Professional Documents

Culture Documents

TEMA designation heat exchanger types

Uploaded by

mohammadazraiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TEMA designation heat exchanger types

Uploaded by

mohammadazraiCopyright:

Available Formats

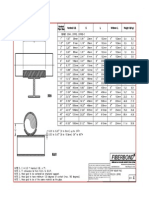

TEMA DESIGNATION

Front End Stationary Head

Shell Type

Rear End Stationary Head

CHANNEL AND REMOVABLE COVER

ONE PASS SHELL

FIXED TUBESHEET, LIKE 'A' STATIONARY HEAD

BONNET (INTEGRAL COVER)

TWO PASS SHELL WITH LONGITUDINAL M BAFFLE

FIXED TUBESHEET, LIKE 'B' STATIONARY HEAD

CHANNEL INTEGRAL WITH TUBESHEET AND REMOVABLE COVER Shown: Removable Tube Bundle only

SPLIT FLOW

FIXED TUBESHEET, LIKE 'C' STATIONARY HEAD

CHANNEL INTEGRAL WITH TUBESHEET AND REMOVABLE COVER Shown: Fixed Tube sheet only

DOUBLE SPLIT FLOW

OUTSIDE PACKED FLOATING HEAD

SPECIAL HIGH PRESSURE CLOSURE

DIVIDED FLOW

FLOATING HEAD WITH S BACKING DEVICE (SPLIT RING)

KETTLE TYPE REBOILER

PULL THROUGH FLOATING HEAD

U-TUBE BUNDLE

PACKED FLOATING TUBE SHEET WITH LANTERN RING

Some examples of the TEMA designation for Heat Exchangers

BE Bonnet (Intergral Cover), One Pass Shell, Fixed Tubesheet Bonnet M Fixed tubesheet heat exchanger. This is a very popular version as the heads can be removed to clean the inside of the tubes. The front head piping must be unbolted to allow the removal of the front head, if this is undesired this can be avoided by applying a type A front head. In that case only the cover needs to be removed. It is not possible to clean the outside surface of the tubes as these are inside the fixed part. Chemical cleaning can be used. Shown is a version with one shell pass and two tube passes.

BE This is the same type of heat exchanger as above, but with one tube pass. M

AE Channel with Removable Cover, One Pass Shell, Fixed Tubesheet Bonnet M This is almost the same type of heat exchanger as the first BEM, the removable cover allows the inside of the tubes to be inspected and cleaned without unbolting the piping.

AES Channel and Removable Cover, One Pass Shell, Floating Head with Backing Device Floating Head Heat Exchanger. A floating head is excellent for applications where the difference in temperature between the hot and cold fluid causes unacceptable stresses in the axial direction of the shell and tubes. The floating head can move, i.e. provides the possibility to expand in the axial direction. Note that the bundle can not be pulled from the front end. For maintenance both the front and rear end head, including the backing device, must be disassembled. If pulling from the front head is required a type AET should be selected

Shell & Tube Heat Exchanger Heat Exchanger Design, Inc. offers shell and tube exchangers starting at 2" IPS in all TEMA types. We design and fabricate to ASME code and TEMA standards. Our shell and tube line utilizes bare tube (straight and u-tubes), helical low-fin outside, longitudinal fins (inside & outside are available). These exchangers are suitable for a variety of applications and are offered in fixed tube sheets or removable bundles. The surface area ranges from (1) square foot to 40,000 square feet. Pressure range is from full vacuum to over 14,000 PSI (limited by size, material and design condition). Types and applications of shell & tube heat exchangers: 1. Type U U-Tube Exchangers: These units are constructed using U shape tubes that are attached to the same tubesheet. This design may be used with A, B, C, N, or D type front end. Advantages: 1. Tube bundle is removable; therefore mechanical cleaning is possible on the shell side. 2. Attachment of tubes to single tubesheet eliminates the need for differential expansion joint. 3. This type is suitable for high pressure. 4. High degree of protection from leakage is possible. 5. Double tubesheet is possible to provide further protection Limitations: 1. Only chemical tube side cleaning is possible. 2. Access to the tubes other that the outside row is limited.

from leakage. For the above reason, this type is recommended for clean process fluids and those subject to chemical removal.

2. Type L, M, and N Fixed tubesheets: These units are constructed with the tubesheets integral with the shell. They may be used with A, B, or N Type front head. Advantages: 1. High degree of protection against contamination of streams. 2. Double tubesheet is possible. 3. Mechanical tube side cleaning is possible. Limitations: 1. Differential expansion is possible only by using expansion joint. 2. High pressure application is limited. 3. Tube bundle is not removable. 4. Shell side mechanical cleaning is not possible.

