Professional Documents

Culture Documents

Hornification-Its Origin and Interpretation in Wood Pulps

Uploaded by

lyoufOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hornification-Its Origin and Interpretation in Wood Pulps

Uploaded by

lyoufCopyright:

Available Formats

Wood Sci Technol 37 (2004) 489494 DOI 10.

1007/s00226-003-0216-2

Original

Hornificationits origin and interpretation in wood pulps

J.M.B. Fernandes Diniz, M.H. Gil, J.A.A.M. Castro

489 Abstract Although perfectly diagnosed in terms of the occurrence of physical changes, the hornication phenomenon, in its origin, has frequently been associated with the formation of irreversible or partially reversible hydrogen bonding in wood pulps or paper upon drying or water removal. Its characterisation has therefore been confusing and unsatisfactory. The authors propose that a sufciently varied source of experimental data already exists to show that hornication is only a particular case of lactone bridge formation in lignocellulosic materials.

Introduction The term hornication is a technical term used in wood pulp and paper research literature that refers to the stiffening of the polymer structure that takes place in lignocellulosic materials upon drying or water removal. When wood pulp bres are dried, the internal bre volume shrinks, because of structural changes in wood pulp bres. If bres are resuspended in water, the original water-swollen state is not regained (Minor 1994). The effect of hornication may be identied in those physical paper or wood pulp properties that are related to hydration or swelling, such as burst or tensile properties. Repeated recycles showed progressive variations in these properties for several cycles (Howard 1990). This concept, which was introduced by G. Jayme in 1944, was originally expressed by the German word Verhornung, initially translated into English as cornication, and later changed to hornication (Minor 1994). Jayme introduced the water retention value (WRV) measurement by centrifugation and dened irreversible hornication as a decrease in WRV, expressed in percentage of the original value (Jayme 1944). The decrease in WRV was found to correlate in multiple recycling very well with bre thickness as measured from electron microscopic images, whereas no change in bre width was detected after multiple bre drying (Bawden and Kibblewhite 1995; Weise and Paulapuro 1996).

Received: 12 November 2001 Published online: 2 March 2004 Springer-Verlag 2004

J.M.B. Fernandes Diniz (&), M.H. Gil, J.A.A.M. Castro Departamento de Engenharia Qumica, Universidade de Coimbra, 3030-290 Coimbra, Portugal E-mail: jmfdinis@ci.uc.pt Fax: +351-239-798703

Further research showed that the process of drying of bres causes a signicant loss of large pores (Stone and Scallan 1966, 1968; Stone et al. 1968; Ehrnrooth 1984) and a reduction of surface area (Klungness and Caueld 1982; Krassig 1984). Wet pressing has also been found to produce hornication (Robertson 1964; Maloney et al. 1997).

490

Early mechanism characterisation Following some early reported ndings (Jayme 1943; Frey-Wyssling 1951), the rst description of the hornication mechanism was put forward in the 1950s (Jayme and Hunger 1956, 1957). In this theoretical framework, wet brils are envisaged as being brought into contact as a drying process proceeds (Jayme and Hunger 1956, 1957). The polysaccharide chains of cellulose are packed tighter with the removal of water upon drying (Jayme 1943), and microbrils were observed to join in at ribbons, in the dry state, as a result of tight packing (FreyWyssling 1951). The drying process would progressively close the capillary voids, which might not be completely reopened by newly intruding water (Jayme 1943). As a consequence, the irreversible hornied cell wall was believed to be less swollen and less exible compared to the state before drying. When remoistered some surfaces remain coalescent, thus reducing the bre surface accessed by water. This phenomenon was described as essentially a feature of low-yield wood pulps (Jayme and Hunger 1956) once lignied pulps, such as mechanical pulps do not hornify to the extent that chemical pulps do (Jayme and Hunger 1957; Laivins and Scallan1993). In this context, hornication has thus been described as an increase in the degree of crosslinking within the bre microstructure. Cross linking was viewed as an irreversible (Lindstrom 1986) or partially irreversible (Laivins and Scallan 1993) connection of interbril hydrogen bonding. Alternative mechanism characterisation The rst contribution to an alternative interpretation of hornication was put forward in the 1960s by the proposal that thermal crosslinking takes place through the formation of esters (Rufni 1966; Back 1967). It is known that a hydroxycarboxylic acid can undergo intramolecular esterication to yield a cyclic ester, called a lactone (Streitwieser and Heathcock 1989). The recognition of the presence of lactones in cellulosic materials can be traced to the early 1950s (Stakheeva-Kaverzneva and Salova 1951). In the 1960s the formation of lactones in cellulosic materials induced by fairly acidic media (pH 2) (Samuelson and Tornell 1961; Wilson 1966; Slavik and Kucerova 1967) or by drying (Rufni 1966; Slavik and Kucerova 1967, 1969) was reported. The lactone presence was qualitatively detected through the pink colour originated in the hydroxylamineferric chloride test (Stakheeva-Kaverzneva and Salova 1953) in hornied pulps but not detected in never-dried pulps (Rufni 1966). The quantitative determination of lactones was performed colorimetrically (Slavik and Kucerova 1967, 1969) or through the variation of the carboxylic acid content (Rufni 1966). Reversing hornification The irreversible character of hornication was a feature of the original description by G. Jayme (Jayme 1944; Weise 1998); it is still adopted by recent authors (Oksanen et al. 1997; Kato and Cameron 1999). Later experimentation showed that the swelling capacity of hornied bres can be partly restored (Laivins and

