Professional Documents

Culture Documents

Machine Capability

Uploaded by

Anurag SrivastavaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Machine Capability

Uploaded by

Anurag SrivastavaCopyright:

Available Formats

Machine capability Machine capability is measured in Cm and Cmk; it is a snapshot picture that shows how well a machine is performing

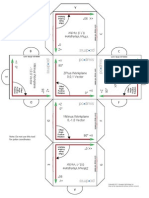

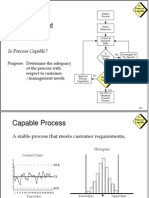

right now in relation to the tolerance limits. When measuring machine capability you must not alter measurements or change tools, materials, operators or measurement methods, stop the machine, etc. In other words: Out of the six factors, only machine and measurement are allowed to affect the result. Cm (capability machine) The Cm index describes machine capability; it is the number of times the spread of the machine fits into the tolerance width. The higher the value of Cm, the better the machine. Example: if Cm = 2.5, the spread fits 2 times into the tolerance width, while Cm = 1 means that the spread is equal to the tolerance width. Note that even if the spread is off-centre, it is still the same size (Cm index). The figure takes no account of where the spread is positioned in relation to the upper and lower tolerance limits, but simply expresses the relation ship between the width of the spread and the tolerance width (see Fig. 1). The six factors These are the factors that are generally regarded as causing variation in capability measurements: Machine (e.g. degree of wear and choice of tooling); Measurement (e.g. resolution and spread of measuring instrument); Operator (e.g. how experienced and careful he/she is); Material (e.g. variations in surface smoothness and hardness); Environment (e.g. variations in temperature, humidity and voltage); Method (e.g. type of machining operation). Cmk (capability machine index) If you also want to study the position of the machines capability in relation to the tolerance limits, you use the Cmk index, which describes the capability corrected for position. It is not much use having a high Cm index if the machine setting is way off centre in relation to the middle of the tolerance range. A high Cmk index means, then, that you have a good machine with a small spread in relation to the tolerance width, and also that it is well centred within that width. If Cmk is equal to Cm, the machine is set to produce exactly in the middle of the tolerance range (see Fig. 2). A normal requirement is that Cmk should be at least 1.67. Machine capability Cm and Cmk Machine & measurement Not to be included Not to be included 2050 in succession Short Process capability Cp and Cpk All six factors Included Included 50250 Long

Index Factors influencing result Stoppages Adjustments No. of components Time

You might also like

- CP, CPK, CM, CMK, Control LimitsDocument5 pagesCP, CPK, CM, CMK, Control LimitsMaitreyee GoswamiNo ratings yet

- Statistical Process Control ChartsDocument40 pagesStatistical Process Control ChartsTalha Imran100% (1)

- 6.4 Process CapabilityDocument13 pages6.4 Process CapabilitychuszNo ratings yet

- MSA WorksheetDocument29 pagesMSA Worksheetmohammad wasimNo ratings yet

- Meet Customer Requirements with Process CapabilityDocument30 pagesMeet Customer Requirements with Process CapabilityAniket Jain100% (1)

- Six Sigma LEANDocument7 pagesSix Sigma LEANAkshita MuskanNo ratings yet

- Process Capability AnalysisDocument37 pagesProcess Capability Analysisabishank09100% (1)

- Advanced Tecniques SPCDocument71 pagesAdvanced Tecniques SPCIvan Bolivar Barraza100% (1)

- MSA & Destructive TestDocument4 pagesMSA & Destructive Testanon_902607157100% (1)

- Statistical Process ControlDocument79 pagesStatistical Process ControlKrunal PandyaNo ratings yet

- SPC Chart BlankDocument1 pageSPC Chart BlankbowlinglmNo ratings yet

- 8 Run DOE TemplateDocument10 pages8 Run DOE Templatesumitjain2No ratings yet

- Msa 4th Edition ChangesDocument3 pagesMsa 4th Edition ChangesNasa00No ratings yet

- Measurement Systems Analysis: Total Quality ManagementDocument17 pagesMeasurement Systems Analysis: Total Quality Managementtlatuani1000No ratings yet

- Attribute Gauge R&RDocument5 pagesAttribute Gauge R&Rhel2905No ratings yet

- MsaDocument25 pagesMsaMonu SharmaNo ratings yet

- 8D Problem SolvingDocument14 pages8D Problem SolvingHiệp Hài HướcNo ratings yet

- Process and Measurement System Capability AnalysisDocument18 pagesProcess and Measurement System Capability AnalysisUtkarsh MittalNo ratings yet