These types are recommended for low and high pressure, and low fouling fluids.

3. Type W Externally sealed tubesheets: The shell side and tubeside streams are individually sealed by individual packing and are separated by a lantern ring. This is the lowest cost of the floating head designs and can be used with type A, B, or C front head. Advantages: 1. Differential expansion between tubes is possible thru the floating head design, therefore eliminates the need for an expansion joint. 2. Tube bundle is removable. (Also individual tubes) 3. Tube side mechanical cleaning is possible. 4. Shell side mechanical cleaning is possible. Limitations: 1. Maximum of only two tube side passes is possible. 2. The shell and tube side leakage is possible. 3. Maximum temperatures of 375 degrees F and maximum pressure of 300 psi limits the usage of these units at higher pressure and temperature.

This type is recommended for low pressure, low temperature and nonhazardous fluids.

4. Type P outside packed floating head: A skirt attached to the floating tubesheet passes through the back end of the shell. The space between the skirt and the shell is sealed by several layers of packing and packing gland. Advantages: 1. High pressure on tube side is possible. 2. Tube bundle is removable. (Also individual tubes) 3. Shell and tube mechanical cleaning is possible. 4. More than two tube passes is possible to utilize the allowable pressure drop. 5. Packing failure is externally visible under operation. 6. Double tubesheet is possible. 7. Differential expansion is provided by the packing. Limitations: 1. Hazardous material should not be used on the shell side because of the possible leakage. 2. Packing will tend to limit shell fluids to temperatures below 300 degrees F and pressure below 150 psi.

The above types are recommended for low pressure, low temperature nonhazardous fluids.

5. Type T pull through floating heads: The floating tubesheet is designed with a larger diameter than required for the tube array. Advantages: 1. Tube bundle is removable. (Also individual tubes) 2. Differential expansion is provided by the floating head. 3. Shell and tube side mechanical cleaning is possible. 4. Double tubesheets are possible. Limitations: 1. The seal is not externally visible; therefore leakage might be undetected for some time. 2. This type will tend to be more expensive than other types.

6. Type S Inside split backing ring: The floating tubesheet is sealed to a floating head cover using a split backing ring and a gasketed surface. Advantages: Limitations:

1. High pressure is possible. 2. Differential expansion is provided by the floating head. 3. Shell and tube mechanical cleaning is possible. 4. Tube bundle is removable.

1. Failure of gasket is not externally visible, therefore leakage might go undetected for sometime.

The above type is recommended for high pressure, non-hazardous process fluids.

Hairpin Heat Exchanger HEAT EXCHANGER DESIGN,INC. offers a complete line of Hairpin Exchangers. These exchangers provide true counter-current flow and are especially suitable for extreme temperature crossing, high pressure, high temperature, and low to moderate surface area requirements. Our Hairpin Exchangers are available in single tube (Double Pipe) or multiple tubes within a hairpin shell (Multitube), bare tubes, finned tubes, U-tubes, straight tubes (with rod-thru capability), fixed tube sheets and removable bundle. The surface area ranges from (1) square foot to 6,000 square feet (Finned tubes). Pressure capabilities are full vacuum to over 14,000 PSI (limited by size, material, and design condition). Hairpin Exchangers are designed and fabricated per ASME code, and TEMA standards.

Click on this image for a PDF Printable Brochure

1. Double-pipe Hairpin Bare and Multi-tube (Table 1 & 2): These units are constructed using U shape tubes or pipe that are attached to two tubesheets and are loaded inside a hairpin shape shell. Advantages: 1. Tube bundle is removable; therefore mechanical cleaning is possible on the shell side. 2. The U shape bundle is free for expansion and contraction inside the Hairpin shell eliminating the need for Limitations: 1. Only chemical tube side cleaning is possible.

3.

4.

5.

6.

expansion joint. Are capable of carrying the maximum pressure allowable by ASME Code per given wall thickness. (Up to 14600 psi with no corrosion allowance). Higher pressure ratings are possible using materials with higher stress values For processes that require frequent mechanical cleaning, bare tube offers ease of cleaning and accessibility. Bare Multi-Tube and DoublePipe Exchangers offer the least pressure drop among most exchangers. Very often a process might be modified or completely changed. The streams flow rate or other conditions might also change. A Double Pipe Hairpin is designed so as to accommodate these changes, simply by rearranging the sections. Unlimited numbers of sections could be arranged in parallel and series to fit new requirements of the process conditions.