Scallan 1993; Klungness and Caueld 1982), and hornication reduced by beating (Brecht and Globig 1954; Kitayama et al. 1983), by the addition of bulking agents, like sucrose or glycerol adsorbed by the polymeric structure (Higgins and McKenzie 1963) or by insertion of spacer groups through derivatisation (Gruber and Weigert 1998). A hornication reversion of 55% by alkali cooking has already been reported (Weise et al. 1998) and a US patent was issued on a process that was claimed to prevent hornication (Yasnovsky and MacDonald 1983). Heating the suspension of pulp under 120 psi of saturated steam at pH=8.1 improved the subsequent reactivity of the pulp, and the patent authors proposed that the reason for the improvement was an inhibition of hornication.

491

Discussion The readiness of hydrolization of lactones by dilute alkaline solutions in oxycelluloses has been long recognized (Kaverzneva et al. 1952; Samuelson and Wennerblom 1955; Slavik et al. 1967). The prevention of lactone formation in lignocellulosic materials was also proposed by the use of fairly alkaline solutions (Stakheva-Kaverzneva and Salova 1953) or lightly alkaline solutions of pH=8 (Samuelson and Tornell 1961; Wilson 1966) to be taken into account in alkalimetric studies of wood pulps (Fernandes Diniz and Pethybridge 1995). Because of the existence of a Donnan equilibrium (Fernandes Diniz 1996), the pH of an external solution does not equal that of the internal pores of lignocellulosic materials (Scallan et al. 1989). Therefore, either a multiple cyclic exposure to fresh alkaline solutions of pH8 or an external pressure sufcient to overcome the osmotic pressure between the external solution and the pore solution is capable of a total reversal of the hornication process. The latter condition is actually proposed in US patent 4,385,172 (Yasnovsky and MacDonald 1983). The carboxyl groups contained in the wood pulp have been shown to have a major inuence on the hornication of kraft bres. When in their hydrogen or acidic form, they promote more hornication (Lindstrom and Carlsson 1982) in such a way that the degree of hornication increases with the growing number of carboxyl groups (Racz and Borsa 1997). Conversely, a drying process that promotes hornication generates a drop in carboxylic acid content in pulps (Rufni 1966). It was also shown that the velocity of crosslinking for a mechanical pulp during heat treatment increased with a periodate oxidation, which produced dialdehyde groups and decreased with the reduction of the mechanical pulp with sodium borohydride. Finally, the activation energy involved in the crosslinking process associated with hornication has been calculated and estimated between 80 and 130 kJ mol-1 (Back 1967), a value very much higher than hydrogen bonding, typically between 10 and 40 kJ mol-1(Israelachvili 1991). Conclusions Although perfectly diagnosed in terms of the occurrence of physical changes, the hornication phenomenon, in its origin, has frequently been associated with the formation of irreversible or partially irreversible hydrogen bonding in wood pulps or paper upon drying or water removal (Smook 1990), thus overlooking research ndings published in the 1950s and 1960s. The chemical description of hornication based on hydrogen bond crosslinking raises a few questions. One nds puzzling that certain polymeric intramolecular hydrogen bonds may be broken by water molecules, whereas some other hydrogen bonds cannot.

