Professional Documents

Culture Documents

Total Head Calculation of Pipe Line and Pump Station

Uploaded by

thakur_raghabOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Total Head Calculation of Pipe Line and Pump Station

Uploaded by

thakur_raghabCopyright:

Available Formats

TOTAL HEAD CALCULATION OF FORCE MAIN AND PUMP STATION

Basic data TDH= Total discharge head hs = Static head hf f L D V g T e = head loss (m) = friction factor = length of pipe work (m) = inner diameter of pipe work (m) = velocity of fluid (m/s) = acceleration due to gravity (m/s) = Temperature (25) = Kinematic Viscosity = Pipe roughness .

Qt = Flow q = Flow for pump (0.105) m3/s.

Pipe material ( grp) Number of pumps 3(2+1 )

The loss due to friction in pipe flow systems can be calculated with the DarcyWeisbach equation hf = f ( L/D) (v^2/2g) Friction factor is being calculated following the value of Reynolds number: if Re<2000 (Laminar flow), then f=64 / Re

if RE>4000 (Turbulent flow), then as per Colebrook equation 1/f = 2log ( e/3.7(D) ) +( 2.51/Ref ) For Re >10^4 and r between 10^-5 & .04 Then modified woodsequation for colebrook is: f = a + bRe^-c

Where a = (0.094 r^0.225 ) +(0.53 r ) b = 88 r^0.44 c = 1.62 r^0.134 r = e /D e = 0.03 mm ( grp ) Re = VD/ hf = k V^2/2g V = Q/ D^2/4 = 0.210 /3.14 (0.5/2)^2 = 1.07 m/s CALCULATE REYNOLD NUMBER Re = VD/ Where D = 0.5 m V = 1.07 m = 10^-6 m^2/s

Reynolds number Head loss in fittings Velocity inside pipe

Re = 1.07 0.5 / 0.897 10^-6 = 5.96 10^5 > 10^4 CALCULATE FRICTION FACTOR Used woods equation for Colebrook a b c r 0.0106 1.22 0.44 0.00006 (f) f = a + bRe^-c

f = 0.0106 +1.22( 5.9610^5)^-0.44 f = 0.014

A Calculate pump station losses

where L V D g 20 m 1.07 m/s 0.5 m 9.81m2/s

Used Darcy equation hf = f ( L/D) (v^2/2g) = 0.014 (20/0.5 (1.07)^2/19.62 = 0.032 m

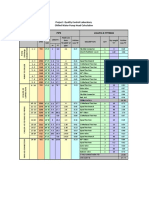

B - Losses due to fitting inside pump station Fitting In let Tee 500/300 Buterfly Valve check valve Reducer Flow meter K value 1 1.3 0.3 2.3 0.2 5 total Therefore, Losses = K*v2/2g = 16.2 * (1.07 )2 / 2(9.81) = 0.94 m qty 2 2 4 2 4 1 K*qty 2.0 2.6 1.2 4.6 0.8 5.0 16.2

C- head loss in pipe line

Used DARCY Equation Head losses Q D L V = = = = = f (L/D) (v^2/2g) 0.210 m/sec 0.5 m 24150 m 1.07m/sec

= 0.014 (24150/0.5) (1.07^2/2g) = 39.45 m (ok)

CHIK BY Hazen Williams equation

V S c (1.07) S Losses in pipe

= 0.355 * C * D^0.63 * S^0.54 = friction coefficient =150 ( GRP)

Hazen-Williams

= 0.335 * 150 * (0.5)^0.63 * S^0.54 = 1.618m/km = 1.618 * 24150 = 39.07 m choose above

D - losses due to fitting

Fitting outflow Elbow45 Elbow90 Elbow22.5 Tee 90 turn Butterfly valve on line tee

K value 1 0.19 0.33 0.11 1.8 o.3 0.2 Total

qty 1 6 2 4 1 8 48

K*qty 1.00 1.14 0.66 0.44 1.80 2.40 9.60 17.04

Therefore, losses = K*v2/2g = 17.04 * (1.07)^2 / 2(9.81) = 0.99 m

total loss hf = A+B+C+D = 0.032 + 0.96 + 39.45 +0.99 = 41.43 m 10% Safety factor on the total friction loss 4.14 m

Net total friction loss hf = 45.57m

Total static head Height between the lowest point when inlet-and- tank top level of the tank out.( hs) hs = 54.34m Total discharge head ( TDH ) = hs + hf = 54.34 + 45.57 = 99.91 m Required discharge head of the pump 100.0 m