Click here to view Table 1 Click here to view Table 2

2. Finned Double Pipe & Multi-tube (Table 3 & 4): Advantages: 1. The same advantages as the bare tubes above (A, B, C, E, and F) 2. The finned hairpin usually has up to four times more heat transfer surface than bare tube hairpin. This would especially be more advantageous when the shell side heat transfer coefficient is low, therefore requires more Limitations: 1. Only chemical cleaning of the tubes finned surface is possible.

surface 3. Good application for high shell side viscosity with low heat transfer coefficient. Finned hairpins are particularly good application for cooling viscous fluids. The viscosity on the fin wall is higher than the average bulk viscosity which produces a lower film coefficient on the fin, and reduces heat transfer and causes excessive fouling.

Click here to view Table 3 Click here to view Table 4

Click on this image for a PDF Printable Document

You might also like

- Hairpin Heat ExchangerDocument9 pagesHairpin Heat ExchangerBrandon HaleNo ratings yet

- TEMA Type Heat Exchangers PDFDocument4 pagesTEMA Type Heat Exchangers PDFkinjalpatel123450% (1)

- Double Pipe Heat Exchanger Design CalculationsDocument10 pagesDouble Pipe Heat Exchanger Design CalculationsRhumi ELfver ShawolNo ratings yet

- DownloadDocument94 pagesDownloadChiripal PolyfilmsNo ratings yet

- Condensate Manual - Gestra PDFDocument176 pagesCondensate Manual - Gestra PDFtrpac100% (1)

- 10 Boiler Ash Removal System Commissioning Procedure-TöàtéëTÖñtü T +T+ƑF Âf Ò Ä Û+Document32 pages10 Boiler Ash Removal System Commissioning Procedure-TöàtéëTÖñtü T +T+ƑF Âf Ò Ä Û+kvsagar100% (1)

- Presentation On Heat ExchangersDocument54 pagesPresentation On Heat ExchangersNagendrababu Mahapatruni100% (1)

- Boilers & Thermal Fluid HeatersDocument53 pagesBoilers & Thermal Fluid HeatersannasitNo ratings yet

- Boilers and Thermic Fluid HeatersDocument42 pagesBoilers and Thermic Fluid HeatersArvind ShuklaNo ratings yet

- Mass Transfer EquipmentsDocument32 pagesMass Transfer EquipmentsAjaykumarNo ratings yet

- Vapour Compression Refrigeration SlidesDocument41 pagesVapour Compression Refrigeration SlidesLesegoNo ratings yet

- Basic Parts of A BoilerDocument9 pagesBasic Parts of A Boilermessi107No ratings yet

- Brochure Steam AccumulatorDocument2 pagesBrochure Steam AccumulatorFrank HuNo ratings yet

- Furnaces and Furnace ReactorsDocument33 pagesFurnaces and Furnace ReactorsSamyak JainNo ratings yet

- 2.1.1.1 Boiler-General InspectionDocument46 pages2.1.1.1 Boiler-General InspectionSulistyo PujionoNo ratings yet

- APH Maintenance Procedure for Wartsila India Ltd. PlantDocument15 pagesAPH Maintenance Procedure for Wartsila India Ltd. PlantKarthi KeyanNo ratings yet

- Types of Heat ExchangersDocument14 pagesTypes of Heat ExchangersMuhammadFahadIjazNo ratings yet

- Heat Transfer EquipmentDocument28 pagesHeat Transfer Equipmentdeepak.dce.meNo ratings yet

- ChillerDocument12 pagesChillerMard ApikNo ratings yet

- Heat ExchangersDocument47 pagesHeat Exchangersmohammed alaa eldinNo ratings yet

- Navigation Search Wikipedia:Village Pump Pump (Disambiguation)Document22 pagesNavigation Search Wikipedia:Village Pump Pump (Disambiguation)Aldren Delina RiveraNo ratings yet

- Bangladesh MGI 300TD Continuous Polyester Production Line Bottle FlakeDocument44 pagesBangladesh MGI 300TD Continuous Polyester Production Line Bottle Flakeswapon kumar shillNo ratings yet

- HairpinDocument2 pagesHairpinbrkmechNo ratings yet

- Process Control: An Introductory Guide To Control Modes For Chemical Engineers (3 of 4)Document35 pagesProcess Control: An Introductory Guide To Control Modes For Chemical Engineers (3 of 4)tonful143No ratings yet

