Professional Documents

Culture Documents

PuVRD A 7 Pulse Jet Plans Web

Uploaded by

pinchi877012Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PuVRD A 7 Pulse Jet Plans Web

Uploaded by

pinchi877012Copyright:

Available Formats

Pulse Jet Translated from Russian by John-tom (& Google)

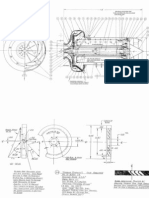

Pulsating air-jet Now, we introduce yet another engine - pulsating air-jet, for short - PuVRD. As the title says - a jet engine, ie, creating cravings by expiring reaction from the combustion of fuel; which he air-jet, is used as fuel oxidizer for oxygen air. And finally, this pulsating engine, because the combustion of fuel and the subsequent expiry of combustion products it is not continuous, but are cyclical in nature. Thrust PuVRD determined expiring products of combustion of fuel - their number and speed also varies cyclically during the work, with its average value much less than the maximum. Pulsating nature of the work of the engine made it uneconomical use of large aircraft, compared with engines having a continuous process of combustion - pryamotochnymi air-jet (PVRD) and turbokompressornymi air-jet (TVRD). But for flying models PVRD inapplicable because of the low velocities flight models, I TVRD are extremely complex design and cost for flying models are not justified. But PuVRD can be applied with success, and they are used as models for the cord, and svobodnoletayuschih. PuVRD develop the airplane big enough traction, low-weight, working at nedefitsitnom fuel, are safe to operate and easy to manufacture. Aeromodeller have developed many types PuVRD. Here we describe only one of them the smallest in the world PuVRD - A-7. Weight this engine only 60 grams and created his thirst more than 200 city Izgotovit it can be when there lathes and apparatus for spot welding or roller. The engine consists of two main parts: the combustion chamber with the resonance pipe and head of engine. Fig. 1. Pulsating air-jet A-7: 1 - stop needle, 2 - nut, 3 - guided; Over - zhikler, 4 - corpus, 5 - Attachment disc, 6 - corpus candles, 7 - Detention; 8 - electrode; 9 - protector, 10 - mounting screw valve; 11 -- Valve, 12 - obechayka safety cones; 23 - bottom safety cones, 14, 15 to 16 - cone of the chamber; 17, 1 B - cylindrical portion of the exhaust pipe: 29 - cone, 20 - electrode Combustion chamber with the resonance pipe made of stainless steel sheet (for example, stamps EI654) thick 0, 15 mm through spot or roller Electric. You can use stainless steel with thickness 0, 1 or 0 2 - 0, 3 mm, but the engine of a thin steel faster progorit combustion chamber and engine of the more thick steel will be heavier. When the thickness of material 0, 2 mm total weight of the engine is equal to 75 g, while the thickness of 0, 3 mm-100 g. In an extreme case, you can boil the combustion chamber and the resonance of the tube neluzhenoy tin thick 0, 3 mm. Resonance tube consists of two parts. By the combustion chamber of the front half of the resonance welded pipes, the rear half into a densely front and can be turned on it. This makes it possible to regulate the model, changing the direction of propulsion engine, which coincides with the axis in the direction of the rear half of the resonance tubes (and not with the axis of the combustion chamber, as is sometimes mistakenly think). Templates parts of the combustion chamber markup, vyrezhi and flex them in accordance with the drawings. Bending billets need for special bars. Vytochi bars of red copper, as they produced and welding parts. Curved harvesting roller or spot welded Electric so that the seams were leakproof. Achieve full tightness in the seam spot Electric could, if put in a 2-3 series at a distance of 1-1, 5 mm. In the combustion chamber is set improvised elektrosvecha. Construction of a candle is clear from the drawing (see fig. 1). When building candles fitted to lead surike central electrode in Porcelain Detention Facility, a detention facility - in the shell candles. The body candles hermetically welded to