SELECTED PUMP CAPCITY IS ( 105 L/S) at 110 m DISCHARGE HEAD

You might also like

- Equilibrium Vapor-Liquid CalculationsDocument8 pagesEquilibrium Vapor-Liquid Calculationsdhea novitaNo ratings yet

- Cooling Tower ComparisonDocument4 pagesCooling Tower ComparisonKiran DasNo ratings yet

- Cooling Tower Calc Efficiency Under 40Document4 pagesCooling Tower Calc Efficiency Under 40Maman HakimNo ratings yet

- Design of Heat ExchangersDocument23 pagesDesign of Heat ExchangersKhalid Turki100% (2)

- 4.4 Heat Ex ChangersDocument7 pages4.4 Heat Ex Changersmukesh kaushikNo ratings yet

- Calculation Sheet For Make - Up Water Tank: #Value!Document4 pagesCalculation Sheet For Make - Up Water Tank: #Value!thanh_79No ratings yet

- Boiler Feed Water Treatment & BlowdownDocument6 pagesBoiler Feed Water Treatment & BlowdownnurulNo ratings yet

- Line Sizing GuidelinesDocument2 pagesLine Sizing GuidelinesHarryBouterNo ratings yet

- Yazd-System Description For Clean Drain System PDFDocument7 pagesYazd-System Description For Clean Drain System PDFace-winnieNo ratings yet

- Pump Sizing Formulas and Calculations GuideDocument3 pagesPump Sizing Formulas and Calculations GuideKehinde AdebayoNo ratings yet

- Design Calculation Sheet: Chilled Water Secondary PumpsDocument2 pagesDesign Calculation Sheet: Chilled Water Secondary PumpsgerrydimayugaNo ratings yet

- Student Surname: Student Name: Student IDDocument6 pagesStudent Surname: Student Name: Student IDKumail Al KhuraidahNo ratings yet

- CBE 417 FlashDrumSizing WankatDocument7 pagesCBE 417 FlashDrumSizing WankatRahmansyah GaekNo ratings yet

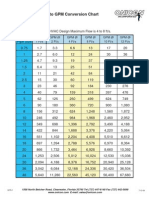

- Flow Velocity (FT/S) To GPM Conversion ChartDocument1 pageFlow Velocity (FT/S) To GPM Conversion Chartmonaco59No ratings yet

- Pump SizingDocument3 pagesPump Sizingtimayaa1000No ratings yet

- CONDENSATE DE-SUPERHEATING CALCULATIONSDocument8 pagesCONDENSATE DE-SUPERHEATING CALCULATIONSMechanicalVee18No ratings yet

- Chilled Water Pump Head CalculationDocument18 pagesChilled Water Pump Head CalculationPeshoMagdyNo ratings yet

- Mollie ChartDocument15 pagesMollie ChartKriz EarnestNo ratings yet

- Transfer Pump-2Document21 pagesTransfer Pump-2sunii19847908100% (1)

- Condenser & EvaporatorDocument21 pagesCondenser & EvaporatorfitratulqadriNo ratings yet

- CALCULATION OF PUMP HEAD AND POWER REQUIREDDocument2 pagesCALCULATION OF PUMP HEAD AND POWER REQUIREDlutfi awn100% (1)

- Plate Type Wet ScrubberDocument6 pagesPlate Type Wet ScrubberRoger IsidoreNo ratings yet

- Losses in Pipe BendsDocument5 pagesLosses in Pipe BendsLove KumarNo ratings yet

- Fgas Refrigerant CalculatorDocument10 pagesFgas Refrigerant CalculatorKumar sssssNo ratings yet

- FAD CALCULATION FOR AIR DELIVERYDocument4 pagesFAD CALCULATION FOR AIR DELIVERYAnonymous JZK84WzfKNo ratings yet

- PUMP CALCULATION SHEETDocument4 pagesPUMP CALCULATION SHEETMuhammad BilalNo ratings yet

- D. Design Load D.1. Loading DataDocument14 pagesD. Design Load D.1. Loading DataEdNo ratings yet

- @S V All FansDocument19 pages@S V All Fanshasanadel88No ratings yet

- Hybrid Cooling TowerDocument12 pagesHybrid Cooling TowerANIMESH JAINNo ratings yet

- Pressuredrop Calculations by Kern Method SRRDocument18 pagesPressuredrop Calculations by Kern Method SRRrajeev50588No ratings yet

- 12-Design Fundamentals of BoilerDocument12 pages12-Design Fundamentals of BoilerVishalVaishNo ratings yet

- Aeroduct Program (Duct Sizing) : Characteristics and Functions of The ProgramDocument4 pagesAeroduct Program (Duct Sizing) : Characteristics and Functions of The ProgramAshraf KamalNo ratings yet