- Liquid ring vacuum pumps: Two-stage LOH 25003, LOH 25007, LOH 25309Document11 pagesLiquid ring vacuum pumps: Two-stage LOH 25003, LOH 25007, LOH 25309Raciel Leon CarlosNo ratings yet

- Boiler and Its Types PDFDocument25 pagesBoiler and Its Types PDFRabinNo ratings yet

- Handbookofsprink00danarich PDFDocument238 pagesHandbookofsprink00danarich PDFmareNo ratings yet

- Whrs ManualDocument41 pagesWhrs ManualAKHLESH JHALLARENo ratings yet

- Heat SinkDocument21 pagesHeat SinkMuhammad Taufik Ali RahmanNo ratings yet

- IME - Bolted Flanged Joints Methods & PracticesDocument188 pagesIME - Bolted Flanged Joints Methods & PracticesHeviiNo ratings yet

- Powell Valve HandbookDocument29 pagesPowell Valve Handbookddoyle1351100% (11)

- PED 5 Heat ExchangersDocument74 pagesPED 5 Heat ExchangersoperationmanagerNo ratings yet

- High-Pressure Polymer PumpDocument5 pagesHigh-Pressure Polymer Pumpy.s.6saputroNo ratings yet

- Fire Tube Boilers - (21.07.2020)Document131 pagesFire Tube Boilers - (21.07.2020)Dr. BIBIN CHIDAMBARANATHANNo ratings yet

- Heat Exchanger Tube Plugging Relative To ASME PCC 2 2011 PDFDocument5 pagesHeat Exchanger Tube Plugging Relative To ASME PCC 2 2011 PDFNomi A100% (1)

- 12 - OLGA UGM Curtin PresentationDocument40 pages12 - OLGA UGM Curtin PresentationGui Do Esp100% (1)

- Tube Removal Catalog Web ELLIOTDocument24 pagesTube Removal Catalog Web ELLIOTJose Luis RattiaNo ratings yet

- BreechLock HEDocument1 pageBreechLock HEibrahim1961No ratings yet

- Solutions For Detecting Rips in ConveyorDocument10 pagesSolutions For Detecting Rips in ConveyorJuan CarlosNo ratings yet

- Thermal expansion of boilers explainedDocument5 pagesThermal expansion of boilers explainedThusitha DalpathaduNo ratings yet

- HX HN Compressors Brochure 2015 0318 LRDocument20 pagesHX HN Compressors Brochure 2015 0318 LRAlbert Paco GoytiaNo ratings yet

- AFT XStream Data SheetDocument2 pagesAFT XStream Data SheetdelitesoftNo ratings yet

- Bof ControlDocument46 pagesBof ControlYoung-seok HwangNo ratings yet

- Air CoolerDocument13 pagesAir CoolerMina RemonNo ratings yet

- Introduction To Heat Exchangers (HXS) : DR Rashid AliDocument36 pagesIntroduction To Heat Exchangers (HXS) : DR Rashid AliUsama IbrahimNo ratings yet

- Boilers BasicsDocument19 pagesBoilers BasicsShayan Hasan KhanNo ratings yet

- Why A Shell and Tube Heat Exchanger?Document17 pagesWhy A Shell and Tube Heat Exchanger?Avishek KumarNo ratings yet

- Burner Controls for Gas, Oil or Dual-Fuel BurnersDocument26 pagesBurner Controls for Gas, Oil or Dual-Fuel BurnersbledmikifrNo ratings yet

- Rolling Process GuideDocument9 pagesRolling Process GuideHarish HNo ratings yet

- Bolt Tightening Methods and Torque-Tension RelationshipsDocument12 pagesBolt Tightening Methods and Torque-Tension RelationshipsJuanGómezNo ratings yet

- Sec.6 - Class C Heat ExchangerDocument33 pagesSec.6 - Class C Heat ExchangerAgung Dewandaru MahatmantoNo ratings yet

- Fan Calculation MooreDocument8 pagesFan Calculation MooreArjun GirishNo ratings yet

- 8 Steps - Control of Heating SystemsDocument192 pages8 Steps - Control of Heating SystemsIvanNo ratings yet

- Basics of Double Pipe Heat Exchanger (Heat Transfer Slides)Document38 pagesBasics of Double Pipe Heat Exchanger (Heat Transfer Slides)Asad Imran Munawwar100% (2)

- Floating Head Heat ExchangerDocument5 pagesFloating Head Heat ExchangerniralNo ratings yet