492

In relation to thermochemistry and chemical bond theory, it is hard to envision this description of hornication as a coherent body of theory. The fact that the prevention or reduction of hornication is attained by alkaline solutions and sodium borohydride, which are known to produce the cleavage of hemiacetal bonds (lactone bridges) in low polymer carbohydrates, and that both the hydroxyl and carboxyl groups play a signicant role in the degree of hornication clearly suggest the ester linkage crosslinking nature of hornication. Furthermore, the esterication process of interlocking lignocellulosic chains also explains the increase in strength properties and loss of hygroscopicity acquired after a treatment with monochloroacetic acid for unbeaten pulps (Rufni 1966). Therefore the authors conclude that a sufciently varied source of experimental data already exists to show that hornication is only a particular case of lactone bridge formation in lignocellulosic materials. In this perspective, water completely breaks hydrogen bonds in the amorphous part of the lignocellulose material, especially between bres. Conversely, the removal of water may bring the solid material in close proximity and regenerate hydrogen bonding formation. Part of the existent carboxylic acid groups in the lignocellulosic structure will interact with hydroxyl groups in neighbouring polymeric chains and establish covalent lactone bridges. These lactone bridges will further condition the physical properties of the polymeric material such as a swelling decrease and an increase in wet strength parameters (wet breaking load, wet stiffness or wet modulus of elasticity). This covalent crosslinking is not broken by water molecules and will only disappear under the specic chemical conditions that reverse the lactone formation.

References

Back EL (1967) Thermal auto-crosslinking in cellulose material. Pulp Pap Mag Can 68:T165T171 Bawden AD, Kibblewhite RP (1995) Effects of multiple drying treatments on kraft bre walls. In: Third research forum on recycling. CPPA, Vancouver, pp 171177 Brecht W, Globig C (1954) Untersuchung eines gebleichten Strohzellstoffes auf seine papiertechnologischen Eigenschaften. Wochenbl Papierfabr 82:807813 Ehrnrooth EML (1984) The swelling of dried and never-dried acid chlorite delignied bers. Svensk Papperstidn 87:R74R77 Fernandes Diniz JMB (1996) Application of chemical equilibrium to wood pulps. Holzforschung 50:429433 Fernandes Diniz JMB, Pethybridge AD (1995) Interfering lactone formation in alkalimetric studies of paper woodpulps. Holzforschung 49:8183 Frey-Wyssling A (1951) Uber verbanderte Cellulosemikrobrillen in Zellwanden. Holz als Rohund Werkstoff 9:333334 Gruber E, Weigert J (1998) Chemische Modizierung von Zellstoffen zur Verminderung ihrer Verhornungsneigung. Papier 52:V20V26 Higgins HG, McKenzie AW (1963) The structure and properties of paper. XIV. Effects of drying on cellulose bres and the problem of maintaining pulp strength. Appita J 16:145161 Howard RC (1990) The effects of recycling on paper quality. J Pulp Pap Sci 16:J143J149 Israelachvili JN (1991) Intermolecular and surface forces, 2nd edn. Academic, San Diego, pp 123 125 Jayme G (1943) Uber die Reaktionsfahigkeit von Zellstoffen. Cellulosechemie 21:7386 Jayme G (1944) Mikro-Quellungsmessungen an Zellstoffen. Wochenbl Papierfabr 6:187194 Jayme G, Hunger G (1956) Verhornungserscheinungen an Cellulosefaserstrukturen in elekt roneoptischer Sicht. Monatshefte fur Chemie 87:823 Jayme G, Hunger G (1957) The rearrangement of microbrils in dried cellulose and the implication of this structure alteration on pulp properties. In: Bolam F (ed) Fundamentals of papermaking bres. BPBMA, Cambridge, pp 263270 Kato KL, Cameron RE (1999) A review of the relationship between thermally-accelerated ageing of paper and hornication. Cellulose 6:2340

