWind Energy SyllabusShivanand ArwatNo ratings yet

- Harnessing the Power of WindDocument15 pagesHarnessing the Power of WindShivanand ArwatNo ratings yet

- Wind Energy SyllabusDocument3 pagesWind Energy SyllabusShivanand ArwatNo ratings yet

- torque 정의Document40 pagestorque 정의valmaxjeonNo ratings yet

- Becker 1987Document16 pagesBecker 1987Luis Fernando Vergaray AstupiñaNo ratings yet

- Ossd U1Document26 pagesOssd U1huangjunxiang4No ratings yet

- Motion of Charged Particles in Electric Fields W BlanksDocument4 pagesMotion of Charged Particles in Electric Fields W BlanksAshir50% (2)

- Thesis ReportDocument132 pagesThesis ReportOana UdreaNo ratings yet

- Engineering Mechanic Sem 1 Session 0809Document10 pagesEngineering Mechanic Sem 1 Session 0809Amirul AizatNo ratings yet

- Flange CouplingDocument16 pagesFlange CouplingARUN VNo ratings yet

- Download Physics Formula ListDocument19 pagesDownload Physics Formula Listanwar9602020No ratings yet

- Design and Fabrication of Hand Water Pump Operated by A PendulumDocument6 pagesDesign and Fabrication of Hand Water Pump Operated by A PendulumAyyanrajNo ratings yet

- Energy and Linear and Angular Momenta in Simple Electromagnetic SystemsDocument24 pagesEnergy and Linear and Angular Momenta in Simple Electromagnetic SystemsJennifer RibeiroNo ratings yet

- Grade 6 Science Notes Term II Magnets LessonDocument4 pagesGrade 6 Science Notes Term II Magnets LessonShaik Md Shoaib Anas 5A (Shoaib Anas)No ratings yet

- Lectu 14Document4 pagesLectu 14YeviraArinDiyanaNo ratings yet

- Degree of Freedom PDFDocument13 pagesDegree of Freedom PDFAnasNo ratings yet

- Earthquake Resistant Buildings Dynamic Analyses Numerical Computations Codified Methods Case Studies and ExamplesDocument12 pagesEarthquake Resistant Buildings Dynamic Analyses Numerical Computations Codified Methods Case Studies and ExamplesSindura SwarnakariNo ratings yet

- SSP Tut and Ia QaDocument36 pagesSSP Tut and Ia QaHarsh MehtaNo ratings yet

- 3-7 Fluids in Rigid-Body Motion: - We ObtainedDocument6 pages3-7 Fluids in Rigid-Body Motion: - We ObtainedAsmaa Ali El-AwadyNo ratings yet

- New Regulations For Geotech GermanyDocument10 pagesNew Regulations For Geotech GermanySâu HeoNo ratings yet

- Lever Problems 1bDocument2 pagesLever Problems 1bmaylynXiXNo ratings yet

- Section A: Multiple Choice Questions (20 Marks)Document4 pagesSection A: Multiple Choice Questions (20 Marks)saed cabdiNo ratings yet

- Pemfc Modeling Mvkf25Document37 pagesPemfc Modeling Mvkf25Xiaoqiang zhangNo ratings yet

- Bulk DensityDocument4 pagesBulk DensitydeniNo ratings yet

- Experiment 3 (A) : Cc205 Lab Mechanic of StructuresDocument5 pagesExperiment 3 (A) : Cc205 Lab Mechanic of StructuresZol HasNo ratings yet

- ENCH4PP: Petroleum & Synthetic Fuel ProcessingDocument16 pagesENCH4PP: Petroleum & Synthetic Fuel ProcessingAshrafNo ratings yet

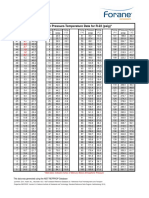

- Forane 22 Saturation Pressure Temperature DataDocument1 pageForane 22 Saturation Pressure Temperature Datavineeth100% (1)

- 2018 Experimental and CFD Analysis of Solar Air Heater With Rectangular ShapedDocument5 pages2018 Experimental and CFD Analysis of Solar Air Heater With Rectangular ShapedaliNo ratings yet

- Deber Coeficientes Globales de La Transferencia de CalorDocument13 pagesDeber Coeficientes Globales de La Transferencia de CalorJuan Francisco JácomeNo ratings yet