Professional Documents

Culture Documents

Generator Start Up Checklist 1 0

Uploaded by

quynh_nguyen017724Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Generator Start Up Checklist 1 0

Uploaded by

quynh_nguyen017724Copyright:

Available Formats

Applications requirements Liquid cooled generator sets

Generator set start-up checklist

Open & enclosed generator sets

This checklist should be used to validate the completion of generator set start-up procedure. A check-list should be completed for each generator set of a multiple installation.

Coolant heater operational Leak check DCA dosing cartridges fitted & valves open

Remote mounted radiator systems

Radiator, engine & pipework checked for leaks Coolant heater operational Fans, pumps and controls checked Leak check DCA dosing cartridges fitted & valves open

Project Details

Project Name ... .... Customer (End User)...... .... Address .... ... Customer representative.... Tel. No .. Email.

Heat exchanger & cooling tower systems

System, engine & pipework checked for leaks Coolant heater operational Secondary cooling system checked Fans, pumps and controls checked DCA dosing cartridges fitted & valves open Legionnella dosing checked where applicable Record dosing chemical & concentration.............................

Generator set details

Generator set model... Generator set serial number.Set no. Control type... Control serial number.. System control type (if applicable)

Diesel Fuel System

Bulk storage facility

Isolating valves correctly positioned Transfer pump & controls operational Pipeline / tank heating system operational Fill point alarm operational Leaks check Storage facility secure

Generator set environment and services

Precommissioning work & checklist complete Surroundings clean & clear from obstruction Lighting / heating, etc., systems operational Observations....

Day tank

Isolating and solenoid valves checked Tank filled Spillage containment & alarms operational Transfer pump operational Leak check Fire valves & release tested and operational

Safety Checks

Ensure starting is inhibited until start-up is required Set clean and fully assembled No loose materials near set Air ducts clear and clean Access & egress routes unobstructed & labelled Control & maintenance positions unobstructed Room secure no unauthorised access Personnel warned of start-up process

Gas Fuel System

Isolating valves correctly positioned Regulator set to correct pressure Gas leak detection equipment operational Double shut-off device operational Leak test complete Purging complete

Cooling System

Set mounted radiator

Radiator, engine & pipework checked for leaks Belts & guards checked for security / slipping

Document Number: PGK FCD 04-0184 1

Fire alarm / suppression system

Fire alarm / suppression system operational Suppression system lock-off operational Operator instructed in fire system operation

Start-up checklist V1.0 2004 Cummins Power Generation Ltd

Applications requirements Liquid cooled generator sets

Lubrication system

Engine oil pan filled to correct level Oil make up system operational

Generator set voltage & frequency correct to order Control system calibrations checked Phase rotation checked Paralleling sets phase coincidence check Generator set switchgear manual operation correct Local stop / emergency stop control checked Remote start / stop / emergency stop checked

Starting system

Battery starting

Batteries installed, filled and connected Battery charger commissioned

Compressed air / hydraulic starting

Isolating valves correctly positioned Compressor operational HP & LP air / hydraulic pressures checked Condensate drained

Generator set load test

Note: Load test is carried out on customers site load unless agreed in writing prior to start-up. Artificial load bank test will be performed using resistive load unless otherwise specified. Load test completed using customers load Record load achievedkW

Exhaust system

Check security of pipework & muffler Check cowl and/or rain cap are operational Check water drain pipework and valves correct Leak check Check for exhaust gas recirculation

Load bank test (if applicable)

Check load bank voltage & power capability Check cables installed correctly & tightened Energise auxiliary supplies and check functionality Load test completed Result sheet completed Record load achievedkW Record power factor

Ventilation & attenuation

Check louvers are clear and operational Forced ventilation system operational if applicable Check for hot air recirculation

System start-up completion

Generator set operational Changeover / transfer switch operational Paralleling switchgear operational Automatic operations checked Master control operational All safety shutdowns and warnings operational Electrical HV/MV/LV rules and procedures in place Comments on any item that may affect acceptance: Checklist completed by . Date... Print Name Company..

Note: Completion of this checklist does not relieve the installer of contract obligations.