- Basic Heat ExchangerDocument15 pagesBasic Heat Exchangeraw_aeNo ratings yet

- Heat Exchanger - StudyDocument22 pagesHeat Exchanger - StudyDedy WindiyantoNo ratings yet

- Shell and Tube Heat ExchangersDocument36 pagesShell and Tube Heat ExchangersMumahmmad Rizwan RNo ratings yet

- Heat Exchanger BasicsDocument18 pagesHeat Exchanger BasicsJefferson WintersNo ratings yet

- Heat Transfer by Heat ExchangersDocument7 pagesHeat Transfer by Heat ExchangerssugiantobarusNo ratings yet

- Flare Tip FailureDocument4 pagesFlare Tip FailuremohammadazraiNo ratings yet

- Factors, Multiples, Primes, Prime Factors, LCM and HCFDocument2 pagesFactors, Multiples, Primes, Prime Factors, LCM and HCFKatrice LiNo ratings yet

- TUV Nord TrainingDocument39 pagesTUV Nord TrainingmohammadazraiNo ratings yet

- Schools Must Ensure Student FitnessDocument83 pagesSchools Must Ensure Student FitnessIshtiaque AhmedNo ratings yet

- Expansion Loop Guideline ExtractDocument8 pagesExpansion Loop Guideline ExtractmohammadazraiNo ratings yet

- Painting & Coating SpecDocument19 pagesPainting & Coating SpecmohammadazraiNo ratings yet

- Outreach P2 Math PDFDocument131 pagesOutreach P2 Math PDFmohammadazraiNo ratings yet

- Outreach P2 Math PDFDocument131 pagesOutreach P2 Math PDFmohammadazraiNo ratings yet

- Supports 20FREDocument6 pagesSupports 20FREmohammadazraiNo ratings yet

- DS68 9-597 PDFDocument9 pagesDS68 9-597 PDFRamon FragaNo ratings yet

- Ptsme 2015 Abu Dhabi - TrainingDocument6 pagesPtsme 2015 Abu Dhabi - TrainingmohammadazraiNo ratings yet

- Pipe SupportsDocument234 pagesPipe SupportsSam Weber100% (1)

- Nitrogen Generation by PSADocument12 pagesNitrogen Generation by PSALakshmi Pathi Bojja100% (1)

- Calcium CarbonateDocument2 pagesCalcium CarbonatemohammadazraiNo ratings yet

- Pbe 20050301 31Document3 pagesPbe 20050301 31mohammadazraiNo ratings yet

- Soda AshDocument2 pagesSoda AshmohammadazraiNo ratings yet

- CPD 002 RevisedDocument7 pagesCPD 002 Revisedanlekgen99No ratings yet

- Momentum 2 2012.ashxDocument52 pagesMomentum 2 2012.ashxmohammadazraiNo ratings yet

- Jiangyinshi BeihaiDocument1 pageJiangyinshi BeihaiNazhani Rohaidin100% (1)

- LIQUITOTE IBC Tanks PDFDocument2 pagesLIQUITOTE IBC Tanks PDFpramodtryNo ratings yet

- Momentum 2 2012.ashxDocument52 pagesMomentum 2 2012.ashxmohammadazraiNo ratings yet

- Document review and approval workflow guideDocument2 pagesDocument review and approval workflow guidemohammadazraiNo ratings yet

- CPD 002 RevisedDocument7 pagesCPD 002 Revisedanlekgen99No ratings yet

- DNV Publication ListDocument14 pagesDNV Publication ListmohammadazraiNo ratings yet

- Class Notations TableDocument247 pagesClass Notations TableRobert DelafosseNo ratings yet

- 3D & 5D Pipe Bend For PipelineDocument6 pages3D & 5D Pipe Bend For PipelinemohammadazraiNo ratings yet

- Dupre - Travis Crane Operation and MaintenanceDocument23 pagesDupre - Travis Crane Operation and MaintenancemohammadazraiNo ratings yet

- 3D & 5D Pipe Bend For PipelineDocument6 pages3D & 5D Pipe Bend For PipelinemohammadazraiNo ratings yet

- ASSAI Booklet Ver2Document2 pagesASSAI Booklet Ver2mohammadazraiNo ratings yet

- Notaries Public KL & SelangorDocument3 pagesNotaries Public KL & SelangormohammadazraiNo ratings yet

- Ground Movements - A Hidden Source of Loading On Deep FoundationsDocument17 pagesGround Movements - A Hidden Source of Loading On Deep Foundationsedward the iiiNo ratings yet