- Statistical Process ControlDocument43 pagesStatistical Process ControlninaswayNo ratings yet

- 13-Process Capability TrainingDocument43 pages13-Process Capability TrainingMansoor Ali100% (1)

- The Process Capability AnalysisDocument18 pagesThe Process Capability AnalysisMohamed HamdyNo ratings yet

- IOE 466 W08: Gage and Measurement System AnalysisDocument29 pagesIOE 466 W08: Gage and Measurement System AnalysisobvertNo ratings yet

- Xyzcube PC DmisDocument1 pageXyzcube PC DmisEdgar IvanNo ratings yet

- Process Capability and Capability Index ExplainedDocument18 pagesProcess Capability and Capability Index ExplainedBhavesh Rana100% (1)

- Gage R&RDocument1 pageGage R&Rshobhit2310No ratings yet

- Aql Plan Zero DefectDocument2 pagesAql Plan Zero DefectFarrukh JamilNo ratings yet

- PPAP Manual Supplier QualityDocument51 pagesPPAP Manual Supplier QualityGuru PrasadNo ratings yet

- Statistical Process Control FundamentalsDocument32 pagesStatistical Process Control FundamentalsEd100% (1)

- DOE Design & Analysis Using MinitabDocument48 pagesDOE Design & Analysis Using MinitabLibyaFlowerNo ratings yet

- Gage Linearity Bias StudyDocument3 pagesGage Linearity Bias StudyJuan Pablo Rebolledo VNo ratings yet

- Process Capability Analysis ExplainedDocument14 pagesProcess Capability Analysis ExplainedSachin ModgilNo ratings yet

- MSA - Dial Vernier Calipers - ExampleDocument1 pageMSA - Dial Vernier Calipers - ExampleSachin Ramdurg100% (3)

- 8d's y 5 Por Que de NissanDocument8 pages8d's y 5 Por Que de NissanSergio RuizNo ratings yet

- MSA StudyDocument22 pagesMSA StudyNarayanKavitakeNo ratings yet

- SPC SpreadsheetDocument8 pagesSPC Spreadsheetikesh mNo ratings yet

- Measurement System AnalysisDocument29 pagesMeasurement System AnalysissidwalNo ratings yet

- 7 QC Tools: Q7T/PPT-1Document118 pages7 QC Tools: Q7T/PPT-1Amit Kumar SinghNo ratings yet

- Basics of CapabilityDocument18 pagesBasics of Capabilitymancheung6429No ratings yet

- Control PlanDocument2 pagesControl PlanJames YenchoNo ratings yet

- Gage RR Variable Data Graphical 1analysisDocument13 pagesGage RR Variable Data Graphical 1analysisdipak5939No ratings yet

- Statistical Process Control Chart V1.03vikasDocument5 pagesStatistical Process Control Chart V1.03vikasVandana Mehra100% (1)

- Template Format Gauge R & RDocument5 pagesTemplate Format Gauge R & RQC-Metinca Prima Industrial WorksNo ratings yet

- TM - Msa: Taskmaster Series in CimDocument2 pagesTM - Msa: Taskmaster Series in Cimjrlr65No ratings yet

- SPC FormatDocument4 pagesSPC FormatAshish Gupta100% (6)

- Ch03 SPC and Process CapabilityDocument55 pagesCh03 SPC and Process CapabilityRaj Kumar100% (1)

- Statistical Process Control Chart KjashdDocument5 pagesStatistical Process Control Chart Kjashdanon_216770716No ratings yet

- Process Capability-7Document24 pagesProcess Capability-7azadsingh1No ratings yet

- Control Chart Analysis for Seaming OperationDocument6 pagesControl Chart Analysis for Seaming Operationsudar1477No ratings yet

- Workshop On GD & T: Faculty: Abhijeet ChinchorkarDocument75 pagesWorkshop On GD & T: Faculty: Abhijeet ChinchorkarRajdeep SinghNo ratings yet

- Enter and analyze data using statistical process control chartDocument6 pagesEnter and analyze data using statistical process control chartAhmed TeranNo ratings yet

- Statistika U Proizvodnji CP, CPK, (En)Document10 pagesStatistika U Proizvodnji CP, CPK, (En)milanstrNo ratings yet

- CP, CPK, CM, CMK, Control LimitsDocument5 pagesCP, CPK, CM, CMK, Control LimitsBruno MauroNo ratings yet

- Coordinate Measuring Machine (CMM)Document18 pagesCoordinate Measuring Machine (CMM)Smw SmsNo ratings yet