Electrical system

Control systems

Auxiliary supplies energised Generator set local controls checked Generator set remote controls checked Generator set system controls checked Customer remote indication / controls checked

Changeover switchgear / transfer switch

Auxiliary supplies energised Utility supply energised Voltage / phase rotation checked Indications correct All covers in position

Paralleling switchgear

Auxiliary supplies energised Indications correct All covers in position

Initial start-up

Manual start-up, idle & full speed checks complete

Document Number: PGK FCD 04-0184 2

Start-up checklist V1.0 2004 Cummins Power Generation Ltd

You might also like

- Liquid-Cooled Generator Startup ChecklistDocument2 pagesLiquid-Cooled Generator Startup ChecklistHaroon ZafarNo ratings yet

- Generator Set Work Instruction: Procedure IllustrationDocument1 pageGenerator Set Work Instruction: Procedure IllustrationAlvin LagascaNo ratings yet

- Satip-P-103-01 Rev 1Document6 pagesSatip-P-103-01 Rev 1AdamuNo ratings yet

- Installation of Diesel GeneratorDocument5 pagesInstallation of Diesel GeneratornmamNo ratings yet

- Copie de Start Up and Commissioning Checklist 1Document7 pagesCopie de Start Up and Commissioning Checklist 1Amin ThabetNo ratings yet

- Method Statement For On Site Installation of DiffusersDocument2 pagesMethod Statement For On Site Installation of Diffusersamg007No ratings yet

- 23-022 Installation Procedures ValvesDocument6 pages23-022 Installation Procedures ValvesAli Khalid QureshiNo ratings yet

- Wem Aw 011: Method StatementDocument5 pagesWem Aw 011: Method StatementPrinterHaapcolNo ratings yet

- EAST AFRICAN MEDICAL VITALS LIMITED DAILY CHILLER INSPECTIONDocument1 pageEAST AFRICAN MEDICAL VITALS LIMITED DAILY CHILLER INSPECTIONamuronegaduNo ratings yet

- Iphone 6 Silver InvoiceDocument1 pageIphone 6 Silver InvoiceMihir KumarNo ratings yet

- Method Statement RISK ASSESSMENT For Mechanical Piping CompressDocument41 pagesMethod Statement RISK ASSESSMENT For Mechanical Piping CompressVlad KaroNo ratings yet

- Method Statement For Hvac Equipments InstallationDocument15 pagesMethod Statement For Hvac Equipments InstallationzahidNo ratings yet

- 3.1 Pre-Delivery and Storage Preparation 3.2 Incoming Storage at SiteDocument4 pages3.1 Pre-Delivery and Storage Preparation 3.2 Incoming Storage at SiteAnis NabilaNo ratings yet

- SWMS 1 Loading, Unloading & ShiftingDocument8 pagesSWMS 1 Loading, Unloading & ShiftingJ.j.JijoNo ratings yet

- Front Loader Maintenance PlanDocument2 pagesFront Loader Maintenance PlanScribdTranslationsNo ratings yet

- Daily Plant Inspection ChecklistDocument2 pagesDaily Plant Inspection ChecklistFeroz GullNo ratings yet

- Fcu Method StatementDocument3 pagesFcu Method StatementBalajiNo ratings yet

- Transformer Installation MethodDocument12 pagesTransformer Installation MethodAmmar Alkindy100% (1)

- Daily Plant Inspection ChecklistDocument2 pagesDaily Plant Inspection ChecklistFeroz Gull100% (1)

- Water Flushing Witnessing and TestDocument3 pagesWater Flushing Witnessing and TestNeguib FarahNo ratings yet

- Orbinox VG08 Knife Gate ValveDocument8 pagesOrbinox VG08 Knife Gate ValveYorkistNo ratings yet

- Testing and Commissioning Check ListDocument1 pageTesting and Commissioning Check ListarifzakirNo ratings yet

- EX-5 Isolation, Safety Procedure Prior Overhauling Air Compressor, AC Compressor and Reefer Compressor and Inspection of Air ReservoirDocument3 pagesEX-5 Isolation, Safety Procedure Prior Overhauling Air Compressor, AC Compressor and Reefer Compressor and Inspection of Air ReservoirAayush AgrawalNo ratings yet

- 23.plumbing Method Statement GN23Document4 pages23.plumbing Method Statement GN23m_salah20202000No ratings yet

- Avk Butterfly Valve - Installation Instruction 820Document5 pagesAvk Butterfly Valve - Installation Instruction 820DjapaNo ratings yet

- Electrical Isolator or Electrical Isolation SwitchDocument3 pagesElectrical Isolator or Electrical Isolation Switchfathonix100% (1)

- RISK ASSESSMENT FOR Ac Cleaning ServicesDocument5 pagesRISK ASSESSMENT FOR Ac Cleaning ServicesEGSC HSENo ratings yet

- Method Statement For Testing & Commissioning of Diesel GeneratorDocument8 pagesMethod Statement For Testing & Commissioning of Diesel GeneratornmamNo ratings yet

- Advanced Oilfield Technology Company LLC: Work ProcedureDocument6 pagesAdvanced Oilfield Technology Company LLC: Work ProcedureAhmed M. AbdelazizNo ratings yet