Kaverzneva ED, Ivanov VI, Salova AS (1952) Chemical transformations of the macromolecule of cellulose under the action of oxidizing agents. VI. The presence in oxycelluloses of the groupings of carbonic esters and their effect on the determination of uronic carboxylic groups. Izvest Akad Nauk SSSR, Otdel Khim Nauk, pp 185189 Kitayama T, Okayama T, Oye R (1983) Changes of chemical pulp bres during recycling. In: International symposium on wood and pulping chemistry, vol 3. Japanese TAPPI, Tsukuba, pp 118123 Klungness JH, Caueld DF (1982) Mechanisms affecting ber bonding during drying and aging of pulps. TAPPI J 65:9497 Krassig H (1984) Struktur und Reaktivitat von Cellulosefasern. Papier 38:571582 Laivins GV, Scallan AM (1993) The mechanism of hornication of wood pulps. In: Baker CF (ed) Products of papermaking. Trans 10th fundamental research symposium. Pira International, Oxford, pp 12351260 Lindstrom T (1986) The porous lamellar structure of the cell wall. In: Bristow JA, Kolseth P (eds) Paper, structure and properties. Marcel Dekker, New York, pp 99109 Lindstrom T, Carlsson G (1982) The effect of carboxyl groups and their ionic form during drying on the hornication of cellulose bers. Svensk Papperstidn 85:R146R151 Maloney TC, Li TQ, Weise U, Paulapuro H (1997) Intra- and inter-bre pore closure in wet pressing. Appita J 50:301306 Minor JL (1994) Hornicationits origin and meaning. Progr Pap Recycling 3:9395 Oksanen T, Buchert J, Viikari L (1997) The role of hemicelluloses in the hornication of bleached kraft pulps. Holzforschung 51:355360 Racz I, Borsa J (1997) Swelling of carboxymethylated cellulose bres. Cellulose 4:293303 Robertson AA (1964) Some observations on the effects of drying papermaking bres. Pulp Pap Mag Can 65:T161T168 Rufni G (1966) Improvement in bonding of wood pulps by the presence of acidic groups. Svensk Papperstidn 69:7276 Samuelson O, Tornell B (1961) Inuence of lactones upon the determination of carboxyl groups in cellulose. Svensk Papperstidn 64:198203 Samuelson O, Wennerblom A (1955) Determination of carboxyl groups in cellulose. Svensk Papperstidn 58:713716 Scallan AM, Katz S, Argyropoulos DS (1989) Conductometric titration of cellulose bres. In: Schuerch C (ed) Cellulose and wood-chemistry and technology. Wiley, New York, pp 1457 1471 Slavik I, Kucerova M (1967) Formation of lactone bonds in cellulose during acidication and drying. Faserforsch Textiltech 18:396397 Slavik I, Pasteka M, Kucerova M (1967) The behavior of lactone groups in cellulosic materials during the determination of carboxyl groups by different methods. Faserforsch Textiltech 18:48 Slavik I, Kucerova M (1969) Time prole of lactone and ester formation in cellulose upon acidication and drying. Faserforsch Textiltech 20:346347 Smook GA (1990) Hornication (keyword). In: Handbook of pulp & paper terminology. Angus Wilde, Vancouver, p 135 Stakheeva-Kaverzneva ED, Salova AS (1951) Chemical changes of cellulose macromolecule under action of oxidizing agents. IV. Lactone links in the macromolecule of oxycellulose and their effect on determination of carbonyl groups by condensation with hydroxylamine. Izvest Akad Nauk SSSR, Otdel Khim Nauk 782790 Stakheeva-Kaverzneva ED, Salova AS (1953). Specic method of determination of carbonyl groups in oxycellulose. Zhur Anal Khim 8:365369 Stone JE, Scallan AM (1966) Inuence of drying on the pore structures of the cell wall. In: Bolam F (ed) Consolidation of the paper web. BPBMA, London, pp 145174 Stone JE, Scallan AM (1968) A structural model for the cell wall of waterswollen wood pulp bres based on their accessability to macromolecules. Cell Chem Technol 2:343358 Stone JE, Scallan AM, Abrahamson B (1968) Inuence of beating on cell wall swelling and internal brillation. Svensk Papperstidn 71:687694 Streitwieser A, Heathcock CH (1989) Introduction to organic chemistry, 3rd edn. Macmillan, New York, p 859 Weise U (1998) Hornicationmechanisms and terminology. Paperi Puu 80:110115 Weise U, Hiltunen LE, Paulapuro H (1998) Verhornung von Zellstoff und Manahmen zu ihrer Reversion. Papier 52:V14V19

493

Weise U, Paulapuro H (1996) The effect of drying and re-wetting cycles on bre swelling. In: Proc fourth European workshop on lignocellulosics and pulp, advances in characterization and processing of wood, non-woody and secondary bres, Stresa, Italy, 811 September 1996, pp 389394 Wilson K (1966) Determination of carboxyl groups in cellulose. Svensk Papperstidn 69:386390 Yasnovsky VM, MacDonald DM (1983) Prevention of hornication of dissolving pulp. US Patent 4,385,172, assigned to International Paper Co