- CH.3, MENG420 Updated 3.0Document3 pagesCH.3, MENG420 Updated 3.0SANo ratings yet

- CMM Inspection ModuleDocument93 pagesCMM Inspection Modulejaskaran singhNo ratings yet

- Unit - 1 - MMDocument64 pagesUnit - 1 - MMR.Arivazhagan Assistant Professor - MHTNo ratings yet

- Flexible manufacturing systems enable production of different part stylesDocument7 pagesFlexible manufacturing systems enable production of different part stylesmkatweNo ratings yet

- Metrology and Quality Assurance Lab: Department of Mechanical EngineeringDocument6 pagesMetrology and Quality Assurance Lab: Department of Mechanical EngineeringAliNo ratings yet

- CP, CPK, CM, CMK, Control LimitsDocument6 pagesCP, CPK, CM, CMK, Control LimitsCÔNG ANH LÊNo ratings yet

- Sssss D FQQQQ13322AAAAAA122 33DFS DGES11 122 GDGDocument1 pageSssss D FQQQQ13322AAAAAA122 33DFS DGES11 122 GDGAnurag SrivastavaNo ratings yet

- FFFDGFGDocument1 pageFFFDGFGAnurag SrivastavaNo ratings yet

- 3 49eroinrn F F FD GFGDocument1 page3 49eroinrn F F FD GFGAnurag SrivastavaNo ratings yet

- WsssssssssssssssssDocument1 pageWsssssssssssssssssAnurag SrivastavaNo ratings yet

- BK text analysisDocument1 pageBK text analysisAnurag SrivastavaNo ratings yet

- 13322aaaaaa122 33DFS Dges11 122 GDGDocument1 page13322aaaaaa122 33DFS Dges11 122 GDGAnurag SrivastavaNo ratings yet

- Qqqq13322aaaaaa122 33DFS Dges11 122 GDGDocument1 pageQqqq13322aaaaaa122 33DFS Dges11 122 GDGAnurag SrivastavaNo ratings yet

- QQQQQQ Iii IiiDocument1 pageQQQQQQ Iii IiiAnurag SrivastavaNo ratings yet

- D23 LK Xsxs XSXDocument1 pageD23 LK Xsxs XSXAnurag SrivastavaNo ratings yet

- New MicrosoWorksheetDocument1 pageNew MicrosoWorksheetAnurag SrivastavaNo ratings yet

- CFT Wonh NTDocument1 pageCFT Wonh NTAnurag SrivastavaNo ratings yet

- SDD23 LK Xsxs XSXDocument1 pageSDD23 LK Xsxs XSXAnurag SrivastavaNo ratings yet

- CFT Word DocumentDocument1 pageCFT Word DocumentAnurag SrivastavaNo ratings yet

- DDD GFDocument1 pageDDD GFAnurag SrivastavaNo ratings yet

- 1SDC2331 Document DetailsDocument1 page1SDC2331 Document DetailsAnurag SrivastavaNo ratings yet

- MentDocument1 pageMentAnurag SrivastavaNo ratings yet

- FQGDDocument1 pageFQGDAnurag SrivastavaNo ratings yet

- New Microsdsoft Excel WorksheetDocument1 pageNew Microsdsoft Excel WorksheetAnurag SrivastavaNo ratings yet

- LK SXSX Xsxs XSXDocument1 pageLK SXSX Xsxs XSXAnurag SrivastavaNo ratings yet

- DefinitionDocument1 pageDefinitionAnurag SrivastavaNo ratings yet

- 5 Why AnalysisDocument1 page5 Why AnalysisAnurag SrivastavaNo ratings yet

- How to complete an 8D formDocument0 pagesHow to complete an 8D formAnurag SrivastavaNo ratings yet

- 12Document1 page12Anurag SrivastavaNo ratings yet

- 1112 Document CodesDocument1 page1112 Document CodesAnurag SrivastavaNo ratings yet

- DefDocument1 pageDefAnurag SrivastavaNo ratings yet

- 123 AS 12 1 EweewewewDocument1 page123 AS 12 1 EweewewewAnurag SrivastavaNo ratings yet

- New Microsoft Excel WorksheetDocument1 pageNew Microsoft Excel WorksheetAnurag SrivastavaNo ratings yet

- How To Do 5 Why AnalysisDocument1 pageHow To Do 5 Why AnalysisAnurag SrivastavaNo ratings yet

- 1 AS 12 1 Q EweewewewDocument1 page1 AS 12 1 Q EweewewewAnurag SrivastavaNo ratings yet