- Design of foundation and column for 132kV GIS buildingDocument226 pagesDesign of foundation and column for 132kV GIS buildingSivaNo ratings yet

- Hydraulic Calculation For Fire PumpDocument9 pagesHydraulic Calculation For Fire PumpShaifful NizamNo ratings yet

- Kss Cable TieDocument32 pagesKss Cable Tieismail alwainiNo ratings yet

- General Requirements For ValvesDocument16 pagesGeneral Requirements For ValvesKrishna Prasad R100% (1)

- Concrete Construction Article PDF - Site Casting Exposed Aggregate WallsDocument1 pageConcrete Construction Article PDF - Site Casting Exposed Aggregate WallssonofalexanderNo ratings yet

- Boundary Wall NIT 3-1Document2 pagesBoundary Wall NIT 3-1Er Soumen Dey KhanNo ratings yet

- Dispatch Plan - AptarDocument45 pagesDispatch Plan - AptarSaurabh KadamNo ratings yet

- Aluminum Structural Analysis of Porta Batumi FacadesDocument39 pagesAluminum Structural Analysis of Porta Batumi Facadesismail TORLAK100% (1)

- Calculation of Septic Tank & Sock PitDocument11 pagesCalculation of Septic Tank & Sock Pitakram1978No ratings yet

- Minikin: Emflex Vibration Isolators, Inertia Bases and Related Equipment For Pipework and PlantDocument20 pagesMinikin: Emflex Vibration Isolators, Inertia Bases and Related Equipment For Pipework and PlantzecamanuNo ratings yet

- How To Build A Home Climbing WallDocument9 pagesHow To Build A Home Climbing Wallzimmerman steinNo ratings yet

- Electric Convection Built-In Oven: Installation ManualDocument28 pagesElectric Convection Built-In Oven: Installation Manualjulio ariasNo ratings yet

- Building Project ReportDocument32 pagesBuilding Project ReportAssif Yousuf100% (2)

- Regleta 6700 Liquid Level IndicatorDocument4 pagesRegleta 6700 Liquid Level IndicatorJulio PCNo ratings yet

- Week 5 - Elastic AnalysisDocument26 pagesWeek 5 - Elastic AnalysisTris CollectionNo ratings yet

- Design of FRC Tunnel Segments Considering The Ductility Requirements of The Model Code 2010Document23 pagesDesign of FRC Tunnel Segments Considering The Ductility Requirements of The Model Code 2010Freddie KooNo ratings yet

- n+10 EMVS Social-Housing EnglishDocument2 pagesn+10 EMVS Social-Housing Englishe_o_fNo ratings yet

- DEAP Manual Version 4.2.3 FinalDocument212 pagesDEAP Manual Version 4.2.3 FinalSean WalshNo ratings yet

- Influence of Initial Imperfection On The Behaviour of Extended Bolted by Chen 2007Document10 pagesInfluence of Initial Imperfection On The Behaviour of Extended Bolted by Chen 2007fahmi aballiNo ratings yet

- Fan-Coil Units Compliance Statement for Egypt Tower ProjectsDocument9 pagesFan-Coil Units Compliance Statement for Egypt Tower ProjectsLi Liu100% (1)

- Ep61412.PDF - Piping Classes 600#Document10 pagesEp61412.PDF - Piping Classes 600#eke23No ratings yet

- JIS G3101 SS 400 Steel Plate StandardDocument6 pagesJIS G3101 SS 400 Steel Plate StandardArun kumarNo ratings yet

- Clay BlanketDocument2 pagesClay BlanketAhmed Tarek100% (1)

- ResumeABDULKALEEM A MDocument5 pagesResumeABDULKALEEM A MJenniferNo ratings yet

- Reinforced Concrete and Masonry StructurDocument821 pagesReinforced Concrete and Masonry StructurHarley FrenchNo ratings yet

- Forum Fluid End Pump PartsDocument18 pagesForum Fluid End Pump PartsriskvisionNo ratings yet

- FLYER 127A/4127A SERIES Viking PumpsDocument2 pagesFLYER 127A/4127A SERIES Viking PumpsMarcosNo ratings yet

- Sistema Hidraulico CAT308CDocument2 pagesSistema Hidraulico CAT308Cjulianmata100% (12)

- Ministry Hospital Project Coordination IssuesDocument1 pageMinistry Hospital Project Coordination IssuescdnaveenNo ratings yet