the combustion chamber. Joints in the shell with candles combustion chamber cut surikom lead. The second electrode flex them from steel wire 1 mm in diameter, to flatten out one end and welded his spot Electric to the combustion chamber. The head of engine consists of a body and set it on the carburetor, valves and pressure jacket. The body is made of dyuralyuminiya D-1T or electron. Segmental holes in the rear of the hull make sawing nadfilem pre-perforated holes. All sharp edges are rounded. Details carburetor vytochi brass. Carburetor needle made of wire EOD 1 mm in diameter. By the needle nut soldered in a manner which vvertyvanii needles can be completely cut a hole in zhiklere. For more reliable connections needles + nuts before refillable brazed needle tightly wrapped copper wire. Valves vyrezhi steel tape marks U7A, U8A or U9A and carefully zachisti their province - cracks and sharp edges should not be. Constraints vyrezhi of mild steel 0,5-1 mm thick and flex them in accordance with the drawings, their purpose - to limit the angle of deviation valves, to avoid breakage. Pressure hood welded stainless steel EI-654 mm thick 0,1-0,2. Tentatively to make housing on the circle only one series of holes - in the future, setting the engine number of openings will be clarified and probably increased. Heads start to gather with the installation of valves. Priverni to the shell caps and valves podsun under them. Align them so that segment holes in the hull completely overlap, the screws and tighten them in this position. Be sure to install the valves, naden the shell casing pressure, slurred tentatively glue BF-2 seats compounds, and slightly, at two points, his raskerni while keep in mind that in the operation of the engine casing, this would have to withdraw to replace the valves. Insert head tightly in a combustion chamber, also blurry place compounds glue BF-2. The edges of the combustion chamber razvaltsuy the shell head. Carburettor gather at least, by ensuring that the needle was precisely against zhiklera holes. Tightness manufactured engine checks naduvaya its resonance through the pipe smoke. Adjusting and launch. To start the engine are needed (Fig. 2): the source of power - such as magnetite; motor pump; benzobachok. How does the engine run? At the end of the hose pump naden metal tube with an internal diameter of 23 mm. Tube to become flat so that its output hole was oval shape about 1 mm in width. Bachok settle as well. that the level of fuel is not changed dramatically when the engine. Best of all, if the level of fuel will be lower by 15-20 axis engine mm. Attach the ends of magnetite to the engine: one - to the central electrode candles, the other - to the body of the engine. Rotating handle magnetite, check availability listening sparks. Set needle carburetor to its original position adjustment, which wrap needle to complete overlap of the holes in zhiklere and then vyverni its turnover by 2-3. Set pump tubes in the axis of the engine before zhiklerom at a distance of approximately 3-5 mm and start the air pump, while turning a pen magnetite. Vyvertyvaya vvertyvaya or needle, ext first individual cotton, and then sustained a prolonged operation of the engine. It may be that to achieve sustainable operation of the engine could not be immediately. The reason for this, in addition to improper assembly of the engine and not tightness, may be inadequate or excessive holes in the pressure housing. If the engine gives the outbreak only when there is a boost from the pump, the reason for this - the insufficient number of holes in the pressure housing. In this case, removing the head from the engine combustion chamber, the pressure to make another housing several holes. Collect engine and repeat the launch. In the same way producers adjust the engine, increasing the number of openings in the pressure housing until the engine does not work steadily and post-retirement forced the air, and without work magnetite. Do not make a lot of holes at once - with more than you need, the number of holes in the pressure housing engine will work only with the ignition (of the magnetite), in which case the pressure will have to replace the casing. Adjust the engine starts easily and steadily works. However, to avoid premature progoraniya combustion chamber should not be prolonged operation of the engine in place without his air of