- ST Excel WorksheetDocument1 pageST Excel WorksheetAnurag SrivastavaNo ratings yet

- Butterfly-Farming The Flying Gems by Labay PIFGEX 2009Document30 pagesButterfly-Farming The Flying Gems by Labay PIFGEX 2009Anonymous HXLczq375% (4)

- Miriael SabathielDocument1 pageMiriael SabathielPweggleNo ratings yet

- Ophthalmology CurriculumDocument71 pagesOphthalmology CurriculumEdoga Chima EmmanuelNo ratings yet

- THEORY Transformation Question BankDocument7 pagesTHEORY Transformation Question Bankpankaj12345katreNo ratings yet

- DLL Mtb-Mle3 Q2 W2Document6 pagesDLL Mtb-Mle3 Q2 W2MAUREEN GARCIANo ratings yet

- Panasonic - PDP TH 37 42 pv70xx - Gph10deDocument85 pagesPanasonic - PDP TH 37 42 pv70xx - Gph10defaroltek0% (1)

- Cluster Sampling: ProcedureDocument12 pagesCluster Sampling: ProcedureAahil RazaNo ratings yet

- Assessment of The Sanitary Conditions of FoodDocument83 pagesAssessment of The Sanitary Conditions of FoodtebebeNo ratings yet

- Steps To Perform For Rolling Forward A Physical Standby Database Using RMAN Incremental BackupDocument6 pagesSteps To Perform For Rolling Forward A Physical Standby Database Using RMAN Incremental BackupSudhar ShanNo ratings yet

- Adolescent Sleep Patterns and Insomnia Rates in a Large Population StudyDocument8 pagesAdolescent Sleep Patterns and Insomnia Rates in a Large Population StudyPradipta ShivaNo ratings yet

- Astro-Vision Pancha-Pakshi Shastra ExplainedDocument17 pagesAstro-Vision Pancha-Pakshi Shastra ExplainedVensun Reddy100% (5)

- Solution Manual For Mathematics For EconomicsDocument42 pagesSolution Manual For Mathematics For EconomicsMarcia Smith0% (1)

- Open Area Test SitesDocument15 pagesOpen Area Test SitesSravani KorapakaNo ratings yet

- Java Programming EbookDocument110 pagesJava Programming EbookShaina Mae M. UngsonNo ratings yet

- Composing SentencesDocument2 pagesComposing Sentencesapi-250296212No ratings yet

- Scherrer Equation - WikipediaDocument7 pagesScherrer Equation - WikipediaSilviu-Laurentiu BadeaNo ratings yet

- Reading Comprehension Assessment Criteria GridDocument2 pagesReading Comprehension Assessment Criteria GridVioleta DraguNo ratings yet

- Gmath Learning Reinforcement 6 PDFDocument8 pagesGmath Learning Reinforcement 6 PDFSittie Ainna Acmed UnteNo ratings yet

- Civil Engineering Project Thesis PDFDocument5 pagesCivil Engineering Project Thesis PDFgbxm8h7g100% (1)

- Module 7Document40 pagesModule 7Antonia GuiribaNo ratings yet

- Multiple Choice Questions from Past ExamsDocument31 pagesMultiple Choice Questions from Past Examsmasti funNo ratings yet

- Annotated BibliographyDocument6 pagesAnnotated Bibliographybecca hoffmanNo ratings yet

- Purpose Meaning MeaninginlifeDocument2 pagesPurpose Meaning MeaninginlifeTaufik GeodetikNo ratings yet

- wk8 Activity PresentationDocument13 pageswk8 Activity Presentationapi-280934506No ratings yet

- Chapter 1 - Purposive CommunicationDocument70 pagesChapter 1 - Purposive CommunicationEnola HolmesNo ratings yet

- Chapter 3 Loaders and Linkers: - Machine-Independent Loader FeatureDocument7 pagesChapter 3 Loaders and Linkers: - Machine-Independent Loader FeatureNimisha JithNo ratings yet

- Chem 315 - Lab 6 - Simple and Fractional DistilationDocument27 pagesChem 315 - Lab 6 - Simple and Fractional DistilationkNo ratings yet

- Inami, Problem Other MindsDocument19 pagesInami, Problem Other MindsfortyrrNo ratings yet

- Identifying VariablesDocument25 pagesIdentifying Variablesapi-236248022No ratings yet

- Portable Bricks Transfer Conveyor BeltDocument9 pagesPortable Bricks Transfer Conveyor BeltIJRASETPublicationsNo ratings yet