494

You might also like

- Chlorination of Lignin by Ubiquitous Fungi Has A Likely Role in Global Organochlorine ProductionDocument6 pagesChlorination of Lignin by Ubiquitous Fungi Has A Likely Role in Global Organochlorine ProductionCatelia KulmanNo ratings yet

- Ultrasonic NanofibrillationDocument12 pagesUltrasonic NanofibrillationGlen TrinidadNo ratings yet

- 1 s2.0 S0009254115000534 Main PDFDocument8 pages1 s2.0 S0009254115000534 Main PDFMuhanned AljeboryNo ratings yet

- Study of Intermediate Stages in The Kaolin - Metakaolin TransformationDocument10 pagesStudy of Intermediate Stages in The Kaolin - Metakaolin TransformationRalucaNo ratings yet

- stipp and tullis 2006Document19 pagesstipp and tullis 2006maskilj.msgl022003No ratings yet

- Marine sponge morphology adapts to current extremesDocument7 pagesMarine sponge morphology adapts to current extremessurtinaNo ratings yet

- Boenisch 2004 The Dissolution Rates of Natural Glasses As A FunctionDocument16 pagesBoenisch 2004 The Dissolution Rates of Natural Glasses As A FunctionVictor ValdiviaNo ratings yet

- Lyocell ProcessingDocument9 pagesLyocell ProcessingmusmanazeemNo ratings yet

- Buchgraber 2012Document22 pagesBuchgraber 2012Javier E. Guerrero ArrietaNo ratings yet

- Book ReviewsDocument3 pagesBook ReviewsDalka NewsNo ratings yet

- Hubbe 2007 Quimica Del PapelDocument50 pagesHubbe 2007 Quimica Del PapelIvan ValdezNo ratings yet

- Preparation and Properties of Cellulose Nanocrystals: Rods, Spheres, and NetworkDocument8 pagesPreparation and Properties of Cellulose Nanocrystals: Rods, Spheres, and NetworkEndarto YudoNo ratings yet

- CapilaridadDocument23 pagesCapilaridadKatherine Concha ArteagaNo ratings yet

- Yin 2017Document21 pagesYin 2017yonNo ratings yet

- Chapter 8. Reequilibration of Fluid InclusionsDocument20 pagesChapter 8. Reequilibration of Fluid InclusionsGosia CegiełkaNo ratings yet

- Formation of Carbonyl Groups On Cellulose During Ozone Treatment of Pulp - Consequences For Pulp Bleaching - 2014Document7 pagesFormation of Carbonyl Groups On Cellulose During Ozone Treatment of Pulp - Consequences For Pulp Bleaching - 2014Patricia OliveiraNo ratings yet

- Ultra-Rapid Freezing of Water Treatment ResidualsDocument8 pagesUltra-Rapid Freezing of Water Treatment ResidualsRobert Meers DiazNo ratings yet

- Lowered Temperature ResourceDocument18 pagesLowered Temperature ResourceKatherine RamírezNo ratings yet

- 20061-Article Text-29197-1-10-20130804 PDFDocument5 pages20061-Article Text-29197-1-10-20130804 PDFMILEN ANGELIE MEDALLANo ratings yet

- Long Termn DryingDocument5 pagesLong Termn DryingÁngel GascaNo ratings yet

- Fiber Saturation OcrDocument4 pagesFiber Saturation OcrPrameshwar SutharNo ratings yet

- Veksler, I.V., Dorfman, A.M., Borisov, A.A., Wirth, R., and Dingwell, D.B., 2007. Liquid Immiscibility and The Evolution of Basaltic Magmas.Document24 pagesVeksler, I.V., Dorfman, A.M., Borisov, A.A., Wirth, R., and Dingwell, D.B., 2007. Liquid Immiscibility and The Evolution of Basaltic Magmas.Rorisang MalebyeNo ratings yet

- Lamellar Precipitation of The Influence of The Plastic Deformation in The Ni-1, 4 At. % in AlloyDocument7 pagesLamellar Precipitation of The Influence of The Plastic Deformation in The Ni-1, 4 At. % in AlloymokhtarNo ratings yet

- EnvironmentDocument9 pagesEnvironmentapi-264154540No ratings yet

- Decomp of Buried Corpses-Formation of Adipocere PDFDocument10 pagesDecomp of Buried Corpses-Formation of Adipocere PDFAlvaro RiquelmeNo ratings yet