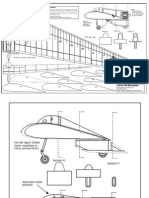

airflow. The engine runs on gasoline, consuming its 0.3 - 0.45 g per second; his thirst with more than 200 city Source power supply disconnected from the engine in 1-2 seconds. sustainable operation of the engine. The principle of work. Consider the operation of the engine since its launch (Fig. 3). With the help pump air pressure applied to the entry engine, opens the valves, dispersing fuel and recorded it in the combustion chamber (A). Iskra of candles sprayed flammable fuel, resulting in pressure in the combustion chamber increases and valves are closed (b). Educated at combustion of fuel gases are beginning to expand, but can only move towards the end of the engine (B). Coming on the resonance tube gases acquire greater speed. In the long pipe resonance, due to inertia in the fast moving exhaust gases in the combustion chamber formed allowable and valves are opened again, but already by atmospheric air pressure (pump no longer needed). Rushed into the combustion chamber air dispersing fuel and recorded it in the combustion chamber (G). Couples fuel soprikosnuvshis with burning in the previous cycle protective casing and the combustion chamber walls, ignite, the pressure in the combustion chamber increases, the valves are closed (D), and the cycle repeats itself for the engine. The length of the resonance system of pipes and valves of the engine well harmonized among themselves. When changing the length of pipe resonance achieve sustainable operation of the engine will fail. Engine resonance with a short pipe would have a greater frequency of pulsations (and therefore greater cravings). But allowable in the combustion chamber it is insufficient for the full opening of valves and combustion chambers fill sprayed fuel. The engine with a long pipe has little resonance frequency fluctuations and small cravings. A-7 engine was used on many models of airplanes, helicopters and "flying boat" (two A-7). Light weight and dimensions make it possible to use this engine is very broadly - as models of free flight, and on the cord. Fig. 3. The engine Scheme A-7: A - excess air to the engine pump; B - ignition of the fuel-air mixture of candles; In - the expansion of combustion of fuel in the chamber and the exhaust pipe; G - education dilution in the combustion chamber and the delivery of the fuel; D - ignition of the fuel-air mixture pressure from cone

You might also like

- Pulse Jet PlansDocument10 pagesPulse Jet PlansSanthosh P100% (2)

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Bruce SimpsonsDocument115 pagesBruce SimpsonsLalit Goyal100% (4)

- MechEngLiquid Fueled Pulsejet EnginesDocument131 pagesMechEngLiquid Fueled Pulsejet Enginespinchi877012No ratings yet

- Complete Puls Engine UitlegDocument35 pagesComplete Puls Engine UitlegadsjhgNo ratings yet

- Jet Engine PlansG8 2 JetDocument90 pagesJet Engine PlansG8 2 Jetcaptain-mental90% (10)

- Constructing A Turbocharger Turbojet EngineDocument52 pagesConstructing A Turbocharger Turbojet Enginerocketman19911No ratings yet

- Project Pulse-Jet Group 4: Jeffrey Dennen Justin Marriott Brian Melo Matthew SkillinDocument37 pagesProject Pulse-Jet Group 4: Jeffrey Dennen Justin Marriott Brian Melo Matthew Skillinpinchi877012No ratings yet

- Practical Design of Small AirplaneDocument4 pagesPractical Design of Small AirplaneSenja RiraNo ratings yet

- Plans Jet Engine Pulsejet BookDocument106 pagesPlans Jet Engine Pulsejet BookLars Wijsman100% (5)

- Atom Jet Pulse Jet Engine PlansDocument2 pagesAtom Jet Pulse Jet Engine Plansjohn424100% (1)

- Design and Fabrication of Pulse Jet - ReportDocument50 pagesDesign and Fabrication of Pulse Jet - ReportVineet Jason100% (1)

- Wren 44i Gold Thrust Instructions - 2016Document27 pagesWren 44i Gold Thrust Instructions - 2016AurangzebNo ratings yet

- Free Piston Engine Working PDFDocument2 pagesFree Piston Engine Working PDFAmyNo ratings yet

- Jet Powered Models, Pulse JetsDocument5 pagesJet Powered Models, Pulse JetsBalaji AeroNo ratings yet

- Instructions For Making The Inflatable KiteDocument15 pagesInstructions For Making The Inflatable KiteLuka NikitovicNo ratings yet

- Screamin Demon Savoy ScientificDocument5 pagesScreamin Demon Savoy ScientificreissmachinistNo ratings yet