- Fire Hose Rack & Reel Testing ProcedureDocument2 pagesFire Hose Rack & Reel Testing ProcedureDong VanraNo ratings yet

- BASIC HYDRAULIC SYSTEMDocument72 pagesBASIC HYDRAULIC SYSTEMFahmy MohazNo ratings yet

- Risk Ass - ProcessDocument4 pagesRisk Ass - ProcessBalakrishnan Sivagnanam SNo ratings yet

- Method Statement For Testing Precommissioning & Commissioning of Fuel Oil PumpsDocument3 pagesMethod Statement For Testing Precommissioning & Commissioning of Fuel Oil Pumpsvin ssNo ratings yet

- Method Statement of Installation of SS Puddle FlangesDocument7 pagesMethod Statement of Installation of SS Puddle Flangessarmad spectrumNo ratings yet

- Sop Installing PumpDocument4 pagesSop Installing PumpilhamNo ratings yet

- M.O.S DismantlingDocument18 pagesM.O.S DismantlingAhmed Khaled100% (1)

- SHEM-SP-08.10 Work Permits ProcedureDocument74 pagesSHEM-SP-08.10 Work Permits ProcedureAjith Kumar AjithNo ratings yet

- Variation Order: DesignDocument67 pagesVariation Order: DesignyayansudiantoNo ratings yet

- Method Statement For Installation of Diesel Generator Set - Safe Work Method of StatementDocument5 pagesMethod Statement For Installation of Diesel Generator Set - Safe Work Method of StatementMohamed AliNo ratings yet

- Installation Hvac Chilled Water PumpDocument5 pagesInstallation Hvac Chilled Water PumpGiovanni Moreno VillamilNo ratings yet

- A Sample Preventative Maintenance Schedule PDFDocument2 pagesA Sample Preventative Maintenance Schedule PDFreda100% (1)

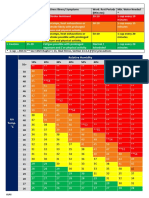

- Aramco Heat IndexDocument1 pageAramco Heat IndexDLPS HSE0% (1)

- Iec62271-200 (Ed1.0) en DDocument6 pagesIec62271-200 (Ed1.0) en DhansamvNo ratings yet

- Excavation ManuallyDocument1 pageExcavation ManuallyJack PNo ratings yet

- Cadet Boiler Installation ManualDocument92 pagesCadet Boiler Installation ManualAnonymous pkqcrsfmF100% (1)

- HN-MECH-31 Progress Report PDFDocument1 pageHN-MECH-31 Progress Report PDFZeshan HaydarNo ratings yet

- DCC T&C Ms-PlumbingDocument11 pagesDCC T&C Ms-Plumbing721917114 47100% (1)

- Fire Pump Churn Test ProcedureDocument2 pagesFire Pump Churn Test ProcedureDwayne YawchingNo ratings yet

- Checklist - Pumps ReciprocatingDocument14 pagesChecklist - Pumps Reciprocatingh_patnaikNo ratings yet

- Compressive Testing Machine Check List - TPLIPMSSAFETYCTMCL048 Rev00 Dt.22.10.2019Document2 pagesCompressive Testing Machine Check List - TPLIPMSSAFETYCTMCL048 Rev00 Dt.22.10.2019MOHAMMEDNo ratings yet

- Install Fresh Air Handling UnitDocument20 pagesInstall Fresh Air Handling Unitsyed mustafa aliNo ratings yet

- Method Statement For Ultrasonic Testing: DCSM Project 2019Document5 pagesMethod Statement For Ultrasonic Testing: DCSM Project 2019Thinh NguyenNo ratings yet

- Check List For: Screed Works: Subcontractor Contractor Section of Work: Civil LOCATION: Parcel 18, Plot 405 LevelDocument6 pagesCheck List For: Screed Works: Subcontractor Contractor Section of Work: Civil LOCATION: Parcel 18, Plot 405 LevelAminovic PlusNo ratings yet

- PCW Installation MethodologyDocument42 pagesPCW Installation MethodologyEZEKIEL VALENCIANo ratings yet

- FM200Document18 pagesFM200a_salehiNo ratings yet

- Sop OPOP Eng 007 - Operating Diesel Bowsers and TanksDocument8 pagesSop OPOP Eng 007 - Operating Diesel Bowsers and Tankscontrax8100% (1)

- Generator Set Pre-Start-Up Checklist: Open & Enclosed Generator Sets Cooling SystemDocument2 pagesGenerator Set Pre-Start-Up Checklist: Open & Enclosed Generator Sets Cooling Systemarkan1976No ratings yet

- Aksa Startup ChecklistDocument2 pagesAksa Startup ChecklistUmar RajputNo ratings yet