- K. E. Peach (2017)Document16 pagesK. E. Peach (2017)Carolina SalvadorNo ratings yet

- Carbon and Oxygen Isotope Dendrochronology inDocument16 pagesCarbon and Oxygen Isotope Dendrochronology in7balasNo ratings yet

- YD FungusDocument16 pagesYD FunguskenwineesqNo ratings yet

- Comparing Colloidal Pitch Adsorption On Different Talcs Guera - 2005Document8 pagesComparing Colloidal Pitch Adsorption On Different Talcs Guera - 2005Thalisia SilvaNo ratings yet

- Oxygen and oil barrier properties of microfibrillated cellulose films and coatingsDocument16 pagesOxygen and oil barrier properties of microfibrillated cellulose films and coatingsmartina.cirronis96No ratings yet

- Some Ways To Decrease Fibre Suspension Occulation and Improve Sheet FormationDocument9 pagesSome Ways To Decrease Fibre Suspension Occulation and Improve Sheet FormationCarlos Alberto Avendaño RestrepoNo ratings yet

- Bo TinopalDocument8 pagesBo TinopalPablo LopezNo ratings yet

- Clay Water SystemDocument6 pagesClay Water SystemAnil RawatNo ratings yet

- Cellulose Nanofibres by sonocatalysed-TEMPO-oxidationDocument9 pagesCellulose Nanofibres by sonocatalysed-TEMPO-oxidationdhy182No ratings yet

- YangDocument11 pagesYangFoopiewNo ratings yet

- Pani Ps LatexesDocument10 pagesPani Ps LatexesHonorato Maria B. AnaNo ratings yet

- Alonso Pineda 2006Document46 pagesAlonso Pineda 2006riki pahleviNo ratings yet

- Flory 1958Document10 pagesFlory 1958Santiago ZapataNo ratings yet

- Water Sorption in Wood Cell Walls - Data ExploratiDocument16 pagesWater Sorption in Wood Cell Walls - Data ExploratiMateuszNo ratings yet

- Limnology Oceanography: MethodsDocument11 pagesLimnology Oceanography: MethodsUsman AliNo ratings yet

- Clement Etim EkongDocument6 pagesClement Etim EkongOkey NwaforNo ratings yet

- Wood Charcoal Analysis in Archaeology: Ceren KabukcuDocument22 pagesWood Charcoal Analysis in Archaeology: Ceren KabukcuMahletmelakuNo ratings yet

- Consolidation of Wood With ResinsDocument14 pagesConsolidation of Wood With ResinsMaja SMNo ratings yet

- Responses of Foliar 13C Gas Exchange and Leaf Morp PDFDocument9 pagesResponses of Foliar 13C Gas Exchange and Leaf Morp PDFYulo AugustoNo ratings yet

- Kinetics of Dehydration of CA-montmorilloniteDocument10 pagesKinetics of Dehydration of CA-montmorilloniteHidup TertibNo ratings yet

- Contaminant release from aged microplasticsDocument12 pagesContaminant release from aged microplasticsJavier AlcodoriNo ratings yet

- The Enhanced Flotation of Coal by Nanosilica ParticlesDocument14 pagesThe Enhanced Flotation of Coal by Nanosilica ParticlesKumarNo ratings yet

- 9 Foaming in Non-Aqueous LiquidsDocument24 pages9 Foaming in Non-Aqueous LiquidspadungekNo ratings yet

- Independent control of dual-frother systems for flotation process optimizationDocument11 pagesIndependent control of dual-frother systems for flotation process optimizationJose Luis Barrientos RiosNo ratings yet

- The Morphological Changes Produced in During Pickling, and Their Relationship ParametersDocument17 pagesThe Morphological Changes Produced in During Pickling, and Their Relationship Parametersrocanrol2No ratings yet

- Ioncell-F: A High-Strength Regenerated Cellulose FibreDocument15 pagesIoncell-F: A High-Strength Regenerated Cellulose FibreLarisse BatalhaNo ratings yet

- Kapur and Fuerstenau, 1967Document5 pagesKapur and Fuerstenau, 1967stevenNo ratings yet

- 1 s2.0 S0277379104000150 Main PDFDocument31 pages1 s2.0 S0277379104000150 Main PDFtoots sifrutiNo ratings yet