- Pietenpol Sky ScoutDocument11 pagesPietenpol Sky Scoutconfused597100% (4)

- GT2000 TurbineplansDocument27 pagesGT2000 TurbineplansSzabolcs Szalai100% (1)

- Development in The Performance of Valve Less Pulsejet EngineDocument3 pagesDevelopment in The Performance of Valve Less Pulsejet EngineInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Structural Testing of Homebuilt AircraftDocument8 pagesStructural Testing of Homebuilt Aircraftproxymo1100% (2)

- Steam Engine Muncaster-06Document4 pagesSteam Engine Muncaster-06Алексей МоисеевNo ratings yet

- Model Submarines For Dumb AssesDocument80 pagesModel Submarines For Dumb AssesRod Jordan100% (1)

- Ramjets & Pulse JetsDocument10 pagesRamjets & Pulse JetsInterogator5No ratings yet

- Builder's Assistance Manual: Building TheDocument25 pagesBuilder's Assistance Manual: Building Theviorelu99No ratings yet

- 110 mAh cells power Horten motorgliderDocument2 pages110 mAh cells power Horten motorglidersandman67100% (2)

- A Mini Spark Erosion Machine for Model EngineersDocument11 pagesA Mini Spark Erosion Machine for Model EngineersWedy Lim100% (1)

- GiroplanoDocument14 pagesGiroplanooscarin1119No ratings yet

- FD3 Turbine (PDF Library)Document19 pagesFD3 Turbine (PDF Library)l75aukkanen100% (3)

- Gluehareff Pressure Jet Engine: Past. Present and FutureDocument9 pagesGluehareff Pressure Jet Engine: Past. Present and FuturesnizzNo ratings yet

- 15 Pulsejet PlansDocument19 pages15 Pulsejet Plansjwzumwalt100% (3)

- BHManual Wing1 28rev0Document28 pagesBHManual Wing1 28rev0viorelu99100% (1)

- Project Pulse-Jet Group 4: Jeffrey Dennen Justin Marriott Brian Melo Matthew SkillinDocument37 pagesProject Pulse-Jet Group 4: Jeffrey Dennen Justin Marriott Brian Melo Matthew SkillinultimatesrNo ratings yet

- Available ComponentsDocument8 pagesAvailable ComponentsMolly Hegarty-PetersenNo ratings yet

- Pulse Detonation Engine: Nitish Kumar Regd No:-0701223318Document16 pagesPulse Detonation Engine: Nitish Kumar Regd No:-0701223318Vishal KumarNo ratings yet

- The X Jet BookDocument4 pagesThe X Jet Bookmarkrobertza0% (1)

- Thomas Kamps - Model Jet Engines - 190037191XDocument109 pagesThomas Kamps - Model Jet Engines - 190037191Xllagosti94% (17)

- Build Your Own TurbineDocument16 pagesBuild Your Own TurbineJack D'Roca100% (5)

- Model Rockets Designers ManualDocument32 pagesModel Rockets Designers Manualpambihira01100% (6)

- WD OD 0017 - Gatling Guns PDFDocument80 pagesWD OD 0017 - Gatling Guns PDFDongelxNo ratings yet

- Zenith expands with new STOL CH 750 Light Sport gap fillerDocument7 pagesZenith expands with new STOL CH 750 Light Sport gap fillerfintineanu_narcisNo ratings yet

- Pulse Jet EngineDocument21 pagesPulse Jet EngineAjin Sathyababu100% (1)

- The Donkey Engine Model Has Strong Steam Power AppealDocument4 pagesThe Donkey Engine Model Has Strong Steam Power AppealimgopalNo ratings yet

- Scratch Building RC Model AirplanesDocument28 pagesScratch Building RC Model AirplanesAlex GurovichNo ratings yet

- Pulse JetDocument65 pagesPulse Jetarjun kumarNo ratings yet

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationFrom EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationNo ratings yet