- Single Effect Evaporation (SEE) ProcessesDocument28 pagesSingle Effect Evaporation (SEE) ProcessesAl- Dhaheri0% (1)

- EIND 3184 15 Liquid Flash Vessel SizingDocument20 pagesEIND 3184 15 Liquid Flash Vessel SizingzamijakaNo ratings yet

- PRESSURE DROP CALCULATION FOR DRILL WATER PIPEDocument9 pagesPRESSURE DROP CALCULATION FOR DRILL WATER PIPEdasubhaiNo ratings yet

- Orifice, Nozzle and Venturi Flow Rate Meters: Water & Air FlowmetersDocument4 pagesOrifice, Nozzle and Venturi Flow Rate Meters: Water & Air Flowmeterssiva_nagesh_2No ratings yet

- Energy BalanceDocument11 pagesEnergy BalanceBharat VaajNo ratings yet

- Pressure Drop CalculationDocument6 pagesPressure Drop CalculationNaveen Pete100% (1)

- Heat ExchangerDocument53 pagesHeat ExchangerNurulHidayahNo ratings yet

- Design of A Vapor-Liquid SeparatorDocument2 pagesDesign of A Vapor-Liquid SeparatorpowerveeNo ratings yet

- 13-391 Strainers Datasheet - GrottoDocument3 pages13-391 Strainers Datasheet - GrottoAniket GaikwadNo ratings yet

- Thermal vapor-compression system design and performance analysisDocument8 pagesThermal vapor-compression system design and performance analysisBagus HutomoNo ratings yet

- Potable Water Pumps: Lamah EstDocument18 pagesPotable Water Pumps: Lamah Estفتحى أحمدNo ratings yet

- Hd-54 Single Stage Air CompressorDocument8 pagesHd-54 Single Stage Air CompressorErGiteshAroraNo ratings yet

- Clarifier hopper volume and HRT calculationsDocument1 pageClarifier hopper volume and HRT calculationsHemantk8731100% (1)

- MODEL: PFTA 1500-4: Ratings & Performance DataDocument4 pagesMODEL: PFTA 1500-4: Ratings & Performance DataAnonymous izGbhcNo ratings yet

- Lecture 04c - Shortcut Exchanger Design ProcedureDocument47 pagesLecture 04c - Shortcut Exchanger Design Proceduresds0% (1)

- Heat HXerDocument2 pagesHeat HXerGade JyNo ratings yet

- Plate Heat Exchanger DesignDocument1 pagePlate Heat Exchanger Designrick_owen82001No ratings yet

- All HVAC CalculationDocument52 pagesAll HVAC CalculationSlam HassanNo ratings yet

- EmersonDocument21 pagesEmersoncrustytheclown99No ratings yet

- WLTSR (Lvl-04) Tower C - (25.07.2015)Document1 pageWLTSR (Lvl-04) Tower C - (25.07.2015)Syed Shahbaz100% (1)

- HW10 SolutionDocument9 pagesHW10 SolutionMuath AlShehriNo ratings yet

- Static Regain Method NEWDocument6 pagesStatic Regain Method NEWMarzookNo ratings yet

- Chlorine_Design-2520of-2520EquipmentsDocument23 pagesChlorine_Design-2520of-2520EquipmentsAditya KumarNo ratings yet

- Divinylbenzene Equipment DesignDocument20 pagesDivinylbenzene Equipment DesignMehul DeshpandeNo ratings yet

- HYDRAULIC DESIGN OF DELIVERY CISTERN (Designing Cistern As A Vertical Drop)Document14 pagesHYDRAULIC DESIGN OF DELIVERY CISTERN (Designing Cistern As A Vertical Drop)p_ignatiusNo ratings yet

- Rotary Drier DesignDocument29 pagesRotary Drier DesignDharamvir Singh80% (5)

- Line Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Document12 pagesLine Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Engr TheyjiNo ratings yet

- Acetic 2520acid 2520 - Design 2520of 2520equipments PDFDocument41 pagesAcetic 2520acid 2520 - Design 2520of 2520equipments PDFTanuj HandaNo ratings yet

- PEF 2309 Fundamentos de Mecânica Das Estruturas Timoshenko, S.P.,PWS Publishing Company, 1997, Boston, USA, p.408-410, 580-583. Example 8-4Document6 pagesPEF 2309 Fundamentos de Mecânica Das Estruturas Timoshenko, S.P.,PWS Publishing Company, 1997, Boston, USA, p.408-410, 580-583. Example 8-4Jc FortNo ratings yet

- Lab 3 Impact of Jets Virtual Lab F2020 v2Document5 pagesLab 3 Impact of Jets Virtual Lab F2020 v2mabdoljavadiNo ratings yet

- EN DS SG33CX SG40CX SG50CX Datasheet V153 20200723Document2 pagesEN DS SG33CX SG40CX SG50CX Datasheet V153 20200723Alcides Araujo SantosNo ratings yet

- Optimizing With eGaN FETsDocument6 pagesOptimizing With eGaN FETskhsniperNo ratings yet

- Syncrosnap® Centrifugal Switches For Single-Phase Electric MotorsDocument4 pagesSyncrosnap® Centrifugal Switches For Single-Phase Electric MotorsMohit GargNo ratings yet

- MAGNETIC PISTON ENGINEDocument7 pagesMAGNETIC PISTON ENGINERahul YadavNo ratings yet

- A Novel Equivalent Circuit For Eshaped Slot Patch Antenna PDFDocument4 pagesA Novel Equivalent Circuit For Eshaped Slot Patch Antenna PDFbhawnaNo ratings yet

- LEARNING GUIDE 02 AC DC RectifierDocument27 pagesLEARNING GUIDE 02 AC DC Rectifiermeseret sisayNo ratings yet

- Forces and Motion - FrictionDocument7 pagesForces and Motion - FrictionwgwerfweNo ratings yet

- Lecture 4: RL Circuits. Inductive Kick. Diode Snubbers.: Filters ChokesDocument6 pagesLecture 4: RL Circuits. Inductive Kick. Diode Snubbers.: Filters ChokesIman AkbariNo ratings yet

- AGL 50-OMKAR Controller Parameters - Rev 0Document2 pagesAGL 50-OMKAR Controller Parameters - Rev 0mozhi selvam100% (1)

- EasyLogic PM1000 Series - METSEDM6000Document2 pagesEasyLogic PM1000 Series - METSEDM6000materiales OsunNo ratings yet

- Behaviour of Bolts in Tee Connections Subject To Prying ForceDocument164 pagesBehaviour of Bolts in Tee Connections Subject To Prying ForceVivek PandeyNo ratings yet

- Electric Circuits and Forces Between ChargesDocument2 pagesElectric Circuits and Forces Between Charges1149 Vanshika BNo ratings yet

- Stress On Foundations: Motor Serie: MGL 200 SDocument2 pagesStress On Foundations: Motor Serie: MGL 200 SDavy MarceloNo ratings yet

- Sound Acoustics One PagerDocument3 pagesSound Acoustics One PagerGreyBlackNo ratings yet

- Switches PDFDocument106 pagesSwitches PDFYasin ElaswadNo ratings yet

- Physics 20 Unit C: Energy, Work and Circular MotionDocument1 pagePhysics 20 Unit C: Energy, Work and Circular MotionUnzal FatehullahNo ratings yet

- 1.1.1.4 Worksheet - Ohms LawDocument1 page1.1.1.4 Worksheet - Ohms LawPirate Spice100% (2)

- AP Physics 1 06SimpleHarmonicMotionFRQ Quiz1 Key PDFDocument51 pagesAP Physics 1 06SimpleHarmonicMotionFRQ Quiz1 Key PDF백강민No ratings yet

- Blooms Taxonomy Question Stems and Activities For ScienceDocument9 pagesBlooms Taxonomy Question Stems and Activities For ScienceLuis Alberto Mejía García100% (1)

- DC Machine Dimensions and TypesDocument13 pagesDC Machine Dimensions and TypesShang Divina Ebrada100% (1)

- Graph Shows Acceleration of a Single Degree of Freedom SystemDocument2 pagesGraph Shows Acceleration of a Single Degree of Freedom SystemjajajajNo ratings yet

- Eddy Current DrivesDocument36 pagesEddy Current DrivesBenedict EromoseleNo ratings yet

- 2000 Astm E1316-00 PDFDocument38 pages2000 Astm E1316-00 PDFEidertxuNo ratings yet

- Moduł Igbt Mig30j103h Toshiba DatasheetDocument16 pagesModuł Igbt Mig30j103h Toshiba DatasheetAnti-cosmoNo ratings yet

- Tesla Patent,,,,Rotating Magnetic Field Using... Und A Ferrite Toroid1Document5 pagesTesla Patent,,,,Rotating Magnetic Field Using... Und A Ferrite Toroid1anakedya13No ratings yet

- Physics Notes PDF For Class 9Document3 pagesPhysics Notes PDF For Class 9Mithilesh Kr Prem100% (1)

- Exc Cat #20 312Document2 pagesExc Cat #20 312Washington Santamaria100% (1)

- Resonant Induction Heater PDFDocument225 pagesResonant Induction Heater PDFBoodyBedaiweNo ratings yet