- New Directions in Black Carbon Organic Geochemistry: C.A. MasielloDocument13 pagesNew Directions in Black Carbon Organic Geochemistry: C.A. MasielloSardar SaleemNo ratings yet

- 2009 Fouling 2Document10 pages2009 Fouling 2mitsuboshi702No ratings yet

- Are Productivity and Stratification Important To SapropelDocument13 pagesAre Productivity and Stratification Important To SapropelJuan Carlos Caicedo AndradeNo ratings yet

- Excel4 PDFDocument32 pagesExcel4 PDFSteph PamungkasNo ratings yet

- Design Review of Absorbers Used For Gaseous Pollutants RemovalDocument1 pageDesign Review of Absorbers Used For Gaseous Pollutants RemovallyoufNo ratings yet

- Presentation Domsjö FabrikerDocument20 pagesPresentation Domsjö FabrikerlyoufNo ratings yet

- Wood Chips Quality.Document10 pagesWood Chips Quality.lyoufNo ratings yet

- Six Thinking Hats PDFDocument3 pagesSix Thinking Hats PDFlyoufNo ratings yet

- Domsjö Cellulose - Makes A Difference (Broschyr 2012)Document6 pagesDomsjö Cellulose - Makes A Difference (Broschyr 2012)lyoufNo ratings yet

- Packing FactorDocument80 pagesPacking FactorRabya Sana100% (1)

- Lecture 11 - Property-Based Aspects of Regenerated Fibres PDFDocument63 pagesLecture 11 - Property-Based Aspects of Regenerated Fibres PDFlyoufNo ratings yet

- Sappi Brochure Specialities NEW enDocument47 pagesSappi Brochure Specialities NEW enlyoufNo ratings yet

- Textilelearner - Blogspot.ca-Rayon Fiber Characteristics of Rayon Fiber Manufacturing Process of Viscose Rayon End Uses of RayoDocument4 pagesTextilelearner - Blogspot.ca-Rayon Fiber Characteristics of Rayon Fiber Manufacturing Process of Viscose Rayon End Uses of Rayolyouf100% (1)

- Chemical Kinetics Lab: The Formaldehyde Clock ReactionDocument15 pagesChemical Kinetics Lab: The Formaldehyde Clock ReactionlyoufNo ratings yet

- Fibre to Fabric: Textile Processing StepsDocument9 pagesFibre to Fabric: Textile Processing Stepsjack_hero_56100% (2)

- Memory Quality PQMJ-1995 PDFDocument90 pagesMemory Quality PQMJ-1995 PDFVasquez Angel MiguelNo ratings yet

- Quality Control Flow ChartDocument3 pagesQuality Control Flow Chartlyouf0% (1)

- Corrosion Prevention During Acid Cleaning of Pulping EquipmentDocument22 pagesCorrosion Prevention During Acid Cleaning of Pulping EquipmentlyoufNo ratings yet

- Topic 2.4 - Momentum and ImpulseDocument38 pagesTopic 2.4 - Momentum and ImpulseKhánh NguyễnNo ratings yet

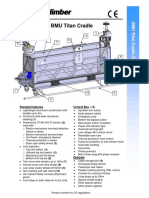

- BMU Titan Cradle: Standard Features Control BoxDocument2 pagesBMU Titan Cradle: Standard Features Control BoxKashyapNo ratings yet

- 2006, Piela Et Al, JECS, ImpedanceDocument13 pages2006, Piela Et Al, JECS, ImpedanceKaustubhNo ratings yet

- r2 Hy-Optima 720as-Gc Technical Data SheetDocument1 pager2 Hy-Optima 720as-Gc Technical Data SheetMohammed SaberNo ratings yet

- Hazardous Areas: European & IEC Classification Definition of Zone or Division North American ClassificationDocument3 pagesHazardous Areas: European & IEC Classification Definition of Zone or Division North American Classificationmuddisetty umamaheswarNo ratings yet

- ABB String Inverters: PVS-50/60-TLDocument4 pagesABB String Inverters: PVS-50/60-TLBianca OlaruNo ratings yet

- Dynamis MaxxDocument14 pagesDynamis MaxxJas SumNo ratings yet

- Project: Layyah Combined Cycle Power Plant: Sub Station: Equipment: Panel Type Bay Ref: DateDocument3 pagesProject: Layyah Combined Cycle Power Plant: Sub Station: Equipment: Panel Type Bay Ref: DatesamlashNo ratings yet