- Northrop N-63 Convoy Fighter: The Naval VTOL Turboprop Tailsitter Project of 1950From EverandNorthrop N-63 Convoy Fighter: The Naval VTOL Turboprop Tailsitter Project of 1950Rating: 5 out of 5 stars5/5 (2)

- A Guide to Model Steam Engines - A Collection of Vintage Articles on the Design and Construction of Steam EnginesFrom EverandA Guide to Model Steam Engines - A Collection of Vintage Articles on the Design and Construction of Steam EnginesNo ratings yet

- A Guide to Model Locomotives - A Collection of Vintage Articles on the Design and Construction of Model Trains and RailwaysFrom EverandA Guide to Model Locomotives - A Collection of Vintage Articles on the Design and Construction of Model Trains and RailwaysNo ratings yet

- Jet - The story of jet propulsion: The inventors The aircraft The companiesFrom EverandJet - The story of jet propulsion: The inventors The aircraft The companiesNo ratings yet

- The Design and Construction of Flying Model AircraftFrom EverandThe Design and Construction of Flying Model AircraftRating: 5 out of 5 stars5/5 (2)

- EPRS Poster v2Document1 pageEPRS Poster v2pinchi877012No ratings yet

- Engineering Maths SolutionsDocument12 pagesEngineering Maths Solutionspinchi877012No ratings yet

- EAT216 Student Assignment 2015-16Document4 pagesEAT216 Student Assignment 2015-16pinchi877012No ratings yet

- AnemiaDocument22 pagesAnemiapinchi877012No ratings yet

- CV SimDocument7 pagesCV Simpinchi877012No ratings yet

- Excess Power Extraction From Water Distribution SystemDocument67 pagesExcess Power Extraction From Water Distribution Systempinchi877012No ratings yet

- Project Pulse-Jet Group 4: Jeffrey Dennen Justin Marriott Brian Melo Matthew SkillinDocument37 pagesProject Pulse-Jet Group 4: Jeffrey Dennen Justin Marriott Brian Melo Matthew Skillinpinchi877012No ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Mechanical FailuresDocument65 pagesMechanical Failurespinchi877012No ratings yet

- AnemiaDocument22 pagesAnemiapinchi877012No ratings yet

- 5643curriculum Vitae 1 (1) .RaoDocument7 pages5643curriculum Vitae 1 (1) .Raopinchi877012No ratings yet

- 634715615452788750Document61 pages634715615452788750pinchi877012100% (2)

- Jet Model EngineDocument2 pagesJet Model Enginepinchi877012No ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 23Document3 pages23pinchi877012No ratings yet

- MechEngLiquid Fueled Pulsejet EnginesDocument131 pagesMechEngLiquid Fueled Pulsejet Enginespinchi877012No ratings yet

- 23Document3 pages23pinchi877012No ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Experimental Investigation of Pulsejet PerformanceDocument68 pagesExperimental Investigation of Pulsejet PerformanceoffgridsidNo ratings yet

- WpsresumeDocument28 pagesWpsresumepinchi877012No ratings yet

- Me Cheng Pulse Jet Experiments 2Document134 pagesMe Cheng Pulse Jet Experiments 2ognen88No ratings yet

- Airplane Design Vol 1-7, ErrataDocument15 pagesAirplane Design Vol 1-7, ErratakamalfliezNo ratings yet

- 52 (Consequence Analysis)Document18 pages52 (Consequence Analysis)Aditya PranotoNo ratings yet

- 1.A.1 Energy Industries 2019Document116 pages1.A.1 Energy Industries 2019izudindNo ratings yet

- 6 Chem PackDocument5 pages6 Chem PackCody YangNo ratings yet

- Automotive Exhaust Emissions Control: by Martyn V. TwiggDocument6 pagesAutomotive Exhaust Emissions Control: by Martyn V. TwiggShaddy MohammedNo ratings yet

- Gas Turbine WHRU - IntroductionDocument12 pagesGas Turbine WHRU - IntroductionLTORRESMNo ratings yet

- B.Tech Machine Design SyllabusDocument25 pagesB.Tech Machine Design SyllabusSanketHedduriNo ratings yet

- PAS 79 Sample Risk AssessmentDocument21 pagesPAS 79 Sample Risk AssessmentHector Leon83% (6)

- Euro FirefighterDocument2 pagesEuro FirefighterGustavo VydraNo ratings yet

- As 4625-2008 Electronic Flame Safeguards and Flame DetectorsDocument7 pagesAs 4625-2008 Electronic Flame Safeguards and Flame DetectorsSAI Global - APACNo ratings yet

- SECOND SUMMATIVE TEST IN SCIENCE GRADE 3Document4 pagesSECOND SUMMATIVE TEST IN SCIENCE GRADE 3GOLDIE TRONGCONo ratings yet

- Whmis SymbolsDocument1 pageWhmis SymbolsEmma CarrNo ratings yet

- G3600A3 Emission Tune Up Procedure - Final - Mar 2012Document76 pagesG3600A3 Emission Tune Up Procedure - Final - Mar 2012巴啦啦No ratings yet

- NFPA For Dust Collection SystemDocument10 pagesNFPA For Dust Collection Systemngocbinh8x100% (1)

- Diesel Fuel MSDS 2019Document12 pagesDiesel Fuel MSDS 2019bobNo ratings yet

- Design and Fabrication of Hydro Tech Water Fuel Saver Kit: Kolbe Joy, Jithin Raj, Ijas K, Adarsh Babu, Rajamani.BDocument6 pagesDesign and Fabrication of Hydro Tech Water Fuel Saver Kit: Kolbe Joy, Jithin Raj, Ijas K, Adarsh Babu, Rajamani.BgonekatNo ratings yet

- Dye Tracing MSDS ENVIRORedi Red LiquidDocument3 pagesDye Tracing MSDS ENVIRORedi Red LiquidPromagEnviro.comNo ratings yet

- Introduction To Fire Behaviour Course SummaryDocument22 pagesIntroduction To Fire Behaviour Course SummaryAyodeji OyelamiNo ratings yet

- EMISSIONS FROM ENGINESDocument11 pagesEMISSIONS FROM ENGINESAJINKYANo ratings yet

- GCSE CHEMISTRY REVISION: TEST 5 ON ORGANIC CHEMISTRYDocument20 pagesGCSE CHEMISTRY REVISION: TEST 5 ON ORGANIC CHEMISTRYryanNo ratings yet

- Name: - Module 3 QuizDocument11 pagesName: - Module 3 QuizIbrahim FareedNo ratings yet

- Installation Operation and Maintenance Manual WIM-9900 Series Wobbe Index MeterDocument121 pagesInstallation Operation and Maintenance Manual WIM-9900 Series Wobbe Index MeterritchyNo ratings yet

- PU insulation boards EPD provides environmental impact dataDocument10 pagesPU insulation boards EPD provides environmental impact dataGiani JurjNo ratings yet

- EPRI Combustion Turbine Experience and Intelligence ReportDocument188 pagesEPRI Combustion Turbine Experience and Intelligence ReportPenjual Air100% (1)

- Ae 2012 PDFDocument11 pagesAe 2012 PDFSubhash KorumilliNo ratings yet

- Product literature for G24M gas furnaceDocument6 pagesProduct literature for G24M gas furnaceSteven WagnerNo ratings yet

- Natural ResourcesDocument64 pagesNatural ResourcesSUPRAVA BEHERA100% (2)

- IOQC (Part-II) 2021-22 - (Answers & Solutions)Document21 pagesIOQC (Part-II) 2021-22 - (Answers & Solutions)Aryan AroraNo ratings yet

- Bureau of Fire Protection: Your Guide to Fire SafetyDocument53 pagesBureau of Fire Protection: Your Guide to Fire SafetyAlliah OlanoNo ratings yet

- Table 1. Natural and Manufactured FuelsDocument24 pagesTable 1. Natural and Manufactured FuelssharmaineNo ratings yet