- Liquid-Cooled Generator ChecklistDocument2 pagesLiquid-Cooled Generator Checklist4685752No ratings yet

- Generator Set Installation Checklist: Enclosed or Containerized Generator Cooling SystemDocument3 pagesGenerator Set Installation Checklist: Enclosed or Containerized Generator Cooling SystemMohamed H. ShedidNo ratings yet

- En 10088-5Document57 pagesEn 10088-5SergeyGalkin100% (1)

- Active Infrared Thermography Technique F PDFDocument14 pagesActive Infrared Thermography Technique F PDFsidNo ratings yet

- Stone Masonry (Training Element and Technical Guide For SPWP Workers Booklet 3)Document86 pagesStone Masonry (Training Element and Technical Guide For SPWP Workers Booklet 3)Wubetie MengistNo ratings yet

- Romold Domestic Grease TrapDocument1 pageRomold Domestic Grease Traprajkumar_chinniahNo ratings yet

- Design of Purlins and TrussesDocument46 pagesDesign of Purlins and TrussesWarrenPresBerdugo100% (1)

- Sm-Etabs GuideDocument5 pagesSm-Etabs GuidetaroNo ratings yet

- Chemical Engineering Test QuestionsDocument1 pageChemical Engineering Test Questionsjake dionisioNo ratings yet

- Underground Pipe THK CalDocument12 pagesUnderground Pipe THK Calmkchy12100% (3)

- Prestressed Concrete AdvantagesDocument18 pagesPrestressed Concrete AdvantagesLarete PaoloNo ratings yet

- Etabs 20.3 Segmented GRDocument2 pagesEtabs 20.3 Segmented GRHjshj ShjhjNo ratings yet

- Arl On ProductsDocument0 pagesArl On Productscasda73No ratings yet

- IATG 02.20 symbolsDocument3 pagesIATG 02.20 symbolsturamyuwiteka samuelNo ratings yet

- ASTM C1602-22 Standard Specification For Mixing Water Used in The Production of Hydraulic Cement ConcreteDocument5 pagesASTM C1602-22 Standard Specification For Mixing Water Used in The Production of Hydraulic Cement ConcreteOmid DeldarNo ratings yet

- Scrap Yard Mochia BOQDocument8 pagesScrap Yard Mochia BOQSAMEERNo ratings yet

- Code of Pactice For Dead and Imposed Loads 2011Document30 pagesCode of Pactice For Dead and Imposed Loads 2011iyhkNo ratings yet

- Arora BookDocument18 pagesArora BookGowtham SmartyNo ratings yet

- Development of A Model Code For Direct Displacement Based Seismic Design Calvi 2009Document31 pagesDevelopment of A Model Code For Direct Displacement Based Seismic Design Calvi 2009pouyamhNo ratings yet

- 150 KV Substation Cost EstimationDocument21 pages150 KV Substation Cost EstimationMuhammadFajar100% (1)

- BS en 10130 2006Document16 pagesBS en 10130 2006Phong TongNo ratings yet

- Stalargo Stainless Steel I-Beams: For Demanding ApplicationsDocument4 pagesStalargo Stainless Steel I-Beams: For Demanding ApplicationsTushar PatilNo ratings yet

- Surface Repair Using Form-and-Pour Techniques: Reported by ACI Committee E 706Document7 pagesSurface Repair Using Form-and-Pour Techniques: Reported by ACI Committee E 706Carlos Gonzalez100% (1)

- Concrete Strength Testing ExplainedDocument32 pagesConcrete Strength Testing ExplainedMinn LwinNo ratings yet

- Deflections Due To Loading As Per ACIDocument8 pagesDeflections Due To Loading As Per ACIRishabh LalaNo ratings yet

- Water Treatment DegasifierDocument6 pagesWater Treatment DegasifierEDUARDONo ratings yet

- Innovation in Civil Engineering 369Document20 pagesInnovation in Civil Engineering 369talatzahoorNo ratings yet

- Complete EDM Handbook - 14Document12 pagesComplete EDM Handbook - 14soheil gazeranNo ratings yet

- DESIGN OF PRESSURE VESSEL Full Report DEDocument48 pagesDESIGN OF PRESSURE VESSEL Full Report DELuis Muñoz100% (1)

- RFP-EAH-2016-008 - Section V - Annex C - Technical SpecificationsDocument147 pagesRFP-EAH-2016-008 - Section V - Annex C - Technical SpecificationsKhlif NadaNo ratings yet

- Equivalent Circulating DensityDocument7 pagesEquivalent Circulating DensityFlorina PrisacaruNo ratings yet

- MODULE 3 - Pertinent Building Laws and RegulationsDocument45 pagesMODULE 3 - Pertinent Building Laws and RegulationsCammyNo ratings yet