- 11th Five Year Plan 2007-12, India, Agriculture, Rural Development, and IndustryDocument537 pages11th Five Year Plan 2007-12, India, Agriculture, Rural Development, and IndustryDeepak Pareek100% (6)

- Documents - MX - Absorption Exercises Treybal PDFDocument6 pagesDocuments - MX - Absorption Exercises Treybal PDFJvson Vens Sance100% (1)

- BIOGAS 5000 Operating ManualDocument107 pagesBIOGAS 5000 Operating ManualmjsampaioNo ratings yet

- Plumbing Systems For BuildingsDocument62 pagesPlumbing Systems For BuildingsDileep Kumar100% (1)

- Straight Differential Expansion - DMXDocument4 pagesStraight Differential Expansion - DMXJurun_BidanshiNo ratings yet

- Physics Chap 3 F5 !!!!!!!!!!!Document46 pagesPhysics Chap 3 F5 !!!!!!!!!!!Ethan Dharshen100% (1)

- CAT079 SwitchDocument232 pagesCAT079 SwitchDan688100% (1)

- Spe 131758 Ms - GL and EspDocument11 pagesSpe 131758 Ms - GL and EspSamuel VmNo ratings yet

- Removable Francis Turbine SealsDocument4 pagesRemovable Francis Turbine SealsmachevelNo ratings yet

- STSMDocument278 pagesSTSMMiguel Ruiz TatajeNo ratings yet

- Saacke Steam Pressure Atomizer PDFDocument2 pagesSaacke Steam Pressure Atomizer PDFKhaled SaadnehNo ratings yet

- Exer 2 - PH and BuffersDocument4 pagesExer 2 - PH and BuffersAsi JenNo ratings yet

- Overview of The Kuraymat Solar Power Plant enDocument4 pagesOverview of The Kuraymat Solar Power Plant enKhaled TahaNo ratings yet

- AQA QMS Pvt. LTD.: S No Company Name Membership NoDocument11 pagesAQA QMS Pvt. LTD.: S No Company Name Membership NoDevasyrucNo ratings yet

- 1.ENERGY SCENARIO-merged PDFDocument188 pages1.ENERGY SCENARIO-merged PDFraj walkeNo ratings yet

- LP2014Document56 pagesLP2014Rodrigo Navarra JrNo ratings yet

- Lista Precios Ahu Mas Accesorios Sinclair 2020Document80 pagesLista Precios Ahu Mas Accesorios Sinclair 2020Jonathan ArboledaNo ratings yet

- Q3 Module 2A - Nature of Solids and Phase Changes 1Document34 pagesQ3 Module 2A - Nature of Solids and Phase Changes 1Rance BobadillaNo ratings yet

- Waterwell Catalog WebDocument96 pagesWaterwell Catalog WebJuan Carlos Sequeira RoblesNo ratings yet

- PAES 233: Multicrop Washer-Peeler StandardDocument16 pagesPAES 233: Multicrop Washer-Peeler StandardFaroukNo ratings yet

- Effinet Service Manual1Document63 pagesEffinet Service Manual1Willian Santiago CardenasNo ratings yet

- Equity Research Report On Bajaj Finserv LTD Authored By: Mohammad Reza PoyaDocument6 pagesEquity Research Report On Bajaj Finserv LTD Authored By: Mohammad Reza Poyashraddha anandNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Guidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisFrom EverandGuidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisNo ratings yet

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Guidelines for Developing Quantitative Safety Risk CriteriaFrom EverandGuidelines for Developing Quantitative Safety Risk CriteriaNo ratings yet

- Guidelines for Siting and Layout of FacilitiesFrom EverandGuidelines for Siting and Layout of FacilitiesNo ratings yet

- Perfume Engineering: Design, Performance and ClassificationFrom EverandPerfume Engineering: Design, Performance and ClassificationRating: 4 out of 5 stars4/5 (5)

- Guidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsFrom EverandGuidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsNo ratings yet

- Bow Ties in Risk Management: A Concept Book for Process SafetyFrom EverandBow Ties in Risk Management: A Concept Book for Process SafetyNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Robotics: Designing the Mechanisms for Automated MachineryFrom EverandRobotics: Designing the Mechanisms for Automated MachineryRating: 4.5 out of 5 stars4.5/5 (8)

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesFrom EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNo ratings yet

- Recognizing and Responding to Normalization of DevianceFrom EverandRecognizing and Responding to Normalization of DevianceNo ratings yet

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet